When it comes to selecting the perfect knife, the type of steel used can make all the difference. For knife enthusiasts navigating the world of blade materials, two popular options often come into play: 12C27 and 440C steel. But what sets these two steels apart, and which one is the better choice for your needs?

In this detailed comparison, we will dive into the chemical compositions, edge retention, sharpness, and corrosion resistance of both 12C27 and 440C steels. You’ll discover how each type performs in terms of durability and maintenance, and we’ll also weigh the cost considerations to help you determine the best value for your investment.

Whether you’re a seasoned knife maker or a hobbyist looking to upgrade your collection, this comprehensive guide will provide the insights you need to make an informed decision. Ready to explore the battle between 12C27 and 440C steel? Let’s find out which one emerges as the ultimate champion in the world of knife making.

Knife steel is a critical component in knife manufacturing, directly influencing a blade’s performance, durability, and ease of maintenance. The type of steel used affects a knife’s hardness, toughness, resistance to corrosion, edge retention, and ease of sharpening.

12C27 is a martensitic stainless steel developed by Sandvik, known for its well-balanced properties. With approximately 12% chromium and 0.27% carbon, it offers excellent corrosion resistance and ease of sharpening, making it popular for everyday carry and kitchen knives.

440C is a high-carbon stainless steel that stands out for its high hardness and excellent edge retention. Containing over 16% chromium and 0.95% to 1.2% carbon, it also includes manganese and molybdenum for added durability. 440C is favored for high-end and professional knives, offering superior performance in demanding applications.

Knife enthusiasts and manufacturers must consider these factors when selecting the appropriate steel for their needs. By understanding the unique properties and applications of 12C27 and 440C steel, users can make informed decisions to achieve the desired performance and longevity in their knives.

Knife materials play a crucial role in determining the performance, durability, and maintenance of a knife. The two primary categories of knife materials are stainless steel and high-carbon steel, each offering distinct advantages and drawbacks.

Stainless steel is a popular choice for knife making due to its excellent resistance to rust and corrosion. This type of steel contains a significant amount of chromium, usually over 10.5%, which forms a passive layer on the surface, protecting the blade from oxidation and rust. Stainless steels are often preferred for kitchen knives, everyday carry (EDC) knives, and outdoor knives where exposure to moisture is common.

Advantages:

Drawbacks:

High-carbon steel contains a higher percentage of carbon compared to stainless steel, which enhances its hardness and edge retention capabilities. This type of steel is favored for tasks that demand a sharp, durable edge, such as in professional chef knives, hunting knives, and tactical knives. However, the lack of chromium makes high-carbon steel more prone to rust and corrosion, necessitating careful maintenance and regular oiling.

Advantages:

Drawbacks:

Knife makers use both stainless steel and high-carbon steel to meet various needs and preferences. Understanding the key characteristics of each material helps in selecting the right steel for specific applications.

Stainless steel knives are ideal for users who prioritize ease of maintenance and resistance to rust. They are ideal for kitchens or outdoor settings where the knife may be exposed to moisture. The balance of chromium and other alloying elements provides a good mix of toughness and corrosion resistance, making these knives reliable and long-lasting with minimal upkeep.

High-carbon steel knives are preferred by users who require a blade with exceptional sharpness and edge retention. These knives are excellent for precision cutting tasks and can maintain a sharp edge for extended periods. However, the higher carbon content means that these knives need diligent maintenance to prevent rust and ensure longevity. They are ideal for professional chefs, hunters, and tactical users who can commit to the necessary upkeep.

When comparing stainless steel and high-carbon steel, several factors need to be considered, including the intended use, maintenance requirements, and desired performance characteristics.

By understanding these differences, knife enthusiasts and manufacturers can make informed decisions about the best material for their specific needs, balancing performance, maintenance, and environmental considerations.

12C27 steel is renowned for its balanced composition, which contributes to its desirable properties in knife making. The key elements in 12C27 steel include:

440C steel is a high-carbon stainless steel known for its high hardness and excellent edge retention. Its chemical composition includes:

12C27 and 440C steels each have distinct chemical compositions and properties suitable for different knife-making applications.

Edge retention refers to the ability of a knife blade to maintain its sharpness over time and through usage. This property is crucial for knife performance, as it determines how often a blade needs to be sharpened and how effectively it can perform cutting tasks.

