When it comes to selecting the right stainless steel for your project, understanding the specific properties and applications of each grade is crucial. One such versatile and high-performing alloy is 318 stainless steel. Known for its exceptional corrosion resistance and durability, 318 stainless steel is a preferred material across various demanding industries. But what exactly sets it apart from other stainless steel grades? In this comprehensive guide, we’ll delve into the key properties of 318 stainless steel, including its chemical composition, mechanical attributes, and unparalleled performance in harsh environments. We’ll also explore its prominent applications in the petrochemical, marine, and chemical processing industries. Whether you’re an engineer, a materials scientist, or simply interested in the technical nuances of this remarkable alloy, this data-driven analysis will provide you with all the insights you need. How does 318 stainless steel measure up against its counterparts like 316L and 304? Let’s find out.

Key Properties of 318 Stainless Steel

Material Composition

318 stainless steel, a type of duplex stainless steel, merges the advantages of both austenitic and ferritic stainless steels. This balanced microstructure, with roughly equal parts austenite and ferrite, enhances its mechanical properties and resistance to corrosion.

Chemical Composition and Corrosion Resistance

The specific elements in 318 stainless steel significantly contribute to its overall performance and suitability for various applications.

- Chromium (Cr): Typically around 18-22%, chromium greatly enhances corrosion resistance by forming a passive surface layer.

- Nickel (Ni): Present in the range of 4-6%, nickel stabilizes the austenitic phase, improving toughness and corrosion resistance.

- Molybdenum (Mo): Approximately 2.5-3.5%, molybdenum increases resistance to pitting and crevice corrosion.

- Nitrogen (N): Added in small amounts (0.08-0.20%), nitrogen boosts tensile strength and pitting resistance.

- Manganese (Mn): Around 1.5%, manganese improves hot-working properties and aids in deoxidation during steelmaking.

- Silicon (Si): Typically 0.5-1%, silicon enhances oxidation resistance and strength.

- Carbon (C): Kept low, around 0.03%, to prevent carbide precipitation that can lead to intergranular corrosion.

This resistance comes from its balanced composition. The combination of chromium, molybdenum, and nitrogen significantly enhances its durability against corrosion.

