When it comes to selecting the right stainless steel for your project, understanding the nuances between different grades is crucial. Among the myriad options, 410 and 420 stainless steel often emerge as top contenders due to their impressive properties and versatile applications. But what sets these two apart? Is it their chemical composition, mechanical properties, or perhaps their suitability for specific applications like cutlery or surgical instruments? In this article, we will delve into the key differences between 410 and 420 stainless steel, exploring their hardness, corrosion resistance, and more. By the end, you’ll have a clear understanding of which stainless steel grade is the best fit for your needs. Ready to uncover the distinctions? Let’s dive in.

410 and 420 stainless steels are part of the martensitic class, recognized for their high strength, hardness, and moderate corrosion resistance. They are widely used in applications where these properties are crucial, such as in cutlery, surgical instruments, and various industrial components.

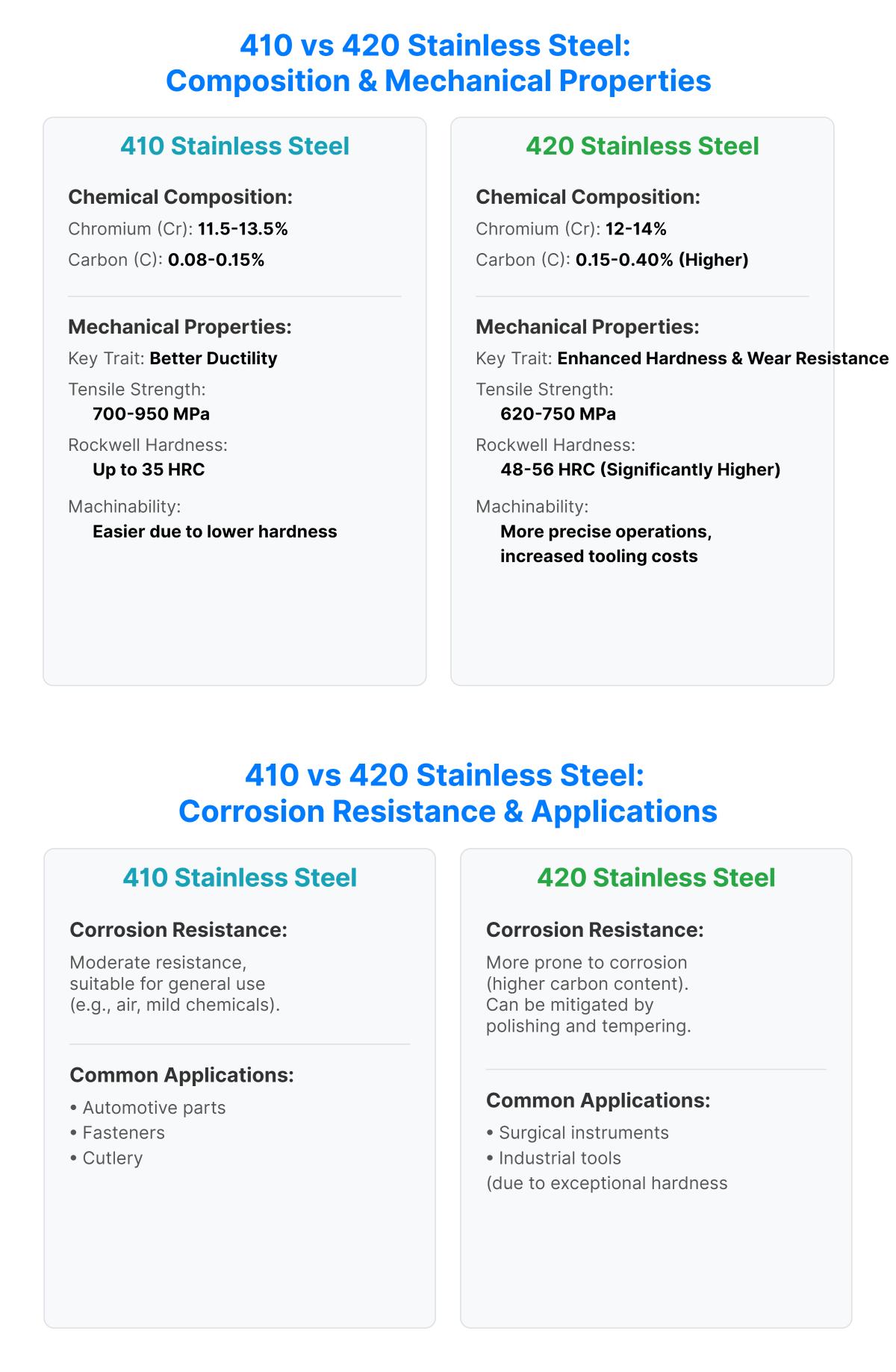

410 stainless steel is a basic martensitic grade with a chemical composition that typically includes 11.5-13.5% chromium and around 0.15% carbon. This balance provides a combination of good corrosion resistance and excellent mechanical properties.

