When it comes to selecting the right stainless steel for your project, understanding the differences between 17-4 PH and 440C stainless steel is crucial. These two materials, each with unique properties and applications, often compete in industries that demand high performance and durability. What sets them apart in terms of chemical composition, mechanical properties, and corrosion resistance? How do their hardness and tensile strength measure up against each other? This article delves into the key distinctions between 17-4 PH and 440C stainless steel, providing you with the insights necessary to make an informed decision for your specific needs. Ready to uncover which stainless steel reigns supreme for your next project? Let’s dive in.

Stainless steel is a popular material in various industries because of its excellent properties, including corrosion resistance, durability, and strength. Among the numerous grades available, 17-4 PH and 440C stainless steels stand out for their unique characteristics and suitability for specific applications. Understanding the differences between these two grades is crucial for engineers and materials specialists when selecting the appropriate material for their projects.

17-4 PH stainless steel, also known as precipitation hardening stainless steel, is highly valued for its high strength and excellent corrosion resistance, thanks to alloying elements such as chromium, nickel, and copper. The precipitation hardening process enhances its mechanical characteristics, making it suitable for demanding environments and applications. Industries such as aerospace, defense, and chemical processing often rely on 17-4 PH for its ability to maintain strength at elevated temperatures and resist corrosion in aggressive environments.

440C stainless steel is a high-carbon martensitic stainless steel known for its exceptional hardness and wear resistance. This grade has a higher carbon content than 17-4 PH, which makes it much harder. 440C is commonly used in applications that require high wear resistance, such as bearings, cutting tools, and valve parts. While its corrosion resistance is adequate for mild environments, it is not as robust as 17-4 PH in aggressive conditions. The high hardness of 440C makes it a preferred choice for components that experience substantial wear and tear.

The primary difference between 17-4 PH and 440C stainless steels lies in their composition. 17-4 PH is alloyed with chromium, nickel, and copper, which aid in the precipitation hardening process and enhance its mechanical properties. In contrast, 440C has a higher carbon content, which is responsible for its superior hardness and wear resistance.

When comparing mechanical properties, 17-4 PH offers a balanced profile of high strength, good corrosion resistance, and relatively easier machinability. It performs well in aerospace and chemical processing applications where toughness and corrosion resistance are critical. On the other hand, 440C excels in hardness and wear resistance, making it ideal for tooling and bearing applications where surface durability is paramount.

17-4 PH stainless steel generally provides better corrosion resistance compared to 440C, especially in aggressive environments. This makes 17-4 PH a preferred choice for marine hardware and chemical processing equipment. 440C, while adequate in mild environments, may not perform as well in highly corrosive conditions.

When it comes to machinability, 17-4 PH stainless steel is relatively easier to machine in its annealed state, akin to stainless 304, although it becomes more challenging after hardening. In contrast, 440C’s higher carbon content makes it tougher to machine and requires careful handling during forging and cooling to avoid cracking.

The chemical composition of 17-4 PH and 440C stainless steels is the foundation of their distinct properties. Here’s a comparative analysis of their core components:

| Element | 17-4 PH Stainless Steel (%) | 440C Stainless Steel (%) |

|---|---|---|

| Chromium (Cr) | 15.0–17.5 | 16.0–18.0 |

| Nickel (Ni) | 3.0–5.0 | ≤1.0 (trace) |

| Copper (Cu) | 3.0–5.0 | – |

| Niobium (Nb) | 0.15–0.45 | – |

| Carbon (C) | ≤0.07 | 0.95–1.20 |

| Manganese (Mn) | ≤1.0 | 1.0–2.0 |

| Silicon (Si) | ≤1.0 | ≤1.0 |

| Molybdenum (Mo) | – | ≤0.75 (grade-dependent) |

440C stainless steel has a high carbon content ranging from 0.95% to 1.20%, which is essential for achieving extreme hardness. This significant carbon presence is crucial for making 440C ideal for applications requiring high wear resistance and hardness. In contrast, 17-4 PH stainless steel features a low carbon content of ≤0.07%, enhancing its corrosion resistance and weldability. The lower carbon content helps prevent carbide precipitation, which can deteriorate corrosion resistance.

440C Stainless Steel comprises 16.0% to 18.0% chromium, providing basic corrosion resistance, and contains minimal nickel (≤1.0%), which does not significantly enhance corrosion resistance. In contrast, 17-4 PH Stainless Steel contains 15.0% to 17.5% chromium and 3.0% to 5.0% nickel, significantly boosting corrosion resistance and stabilizing the austenitic-martensitic structure.