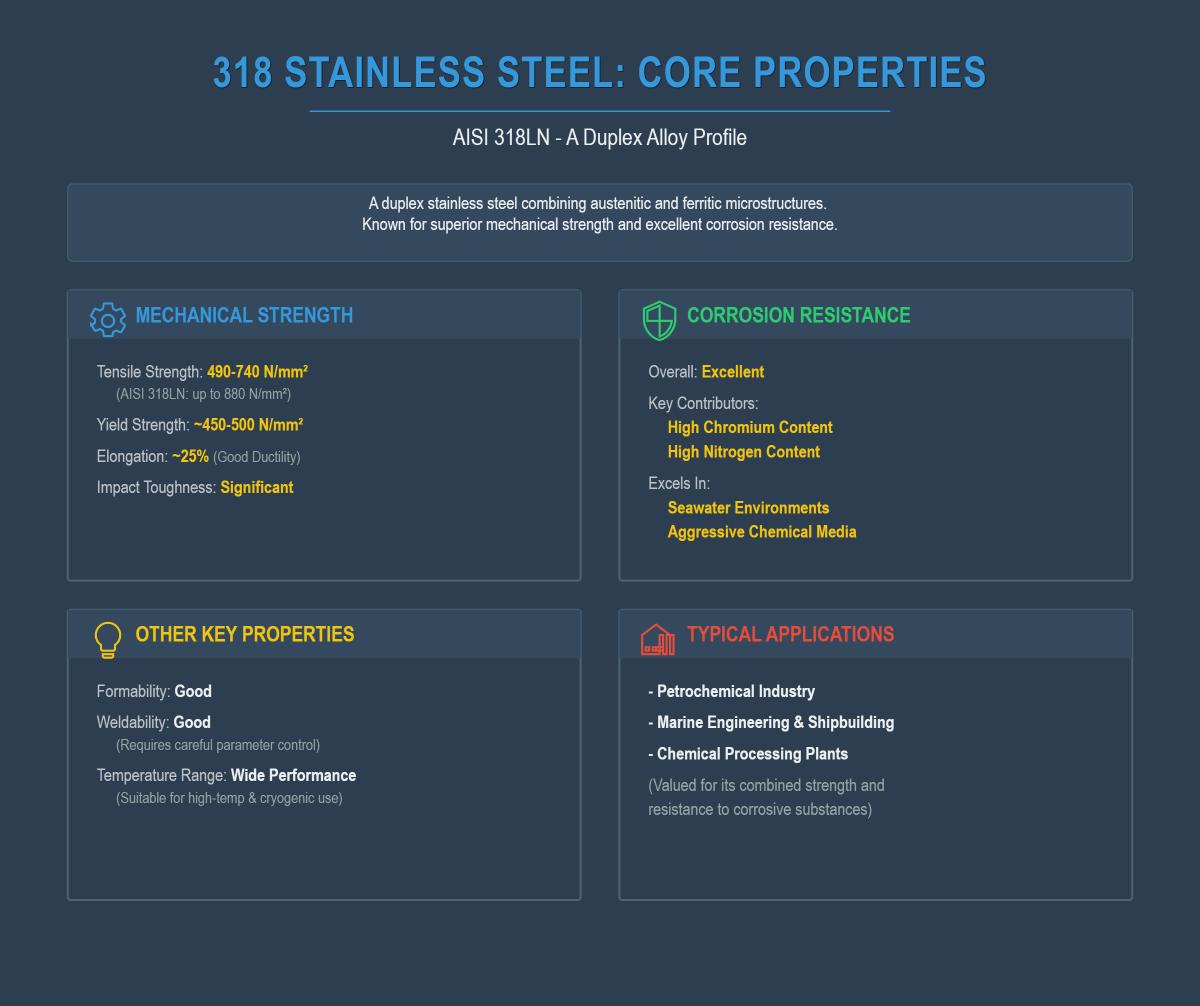

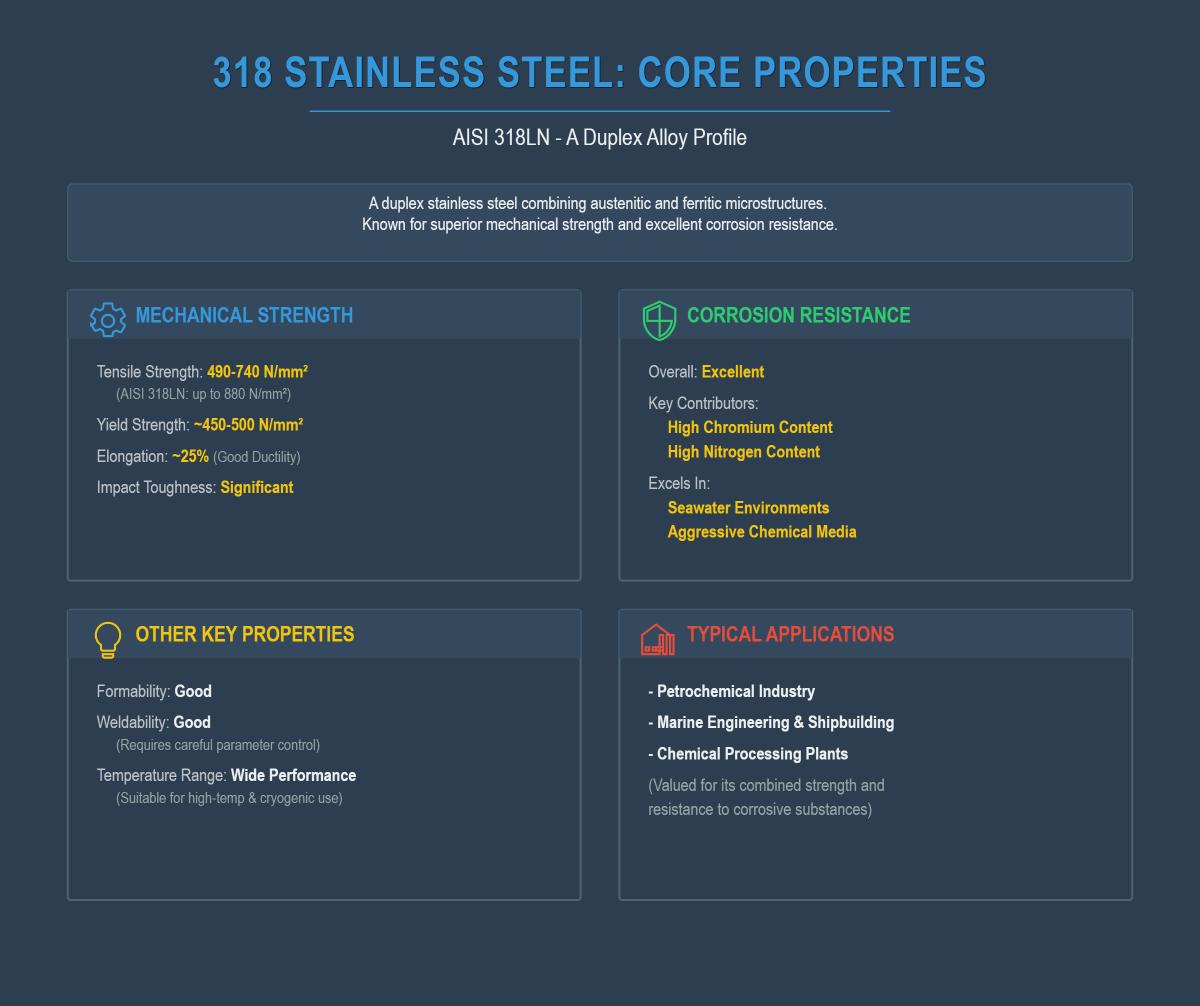

Mechanical Properties

318 stainless steel showcases a robust set of mechanical properties, making it suitable for demanding applications.

- Tensile Strength: Ranges from 490 to 740 megapascals (MPa), indicating its ability to withstand high stress before breaking.

- Yield Strength: Approximately 450 to 500 MPa, reflecting its capacity to endure significant stress without permanent deformation.

- Elongation: Typically around 25% over a 50mm gauge length, suggesting good ductility and the ability to absorb deformation without fracturing.

- Hardness: Balanced hardness ensures durability while maintaining sufficient ductility to avoid brittleness.

- Impact Toughness: High impact toughness enables the material to absorb energy during sudden or repeated impacts, crucial for high-stress applications.

Formability and Weldability

318 stainless steel is known for its good formability, making it suitable for various fabrication processes. It can be easily shaped into components like pipes and tanks, but careful welding is necessary to maintain its integrity. Controlling welding parameters is essential to avoid issues like sigma phase formation, which can impair mechanical properties and corrosion resistance.

Thermal Properties

This alloy maintains its mechanical integrity across a wide range of temperatures, from cryogenic conditions to high-temperature environments. This versatility is particularly beneficial for industries such as oil and gas, where components may experience extreme temperature fluctuations.

Magnetic Properties

