When it comes to selecting the right stainless steel for your project, understanding the differences between 17-4 PH and 316 stainless steel is crucial. These two materials are renowned for their unique properties and applications, but how do they truly compare? Is one more resistant to corrosion than the other? Does one offer superior mechanical strength? This article will delve into the key distinctions between 17-4 PH and 316 stainless steel, exploring their mechanical properties, corrosion resistance, and typical applications across various industries. By the end, you’ll have a comprehensive understanding of which stainless steel best suits your needs, whether for aerospace, automotive, marine, or other demanding environments. Ready to uncover the nuances of these two formidable alloys? Let’s dive in.

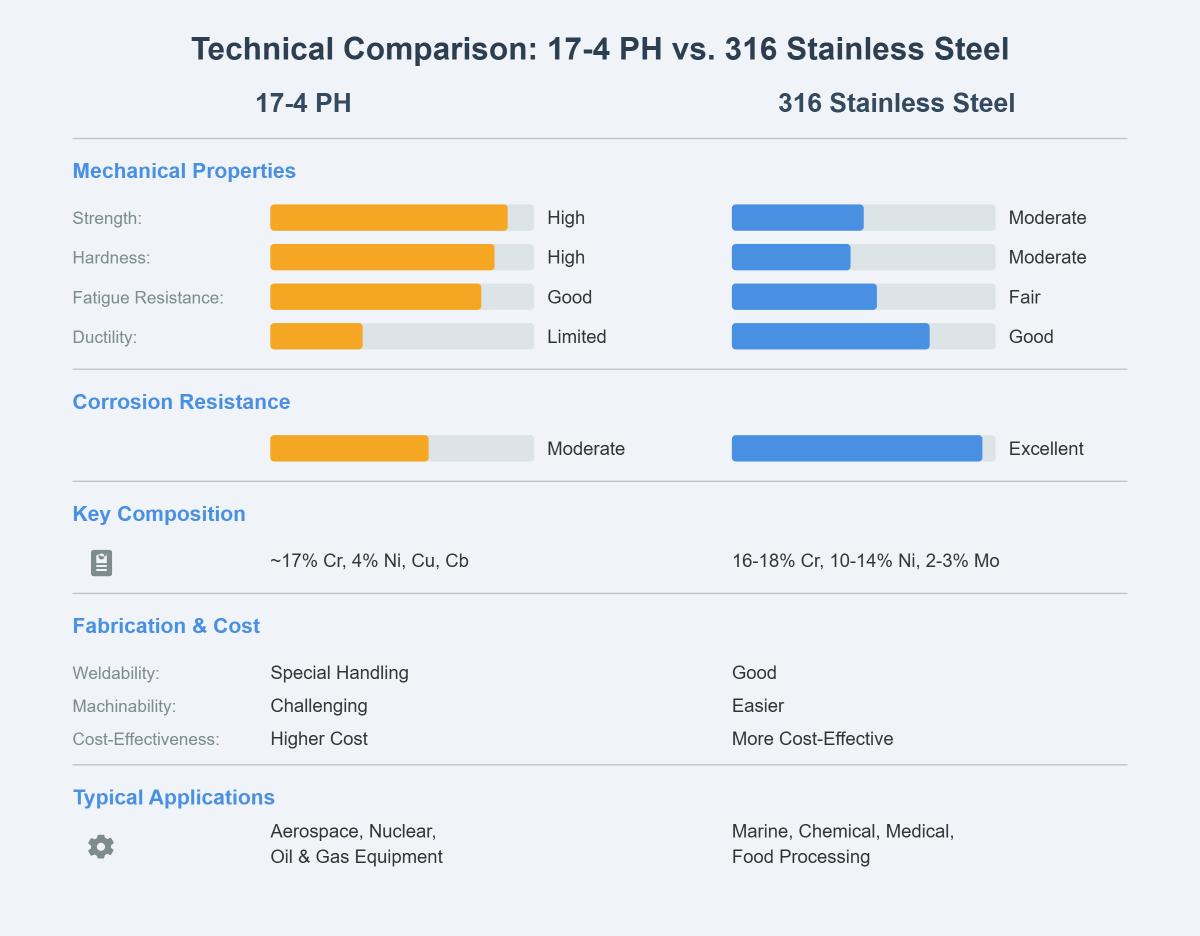

17-4 PH stainless steel, also known as UNS S17400, is a type of precipitation-hardening martensitic stainless steel. It contains about 17% chromium and 4% nickel, along with copper, columbium, and tantalum, which give it unique properties such as high tensile strength, yield strength, and hardness. The material undergoes a heat treatment process to precipitate hardening, further enhancing its mechanical properties.

