When it comes to stainless steel, the choices can seem endless. But when faced with 18/8 and 304 stainless steel, how do you determine which is best for your needs? These two types of stainless steel are often used interchangeably, yet they possess distinct properties that make them suitable for different applications. In this article, we will delve into the key differences between 18/8 and 304 stainless steel, examining their chemical compositions, durability, corrosion resistance, and more. By the end, you’ll have a clearer understanding of their common uses, as well as which industries benefit most from each type. So, which stainless steel will come out on top? Read on to find out.

Stainless steel is a versatile material valued for its strength, durability, and resistance to corrosion. This alloy is primarily composed of iron, chromium, and nickel, with other elements added to enhance specific properties. The presence of chromium is crucial as it forms a passive layer of chromium oxide on the surface, which prevents further corrosion.

Stainless steel can be classified into several families based on their microstructure and composition. The most common types are:

Among the austenitic stainless steels, the 300 series is the most popular, particularly the 18/8 and 304 grades. These materials are highly valued for their versatile applications.

The term “18/8” describes stainless steel with 18% chromium and 8% nickel, offering a balance of corrosion resistance and a polished appearance. This composition provides good corrosion resistance and a shiny appearance, making 18/8 stainless steel a common choice for kitchen appliances and cookware.

304 stainless steel is a specific grade within the 18/8 family, containing additional elements like manganese and carbon. This composition enhances its mechanical properties and corrosion resistance. 304 is often preferred for more demanding applications, such as those involving exposure to harsh chemicals or high temperatures.

The choice between 18/8 and 304 stainless steel often depends on the specific requirements of the application:

Both 18/8 and 304 stainless steels are prized for their outstanding properties, making them widely used across various industries. While they share similarities, subtle differences in composition and characteristics determine their suitability for specific applications.

18/8 stainless steel contains 18% chromium and 8% nickel, a combination that strikes a balance between corrosion resistance and mechanical strength. Additional elements such as carbon, nitrogen, sulfur, phosphorus, silicon, and manganese further enhance its properties, contributing to its durability, formability, and resistance to various environmental factors.

304 stainless steel also features 18% chromium and 8% nickel but includes a carefully controlled amount of carbon, typically limited to 0.08%. This precise composition improves its durability and ability to withstand diverse environmental conditions.

18/8 stainless steel generally exhibits higher tensile strength and yield strength compared to 304 stainless steel. However, 304 stainless steel offers greater ductility, making it better suited for applications that involve forming or shaping without compromising its integrity.

Both materials provide excellent protection against corrosion. However, 304 stainless steel performs better in aggressive environments, such as those exposed to moderate acids or chlorides. This makes 304 stainless steel ideal for marine and outdoor applications, where durability under harsh conditions is critical.

18/8 stainless steel is widely used in everyday items, including cookware and kitchen appliances, due to its cost-effectiveness and ability to perform well in less demanding environments. On the other hand, 304 stainless steel is preferred for more challenging applications that require superior corrosion resistance and mechanical strength, such as in the marine, automotive, architectural, and food processing industries.

18/8 and 304 stainless steel are both types of austenitic stainless steels, known for their excellent corrosion resistance and versatility. While they share similar compositions, there are specific differences that affect their properties and suitability for various applications.

18/8 stainless steel is characterized by its composition of 18% chromium and 8% nickel. This basic composition provides a good balance of corrosion resistance, strength, and formability. However, 18/8 stainless steel can vary in carbon, manganese, and other elements, affecting its properties and performance.

304 stainless steel is a specific grade within the 18/8 family, typically containing 18-20% chromium and 8-10.5% nickel. It also has a controlled carbon content, usually limited to a maximum of 0.08%, which enhances its resistance to intergranular corrosion.

Controlled carbon and higher manganese content make 304 stainless steel ideal for applications needing excellent corrosion resistance and strength.

| Property/Feature | 18/8 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Chromium Content | 18% | 18-20% |

| Nickel Content | 8% | 8-10.5% |

| Carbon Content | Higher than 304 | Up to 0.08% |

| Manganese Content | Varies | Higher |

| Corrosion Resistance | Excellent | Superior, especially in aggressive environments |

Knowing these differences helps in choosing the right stainless steel for specific uses, ensuring the best performance and durability.

The high chromium content (18%) in both types creates a protective chromium oxide layer, shielding the material from environmental damage. However, subtle differences in composition lead to variations in performance.