Due to its ferritic component, 318 stainless steel exhibits magnetic properties. This characteristic can be beneficial in applications where magnetic response is required in combination with high corrosion resistance and mechanical strength.

Applications

318 stainless steel is used across various industries due to its exceptional properties:

- Petrochemical and Oil Industry: Components such as pipelines and drilling equipment benefit from its strength and resistance to corrosive media.

- Marine Industry: Ideal for shipbuilding and offshore installations due to its ability to withstand seawater exposure.

- Chemical Processing: Suitable for handling corrosive chemicals, providing durability and safety.

- Food Processing: Ensures hygiene and longevity in food contact applications.

- Construction: Used in architectural elements requiring both aesthetic appeal and structural integrity.

High Corrosion Resistance and Durability

Material Composition and Corrosion Resistance

318 stainless steel is renowned for its exceptional corrosion resistance, thanks to its unique blend of elements. The alloy contains a balanced mix of components that enhance its ability to withstand various corrosive environments.

Detailed Breakdown of Chemical Elements

- Chromium (Cr) [18-22%]: Chromium helps form a protective oxide layer that prevents oxidation and corrosion.

- Nickel (Ni) [4-6%]: Nickel improves toughness and resistance to corrosion, especially in reducing environments.

- Molybdenum (Mo) [2.5-3.5%]: Molybdenum significantly enhances resistance to pitting and crevice corrosion, particularly in chloride-containing environments.

- Nitrogen (N) [0.08-0.20%]: Nitrogen increases strength and improves resistance to localized corrosion.