12C27 steel, developed by Sandvik, is well-regarded for its balanced composition that ensures good edge retention. The moderate carbon content of around 0.27% contributes to this balance. While 12C27 steel does not hold an edge as long as higher-carbon steels, it offers sufficient edge retention for most everyday tasks, making it suitable for general-purpose knives and kitchen use. This steel is relatively easy to sharpen, which is an advantage for users who prefer to maintain their knives themselves.

440C steel is characterized by its high carbon content, ranging from 0.95% to 1.2%, which significantly enhances its hardness and edge retention. The excellent edge retention of 440C makes it perfect for high-performance uses, like tactical and professional knives, where a sharp edge is essential. However, the increased hardness of 440C steel can make it more challenging to sharpen compared to 12C27 steel.

Thanks to its balanced composition, 12C27 steel can achieve and maintain a very sharp edge, making it ideal for precision cutting tasks. The moderate hardness allows for a keen edge that can be easily maintained.

The higher hardness of 440C steel enables it to achieve and maintain a razor-sharp edge for longer periods. This makes it an excellent choice for applications requiring a consistently sharp blade.

One of the notable advantages of 12C27 steel is its ease of sharpening. The lower carbon content means that it can be quickly resharpened using standard sharpening tools. This makes 12C27 steel particularly user-friendly, especially for those who may not have advanced sharpening skills.

On the other hand, the higher hardness of 440C steel makes sharpening more challenging. You’ll need specialized tools and techniques to keep its edge, which might be a drawback for those without the right equipment or skills.

If you value easy maintenance and frequent sharpening, 12C27 steel is a practical choice. It provides good edge retention and sharpness and is user-friendly for all skill levels.

In contrast, 440C steel is better suited for users who need a blade with exceptional edge retention and are willing to invest the time and effort required for sharpening. Its superior hardness and durability make it ideal for demanding tasks and professional use.

By understanding the edge retention and sharpness characteristics of 12C27 and 440C steels, knife enthusiasts and manufacturers can make informed decisions to match the right steel to the intended application.

Corrosion resistance is crucial in knife making, especially for knives used in moist or corrosive environments. A knife’s ability to resist corrosion not only extends its lifespan but also maintains its performance and aesthetic appeal. Corrosion can weaken the blade, cause pitting, and reduce sharpness, making it essential to choose the right steel with appropriate corrosion resistance properties.

12C27 steel, developed by Sandvik, is renowned for its excellent corrosion resistance, primarily due to its high chromium content of around 13.5%. This chromium helps form a protective layer on the steel surface to prevent rust.

12C27 steel performs well in moderately moist conditions, making it suitable for kitchen and outdoor knives. Regular cleaning, drying, and occasional oiling can help maintain its corrosion resistance.

Now, let’s look at how 440C steel compares in terms of corrosion resistance. With its higher chromium content ranging from 16% to 18%, 440C steel offers superior corrosion resistance compared to many other stainless steels. This makes it highly resistant to rust and corrosion, even in harsh environments.

440C steel is ideal for knives used in marine or coastal environments, where exposure to saltwater is frequent. Its superior corrosion resistance makes it a preferred choice for diving knives and other applications requiring prolonged exposure to moisture. While 440C steel is highly resistant to corrosion, regular maintenance, including cleaning and oiling, is still recommended to preserve its properties over time.

When comparing the corrosion resistance of 12C27 and 440C steel, several key differences and considerations emerge. The higher chromium content in 440C steel (16-18%) provides better corrosion resistance than 12C27 steel (13.5%). This makes 440C more suitable for environments with high moisture or saltwater exposure.

Although both steels require maintenance to maximize their corrosion resistance, 12C27 steel’s balanced properties make it easier to maintain for everyday use. In contrast, 440C steel, while more resistant, benefits from regular oiling to maintain its optimal performance.

12C27 steel is versatile and well-suited for general-purpose knives, including kitchen and outdoor knives that may not face extreme conditions. 440C steel, with its superior corrosion resistance, is better suited for specialized applications like marine or diving knives, where prolonged exposure to corrosive elements is expected.