18/8 stainless steel provides excellent corrosion resistance in mild environments, making it suitable for household applications and items exposed to less aggressive conditions. However, its generic composition may include higher carbon levels, which can slightly increase susceptibility to intergranular corrosion when exposed to higher temperatures or during welding.

304 stainless steel offers superior corrosion resistance compared to 18/8 stainless steel, particularly in aggressive environments involving moderate acids or chlorides. Its controlled carbon content (typically ≤0.08%) reduces the risk of intergranular corrosion, making it a better choice for applications requiring long-term durability in challenging conditions. For environments with high chloride exposure, like marine applications, 316 stainless steel is a better option.

Durability encompasses tensile strength, hardness, and resistance to wear and fatigue. 304 stainless steel exhibits excellent tensile strength and hardness, making it suitable for a wide range of applications, from kitchen appliances to industrial equipment. Its ability to withstand repeated stress and strain without significant degradation ensures a long service life.

While 18/8 stainless steel offers higher tensile strength and hardness, its reduced ductility can limit its use in applications requiring significant deformation or bending. This makes it an effective choice for applications requiring robust mechanical properties, such as in cookware and kitchen utensils.

304 stainless steel, while slightly less hard than 18/8, offers greater ductility and formability. These characteristics allow it to endure processes like deep drawing and complex shaping without cracking or losing structural integrity. Additionally, its balanced mechanical strength makes it ideal for demanding industrial applications, such as food processing equipment or chemical containers.

Weldability refers to the ease with which a material can be joined using welding techniques, and both 18/8 and 304 stainless steel are highly weldable due to their austenitic structure. However, differences in composition affect their welding performance and post-weld requirements.

18/8 stainless steel is compatible with common welding methods, such as TIG and MIG welding. However, higher carbon content can lead to carbide precipitation at grain boundaries during welding, increasing susceptibility to intergranular corrosion. This often necessitates post-weld annealing to restore corrosion resistance.

304 stainless steel stands out for its excellent weldability, particularly in its low-carbon variant, 304L. Lower carbon content reduces carbide precipitation, decreasing the need for post-weld heat treatment. This makes 304 stainless steel a preferred choice for large-scale production and applications where welding is a critical process. Its higher manganese content also enhances hot workability during welding.

| Property | 18/8 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Excellent in mild environments | Superior in aggressive environments |

| Durability | Higher tensile strength and hardness | Better ductility and formability |

| Weldability | Requires post-weld annealing in many cases | Minimal need for post-weld heat treatment |

These differences between 18/8 and 304 stainless steel underscore the need to choose the right grade for specific applications.

When comparing 18/8 and 304 stainless steel, cost is a significant factor. The slight differences in their compositions result in varied pricing, which can impact the overall budget of a project. 18/8 stainless steel, being a more general term for 304 stainless steel, typically has a similar cost. However, depending on the specific requirements and the supplier, there may be slight variations in price. These cost differences can influence decisions in industries where budget constraints are critical, such as in large-scale manufacturing or construction projects.

18/8 stainless steel generally has a lower nickel content compared to 304 stainless steel. Nickel is a relatively expensive element, so reducing its percentage can decrease the Due to its higher and more controlled nickel content, 304 stainless steel tends to be slightly more expensive. However, the cost difference between 18/8 and 304 stainless steel is often negligible when considering the benefits that 304 offers in terms of enhanced properties.

Both 18/8 and 304 stainless steel are highly formable and weldable, but the controlled carbon content in 304 stainless steel, particularly the 304L variant, reduces the need for post-weld heat treatments. This can result in lower processing costs and increased efficiency in manufacturing operations.

304 stainless steel offers superior corrosion resistance, especially in harsh environments such as those with exposure to acids, chlorides, or seawater. This makes it ideal for applications that require long-term durability and minimal maintenance, such as marine equipment, chemical processing, and outdoor architectural elements.

While 18/8 stainless steel offers good corrosion resistance, it is better suited for environments with moderate moisture exposure. For applications in less aggressive environments, the cost savings from using 18/8 stainless steel can be substantial.

304 stainless steel’s superior corrosion resistance results in lower maintenance costs over its lifespan. This is particularly important in industries where downtime for maintenance can be costly. In contrast, while 18/8 stainless steel may require more frequent maintenance or replacement in aggressive environments, it can be a cost-effective choice for less demanding applications.