316 stainless steel, designated as UNS S31600, is an austenitic stainless steel with 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The molybdenum enhances its corrosion resistance, especially in chloride-rich environments. This steel is known for its excellent weldability, formability, and resistance to pitting and crevice corrosion. It is widely used in industries where exposure to harsh environments is common, such as marine, chemical processing, and medical devices.

17-4 PH Stainless Steel:

316 Stainless Steel:

17-4 PH stainless steel has a tensile strength of up to 1276 MPa, yield strength up to 1170 MPa, hardness of HB 280-440, and elongation at break of 8-21%. In comparison, 316 stainless steel offers a tensile strength of up to 545 MPa, yield strength up to 275 MPa, hardness of HB 160-360, and elongation at break of 8-55%.

17-4 PH stainless steel has good general corrosion resistance but is less effective in high-chloride or acidic environments, making it suitable for hydraulic oils and brake fluids. On the other hand, 316 stainless steel excels in chloride-rich and marine environments with excellent resistance to pitting and crevice corrosion.

17-4 PH stainless steel requires specialized tooling and heat treatments for welding, commonly used in aerospace and automotive industries for its high strength and fatigue resistance. Conversely, 316 stainless steel is easier to machine and weld, often used in construction, food processing, and medical devices due to its versatility and superior corrosion resistance.

Hardness is crucial for evaluating how well materials resist wear and maintain durability.

17-4 PH stainless steel is known for its high hardness, typically ranging from 280 to 440 Brinell hardness (HB). Its high hardness comes from a special hardening process, making it ideal for applications that need to resist wear and high stress.

316 stainless steel exhibits a lower hardness compared to 17-4 PH, with values typically between 160 to 360 HB. Its austenitic structure allows for better formability and machinability, but it does not provide the same level of wear resistance as 17-4 PH.

Ductility, the ability to deform under tensile stress, is crucial for applications involving significant bending or stretching.

17-4 PH demonstrates lower ductility, with elongation values ranging from 8% to 21%. This reduced ductility is a trade-off for its higher strength and hardness, making it less ideal for applications requiring extensive deformation.

316 stainless steel offers higher ductility, with elongation values between 8% and 55%. This higher ductility makes it more suitable for applications involving complex shapes and significant deformation, such as deep drawing and forming operations.

Fatigue strength is essential for materials subjected to cyclic loading, where resistance to crack initiation and propagation is crucial.

17-4 PH exhibits superior fatigue strength, typically ranging from 380 to 670 MPa. This high fatigue strength makes it ideal for components experiencing repeated loading and unloading cycles, such as aerospace and automotive parts.

With a fatigue strength of 210 to 430 MPa, 316 stainless steel is adequate for many uses but less suitable for high-cycle fatigue compared to 17-4 PH.

Tensile strength is the maximum stress that a material can withstand while being stretched or pulled before breaking.

Yield strength is the stress at which a material begins to deform plastically.

Shear strength and modulus are important for assessing the material’s response to shear forces.

Thermal expansion measures how much a material changes size with temperature variations.

17-4 PH stainless steel is recognized for its decent corrosion resistance. This material is generally suitable for environments involving mild corrosive conditions, such as exposure to hydraulic oils, brake fluids, and freshwater. The precipitation hardening process enhances its mechanical properties but does not significantly improve its corrosion resistance. Therefore, 17-4 PH is not ideal for high-chloride or acidic environments due to the risk of pitting and crevice corrosion.

316 stainless steel is known for its excellent corrosion resistance, especially in chloride-rich environments. The presence of molybdenum (2-3%) in its composition significantly enhances its resistance to pitting and crevice corrosion. This makes 316 stainless steel an excellent choice for marine applications, chemical processing, and any environment where exposure to salts and acids is prevalent. Additionally, 316 stainless steel exhibits good resistance to hydrogen embrittlement, making it suitable for applications involving hydrogen-rich gases.

When comparing 17-4 PH and 316 stainless steel, it is clear that 316 stainless steel has better corrosion resistance, particularly in harsh environments with chlorides and acids. The following table summarizes the key differences in corrosion resistance between these two materials:

| Feature | 316 Stainless Steel | 17-4 PH Stainless Steel |

|---|---|---|

| Corrosion Resistance | Superior, particularly in chloride environments | Moderate, suitable for mild corrosive conditions |

| Ideal Environments | Marine, chemical processing, hydrogen-rich gases | Hydraulic oils, brake fluids, freshwater |

| Resistance to Pitting and Crevice Corrosion | High | Lower |

| Suitability for High-Chloride Environments | Excellent | Not recommended |

17-4 PH stainless steel is highly valued in the aerospace industry for its excellent combination of high strength, hardness, and fatigue resistance. Components such as gears, shafts, and structural parts benefit from its ability to withstand high-stress environments and repeated loads. The precipitation hardening process enhances its mechanical properties, making it suitable for critical applications where material failure is not an option.