17-4 PH Stainless Steel includes 3.0% to 5.0% copper and 0.15% to 0.45% niobium. These elements are essential for the precipitation hardening process, significantly increasing the tensile strength of the alloy, allowing it to reach up to 190,000 psi. On the other hand, 440C Stainless Steel lacks specific precipitation-hardening elements like copper and niobium. It relies on high carbon content for martensitic transformation, which ensures hardness.

The combination of chromium, nickel, and copper in 17-4 PH stainless steel results in superior corrosion resistance compared to 440C. This makes 17-4 PH more suitable for aggressive environments, such as chemical processing and marine applications.

440C Stainless Steel achieves a hardness level of 58–60 HRC due to its high carbon content, making it perfect for cutting tools, bearings, and other wear-resistant applications. However, this high hardness comes at the expense of toughness. Conversely, 17-4 PH Stainless Steel typically reaches a hardness of around 44 HRC but offers superior ductility and toughness. This balance makes it suitable for aerospace components and other applications where both strength and toughness are required.

440C Stainless Steel requires a heat treatment process involving quenching and tempering to achieve its maximum hardness. This process must be carefully controlled to prevent cracking. In contrast, 17-4 PH Stainless Steel undergoes aging treatments like H900 to enhance its mechanical properties. This aging process improves its strength and toughness without the risk of cracking associated with high-carbon steels.

By understanding these compositional differences, engineers and materials specialists can make informed decisions when selecting the appropriate stainless steel grade for their specific applications.

The hardness of stainless steel is crucial for its performance in wear-resistant applications.

Tensile strength is a measure of the maximum stress a material can withstand while being stretched or pulled before breaking.

Yield strength represents the stress at which a material begins to deform plastically. It is a crucial property for determining the load a material can handle before permanent deformation.

Wear resistance is essential for materials used in applications subject to friction and abrasion.

17-4 PH stainless steel is a staple in the aerospace industry thanks to its impressive strength-to-weight ratio and excellent corrosion resistance. It is commonly used in manufacturing turbine blades, missile fittings, and undercarriage components. The material’s ability to maintain mechanical properties at elevated temperatures makes it ideal for aerospace applications where performance and durability are critical.

In the medical field, 17-4 PH stainless steel is highly valued for its biocompatibility and resistance to sterilization processes, making it ideal for surgical instruments and implants. Its ability to withstand repeated sterilization ensures the longevity and reliability of medical devices.

The chemical processing industry benefits from 17-4 PH stainless steel’s resistance to acidic and alkaline environments. This material is often used in valves, pumps, and reactor components that require durability and corrosion resistance. Its performance in harsh chemical environments ensures the integrity and safety of processing equipment.

Its resistance to saltwater corrosion makes 17-4 PH stainless steel perfect for marine hardware that faces harsh marine environments. This material ensures the reliability and longevity of marine equipment.

440C stainless steel is renowned for its exceptional hardness and wear resistance, making it ideal for cutting tools. It is commonly used in manufacturing high-hardness blades, surgical scalpels, and industrial knives. The material’s ability to retain a sharp edge under demanding conditions makes it a preferred choice for cutting applications.

In applications requiring precision and durability, 440C stainless steel is used for precision bearings and ball-bearing assemblies. Its high hardness ensures minimal wear and extended service life, making it suitable for low-corrosion environments where reliability is crucial.

The firearms industry uses 440C stainless steel for gun barrels and components that require high wear resistance. Its hardness ensures the longevity and performance of firearm parts even under extreme conditions.

Choosing between 17-4 PH and 440C stainless steel depends on specific needs. For environments needing strength, corrosion resistance, and machinability, 17-4 PH is ideal. For applications where wear resistance is crucial and corrosion is less of an issue, 440C stainless steel is the best choice.

17-4 PH stainless steel is known for its exceptional corrosion resistance, thanks to its unique alloy composition. The combination of high chromium and nickel content forms a robust passive oxide layer, significantly enhancing the material’s resistance to general corrosion. Additionally, the low carbon content minimizes the risk of carbide precipitation at grain boundaries, which can lead to intergranular corrosion. The presence of copper in the alloy also contributes to its resistance to stress corrosion cracking.

17-4 PH stainless steel is easy to machine when annealed, similar to stainless steel 304. However, its machinability decreases significantly after heat treatment because the material becomes harder and stronger. Carbide or high-speed steel tools are recommended for machining 17-4 PH stainless steel, especially after heat treatment, with standard lubrication techniques to reduce tool wear and improve cutting performance. Although conventional machining techniques can be used, post-heat treatment operations may require more robust tooling and slower feed rates to avoid tool breakage and maintain precision.

