When it comes to engineering projects, choosing the right type of steel can make a significant difference in performance and durability. Two commonly debated options are 1045 and 1050 steel. But what exactly sets these two apart? Is it the carbon content, their mechanical properties, or perhaps their suitability for specific applications? This comparative guide aims to demystify the differences between 1045 and 1050 steel, providing a thorough analysis of their chemical compositions, mechanical strengths, and practical uses. Whether you’re designing machinery parts or assessing cost-effectiveness for your next project, understanding these nuances is crucial. Dive in to discover which steel might be the better choice for your engineering needs and why.

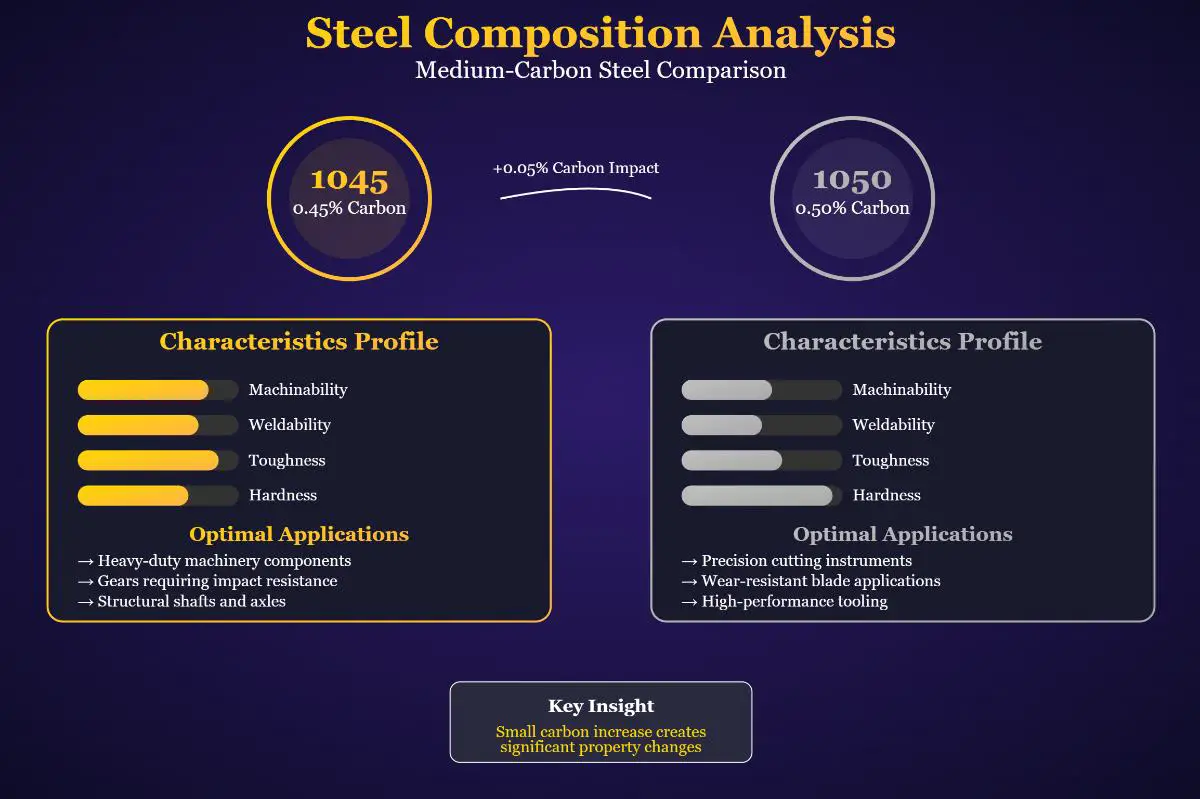

1045 steel is a medium-carbon steel valued for its strength, toughness, and machinability. Containing approximately 0.45% carbon, it achieves moderate hardness and strength while retaining sufficient ductility for various industrial uses. This steel grade is commonly used in manufacturing parts such as gears, shafts, and axles that require a balance of durability and ease of fabrication.

1050 steel, also a medium-carbon steel, contains a slightly higher carbon content of around 0.50%. This increased carbon level enhances its hardness and wear resistance compared to 1045 steel. As a result, 1050 steel is often chosen for applications that demand higher strength and durability, such as cutting tools, blades, and other precision instruments. However, its higher carbon content can make it slightly more challenging to machine and weld.