Although 316 stainless steel is not typically used for high-strength parts, its excellent corrosion resistance makes it perfect for non-structural components. It is often used in fuel and hydraulic lines, fasteners, and other parts exposed to corrosive environments. Its excellent formability and weldability also make it suitable for complex shapes and assemblies.

In the automotive industry, 17-4 PH stainless steel is ideal for parts requiring high strength and wear resistance, like pump shafts and valve components. Its ability to maintain mechanical properties under high stress and its resistance to fatigue make it an excellent choice for critical load-bearing applications.

316 stainless steel finds its place in automotive applications where corrosion resistance is paramount. It is often used in exhaust systems, catalytic converters, and other components exposed to high temperatures and corrosive environments. Its good formability and ease of welding also facilitate its use in complex assemblies and custom parts.

Although 17-4 PH stainless steel offers decent corrosion resistance, it is less favored in marine environments compared to 316 stainless steel. It can be used in marine applications where high strength is required, such as for certain types of fasteners and mechanical components, but additional protective coatings are often necessary to enhance its corrosion resistance.

316 stainless steel is the preferred material for marine applications due to its excellent resistance to corrosion in salty environments. It is commonly used in boat fittings, marine hardware, and underwater equipment. Its high resistance to seawater corrosion ensures long-term durability and reliability in harsh marine conditions.

Beyond aerospace and automotive, 17-4 PH stainless steel is used in various industries where high strength and hardness are essential. This includes the production of high-load machinery parts, industrial valves, and fasteners in the oil and gas sector. Its mechanical properties make it ideal for applications that demand durability and resistance to wear and tear.

316 stainless steel is widely utilized across numerous industries, including food processing, pharmaceuticals, and medical devices, due to its excellent corrosion resistance and biocompatibility. It is used in the manufacture of surgical instruments, pharmaceutical equipment, and food processing machinery. Its ability to withstand rigorous cleaning and sterilization processes without deteriorating makes it a top choice in these industries.

Selecting the appropriate stainless steel for a specific application requires a comprehensive understanding of the material’s properties and the demands of the application environment. Here are the key factors to consider:

Mechanical properties like tensile strength, yield strength, and hardness are vital in assessing a material’s suitability for high-stress applications.

Corrosion resistance is a key factor, especially in environments with exposure to corrosive substances like chlorides and acids.

The specific environment where the material will be used significantly impacts the selection process.

When selecting between 17-4 PH and 316 stainless steel for high-stress environments, consider the following:

In the aerospace industry, selecting the right stainless steel can impact performance and safety.

Marine environments demand materials that can withstand harsh corrosion.

In medical applications, biocompatibility and corrosion resistance are critical.

When selecting between 17-4 PH and 316 stainless steel, it is essential to consider the specific requirements of the application, including mechanical properties, environmental conditions, and the nature of the stress the material will endure. Each material has its strengths and is suited to different applications based on these factors.

17-4 PH stainless steel stands out for its high mechanical strength, with tensile strength reaching up to 1276 MPa and yield strength up to 1170 MPa. Its high strength and fatigue resistance make it ideal for aerospace and automotive components, while its hardness (350 HB) and lower elongation (8-21%) enhance wear resistance but reduce ductility.

316 stainless steel has lower tensile strength (up to 545 MPa) and yield strength (up to 275 MPa) than 17-4 PH, but its higher ductility (up to 50% elongation) makes it better for applications needing significant deformation without breaking. This material is particularly well-suited for environments with high levels of corrosive substances, such as chloride-rich and marine environments.

While both 17-4 PH and 316 stainless steel have excellent corrosion resistance, 316 stainless steel performs better in highly corrosive environments. This enhanced resistance to pitting and crevice corrosion makes 316 stainless steel more sustainable for applications in the chemical processing and marine industries, where prolonged exposure to corrosive agents is common.

316 stainless steel generally offers superior weldability and machinability compared to 17-4 PH. This can lead to more efficient manufacturing processes, as 316 stainless steel requires less specialized tooling and heat treatments. Conversely, 17-4 PH demands careful handling during welding to prevent distortion, which can increase production time and costs.