440C stainless steel is more challenging to machine due to its high carbon content and resultant hardness. In its annealed state, careful forging and cooling are essential to prevent cracking. High-speed steel or carbide tools are also recommended, but the machining process requires meticulous attention to detail, including precise temperature control and lubrication. The hardness of 440C makes it susceptible to tool wear and breakage, necessitating slower cutting speeds and more frequent tool changes to maintain accuracy and surface finish quality.

17-4 PH stainless steel can be heat-treated in different ways to meet specific mechanical requirements:

These conditions allow engineers to select the appropriate heat treatment based on specific application requirements, ensuring optimal performance.

440C stainless steel requires a hardening process involving quenching and tempering. Its high carbon content makes 440C stainless steel very hard after heat treatment. The typical process includes:

Careful control of the heat treatment parameters is crucial to prevent cracking and achieve the desired mechanical properties. This process makes 440C suitable for applications requiring high wear resistance and hardness.

The heat treatment processes for 17-4 PH and 440C stainless steels result in distinct differences in hardness and strength:

Carbide or high-speed steel tools are recommended for machining 17-4 PH stainless steel, especially after heat treatment, with standard lubrication techniques to reduce tool wear. Adjusting feed rates and cutting speeds based on the material’s hardness and strength post-heat treatment ensures precision and minimizes tool damage.

Due to its high hardness, machining 440C stainless steel demands robust tools. High-speed steel or carbide tools are essential, and meticulous attention to lubrication and temperature control is necessary to prevent cracking. Slower cutting speeds and frequent tool changes are recommended to maintain accuracy and surface finish quality.

17-4 PH stainless steel is extensively used in the aerospace industry due to its ability to significantly enhance mechanical properties through precipitation hardening. Case studies have shown that 17-4 PH components, such as structural elements, fasteners, and engine parts, maintain high tensile strengths exceeding 1,300 MPa after H900 treatment at 482°C. The material demonstrates superior corrosion resistance in high-temperature, high-stress environments, with no signs of discoloration or corrosion after 30 autoclave sterilization cycles. This makes 17-4 PH an excellent choice for critical aerospace applications where durability and reliability are paramount.

Despite its excellent wear resistance, 440C stainless steel is less used in aerospace due to moderate corrosion resistance and brittleness when fully hardened. However, its hardness (HRC 58–60) makes it suitable for specific applications like valve seats or bearings. Case studies highlight that while 440C performs well in wear-critical roles, it faces machining challenges and requires coatings to mitigate surface rusting, especially in high-stress conditions.

In medical devices, 17-4 PH stainless steel is favored for its ability to withstand autoclave sterilization. Studies show that both coated and uncoated 17-4 PH samples remain corrosion-free after multiple sterilization cycles, even without passivation. This material’s combination of strength and biocompatibility ensures compliance with stringent medical standards, making it ideal for surgical instruments and implants that demand high reliability and longevity.

440C stainless steel requires surface refinishing or coatings, such as ME-92 thin dense chrome, to mitigate corrosion risks in medical applications. Case studies reveal that uncoated passivated 440C exhibited surface rusting after limited exposure, while coated variants demonstrated minimal staining under stress. This suggests that while 440C can be used for specific medical tools, it needs additional treatments to ensure adequate performance in sterilization environments.

| Property | 17-4 PH (H900) | 440C (Hardened) |

|---|---|---|

| Tensile Strength | 1,300+ MPa | ~760 MPa |

| Hardness | HRC 40–45 | HRC 58–60 |

| Impact Toughness | Moderate | Low |

17-4 PH is ideal for high-stress applications like aircraft landing gear because of its balanced strength and toughness. Conversely, 440C prioritizes wear resistance, making it suitable for cutting tools and bearings. The aging process in 17-4 PH enhances intergranular corrosion resistance through Cu-rich precipitates, while 440C’s quenching from 1,010°C maximizes hardness but reduces ductility, necessitating tempering to balance stress relief and performance.

Case studies demonstrate that 17-4 PH has austenitic-grade corrosion resistance in chloride-rich environments, outperforming 440C in salt spray and humidity tests. Its Cr-Ni-Cu alloy matrix provides passive film stability, crucial for marine and chemical processing applications. This material’s robust corrosion resistance makes it suitable for demanding environments where long-term durability is essential.