304 stainless steel is known for its superior mechanical properties, including higher strength and ductility. This makes it suitable for applications requiring significant forming, shaping, or welding without compromising the material’s integrity. The higher initial cost of 304 stainless steel can be offset by its performance benefits in demanding applications.

While 18/8 stainless steel generally offers good strength and durability, it is harder and less ductile than 304 stainless steel, making it a cost-effective choice for applications where extreme mechanical properties are not essential.

The choice between 18/8 and 304 stainless steel often depends on the specific requirements of the application. For instance:

18/8 stainless steel is used in chemical processing applications where moderate corrosion resistance suffices. Its affordability and resistance to less harsh chemicals make it a cost-effective choice for equipment such as storage tanks, low-pressure piping, and processing vessels. However, its performance may be limited in environments containing high concentrations of chlorides or aggressive acids.

304 stainless steel is the preferred choice for chemical processing environments involving exposure to more aggressive substances, such as organic acids, nitric acid, and cleaning agents. Its superior corrosion resistance and durability make it suitable for equipment like reactors, heat exchangers, and pressure vessels. Additionally, its weldability and formability allow for seamless fabrication of intricate components.

18/8 stainless steel is commonly used in food processing equipment for tasks that do not involve prolonged exposure to highly acidic or salty conditions. Its smooth surface and resistance to staining make it ideal for items like mixing bowls, utensils, and general food preparation surfaces, though it may not withstand frequent exposure to cleaning chemicals or acidic foods.

304 stainless steel is widely utilized in the food and beverage industry because it resists corrosion well and is easy to clean. It is particularly suited for applications such as dairy processing, brewing, and meat processing, where frequent cleaning with strong detergents or exposure to acidic substances is required. Its durability and hygienic properties also make it a top choice for conveyor systems, storage tanks, and food-grade piping.

18/8 stainless steel is often selected for architectural applications where cost is a major consideration and exposure to harsh environmental conditions is minimal. It is used in interior elements such as decorative panels, light fixtures, and handrails. While it offers good aesthetic appeal, its corrosion resistance may degrade in outdoor or coastal environments over time.

304 stainless steel is popular for both interior and exterior architectural elements due to its superior resistance to corrosion and weathering. It is commonly used in structural components, cladding, outdoor sculptures, and railings. Its ability to maintain its appearance and integrity in challenging environments, including urban and coastal areas, makes it a reliable material for long-term applications.

| Application Area | 18/8 Stainless Steel | 304 Stainless Steel |

|---|---|---|

| Chemical Processing | Suitable for mild chemical environments and low-cost setups | Ideal for aggressive chemicals and high-pressure systems |

| Food Processing | Good for general food tools and surfaces | Best for acidic, salty, or frequently cleaned equipment |

| Architectural Elements | Best for interior designs and cost-sensitive projects | Preferred for outdoor and long-lasting architectural uses |

This comparison highlights how the choice between 18/8 and 304 stainless steel depends on the specific requirements of industrial applications, balancing performance needs with cost considerations.

Both 18/8 and 304 stainless steels contain 18% chromium and 8% nickel, but 304 stainless steel has a more precisely controlled composition, leading to slightly better consistency in its properties.

304 stainless steel offers superior resistance to corrosive environments, especially those rich in chlorides, making it more suitable for marine and industrial applications.

304 stainless steel generally has better mechanical properties at extreme temperatures and is easier to form and weld compared to 18/8 stainless steel.

18/8 stainless steel is commonly used in wastewater treatment, medical equipment, and kitchenware due to its cost-effectiveness, excellent corrosion resistance, and ability to withstand acidic foods.

304 stainless steel is used in food processing and dairy equipment for its superior corrosion resistance and ease of cleaning, making it ideal for applications requiring high hygiene standards. It is also utilized in construction and building for structural components due to its excellent mechanical properties and resistance to environmental corrosion.

Marine environments are challenging due to high chloride levels. While 304 stainless steel offers better resistance than 18/8, 316 stainless steel, which contains molybdenum, is often preferred for critical marine applications.

Applications requiring materials to withstand high temperatures without scaling benefit from 304 stainless steel, as it can maintain its integrity up to 925°C, compared to 870°C for 18/8 stainless steel.

In the food industry, the need for materials that are easy to clean and resistant to organic chemicals makes both grades useful, but 304 stainless steel is preferred for its better resistance to corrosion and ease of fabrication.