12C27 steel is well-known for its toughness, making it resistant to chipping, breaking, and cracking—essential for general-use knives. This characteristic ensures that 12C27 can withstand impacts and heavy usage without significant damage. However, while 12C27 is durable, its edge retention may not be as high as some other steels, such as 440C. This means that while the blade itself remains intact, it might require more frequent sharpening to maintain its cutting performance.

440C steel, on the other hand, offers superior durability and edge retention because of its higher carbon content and increased hardness. This makes it an excellent choice for high-performance knives that are expected to endure rigorous use. The high hardness of 440C steel means it can maintain a sharp edge for longer periods, reducing the need for frequent sharpening. However, this increased hardness can also make the steel more brittle, leading to a higher risk of chipping under extreme conditions compared to 12C27.

Despite its excellent corrosion resistance, 12C27 steel requires more frequent maintenance to prevent rust. This involves regular cleaning, drying, and occasional oiling to keep the blade in optimal condition. One of the advantages of 12C27 is its ease of sharpening. Users can easily restore a sharp edge with standard sharpening tools, which is beneficial for those who prefer to maintain their knives regularly. However, the need for consistent polishing and oiling can be a drawback for those seeking a low-maintenance option.

440C steel requires minimal maintenance due to its high corrosion resistance. The high chromium content in 440C provides a protective layer that prevents rust and corrosion, even in harsh environments. This makes it a preferred choice for users who want a durable blade with less frequent upkeep. However, the higher hardness of 440C steel makes it more challenging to sharpen. Specialized tools and techniques are often needed to maintain its edge, which can be challenging for users who prefer easy maintenance. Once sharpened, 440C steel retains its edge well, reducing the frequency of sharpening required.

When comparing the durability and maintenance requirements of 12C27 and 440C steel, several key differences emerge:

Understanding these differences helps knife enthusiasts and manufacturers select the steel that best balances performance, durability, and maintenance needs.

Comparing 12C27 and 440C steels for knife making requires understanding their cost differences.

12C27 steel is generally less expensive to produce than 440C due to its simpler manufacturing process, which uses conventional ingot technology and less specialized equipment. In contrast, 440C steel requires a more precise heat treatment process and higher-grade manufacturing equipment, leading to increased production costs. Additionally, the higher carbon and chromium content in 440C steel makes it more expensive.

Knives made from 12C27 steel are typically more affordable due to the lower production and material costs. This affordability makes 12C27 knives appealing to beginners or casual users who seek reliable performance without a high upfront investment. On the other hand, 440C knives are generally more expensive at the point of purchase because of the higher costs associated with their production and material composition.

While 440C knives have a higher initial price, their superior durability and edge retention can offset these costs over time. The longer-lasting edge means less frequent sharpening, and the enhanced durability reduces the likelihood of needing to replace the knife. In contrast, 12C27 knives, although cheaper initially, may incur higher long-term costs due to more frequent maintenance and potential replacements if the blade wears out faster.

12C27 steel is easy to sharpen but requires regular cleaning, drying, and occasional oiling to prevent rust. The frequent need for sharpening also means users might spend more time and resources keeping the blade in optimal condition.

440C steel is more resistant to corrosion and wear, which reduces the frequency of maintenance compared to 12C27. However, sharpening 440C is more challenging and may require specialized tools and techniques, potentially increasing the cost and effort involved in maintaining the knife. Despite this, the less frequent need for sharpening can make 440C a cost-effective choice in the long run.

For everyday activities like cooking or general outdoor use, 12C27 steel is a cost-effective and reliable option. Its affordability and ease of maintenance make it suitable for users who need a reliable knife without significant long-term investment. The balance of properties in 12C27 steel makes it versatile and practical for a wide range of tasks.

For high-performance applications, such as tactical or heavy-duty knives, 440C steel is preferred despite its higher cost. The superior edge retention and durability justify the expense for professionals and enthusiasts who demand a robust and long-lasting blade. The initial investment in 440C steel can be seen as a long-term saving due to its reduced need for frequent maintenance and sharpening.

Choosing the right steel for your knife depends on your specific needs and preferences, and involves considering several important factors.

The intended use of your knife is crucial in determining the best steel.

Consider how much maintenance you’re willing to do when choosing your knife steel.