Carbon steel is categorized by its carbon content into low, medium, and high carbon steels, influencing its hardness, strength, and ductility. Medium-carbon steels, such as 1045 and 1050, offer a good compromise between strength and workability, making them suitable for a wide range of industrial applications.

1045 steel’s chemical composition is as follows:

This composition provides 1045 steel with adequate strength and hardness while maintaining good machinability and weldability. The presence of manganese helps improve the steel’s strength and hardenability.

1050 steel has a similar composition to 1045 steel but with a higher carbon content:

The higher carbon content in 1050 steel increases its hardness and wear resistance, making it ideal for applications needing higher mechanical performance. However, the higher carbon content can also reduce its machinability and weldability compared to 1045 steel.

1045 steel, with 0.43–0.50% carbon, offers good machinability and moderate strength. In contrast, 1050 steel, with 0.48–0.55% carbon, provides higher hardness and strength but is less machinable and weldable. Both steels have similar amounts of manganese, phosphorus, and sulfur, which contribute to their mechanical properties and overall performance.

Tensile strength is the maximum stress a material can endure while being stretched or pulled before it breaks.

Yield strength measures the stress at which a material begins to deform plastically. Knowing the yield strength is essential for applications that involve significant loads.

Elongation at break shows how much a material can stretch before it fractures, indicating its ductility.

Hardness measures a material’s resistance to deformation, particularly permanent indentation.

Wear resistance is crucial for materials used in environments where surface degradation can occur due to mechanical action.

Both machinability and weldability are crucial for the ease of manufacturing and fabricating components from steel. 1045 steel is known for its better machinability and weldability, making it a preferred choice for complex parts and assemblies.

Heat treatment can significantly alter the mechanical properties of steel, enhancing its performance for specific applications.

1045 steel is popular in many industrial applications because of its balanced mechanical properties, such as moderate strength, toughness, and good machinability.

1045 steel is often utilized in the manufacturing of gears and shafts. Its tensile strength and toughness make it suitable for components that must withstand significant stress and impact without deforming. Its easy machinability allows for precise part fabrication.

The high ductility and strength of 1045 steel make it ideal for producing axles and bolts. These parts need a material that can endure heavy loads and repeated stress without breaking. The steel’s moderate hardness ensures that the axles and bolts maintain their structural integrity over time.

1045 steel is a popular choice for various machine parts, including couplings, pins, and keys. Its machinability and weldability make it versatile for creating complex components. The steel’s toughness ensures these parts can withstand dynamic loads and impacts in heavy-duty machinery.

1050 steel, with its higher carbon content, exhibits superior hardness and wear resistance, making it suitable for applications requiring enhanced mechanical performance.

The increased hardness of 1050 steel makes it an excellent material for blades and cutting tools. The steel’s wear resistance keeps these tools sharp and effective over long periods. The higher carbon content provides the necessary edge retention and durability for precision cutting.

1050 steel is also used in the production of springs, where higher strength and resilience are critical. The steel’s ability to withstand repeated stress and deformation without losing its shape makes it ideal for such applications. Springs made from 1050 steel are commonly found in automotive and industrial equipment.

Due to its higher wear resistance and strength, 1050 steel is often used in precision instruments that demand high accuracy and durability. These instruments include measuring devices and calibration tools that require consistent performance over time without significant wear.

1045 steel is more versatile and easier to machine and weld compared to 1050 steel. This makes 1045 steel a preferred choice for applications requiring complex shapes and detailed fabrication. Its lower carbon content allows for smoother machining processes and less susceptibility to cracking during welding.

While 1045 steel offers good wear resistance, 1050 steel provides superior wear resistance due to its higher carbon content. This makes 1050 steel more suitable for applications where surface durability and longevity are crucial, such as in cutting tools and precision instruments.

In terms of cost-effectiveness, 1045 steel is generally more economical due to its wider availability and lower production costs. It is often chosen for applications where the balance of cost and performance is essential. On the other hand, 1050 steel, despite being slightly more expensive, is selected for applications where its enhanced mechanical properties justify the higher cost.

