When it comes to choosing the right wire for your electrical projects, the differences between 14-gauge and 16-gauge wires can significantly impact performance and safety. Understanding these distinctions is crucial for making informed decisions that ensure your installations are efficient and secure. Whether you’re wiring a home, setting up a professional audio system, or planning lighting configurations, knowing when to use 14-gauge versus 16-gauge wire can save you time, money, and potential headaches. In this comprehensive guide, we’ll delve into the nuances of the AWG system, compare the physical and electrical properties of these wires, and explore their specific applications. Ready to unravel the intricacies of wire selection? Let’s dive in and discover which gauge suits your needs best.

The American Wire Gauge (AWG) system, created in 1857, standardizes the measurement of electrical wire thickness and diameter in North America. This system ensures uniformity and consistency across various applications, making it easier for manufacturers, electricians, and engineers to select the appropriate wire gauge for specific tasks. The AWG system uses a numerical scale where lower numbers indicate thicker wires, and higher numbers represent thinner wires.

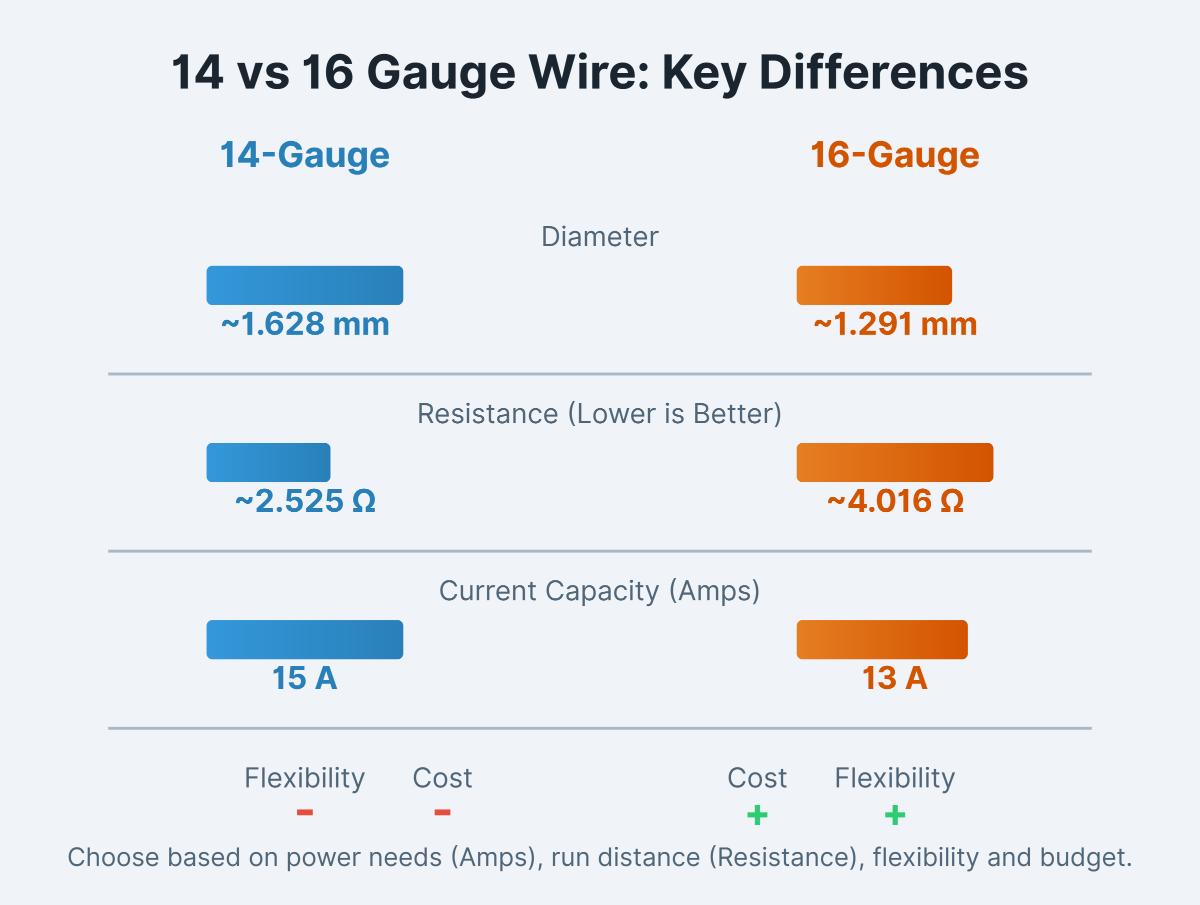

In the AWG system, each wire gauge corresponds to a specific diameter. For example, a 14-gauge wire has a diameter of approximately 0.0641 inches (1.628 mm), while a 16-gauge wire has a diameter of about 0.0508 inches (1.291 mm). The difference in diameter directly affects the wire’s physical and electrical properties, making the selection of the correct gauge crucial for safety and performance.

Thicker wires (with lower AWG numbers) have less resistance, allowing more current to flow and reducing energy loss. For instance, a 14-gauge wire has an electrical resistance of approximately 2.525 ohms per 1000 feet, whereas a 16-gauge wire has a higher resistance of about 4.016 ohms per 1000 feet. Lower resistance in thicker wires makes them suitable for high-power applications and longer distances, as they can handle higher currents with minimal voltage drop.

Ampacity, the current-carrying capacity of a wire, is another critical factor influenced by the AWG system, with thicker wires able to carry more current without overheating. For example, a 14-gauge wire can handle up to 15 amps, making it suitable for higher power systems or longer wiring runs. In contrast, a 16-gauge wire can handle up to 13 amps, making it more appropriate for lower power needs and shorter distances.

The differences between 14-gauge and 16-gauge wires in terms of thickness, resistance, and ampacity are clear when compared. Understanding these differences is essential for selecting the right wire gauge for specific applications:

These characteristics are crucial when determining the appropriate wire gauge for different electrical projects, ensuring both efficiency and safety.