For those new to knife ownership or making, 12C27 steel is often recommended. Its balanced properties, affordability, and ease of sharpening make it a user-friendly choice for beginners. It allows new users to experience high-quality performance without the challenges of maintaining a harder steel.

Experienced users and professionals who require superior performance might opt for 440C steel. Its great edge retention and hardness make it ideal for demanding tasks. While it requires more effort to sharpen, the long-lasting edge and durability justify the investment for those who need top-tier performance.

Budget constraints are another significant factor in choosing between 12C27 and 440C steel.

For daily tasks, such as opening packages or preparing food, a knife made from 12C27 steel is practical and efficient. Its ease of maintenance and affordability make it ideal for casual users.

For more rigorous applications, like camping, hunting, or tactical use, 440C steel shines. Its ability to maintain a sharp edge under tough conditions and resist wear and corrosion makes it suitable for heavy-duty use.

When choosing between 12C27 and 440C steel for knife-making, understanding their practical applications and user experiences can help you make an informed decision. Both steels have distinct properties that make them suitable for various uses, from everyday tasks to more demanding applications.

12C27 steel is highly favored for everyday use because of its well-balanced properties. It is commonly used in kitchen knives and general-purpose outdoor knives. The steel’s ease of sharpening makes it ideal for tasks where a sharp edge needs to be quickly restored. Users appreciate its corrosion resistance, which is crucial in kitchens and outdoor activities where the knife might get wet. Additionally, 12C27’s moderate hardness ensures that it is tough enough to withstand regular use without chipping.

While 440C steel is less commonly used for everyday tasks due to its higher hardness and maintenance requirements, it is still a viable option for those who need a knife that retains its edge for longer periods. Its superior edge retention means that it can handle repetitive cutting tasks without frequent sharpening. However, the increased difficulty in sharpening 440C steel makes it less practical for users who prefer low-maintenance knives.

For tactical and hunting applications, 12C27 steel is appreciated for its toughness and ease of maintenance. Hunters and outdoor enthusiasts often favor 12C27 steel knives for their ability to be quickly resharpened in the field. The steel’s excellent corrosion resistance ensures that the blade remains in good condition even when exposed to harsh environmental conditions. However, for tasks that need extreme edge retention, 12C27 may not perform as well as 440C steel.

440C steel excels in tactical and hunting applications where superior edge retention and hardness are critical. Its high carbon content provides the necessary hardness to maintain a sharp edge through rigorous use. This makes 440C steel ideal for hunting knives that need to perform well during skinning and field dressing. The steel’s excellent wear resistance also ensures that it can withstand the abrasive conditions often encountered in tactical situations. Users appreciate 440C steel for its long-lasting performance, although they must be prepared for more challenging sharpening processes.

Users of 12C27 steel often highlight its ease of sharpening as a significant advantage. Whether in a kitchen setting or out in the field, the ability to quickly restore a sharp edge is highly valued. This makes 12C27 steel particularly user-friendly, especially for those who do not have advanced sharpening skills or equipment.

In contrast, users of 440C steel note that while the initial sharpening process can be more demanding, the steel’s superior edge retention compensates for this by reducing the frequency of sharpening needed. This makes 440C steel a preferred choice for users who prioritize a long-lasting edge and are willing to invest the effort in maintaining it.

Both 12C27 and 440C steels offer excellent corrosion resistance, but user experiences highlight some differences. 12C27 steel’s balanced composition provides robust corrosion resistance, making it suitable for kitchen knives and outdoor use where exposure to moisture is frequent. Users find that regular cleaning and minimal maintenance are sufficient to keep 12C27 steel in good condition.

Users who need knives for diving or activities with prolonged water exposure often prefer 440C steel for its superior rust resistance. The steel’s higher chromium content offers enhanced corrosion resistance, making it ideal for more extreme environments, such as marine or coastal areas.

The choice between 12C27 and 440C steel For users who demand high performance and are willing to invest in more rigorous maintenance routines, 440C steel provides exceptional edge retention and durability. It is ideal for tactical and hunting applications where a long-lasting sharp edge is crucial. Although sharpening 440C steel can be challenging, its superior properties make it a worthwhile choice for demanding environments and professional use.