The energy efficiency of these materials varies by application. 17-4 PH’s high strength-to-weight ratio allows for lighter designs, reducing material usage and potentially lowering energy costs in production and operation. On the other hand, 316 stainless steel’s superior corrosion resistance can lead to longer product lifespans, thereby decreasing the frequency of replacements and the associated energy consumption.

316 stainless steel’s outstanding corrosion resistance contributes to its longer lifespan in demanding environments. This longevity reduces waste and the need for frequent replacements, aligning with sustainable practices by minimizing environmental impact over time.

Both 17-4 PH and 316 stainless steel are recyclable, which is a crucial factor in their sustainability. The recycling processes for these materials can vary depending on local infrastructure and practices, but their inherent recyclability supports the principles of a circular economy.

Understanding the chemical composition and standards compliance of 17-4 PH and 316 stainless steel is crucial for selecting the right material for specific applications.

17-4 PH stainless steel, known as UNS S17400, is a type of martensitic stainless steel that gains high strength and hardness through heat treatment. It contains about 17% chromium and 4% nickel, with added elements like copper and niobium. Compliance with standards like ASTM A564 and SAE J467 ensures that the material meets specific chemical composition and mechanical property requirements, making it suitable for high-stress applications.

316 stainless steel, identified as UNS S31600, is an austenitic stainless steel with 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. Molybdenum enhances its resistance to corrosion, particularly in chloride environments. Standards such as ASTM A240 and SAE J405 govern the chemical composition and mechanical properties of 316 stainless steel, ensuring its suitability for applications requiring excellent corrosion resistance.

The mechanical properties of these stainless steels are influenced by their chemical composition and compliance with specific standards.

17-4 PH stainless steel is very strong, with a tensile strength of up to 1276 MPa and a yield strength of 1170 MPa. Its hardness can reach 350 HB, and it has a high fatigue strength between 380 and 670 MPa. These properties are standardized under ASTM A564 and SAE J467, which specify the requirements for mechanical performance, making this material ideal for dynamic load applications.

In comparison, 316 stainless steel offers a lower tensile strength of about 545 MPa and a yield strength of 275 MPa. However, it provides better ductility, with an elongation at break of up to 55%. These mechanical properties are regulated by standards such as ASTM A240 and SAE J405, ensuring that 316 stainless steel is suitable for applications where moderate mechanical strength and high formability are required.

Corrosion resistance is a critical factor in selecting stainless steels for various environments.

17-4 PH stainless steel resists corrosion well in mild environments, like those with hydraulic oils. However, it is more prone to pitting and crevice corrosion compared to 316 stainless steel. Standards like ASTM A564 ensure it is used appropriately in moderately corrosive conditions.

316 stainless steel is renowned for its excellent corrosion resistance, particularly in chloride environments, making it ideal for marine and chemical processing applications. Standards such as ASTM A240 and SAE J405 specify its superior resistance to pitting and crevice corrosion, ensuring its reliability in harsh environments.

Weldability is an important consideration in the fabrication of stainless steel components.

17-4 PH stainless steel is easier to weld due to its higher carbon content, but welding must be carefully controlled to prevent corrosion. ASTM A564 provides guidelines for welding and post-weld treatments to maintain its properties.

316 stainless steel offers better weldability with preheating, which helps to ensure durability and resistance to wear and tear over time. Standards such as ASTM A240 outline the requirements for welding procedures and heat treatments to preserve its mechanical and corrosion-resistant properties.

Thermal properties affect the performance of stainless steels under varying temperature conditions.

17-4 PH stainless steel has a lower coefficient of thermal expansion and can withstand temperatures up to approximately 600°F (316°C). This property reduces the risk of dimensional changes under temperature variations. Standards like ASTM A564 specify the thermal properties and heat treatment processes to ensure consistency in performance.

316 stainless steel exhibits a higher thermal expansion coefficient and can withstand temperatures up to 1200°F (649°C). This makes it suitable for applications requiring high thermal stability. Standards such as ASTM A240 provide guidelines for its thermal properties, ensuring its suitability for high-temperature applications.

Below are answers to some frequently asked questions:

The key differences between 17-4 PH and 316 stainless steel lie primarily in their mechanical properties, corrosion resistance, and typical applications.

17-4 PH stainless steel is known for its high strength, hardness, and fatigue resistance, making it suitable for high-stress environments such as aerospace components, nuclear reactor parts, and oil and gas equipment. It contains approximately 17% chromium and 4% nickel, along with copper and columbium, contributing to its superior mechanical properties. However, it has limited ductility and requires special handling during welding and fabrication due to its precipitation-hardening nature.