440C stainless steel relies on passivation or coatings to achieve usable corrosion resistance. Uncoated parts showed rapid degradation in autoclave and sterilization tests, whereas ME-92-coated samples survived multiple cycles with minimal staining. This indicates that while 440C can be used in harsh environments, it requires additional treatments to maintain its integrity.

17-4 PH is optimal for applications involving multi-axis loading, corrosive environments, and post-fabrication hardening. It is ideal for aerospace, medical, and marine applications due to its balance of strength, toughness, and corrosion resistance.

440C stainless steel is best suited for wear-critical, low-corrosion applications where extreme hardness is prioritized. It requires additional surface treatments for harsh environments but remains a top choice for applications demanding superior wear resistance.

Below are answers to some frequently asked questions:

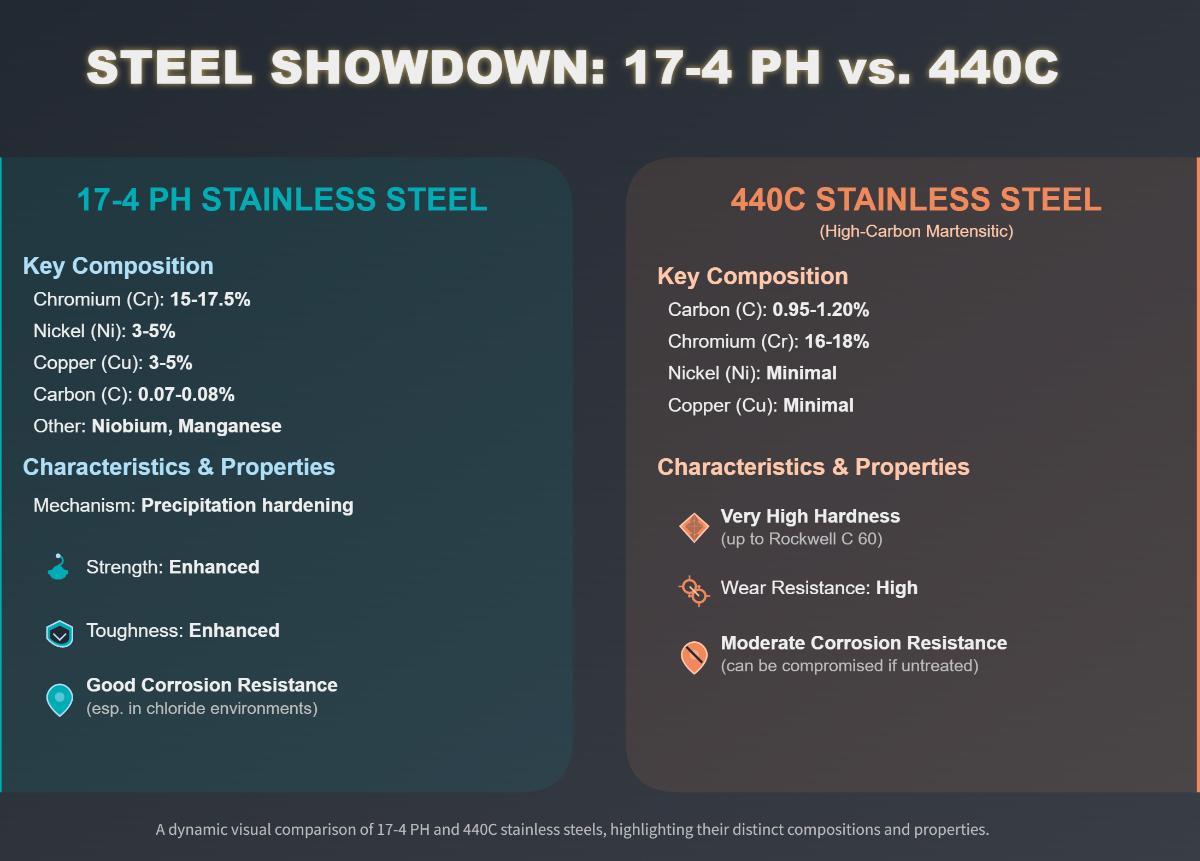

The key compositional differences between 17-4 PH and 440C stainless steel significantly influence their properties and applications. 17-4 PH stainless steel contains approximately 15-17.5% chromium, 3-5% nickel, and 3-5% copper, with a carbon content around 0.07-0.08%. It also includes niobium and small amounts of manganese. This composition allows for precipitation hardening, which enhances its strength and toughness while providing good corrosion resistance, particularly in chloride environments.