For heavy-duty machinery parts like gears, shafts, and axles, 1045 steel is a reliable choice due to its toughness and ease of fabrication. In contrast, 1050 steel is better suited for applications requiring higher hardness and wear resistance, such as in the production of blades, springs, and precision instruments.

The hardening process for 1045 steel involves heating the material to a temperature range of 820-850°C (1508-1562°F) and then quenching it in water or oil. Due to its moderate carbon content, 1045 steel exhibits moderate hardenability, achieving good surface hardness while maintaining relatively uniform core hardness. The typical surface hardness after quenching and tempering ranges between HRC 50-55.

1050 steel, with its higher carbon content, requires a slightly higher hardening temperature, typically around 840-870°C (1544-1598°F), followed by quenching in water or oil. The increased carbon content enhances its hardenability, allowing for deeper hardness penetration. As a result, 1050 steel can achieve higher surface hardness compared to 1045 steel, with typical values also around HRC 50-55 but with marginally higher surface hardness.

Tempering of 1045 steel typically occurs at temperatures between 400°F (204°C) and 1200°F (649°C), with lower temperatures preserving hardness and higher temperatures enhancing toughness.

For 1050 steel, tempering also occurs within the 400°F to 1200°F range. However, the process requires more precise temperature control to prevent brittleness. Lower tempering temperatures help maintain the steel’s hardness and wear resistance, while higher temperatures improve toughness. The higher carbon content in 1050 steel makes it more susceptible to brittleness if not tempered correctly, necessitating careful process control.

The mechanical properties of 1045 and 1050 steels vary after heat treatment, with 1045 generally offering better impact resistance and 1050 providing higher surface hardness.

| Property | 1045 Steel | 1050 Steel |

|---|---|---|

| Tensile Strength | 690–790 MPa | 565–650 MPa |

| Yield Strength | 330–580 MPa | 310–650 MPa |

| Elongation at Break | ~12–20% | ~10–15% |

| Impact Resistance | Superior due to lower carbon | Reduced toughness at higher hardness |

1045 steel is easier to machine due to its lower carbon content, while 1050 steel requires annealing to reduce tool wear during machining.

Welding 1045 steel typically requires preheating and post-weld heat treatment to avoid cracking. The steel’s moderate carbon content makes it more weldable than 1050 steel. In contrast, 1050 steel’s higher carbon content increases its susceptibility to cracking during welding. Preheating and post-weld heat treatment are critical to ensure the integrity of the weld. Welding 1050 steel in its normalized or annealed state is recommended to minimize the risk of defects.

1045 steel is ideal for gears, shafts, and structural components. Its good machinability and weldability make it versatile for various manufacturing processes.

1050 steel is suited for cutting tools and wear-resistant parts. The steel’s higher carbon content makes it less machinable and weldable, but its mechanical properties make it ideal for demanding applications where surface durability is critical.

Producing 1045 steel is typically less expensive than producing 1050 steel. This is primarily due to its lower carbon content (around 0.45%) and simpler manufacturing processes that do not require the precise temperature controls needed for 1050 steel. The production of 1050 steel, with a higher carbon content of approximately 0.50%, involves more stringent controls and specialized equipment, resulting in higher costs and limited availability.

The market prices for these steels reflect their production costs and availability.

The higher cost of 1050 steel is driven by its specialized production requirements and limited availability.

1045 steel is widely used in many industries, ensuring a stable and reliable supply chain. Its widespread use in automotive and heavy machinery sectors makes it readily available, simplifying procurement.

On the other hand, 1050 steel’s niche demand for high-wear applications such as cutting tools and racing components can complicate its supply chain. The specialized nature of its applications and more limited production capabilities result in less consistent availability.

The availability and pricing of 1050 steel are more volatile because of regional production differences and lower global inventory.

| Property | 1045 Steel | 1050 Steel |

|---|---|---|

| Tensile Strength | Moderate | Higher |

| Hardness | Lower | Superior |

| Wear Resistance | Adequate | Exceptional |

| Machinability | Better | Moderate |

| Resilience | 84–93 MJ/m³ | 81–100 MJ/m³ |

Both 1045 and 1050 steels are carbon-intensive in their manufacturing processes. However, the stricter process controls for 1050 steel amplify its energy use and environmental impact.