Below are answers to some frequently asked questions:

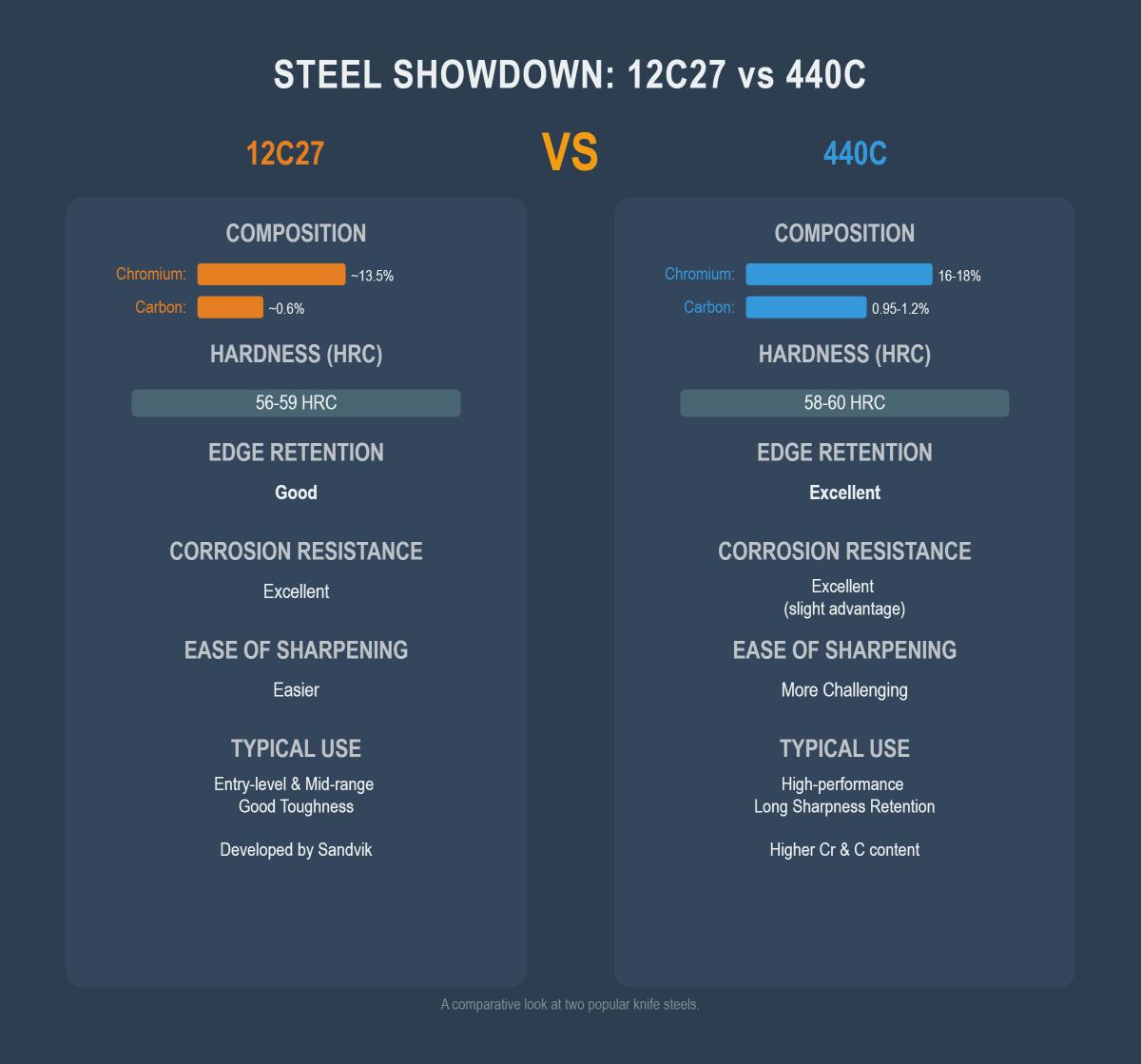

The primary differences between 12C27 and 440C steel for knife making lie in their chemical composition, hardness, edge retention, corrosion resistance, and ease of sharpening.

12C27 steel, developed by Sandvik, contains approximately 13.5% chromium and 0.6% carbon, resulting in a balanced hardness of HRC 56-59. This composition makes 12C27 easier to sharpen and provides good toughness, making it suitable for entry-level and mid-range knives.