Below are answers to some frequently asked questions:

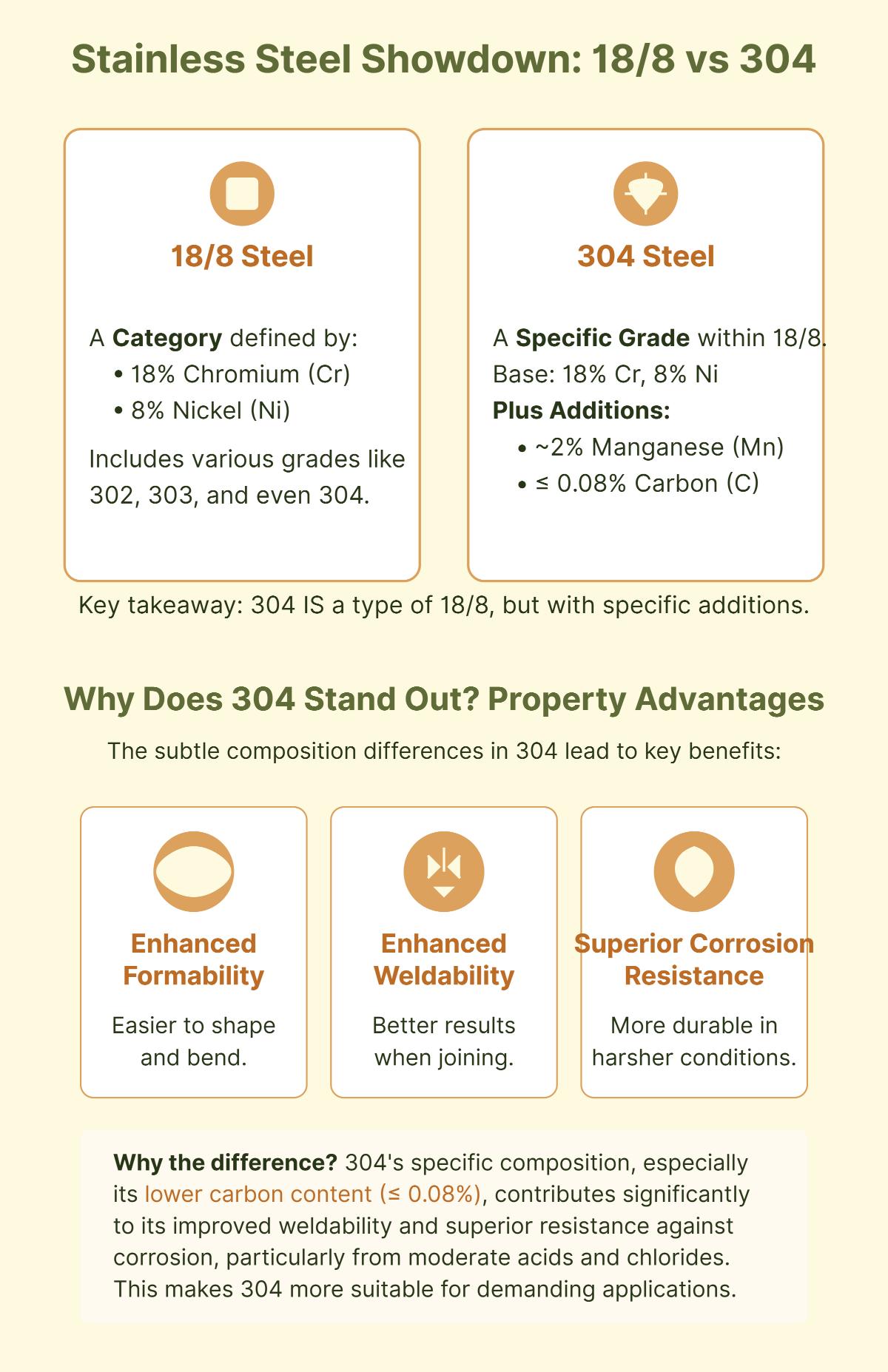

18/8 stainless steel and 304 stainless steel are often used interchangeably due to their similar chemical compositions. The term “18/8” generally refers to a category of stainless steels containing 18% chromium and 8% nickel, which includes various grades like 302, 303, and 304. However, 304 stainless steel is a specific grade within this category that also includes additional elements such as 2% manganese and up to 0.08% carbon.