In contrast, 440C stainless steel is a high-carbon martensitic stainless steel with a carbon content typically around 0.95-1.20% and chromium content between 16-18%. It has minimal nickel and copper, focusing on high hardness and wear resistance due to its carbon and chromium levels. The high carbon content enables 440C to achieve very high hardness (up to Rockwell C 60) after appropriate heat treatment, making it ideal for wear-resistant applications. However, its corrosion resistance is moderate and can be compromised in harsh environments if not properly treated.

The mechanical properties of 17-4 PH and 440C stainless steels differ significantly, reflecting their distinct applications and advantages. 17-4 PH stainless steel, known for its balance of strength and corrosion resistance, achieves a hardness of up to 44 HRC after heat treatment. It boasts a tensile strength ranging from 140,000 to 190,000 psi and a yield strength of 110,000 to 160,000 psi. These properties make it suitable for demanding environments in aerospace and medical industries.

In contrast, 440C stainless steel is characterized by its exceptional hardness and wear resistance, reaching a hardness of up to 58-60 HRC after heat treatment. However, it offers a lower tensile strength of up to 110,000 psi and a yield strength of up to 65,000 psi. This high-carbon martensitic alloy is ideal for applications requiring maximum hardness and wear resistance, such as cutting tools and bearings.

When considering stainless steel for applications requiring high corrosion resistance in harsh environments, 17-4 PH is generally better suited than 440C. 17-4 PH stainless steel offers superior corrosion resistance due to its composition, which includes approximately 17% Chromium and the benefits of its precipitation hardening process. This makes it highly effective in demanding environments such as aerospace, medical, and chemical processing industries. In contrast, 440C stainless steel, while providing excellent hardness and wear resistance due to its high carbon content, has moderate corrosion resistance that is less effective in harsh conditions. Therefore, for environments with higher corrosion demands, 17-4 PH is the preferred choice.

17-4 PH and 440C stainless steels serve different industrial applications due to their unique properties.

17-4 PH stainless steel, known for its high strength, toughness, and good corrosion resistance, is commonly used in aerospace components, medical devices, chemical processing equipment, and marine hardware. Its ability to maintain mechanical properties in harsh environments makes it ideal for structural parts, shafts, and fittings.

On the other hand, 440C stainless steel is characterized by its high hardness and exceptional wear resistance due to its high carbon content. This makes it suitable for applications such as cutlery, bearings, valve components, and surgical instruments. It is especially valued in industries requiring durable, wear-resistant parts that can maintain sharp edges and withstand friction.

Machinability between 17-4 PH and 440C stainless steel differs significantly due to their distinct compositions and properties.

17-4 PH stainless steel generally exhibits good machinability, especially in its annealed state. It maintains this characteristic even after heat treatment, making it suitable for applications requiring both high strength and corrosion resistance. High-speed steel (HSS) or carbide tools are typically used for machining 17-4 PH.

Conversely, 440C stainless steel, known for its high hardness and wear resistance, has poor machinability. Its high carbon content, which contributes to its hardness, makes machining more challenging, especially after hardening. In its annealed state, 440C is somewhat easier to machine, but it remains more difficult compared to 17-4 PH. Carbide or ceramic tools are recommended to handle the increased hardness.

Yes, there are case studies that illustrate the performance of 17-4 PH and 440C stainless steels in real-world applications.

In aerospace, 17-4 PH stainless steel is favored for components like turbine blades and undercarriage parts due to its high-temperature stability, maintaining mechanical properties up to 316°C, and its excellent precipitation hardening capabilities through H900 treatment, achieving a tensile strength of 1,310 MPa. Additionally, it offers corrosion resistance comparable to 304 stainless steel, with autoclave testing showing no discoloration after 30 sterilization cycles.

Conversely, 440C stainless steel, although limited in aerospace due to moderate corrosion resistance, excels in applications requiring high wear resistance, such as cutting tools and bearings. Its high carbon content allows it to reach hardness levels of 60+ HRC post-quenching, making it ideal for parts subjected to significant wear.

In the medical device industry, 17-4 PH stainless steel demonstrates exceptional biocompatibility and stability under autoclave sterilization, with no corrosion after 30 cycles and resistance to nickel leaching in saline solutions. On the other hand, 440C requires additional processing, such as passivation and coatings, to prevent surface rusting and ensure medical-grade performance.

These case studies highlight how the distinct properties of each alloy make them suitable for specific applications, leveraging the strengths of 17-4 PH in corrosion resistance and high-temperature stability, and the wear resistance and hardness of 440C.