- Manganese (Mn) [~1.5%]: Manganese aids in deoxidizing the steel and improves its hot-working properties.

- Silicon (Si) [0.5-1%]: Silicon contributes to the – Carbon (C) [≤0.03%]: Low carbon content minimizes the risk of carbide precipitation, which can lead to intergranular corrosion.

Corrosion Resistance Analysis

General and Localized Corrosion Resistance

318 stainless steel exhibits excellent corrosion resistance, making it highly suitable for use in harsh environments, including marine and chemical processing applications. Its superior resistance to pitting and crevice corrosion, particularly in chloride-containing environments, is due to the addition of molybdenum.

Performance in Various Environments

- Marine Environments: The alloy’s resistance to chloride-induced corrosion is crucial for marine applications. It performs exceptionally well in seawater, resisting pitting and crevice corrosion that can compromise structural integrity.

- Chemical Processing: In the chemical industry, 318 stainless steel resists corrosive chemicals, acids, and bases, ensuring long-lasting performance in harsh conditions.

- High-Temperature Applications: The alloy retains its corrosion resistance at elevated temperatures, making it suitable for applications where both high temperature and corrosive conditions are present.

Comparison with Other Stainless Steel Grades

316L vs. 318 Stainless Steel

Although 316L stainless steel is corrosion-resistant, 318 stainless steel is better at resisting stress corrosion cracking and pitting, particularly in chloride-rich environments. This makes 318 stainless steel more suitable for applications in marine and chemical processing industries.

304 vs. 318 Stainless Steel

304 stainless steel is widely used for its general corrosion resistance and cost-effectiveness. However, 318 stainless steel provides superior resistance to localized corrosion, making it a better choice for more demanding environments. The higher resistance to stress corrosion cracking and better performance in chloride conditions further differentiate 318 stainless steel.

Durability and Mechanical Properties

The durability of 318 stainless steel is not solely due to its corrosion resistance but also its mechanical properties:

- Tensile Strength: The material’s tensile strength (490-740 MPa) ensures it can withstand significant stress without permanent deformation.

- Yield Strength: With a yield strength of 450-500 MPa, 318 stainless steel maintains its shape under high loads.

- Elongation: High elongation (around 25%) indicates good ductility, allowing the material to absorb deformation without fracturing.

- Impact Resistance: The alloy’s ability to absorb energy from impacts makes it suitable for dynamic and high-stress applications.

- Hardness: Balanced hardness ensures resistance to wear and mechanical damage while maintaining sufficient ductility.

Comparing 318 Stainless Steel with Other Grades

316L vs 318 Stainless Steel

Chemical Composition

- 316L Stainless Steel: Contains approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The molybdenum addition enhances corrosion resistance, especially against chlorides and other industrial solvents, making it particularly effective against pitting and crevice corrosion.

- 318 Stainless Steel: It typically contains 18-22% chromium, 4-6% nickel, and 2.5-3.5% molybdenum. It also includes nitrogen (0.08-0.20%) to increase its strength and resistance to pitting corrosion.

Corrosion Resistance

- 316L: Known for its excellent resistance to corrosion in a variety of environments, particularly effective against pitting and crevice corrosion due to the presence of molybdenum.

- 318: Offers superior resistance to stress corrosion cracking and pitting corrosion, especially in chloride-rich environments, making it more suitable for marine and chemical processing applications.

Mechanical Properties

- 316L: Exhibits good mechanical properties with a tensile strength of approximately 485 MPa and a yield strength around 170 MPa. It is also known for its excellent formability and weldability.

- 318: Displays enhanced mechanical properties with a tensile strength ranging from 490 to 740 MPa and a yield strength of 450 to 500 MPa. These properties provide higher strength and better performance in high-stress applications.

Applications

- 316L: Commonly used in environments exposed to marine atmospheres, chemical processing, and medical implants due to its excellent corrosion resistance and biocompatibility.

- 318: Ideal for demanding environments like petrochemical industries, marine settings, and chemical processing facilities due to its high strength and superior corrosion resistance.

304 vs 318 Stainless Steel

Chemical Composition

- 304 Stainless Steel: Contains 18-20% chromium and 8-10.5% nickel, with minimal molybdenum content. The lack of molybdenum makes it less resistant to pitting and crevice corrosion compared to other grades.