These subtle differences give 304 stainless steel enhanced formability and weldability, making it more suitable for demanding applications. While both types exhibit excellent corrosion resistance, 304 stainless steel offers superior resistance in harsher environments, such as those with moderate acids and chlorides, due to its lower carbon content. This makes it more durable in aggressive conditions.

18/8 stainless steel and 304 stainless steel are widely used due to their excellent properties, including corrosion resistance, durability, and ease of maintenance.

18/8 stainless steel is commonly used in cookware and kitchen appliances, such as pots, pans, and utensils, due to its non-reactive surface and ease of cleaning. It is also favored in the food processing industry for its hygiene and corrosion resistance. Additionally, 18/8 stainless steel finds applications in architectural elements for its aesthetic appeal and durability, automotive components like grilles and exhaust pipes, and medical equipment due to its biocompatibility and easy sterilization.

304 stainless steel is extensively used in the food and beverage industry for processing equipment, brewery tanks, and dairy applications due to its high corrosion resistance and durability. It is preferred for marine and outdoor applications where exposure to moderate acids and chlorides is common, thanks to its superior corrosion resistance. Moreover, 304 stainless steel is utilized in the automotive and aerospace industries for its strength and resistance to extreme temperatures, and in household appliances like sinks and tables for its versatility and aesthetic appeal.

While both types are versatile, 304 stainless steel is often chosen for applications requiring higher corrosion protection and mechanical strength, whereas 18/8 stainless steel is more cost-effective for less demanding environments.

The properties of 18/8 and 304 stainless steel are quite similar due to their nearly identical chemical compositions, both containing 18% chromium and 8% nickel. However, 304 stainless steel offers slightly superior corrosion resistance, making it more suitable for environments with moderate acids and chlorides, such as marine and outdoor applications. In terms of mechanical properties, 18/8 stainless steel generally exhibits higher tensile and yield strengths, making it harder and more durable in less aggressive environments. Conversely, 304 stainless steel is more ductile and formable, providing better weldability and ease of fabrication, especially in its 304L variant, which minimizes post-weld annealing.

Industries that benefit most from using 18/8 stainless steel include the food and beverage industry, medical and pharmaceutical industries, automotive industry, architecture and construction, chemical and petroleum industries, and the household appliances and consumer goods sector.

In the food and beverage industry, 18/8 stainless steel is prized for its corrosion resistance and non-reactive nature, making it suitable for cookware, cutlery, and food processing equipment. The medical field values its biocompatibility and ease of sterilization for surgical instruments and hospital equipment. The automotive sector utilizes its high strength and thermal properties for components like exhaust systems and fuel tanks. In architecture, its aesthetic appeal and durability make it ideal for building facades and railings. The chemical and petroleum industries rely on its superior corrosion resistance for processing equipment and storage vessels.

When comparing the costs of 18/8 and 304 stainless steel, it’s important to note that 18/8 is a generic term describing stainless steel with approximately 18% chromium and 8% nickel. In contrast, 304 stainless steel is a specific grade within this category, often containing additional elements like manganese, which enhance its properties.

Generally, 18/8 stainless steel can be slightly less expensive than 304 stainless steel due to its broader classification and lower nickel content. However, the cost difference is typically minimal. The higher demand for 304 stainless steel, driven by its superior mechanical properties and corrosion resistance, often justifies its slight cost increase.

For everyday applications such as cookware and kitchen appliances, 18/8 stainless steel offers a cost-effective solution without significant compromise on essential properties. In contrast, for more demanding environments like marine and automotive industries, the enhanced performance of 304 stainless steel makes it worth the additional expense.

18/8 and 304 stainless steel can often be used interchangeably due to their nearly identical chemical composition, with both containing approximately 18% chromium and 8% nickel. However, 304 stainless steel is a specific grade within the 18/8 category, defined by additional controlled elements like carbon, manganese, and silicon, which enhance its properties. While their performance is similar in many applications, 304 stainless steel offers slightly better corrosion resistance and durability due to its standardized formulation and manufacturing processes.

In practical terms, they are interchangeable for general-purpose uses such as kitchen utensils, food processing equipment, and decorative applications. However, for environments requiring higher durability or exposure to corrosive conditions, 304 stainless steel is preferred. Ultimately, the choice depends on specific performance requirements, with 304 being the more reliable option when stricter specifications are necessary.