The AWG system is crucial in shaping a wire’s electrical performance. By selecting the appropriate gauge, one can ensure optimal current-carrying capacity, minimize resistance, and prevent voltage drops over long distances. This is particularly important in high-power applications where the demand for current is higher, and the risk of overheating and energy loss must be minimized.

Understanding the AWG system is vital for various practical applications, including home wiring, professional audio setups, and lighting systems. For example, in home wiring, selecting the right gauge ensures that the wiring can handle the electrical load without overheating or causing voltage drops. In professional audio setups, using the correct gauge helps maintain signal integrity and prevent power loss, ensuring high-quality sound output. In lighting systems, the appropriate gauge ensures that the lights receive sufficient power, maintaining consistent brightness and performance.

By comprehending the AWG system and its implications on wire gauges, users can make informed decisions that enhance the safety, efficiency, and performance of their electrical projects.

When comparing 14-gauge and 16-gauge wires, one of the most noticeable differences is their thickness.

Electrical resistance is a key factor in determining a wire’s efficiency and suitability for various applications.

Ampacity, or the current-carrying capacity of a wire, is crucial for ensuring safe and efficient electrical systems.

The higher ampacity of the 14-gauge wire makes it ideal for higher power systems or applications requiring longer wiring runs, reducing the risk of overheating and improving overall system reliability.

The choice between 14-gauge and 16-gauge wires largely depends on the specific application and requirements.

Cost is often a significant factor in wire selection, and the price difference between 14-gauge and 16-gauge wires can influence the decision.

The physical properties of the wire also affect its ease of use in various installations.

To help you choose between 14-gauge and 16-gauge wires, here’s a side-by-side comparison of their key specifications. This table highlights the critical differences and performance characteristics that can influence your decision based on application needs.

| Aspect | 14-Gauge Wire | 16-Gauge Wire |

|---|---|---|

| Thickness | 0.0641 inches (1.628 mm) | 0.0508 inches (1.291 mm) |

| Cross-Sectional Area | 2.05 mm² | 1.31 mm² |

| Resistance | 2.525 ohms per 1000 feet | 4.016 ohms per 1000 feet |

| Current Capacity | Up to 15 amps | Up to 13 amps |

| Power Handling | Suitable for high-power applications | Suitable for low-power applications |

| Voltage Drop | Minimal over long distances | Significant over long distances |

| Durability | More durable and robust | Less durable, more flexible |

| Flexibility | Less flexible | More flexible and easier to handle |

| Applications | High-power speaker systems, long-distance wiring | Standard audio setups, short-distance wiring |

| Budget | Generally more expensive | More budget-friendly |

The 14-gauge wire has a larger thickness and cross-sectional area compared to the 16-gauge wire. This increased size provides better durability and the ability to handle higher current loads, making it suitable for more demanding applications.