On the other hand, 316 stainless steel is prized for its excellent corrosion resistance, ductility, and weldability, making it ideal for marine environments, chemical processing, medical devices, and food processing equipment. It comprises 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, which enhances its resistance to corrosive substances. Additionally, 316 stainless steel is generally more cost-effective and easier to machine and weld compared to 17-4 PH.

When prioritizing corrosion resistance, 316 stainless steel generally outperforms 17-4 PH stainless steel. The chemical composition of 316 stainless steel, which includes 16-18% chromium, 8-10% nickel, and 2.1% molybdenum, provides excellent resistance to pitting and crevice corrosion, particularly in chloride-rich environments such as marine settings and chemical processing. This makes 316 stainless steel highly effective against corrosion and suitable for harsh environments.

On the other hand, 17-4 PH stainless steel, with its 17.5% chromium and 4% nickel content, along with copper, columbium, and tantalum, offers moderate corrosion resistance. It is typically used in environments with less severe corrosive conditions, such as those involving hydraulic oils and brake fluids, where its high strength is more critical than its corrosion resistance.

Therefore, for applications in highly corrosive environments, 316 stainless steel is the better choice. However, if the application requires high mechanical strength with moderate corrosion resistance, 17-4 PH stainless steel may be more suitable.

The mechanical properties of 17-4 PH and 316 stainless steel differ significantly, making them suitable for different applications. 17-4 PH stainless steel exhibits higher tensile strength (910 to 1390 MPa) and yield strength (580 to 1250 MPa), making it ideal for high-stress environments. It also has higher hardness (280 to 440 HB) and fatigue strength (380 to 670 MPa), contributing to its wear resistance and ability to withstand repeated stress cycles. However, it has lower elongation at break (8% to 21%), indicating less ductility.

In contrast, 316 stainless steel has lower tensile strength (520 to 1180 MPa) and yield strength (230 to 850 MPa) but offers greater ductility, with elongation at break ranging from 8% to 55%. It has lower hardness (160 to 360 HB) and fatigue strength (210 to 430 MPa) compared to 17-4 PH. These properties make 316 stainless steel more suitable for applications that require significant deformation before failure and environments where corrosion resistance is crucial.

17-4 PH stainless steel, also known as grade 630, is commonly used in applications that require high strength, hardness, and moderate corrosion resistance. In the aerospace industry, it is utilized for components like fasteners, turbine blades, and undercarriage parts due to its excellent tensile strength and fatigue resistance. The food processing industry favors 17-4 PH for equipment fabrication because of its corrosion resistance and ease of cleaning. In the oil and gas sector, it is suitable for components exposed to hydraulic oils and brake fluids, though it is less ideal for environments with high chloride exposure. Additionally, the chemical and petrochemical industries use 17-4 PH in applications where both mechanical properties and moderate corrosion resistance are essential.

316 stainless steel is highly valued for its excellent corrosion resistance and versatility, making it a popular choice across various industries. In the chemical and petrochemical industries, it is used for equipment such as tanks, reactors, and piping systems due to its resistance to aggressive chemicals and acids. In the food service and hospitality sectors, it is commonly employed for commercial kitchen equipment and appliances because of its durability and resistance to harsh cleaning agents. The pulp and paper industry utilizes 316 stainless steel to prevent iron contamination in processing equipment, ensuring product quality. Additionally, it is used in medical equipment for surgical instruments and implants due to its non-toxic nature and corrosion resistance. In the energy sector, 316 stainless steel is used in power generation components and nuclear power plants for its strength and resistance to corrosion. It is also essential in marine environments for boat fittings and coastal architectural features, where resistance to chlorides is crucial. In architectural and construction applications, 316 stainless steel is employed in building facades, handrails, and bridges for its aesthetic appeal and durability in corrosive environments.

To choose the right stainless steel for your application, consider the specific requirements of your project in terms of corrosion resistance, mechanical properties, fabrication needs, cost, and environmental conditions.

17-4 PH stainless steel offers high strength, hardness, and fatigue resistance, making it ideal for high-stress applications in aerospace and automotive industries. However, it has moderate corrosion resistance, not suitable for environments with high levels of chlorides or acids.

On the other hand, 316 stainless steel excels in corrosion resistance, particularly in marine and chemical processing environments due to its ability to withstand chlorides and acids. It also offers better ductility and is easier to machine and weld, making it a versatile choice for applications requiring significant deformation and extensive fabrication.

Evaluate the environmental conditions, including exposure to corrosive substances and temperature variations, and balance the material cost with its performance and longevity to make an informed decision.