- 318 Stainless Steel: It typically contains 18-22% chromium, 4-6% nickel, and 2.5-3.5% molybdenum, enhancing its resistance to pitting and crevice corrosion, especially in chloride environments.

Corrosion Resistance

- 304: While it provides good general corrosion resistance, it is less effective against chloride-induced corrosion. This limitation restricts its use in marine environments and other chloride-rich settings.

- 318: Offers superior resistance to chloride-induced pitting and crevice corrosion, making it a better choice for more aggressive environments such as seawater and chemical processing.

Mechanical Properties

- 304: It typically has a tensile strength of 515 MPa and a yield strength of 205 MPa. It is valued for its excellent formability and weldability, making it versatile for various applications.

- 318: Provides higher tensile and yield strengths (490-740 MPa and 450-500 MPa, respectively), which makes it suitable for applications requiring high strength and durability under stress.

Applications

- 304: Widely used in general-purpose applications, including kitchen equipment, storage tanks, and construction materials, due to its cost-effectiveness and ease of fabrication.

- 318: Ideal for high-stress and high-corrosion environments such as offshore platforms, chemical reactors, and heat exchangers, where both mechanical robustness and superior corrosion resistance are critical.

Advantages and Disadvantages for Specific Applications

Advantages of 318 Stainless Steel

- Higher Mechanical Strength: Provides greater tensile and yield strengths compared to both 316L and 304, making it suitable for high-stress applications.

- Superior Corrosion Resistance: Especially effective against pitting and crevice corrosion in chloride-rich environments, outperforming 316L and 304 in such conditions.

- Durability: Its balanced composition of chromium, molybdenum, and nitrogen ensures enhanced durability and long-term performance in tough environments.

Disadvantages of 318 Stainless Steel

- Machining Difficulty: More challenging to machine compared to 316L and 304, potentially increasing manufacturing costs.

- Higher Cost: Generally more expensive due to its superior properties and alloying elements, making it less economical for general-purpose applications.

Industrial Applications of 318 Stainless Steel

Petrochemical Industry

318 stainless steel is widely used in the petrochemical industry due to its excellent resistance to corrosion and strong mechanical properties. This material is employed in various components such as reactors, storage tanks, pipelines, and heat exchangers. Its ability to withstand high pressure and harsh chemical environments makes it ideal for processes involving the handling and storage of aggressive chemicals.

Case Studies and Examples

- Storage Tanks: In petrochemical plants, 318 stainless steel storage tanks are used to store corrosive substances such as sulfuric acid and caustic soda. The alloy’s resistance to pitting and crevice corrosion ensures long-term durability and safety.

- Pipelines: 318 stainless steel pipelines are utilized to transport crude oil and natural gas. The material’s high tensile strength and corrosion resistance prevent leaks and ensure efficient operation.

Marine Industry

The marine industry benefits significantly from the use of 318 stainless steel, primarily due to its excellent resistance to chloride-induced corrosion. This property is crucial for applications exposed to seawater and marine atmospheres, where conventional materials often fail.

Examples of Marine Applications

- Shipbuilding: The alloy is used in constructing ship hulls, decks, and other structural components. Its mechanical strength and resistance to seawater corrosion ensure the longevity and safety of marine vessels.

- Offshore Platforms: In offshore drilling and production platforms, 318 stainless steel is used for structural frameworks, pipelines, and equipment exposed to harsh marine conditions. Its durability and resistance to corrosion help maintain operational integrity and safety.

Chemical Processing

In chemical processing applications, 318 stainless steel is chosen for its ability to resist a wide range of corrosive chemicals, acids, and bases. The alloy’s robustness ensures reliable performance and safety in environments where chemical exposure is frequent.

Real-World Usage Scenarios

- Reactors and Containers: Reactors and containers made from 318 stainless steel can handle aggressive chemicals without deteriorating, ensuring consistent and safe operation.

- Heat Exchangers: The material’s resistance to corrosion and high mechanical strength make it suitable for heat exchangers, which are often exposed to fluctuating temperatures and corrosive fluids.

Aerospace Industry

In aerospace, 318 stainless steel is used for high-strength, lightweight components, making it ideal for critical applications where both weight reduction and structural integrity are essential.