The 14-gauge wire has a lower resistance (2.525 ohms per 1000 feet) compared to the 16-gauge wire (4.016 ohms per 1000 feet), allowing for more efficient current flow and reducing energy loss. Lower resistance in the 14-gauge wire makes it ideal for high-power applications and longer distances.

Ampacity refers to the maximum current a wire can safely carry without overheating. The 14-gauge wire can handle up to 15 amps, while the 16-gauge wire can handle up to 13 amps. This difference makes the 14-gauge wire more suitable for higher power systems and longer wiring runs.

Voltage drop is a critical factor, especially for long-distance wiring. The 14-gauge wire experiences minimal voltage drop over long distances, which helps maintain signal quality and power efficiency. In contrast, the 16-gauge wire is more prone to significant voltage drop, which can affect performance over longer runs.

The 14-gauge wire is more durable and robust due to its thicker diameter, making it less susceptible to damage, although it is less flexible and harder to work with in tight spaces. The 16-gauge wire, while less durable, offers greater flexibility and ease of handling, which can be advantageous in certain installations.

The choice between these wires often depends on the specific application:

Cost can be a determining factor in wire selection. The 14-gauge wire is generally more expensive due to its enhanced performance characteristics. Conversely, the 16-gauge wire is more budget-friendly, making it a practical choice for less demanding applications where cost is a significant consideration.

When selecting between 14-gauge and 16-gauge wires, understanding their suitability for high-power applications is crucial.

14-gauge wire is well-suited for high-power applications due to its lower electrical resistance and higher current-carrying capacity. This wire can handle up to 15 amps, making it ideal for systems such as home wiring and large audio setups that demand substantial power. This wire is ideal for various high-power needs, including:

16-gauge wire, with its higher resistance and lower current capacity (up to 13 amps), is more appropriate for lower power applications. It is commonly used where flexibility and ease of handling are priorities. Typical applications include:

Safety is crucial when choosing wire gauges, and it involves understanding the risks associated with each wire type in various applications.

Using the correct wire gauge is essential to prevent overheating and potential fire hazards.

Voltage drop can impact both the performance and safety of electrical systems.

The physical properties of the wire also play a role in safety and usability.

Selecting the appropriate wire gauge involves balancing safety and application needs.

By carefully evaluating these factors, you can ensure the safe and efficient operation of electrical systems while meeting the specific needs of your project.

When it comes to power requirements, the difference between 14-gauge and 16-gauge wires is significant. A 14-gauge wire, with its lower resistance and higher ampacity of up to 15 amps, is the go-to choice for high-power setups. For instance, a 14-gauge wire can ensure efficient power delivery without any loss of quality in a home theater system with high-performance speakers and a powerful amplifier, whereas a 16-gauge wire is more suitable for low-power systems like a bedside lamp or a small table fan.

In home wiring, safety and efficiency are paramount. For circuits powering multiple outlets or large appliances, which require higher current, 14-gauge wire is the better option. It can handle the load without overheating, reducing the risk of fire hazards. However, for areas where the power demand is low, like the wiring for a single light switch or a small wall socket, 16-gauge wire can be used. It is more budget-friendly and still meets the requirements for these low-power applications.

Signal integrity is crucial in professional audio setups. A 14-gauge wire is ideal for long cable runs and high-power audio systems. It minimizes voltage drop, ensuring that the audio signal remains strong and clear from the source to the speakers. For smaller audio systems, such as those in a home office or a small recording studio, a 16-gauge wire can be sufficient. Its flexibility also makes it easier to route around equipment and through tight spaces.

For lighting systems, the choice between 14-gauge and 16-gauge wire depends on the type and number of lights. In a large commercial lighting installation with high-wattage bulbs, 14-gauge wire is necessary to provide the required power and maintain consistent brightness. In a residential setting with low-voltage LED lights, 16-gauge wire can be used. It is cost-effective and easy to install in tight spaces like ceiling fixtures.

Below are answers to some frequently asked questions:

The primary differences between 14-gauge and 16-gauge wires revolve around their physical characteristics, electrical resistance, and current-carrying capacity.