On the other hand, 440C steel has a higher chromium content (16-18%) and carbon content (0.95-1.2%), leading to a higher hardness of HRC 58-60. This higher hardness translates to excellent edge retention, though it makes sharpening more challenging. 440C is ideal for high-performance knives where maintaining sharpness over long periods is crucial.

Both steels offer excellent corrosion resistance, but 440C might have a slight advantage due to its higher chromium content.

For beginners, 12C27 steel is generally the better choice between 12C27 and 440C. This is primarily due to its ease of sharpening, which is a critical factor for those new to knife maintenance. 12C27’s composition, with approximately 12% chromium and 0.27% carbon, offers good corrosion resistance and adequate hardness, making it less challenging to maintain and sharpen compared to 440C. Additionally, 12C27 steel is more affordable, allowing beginners to experiment and learn without a significant investment.

In contrast, 440C steel, with over 16% chromium and about 1.2% carbon, provides superior edge retention and durability but is harder to sharpen. This can be a deterrent for beginners who may find the maintenance and sharpening process more demanding. While 440C steel is excellent for high-end or tactical knives due to its toughness, it requires more advanced skills to maintain effectively.

Therefore, for those starting out in knife making or usage, 12C27 steel offers a balanced combination of performance, affordability, and ease of maintenance, making it a more accessible and practical choice.

12C27 and 440C steels both have distinct advantages in terms of edge retention and corrosion resistance, making them popular choices for knife enthusiasts.

Edge Retention: 12C27 steel offers good edge retention and is relatively easy to sharpen. It maintains its sharpness well during regular use but may not perform as well under heavy or prolonged use compared to harder steels. On the other hand, 440C steel provides superior edge retention, making it ideal for knives that need to stay sharp over a longer period. However, this comes at the cost of being more challenging to sharpen compared to 12C27.

Corrosion Resistance: 12C27 contains approximately 12% chromium, offering excellent corrosion resistance, suitable for environments with exposure to moisture. 440C, with over 16% chromium content, provides even better corrosion resistance, making it highly resistant to rust and staining, and well-suited for harsh environments.

For maintaining 12C27 and 440C steel knives, there are specific tips to ensure longevity and optimal performance. For 12C27 steel, which is known for its balance of sharpness and durability, regular maintenance involves washing the knife with soap and water, then thoroughly drying it to prevent rust. Avoid using abrasive cleaners and scrubbers. Sharpening should be done using fine-grit sharpening stones or a honing steel. Additionally, applying food-grade oil regularly can protect against corrosion, and storing the knife in a dry place is essential.

440C steel, recognized for its excellent hardness and edge retention, requires similar cleaning and drying practices. However, due to its higher hardness, sharpening can be more challenging; thus, high grit stones or diamond sharpeners are recommended. Even though 440C has superior corrosion resistance, regular oiling can further enhance its protection. As with 12C27, storing the knife in a dry place is crucial to maintain its condition.

Yes, there are significant cost differences between 12C27 and 440C steel. 12C27 steel is generally more affordable due to its lower alloy content and simpler production processes. It is easier to work with, which reduces manufacturing expenses and makes it ideal for producing high-quality, cost-effective knives.

On the other hand, 440C steel is more expensive because of its higher carbon and chromium content, which requires precise heat treatment and higher-quality alloying elements. The increased hardness and wear resistance of 440C make it more challenging to manufacture, leading to higher production costs. Consequently, knives made from 440C steel are usually priced higher, though they offer superior edge retention and corrosion resistance, justifying their cost for users who need high-performance blades.

For outdoor use, 440C steel is generally more suitable due to its superior durability, strength, and edge retention. Its higher carbon content (approximately 1.2%) and increased chromium (over 16%) enhance its hardness and corrosion resistance, making it ideal for heavy-duty tasks and harsh conditions. While 12C27 steel, with about 0.27% carbon and 12% chromium, offers good corrosion resistance and ease of sharpening, it may not withstand extreme outdoor conditions as well as 440C. Therefore, for outdoor enthusiasts who need a reliable, long-lasting blade that maintains its edge, 440C is the preferred choice.