Aerospace Components

- Aircraft Frames: The alloy is used in the construction of aircraft frames and support structures, where its high tensile strength and resistance to environmental factors are beneficial.

- Engine Components: 318 stainless steel is employed in engine components that must withstand high temperatures and corrosive conditions, ensuring reliability and performance.

Food Processing Industry

The food processing industry utilizes 318 stainless steel for equipment and storage solutions, benefiting from the alloy’s reliability at cryogenic temperatures and non-reactive nature. This ensures high hygiene standards and durability in food contact applications.

Cold Storage Equipment

- Refrigeration Units: 318 stainless steel is used in refrigeration units and cold storage equipment due to its ability to maintain mechanical integrity at low temperatures, ensuring food safety and preservation.

- Processing Lines: Equipment used in food processing lines, such as mixers and conveyors, are often made from 318 stainless steel to avoid contamination and maintain hygiene standards.

Oil and Gas Industry

In the oil and gas industry, 318 stainless steel is employed in drilling equipment and pipelines. The material’s ability to withstand high pressures and corrosive conditions is crucial for preventing failures and ensuring continuous operation.

Drilling Equipment and Pipelines

- Drilling Rigs: Components of drilling rigs made from 318 stainless steel can endure the mechanical stresses and corrosive environments encountered during drilling operations.

- Transmission Pipelines: The alloy’s high tensile strength and corrosion resistance ensure the safe and efficient transport of oil and gas.

Medical Applications

318 stainless steel is chosen for medical implants due to its biocompatibility, corrosion resistance, and structural integrity, making it suitable for long-term use in the human body.

Medical Implants

- Orthopedic Devices: The alloy is used in orthopedic devices such as joint replacements and bone screws, where its mechanical strength and biocompatibility are essential.

- Surgical Instruments: 318 stainless steel is utilized in surgical instruments that require durability and resistance to repeated sterilization processes.

Power Generation

In power generation systems, 318 stainless steel is used in turbines and other components that must endure extreme temperatures and corrosive environments. Its durability and efficiency contribute to the reliable operation of power plants.

Turbine Components

- Steam Turbines: The alloy is used in steam turbines where high temperature and pressure conditions are prevalent, ensuring longevity and performance.

- Gas Turbines: 318 stainless steel is employed in gas turbines for its ability to withstand corrosive conditions and maintain mechanical integrity.

Standards and Compliance

Overview of AISI 318LN

AISI 318LN is a type of duplex stainless steel known for its superior corrosion resistance and mechanical strength. This alloy contains a balanced mix of austenitic and ferritic phases, enhanced by low carbon and nitrogen (‘LN’), which together improve resistance to intergranular corrosion and strengthen mechanical properties.

Compliance with DIN EN 10088-3 Standards

DIN EN 10088-3 covers the technical delivery conditions for stainless steels, including duplex grades like AISI 318LN. Compliance with these standards ensures that the material meets stringent quality and performance criteria, making it suitable for demanding industrial applications.

- Chemical Composition: Defines the acceptable ranges for elements such as chromium, nickel, molybdenum, and nitrogen, ensuring the material’s corrosion resistance and mechanical properties.

- Mechanical Properties: Sets minimum requirements for tensile strength, yield strength, elongation, and hardness, ensuring the material can withstand mechanical stresses in various applications.

- Testing and Certification: Mandates specific testing procedures, including tensile tests, impact tests, and corrosion resistance tests, to verify the material’s compliance with the standard.

Importance of Standards in Material Selection

Following recognized standards is essential when selecting materials because:

- Consistency and Reliability: Standards ensure that materials meet consistent quality and performance criteria, reducing the risk of failures in critical applications.

- Safety and Compliance: Compliance with standards helps manufacturers and end-users meet regulatory and safety requirements, particularly in industries like petrochemical, marine, and chemical processing.

- Interchangeability: Standardized materials can be easily sourced and replaced, facilitating maintenance and reducing downtime in industrial operations.

- Market Acceptance: Materials that comply with recognized standards are more likely to be accepted in global markets, enhancing their commercial viability.

How AISI 318LN Meets Industry Requirements

AISI 318LN meets industry requirements through its adherence to established standards and its superior properties:

- Corrosion Resistance: The alloy’s high chromium, molybdenum, and nitrogen content provide excellent resistance to pitting, crevice corrosion, and stress corrosion cracking, making it suitable for harsh environments.