14-gauge wire is thicker, with a diameter of approximately 1.628 mm, and has lower electrical resistance, around 2.525 ohms per 1000 feet. This gauge can handle up to 15 amps, making it suitable for high-power applications such as heavy-duty electrical systems, home theater setups, and long-distance wiring. However, its thickness makes it less flexible and generally more expensive.

In contrast, 16-gauge wire is thinner, with a diameter of about 1.291 mm, and higher resistance at approximately 4.016 ohms per 1000 feet. It is suitable for applications requiring up to 13 amps, like speaker wiring, low-voltage lighting, and automotive accessories. Its thinner size makes it more flexible and easier to work with, particularly in tight spaces, and it is also more cost-effective.

Choosing between the two depends on specific project requirements, including power needs, distance, and budget.

Use 14-gauge wire for high-power applications, long-distance runs (over 50 feet), and when durability is key. It can handle up to 15 amps, has lower resistance (2.525 ohms per 1000 feet), and a cross-sectional area of about 2.05 mm². Ideal for home wiring or high-power audio systems. Opt for 16-gauge wire for short-distance runs (under 50 feet) and low-power applications. It can carry up to 13 amps, has higher resistance (4.016 ohms per 1000 feet), and a 1.31 mm² area. It’s more flexible, economical, and suitable for standard audio setups or short wiring jobs.

The American Wire Gauge (AWG) system is a standardized method used in North America to denote the diameter and cross-sectional area of round, solid electrical wires. The system assigns smaller numbers to thicker wires and larger numbers to thinner wires. For instance, a 14-gauge wire is thicker than a 16-gauge wire.

This system significantly impacts wire selection by determining the wire’s physical characteristics, electrical resistance, and current-carrying capacity (ampacity). Thicker wires (lower AWG numbers) have lower resistance and can carry more current, making them suitable for high-power applications and longer runs where minimizing voltage drop is crucial. Conversely, thinner wires (higher AWG numbers) are typically used for lower-power applications and shorter distances due to their higher resistance and lower ampacity.

Selecting the appropriate wire gauge according to the AWG system ensures safety, efficiency, and the proper functioning of electrical systems, as discussed earlier in the article. Understanding the AWG system helps in making informed decisions for various electrical projects, ensuring compatibility with power requirements and application needs.

14-gauge wire is commonly used in residential lighting circuits, thermostat wiring, speaker wiring, and landscape lighting. It is suitable for 15-amp circuits and applications that require a balance of current-carrying capacity, flexibility, and cost. This makes it ideal for wiring standard 120-volt outlets and lighting fixtures in homes, as well as for professional audio installations that require higher power and longer distances.

16-gauge wire, on the other hand, is often used in standard audio setups, extension cords, automotive wiring, and lighting applications where moderate current demand and flexibility are important. It is preferred for short-distance wiring in home audio systems and small appliances due to its cost-effectiveness and ability to handle moderate current. This wire is also commonly used in automotive systems where flexibility and a slight increase in current capacity over smaller gauges are needed.

To calculate the appropriate wire gauge for your project, follow these steps:

For example, if you’re deciding between 14 AWG and 16 AWG wires, remember that 14 AWG handles higher currents (up to 15 amps) and is better for long distances due to lower resistance and minimal voltage drop. In contrast, 16 AWG is suitable for shorter runs and lower power applications (up to 13 amps). By considering these factors, you can ensure optimal performance and safety for your project.

Using the wrong wire gauge can indeed pose significant safety risks. Specifically, a wire gauge that is too thin for the current it carries can lead to overheating, which may cause electrical fires or equipment malfunctions. For instance, a 14-gauge wire can handle higher current loads than a 16-gauge wire. If a 16-gauge wire is used in a high-power application where a 14-gauge wire is required, the increased electrical resistance in the thinner wire can result in excessive heat buildup.

Additionally, voltage drop is another concern. Thinner wires, like 16-gauge, are more prone to voltage drops over long distances, which can impair the performance of electrical devices and potentially cause damage. Proper wire gauge selection is essential to comply with local electrical codes and ensure safe, efficient operation. Therefore, understanding and choosing the correct wire gauge based on the specific requirements of your electrical project is crucial to prevent these safety hazards.