Both steels have similar recyclability profiles, but 1050 steel’s durability can reduce the frequency of replacements, potentially offsetting its higher initial costs in long-term projects.

For projects where budget constraints are critical, 1045 steel offers superior cost efficiency without compromising performance in non-extreme environments. Its lower production cost and wider availability make it an economical choice.

In applications where performance is paramount, particularly those requiring high wear resistance and hardness, 1050 steel’s enhanced mechanical properties justify its premium pricing. This makes it suitable for mission-critical components where long-term durability and performance are essential.

A heavy machinery manufacturer chose 1045 steel for its gears because it offers a great mix of strength and machinability. The medium carbon content (0.45%) gives the toughness and impact resistance needed for high-load gears, while its good machinability ensures precise gear teeth cutting for reliable performance.

In the automotive industry, 1045 steel is frequently used for axles. Its moderate hardness and high strength allow it to endure the continuous stresses of vehicle operation. 1045 steel’s ductility helps axles absorb impact without breaking, enhancing vehicle safety and durability.

A manufacturer of industrial cutting tools selected 1050 steel for its products. While 1050 steel is harder to machine than 1045, its better edge retention and durability make it ideal for high-precision cutting tools.

1050 steel is used in the production of high-strength industrial springs. The increased carbon content enhances the steel’s resilience and ability to return to its original shape after deformation. This property is crucial for springs that must endure repeated cycles of compression and extension without losing their mechanical integrity. The robustness of 1050 steel ensures that these springs perform reliably under heavy loads.

1045 steel demonstrates superior machinability compared to 1050 steel, making it ideal for complex parts that require intricate machining processes. For instance, in gear manufacturing, the ease of cutting and shaping 1045 steel reduces production time and costs. In contrast, 1050 steel, while more challenging to machine, is chosen for applications where the final product’s performance justifies the additional fabrication effort.

1050 steel’s higher wear resistance makes it suitable for applications where long-term durability is paramount, such as in cutting tools and springs. These applications benefit from the steel’s ability to maintain performance despite extensive use. On the other hand, 1045 steel, with its moderate wear resistance, is adequate for parts like gears and axles where toughness and impact resistance are more critical than surface durability.

1045 steel is generally more cost-effective and readily available, making it a practical choice for large-scale manufacturing of components like automotive axles and machinery gears. The production and procurement of 1050 steel can be more expensive and less consistent due to its specialized applications and higher carbon content. However, the investment in 1050 steel can be justified by the enhanced performance and extended service life it provides in high-wear applications.

These case studies illustrate how the distinct properties of 1045 and 1050 steels influence their selection for various industrial applications, highlighting the importance of choosing the right material based on specific project requirements.

Selecting the appropriate steel for your project involves evaluating multiple factors to ensure optimal performance and cost-efficiency. Here are the key considerations:

It’s essential to understand the mechanical properties of 1045 and 1050 steel to determine which is best for your specific applications.

The ease of machining and welding plays a significant role in the selection process.

Budget considerations often drive material selection, especially for large-scale projects.

Your project’s specific requirements should guide whether you choose 1045 or 1050 steel.

When deciding between 1045 and 1050 steel, consider the following practical guidelines:

Considering cost-effectiveness and sustainability in your decision can lead to better long-term results.

Both steels are recyclable, but the higher durability of 1050 steel may reduce the frequency of replacements, potentially offsetting its higher production impact.

By considering these factors, you can select the steel grade that best aligns with your project’s requirements, ensuring optimal performance, cost-efficiency, and sustainability.

Below are answers to some frequently asked questions:

1045 and 1050 steel are both medium-carbon steels, with the primary difference being their carbon content. 1045 steel contains approximately 0.45% carbon, while 1050 steel has around 0.50% carbon. This slight increase in carbon in 1050 steel significantly impacts its mechanical properties, making it harder and more wear-resistant than 1045 steel.

1045 steel is known for its balanced combination of strength, toughness, and machinability, making it suitable for gears, shafts, and heavy-duty machinery parts where impact resistance is essential. It is easier to machine and weld, offering versatility in various applications.

1050 steel, on the other hand, excels in applications requiring higher hardness and wear resistance, such as blades, cutting tools, and precision instruments. Its higher carbon content provides superior edge retention and abrasion resistance but reduces toughness and machinability, requiring careful processing and potentially higher costs.