- Mechanical Strength: The balanced microstructure of austenite and ferrite ensures high tensile strength and yield strength, which are critical for structural applications.

- Weldability: AISI 318LN offers good weldability, allowing it to be used in complex fabrications without compromising its mechanical or corrosion-resistant properties.

- Thermal Stability: The alloy maintains its mechanical properties across a wide temperature range, making it suitable for both high-temperature and cryogenic applications.

Meeting these strict standards, AISI 318LN provides reliable and durable performance across various industrial applications.

Duplex Stainless Steel: An Overview

Definition and Characteristics

Duplex stainless steel uniquely combines the best features of austenitic and ferritic stainless steels. This results in a microstructure with approximately equal parts ferrite and austenite, enhancing mechanical and corrosion resistance properties.

Key Benefits Over Other Stainless Steel Types

Strength and Ductility

Duplex stainless steels exhibit superior strength compared to austenitic stainless steels, with tensile strength typically ranging from 550 to 750 MPa. Its high strength and good ductility make it suitable for complex structural applications requiring flexibility and toughness.

Corrosion Resistance

They resist pitting, crevice corrosion, and chloride-induced stress corrosion cracking, ideal for corrosive environments like seawater and chemicals.

Cost-Effectiveness

Their lower nickel and molybdenum content makes duplex stainless steels more cost-effective than high-grade austenitic alloys. This cost advantage does not come at the expense of performance, making duplex stainless steels a financially attractive option for many industries.

Weldability and Formability

Modern duplex stainless steel grades offer good weldability and can be formed into complex shapes. However, precise welding techniques are needed to prevent distortion and ensure quality joints. This makes duplex stainless steels suitable for a wide range of fabrication processes.

Thermal and Fatigue Resistance

Duplex stainless steels have high thermal conductivity compared to austenitic stainless steels and can withstand fluctuating mechanical and thermal loads. This makes them suitable for applications in extreme environments, such as those involving rapid temperature changes and high mechanical stress.

Comparison with 318 Stainless Steel

Strengths and Weaknesses

318 stainless steel, a type of duplex stainless steel, shares many of the beneficial properties of duplex stainless steels but with its own unique characteristics. It offers high tensile strength (650 to 880 MPa) and yield strength (450 to 500 MPa), along with excellent corrosion resistance, particularly in chloride-rich environments. However, it may require more precise welding techniques to avoid issues like sigma phase formation, which can affect mechanical properties.

Ideal Applications for Each Type

Duplex stainless steels, including 318 stainless steel, are suitable for demanding applications across various industries. They are commonly used in:

- Oil and Gas: Pipelines, offshore platforms, and pressure vessels benefit from their high strength and corrosion resistance.

- Marine Environment: Shipbuilding and components exposed to seawater leverage their excellent resistance to chloride-induced corrosion.

- Chemical Processing: Plant components and pipelines are made from duplex stainless steels to withstand aggressive chemicals and corrosive environments.

- Food Processing: Equipment used in food processing takes advantage of their hygienic properties and durability.

- Desalination Plants: Their resistance to seawater corrosion makes them ideal for desalination equipment.

Super Duplex Stainless Steel

Super duplex stainless steels represent an advanced category within duplex stainless steels, offering even higher levels of strength and corrosion resistance. These steels are used in more extreme environments, such as deep-sea oil platforms and chemical processing facilities. Super duplex grades like UNS S32750 and S32760 contain higher amounts of chromium, molybdenum, and nitrogen, which further enhance their resistance to corrosion.

Technical Considerations

Welding

Duplex stainless steels can be welded using standard processes, but it is crucial to use appropriate filler materials and techniques to prevent carbide precipitation and ensure quality joints. This careful control is necessary to maintain the material’s mechanical and corrosion-resistant properties.

Machining

While duplex stainless steels are machinable, their high strength makes them difficult to machine. Sharp cutting tools and coolants are required to achieve the desired finish and dimensional accuracy.

Temperature Limitations

Duplex stainless steels are not ideal for use at temperatures above 300°C due to the risk of embrittlement. For applications requiring higher temperature resistance, super duplex or specialized high-temperature alloys are preferred.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the key properties of 318 stainless steel?

318 stainless steel, often referred to in its duplex form as AISI 318LN, is characterized by its superior mechanical strength and excellent corrosion resistance. This alloy combines the properties of both austenitic and ferritic stainless steels, making it highly versatile. Its mechanical properties include a tensile strength ranging from 490 to 740 N/mm², with the AISI 318LN variant reaching up to 880 N/mm², and a yield strength of about 450 to 500 N/mm². The material exhibits an elongation of approximately 25%, indicating good ductility, and maintains significant impact toughness, essential for applications involving sudden or repeated shocks.

318 stainless steel’s high chromium and nitrogen content contribute to its excellent corrosion resistance, suitable for environments exposed to seawater and aggressive chemicals. It offers good formability and weldability, although careful control of welding parameters is necessary to maintain its properties. The alloy performs well across a wide temperature range, making it suitable for both high-temperature and cryogenic applications. Typical uses include the petrochemical, marine, and chemical processing industries, where its strength and resistance to corrosive substances are highly valued.

In which industries is 318 stainless steel typically used?

318 stainless steel is typically used in several key industries due to its high corrosion resistance, mechanical strength, and durability. In the food processing industry, it is favored for its non-reactive nature and ease of cleaning, making it suitable for equipment that must maintain high hygiene standards. The chemical and petrochemical industries utilize 318 stainless steel for plant components, pipelines, storage tanks, and heat exchangers due to its ability to handle aggressive chemicals and high mechanical strength. In the oil and gas industry, it is used in drilling equipment and pipelines, where resistance to stress corrosion cracking and harsh environmental conditions is critical. The marine and offshore industry benefits from its excellent seawater corrosion resistance and high mechanical strength, making it ideal for shipbuilding and offshore structures. Additionally, 318 stainless steel is used in the aerospace industry for lightweight components that can withstand extreme temperatures, in the medical industry for biocompatible implants, and in the power generation sector for turbines and boiler tubes that require heat resistance and mechanical strength.

How does 318 stainless steel compare to duplex stainless steel?

318 stainless steel is a specific type of duplex stainless steel, which means it shares the general characteristics of duplex steels, including a balanced austenitic-ferritic microstructure. This structure provides superior mechanical properties, such as higher tensile and yield strengths compared to austenitic grades like 304 and 316.

In comparison, duplex stainless steels, including 318, offer excellent corrosion resistance, particularly in chloride-rich environments, making them suitable for marine and chemical processing applications. While both 318 and other duplex grades are used in demanding industries like petrochemical and marine, 318 stainless steel is specifically noted for its high strength and good formability. However, like other duplex steels, it requires careful welding procedures to maintain its properties.

What standards does 318 stainless steel comply with?

318 stainless steel complies with several key standards that ensure its quality and performance in various applications. Notably, it adheres to ASTM A240, which specifies requirements for stainless steel sheets, plates, and strips, ensuring consistency in its mechanical and chemical properties. Additionally, it meets the EN 10088 standard, a European classification that defines stainless steels based on their composition and properties. ISO 15510 also applies, offering global specifications for stainless steel, focusing on its composition and mechanical attributes. For welding, standards like AWS A5.4 and AWS A5.9 are relevant for consumables used with 318 stainless steel. These standards collectively ensure that 318 stainless steel maintains high performance and reliability across diverse industrial applications.

Why is corrosion resistance important in stainless steel?

Corrosion resistance is crucial in stainless steel due to its significant impact on the material’s longevity, hygiene, economic efficiency, and environmental protection. This resistance is primarily due to the formation of a thin, passive oxide layer on the steel’s surface, which is predominantly composed of chromium oxide. The presence of at least 10.5% chromium is essential for the formation and maintenance of this protective layer. Additional elements like nickel, manganese, and molybdenum further enhance this property.

In the context of 318 stainless steel, its superior corrosion resistance makes it particularly suitable for harsh environments such as marine, petrochemical, and chemical processing applications. This resistance ensures the material remains structurally sound over time, reducing maintenance costs and preventing contamination in critical applications. By minimizing the risk of corrosion, industries can avoid costly repairs, downtime, and potential environmental damage, making 318 stainless steel a preferred choice for demanding conditions.