Carbon content significantly influences steel properties such as strength, hardness, ductility, and weldability. In the context of 1045 and 1050 steel, both are medium carbon steels, but the slight difference in carbon content (0.45% for 1045 and 0.50% for 1050) results in notable variations in their mechanical properties.

Higher carbon content generally increases strength and hardness while reducing ductility. For example, 1050 steel, with its higher carbon content, exhibits greater strength and hardness compared to 1045 steel, making it suitable for applications that require more robust properties, such as gear components and machine parts. Conversely, 1045 steel, with slightly lower carbon content, offers a better balance of strength and ductility, making it more versatile for general machinery parts and structural components.

Additionally, weldability decreases as carbon content increases, necessitating more stringent preheating and post-weld treatments to avoid cracking. This comparative analysis highlights the importance of selecting the appropriate steel grade based on the specific mechanical requirements of the application.

1045 steel exhibits a tensile strength ranging from 620 to 680 MPa, and sometimes up to 700 MPa depending on various factors such as heat treatment and specific processing methods. This makes 1045 steel robust and suitable for applications requiring high strength, such as gears, axles, and heavy machinery components.

On the other hand, 1050 steel, with a higher carbon content of approximately 0.5%, generally has a slightly higher tensile strength of around 690 MPa. The increased carbon level in 1050 steel enhances its wear resistance, making it ideal for applications such as blades and cutting tools where durability and sharpness are critical.

When deciding between 1045 and 1050 steel for machinery parts, it is essential to consider their mechanical properties, machinability, and specific application needs.

1045 steel, with approximately 0.45% carbon content, offers better toughness and impact resistance, making it suitable for gears, axles, and heavy-duty machinery. Its lower carbon content also makes it more machinable and easier to weld. This steel exhibits tensile strengths between 620 to 680 MPa and is generally more cost-effective due to its wider availability and lower production costs. Additionally, 1045 steel responds well to heat treatment, which can further enhance its properties.

On the other hand, 1050 steel, containing about 0.5% carbon, provides higher tensile strength (around 690 MPa), yield strength, and wear resistance. This makes it ideal for blades, cutting tools, and precision instruments. However, its higher carbon content makes it more challenging to machine and weld, and it is typically more expensive due to its specialized use cases.

Heat treatments significantly impact the performance of both 1045 and 1050 steel by modifying their microstructure and mechanical properties. For 1045 steel, heat treatments such as hardening and tempering enhance hardness and tensile strength, resulting in improved wear resistance and toughness. Rapid cooling (quenching) is essential for achieving martensite formation, which is crucial for hardness. Tempering at various temperatures can adjust brittleness and toughness, making it suitable for components like axles and gears.

1050 steel, with its higher carbon content, attains higher hardness levels compared to 1045 steel after heat treatment, making it ideal for applications requiring moderate wear resistance and toughness. Hardening can achieve Rockwell hardness of approximately 50-55 HRC. However, the higher carbon content also necessitates careful tempering to balance hardness and toughness, crucial for parts needing shock absorption.

Both steels improve in tensile and yield strength through heat treatments, but 1045 steel offers better weldability and machinability, whereas 1050 steel is more challenging to weld and machine due to its increased hardness. Ultimately, the choice between 1045 and 1050 steel depends on the specific application requirements, with 1050 steel being more suitable for demanding applications requiring higher hardness.

Both 1045 and 1050 steels adhere to specific standards and certifications that ensure their quality and suitability for various engineering applications.

1045 steel typically conforms to ASTM A29/A29M for carbon steel bars suitable for forging. It is also subject to ASTM B117 neutral salt spray testing for corrosion resistance, particularly in chrome-plated applications. Mill test reports (MTRs) confirm its chemical composition and mechanical properties.

1050 steel follows ASTM A519 for seamless carbon steel tubes, which stipulates chemical composition, mechanical properties, and dimensional tolerances. This standard includes stringent inspection certificates such as EN 10204 Type 3.1/3.2, ensuring traceability and compliance with supplementary tests like NACE for corrosion resistance, HIC for hydrogen-induced cracking, and impact testing for reliability in demanding applications.