Key Characteristics of 410 Stainless Steel:

420 stainless steel has a higher carbon content (0.15-0.40%) and a chromium content of 12-14%. This composition allows for higher hardness and strength, making it particularly suitable for cutting tools and wear-resistant applications.

Key Characteristics of 420 Stainless Steel:

Both 410 and 420 stainless steels resist corrosion well in mild environments. However, 420 has a slight edge over 410 due to its higher chromium content, making it more resistant to certain corrosive conditions.

410 stainless steel is ideal for fasteners, turbine blades, and petrochemical equipment, while 420 stainless steel is perfect for surgical instruments, knives, and industrial tools due to its higher hardness and wear resistance.

410 stainless steel contains 11.5% to 13.5% chromium and 0.08% to 0.15% carbon, providing moderate corrosion resistance and good mechanical properties. This balance makes it suitable for a variety of general-purpose applications.

On the other hand, 420 stainless steel contains 12% to 14% chromium and 0.15% to 0.40% carbon. The increased carbon content enhances its hardness and wear resistance, which is ideal for applications requiring high durability and strength.

| Property | 410 Stainless Steel | 420 Stainless Steel |

|---|---|---|

| Chromium Content | 11.5-13.5% | 12-14% |

| Carbon Content | 0.08-0.15% | 0.15-0.40% |

| Tensile Strength | 700-950 MPa | 620-750 MPa |

| Yield Strength | 450 MPa | 345-415 MPa |

| Hardness | 20-28 HRC (annealed), up to 35 HRC (hardened) | 48-56 HRC (hardened) |

| Corrosion Resistance | Moderate; suitable for mild environments | Moderate; less resistant in harsh conditions |

| Machinability and Weldability | Easier to machine and weld due to lower carbon content | Challenging to machine; higher risk of cracking during welding due to higher carbon content |

Heat treatment is essential for improving the mechanical properties of 410 and 420 stainless steels. This process involves heating and cooling the material to achieve desired characteristics such as increased hardness, improved ductility, and enhanced machinability. The primary heat treatment processes for these steels include annealing, hardening, and tempering.

Annealing 410 stainless steel involves heating it to a temperature range of 815-900°C, followed by air cooling. This process relieves internal stresses, improves machinability, increases ductility, and results in a softer steel that is easier to work with during subsequent manufacturing processes.

Similar to 410, 420 stainless steel is annealed by heating to 815-900°C and cooling in air. This process also softens the steel, making it more suitable for further processing. The higher carbon content in 420 requires careful control during annealing to prevent excessive grain growth and maintain desired properties.

Hardening 410 stainless steel is achieved by heating it to 925-1010°C and then quenching in oil or air. This process significantly increases the hardness of the steel. However, rapid cooling can cause brittleness, which tempering can address.

420 stainless steel requires higher temperatures for hardening, typically between 950-1050°C, followed by oil or air quenching. The higher carbon content allows 420 to achieve greater hardness levels, often up to 50 HRC. This makes 420 ideal for applications needing high wear resistance. However, the increased hardness can also make the steel more brittle.

Tempering 410 stainless steel involves heating it to 595-705°C. This process reduces brittleness and allows for adjusting the hardness to the desired level. Tempering is critical to achieve a balance between hardness and toughness, ensuring that the material performs well in its intended application.

For 420 stainless steel, tempering is performed at lower temperatures, typically between 150-370°C. This helps to balance hardness and toughness, avoiding the brittleness that can occur at higher tempering temperatures. The lower tempering range is essential for maintaining the high hardness required for cutting and wear-resistant applications.

The manufacturing of 410 and 420 stainless steels starts by melting raw materials in an electric furnace. This step involves heating the materials until they reach a molten state, which can take several hours depending on the production scale. Precise control of temperature and composition during this stage is crucial to ensure the desired properties of the final steel.

Following the melting of raw materials, decarburization is performed to remove excess carbon from the molten steel. This step is essential because excessive carbon can negatively impact the mechanical properties and corrosion resistance of the final product. Once the desired chemical composition is achieved, the molten steel is formed into billets or blooms through hot rolling. This process shapes the steel into large, semi-finished forms that are easier to handle in subsequent processing steps. For applications requiring precise dimensions and surface finishes, cold rolling is employed to further refine the steel’s thickness and surface quality.

Heat treatment includes steps like annealing, hardening, and tempering to enhance the steel’s properties. This stage significantly influences the mechanical characteristics of 410 and 420 stainless steels.

Machinability varies between 410 and 420 stainless steels because of their different carbon contents and hardness levels.

Welding these steels requires special care due to their varying carbon levels and crack susceptibility.

410 stainless steel is commonly used in the automotive industry. It is ideal for components that require both durability and corrosion resistance. Examples include exhaust systems, fasteners, and various engine parts. The material can withstand the harsh conditions under the hood, such as exposure to high temperatures and corrosive environments, making it a reliable choice.

In industrial machinery, 410 stainless steel is preferred for parts requiring both high strength and moderate corrosion resistance. This includes components like shafts, gears, and pump parts. The material’s mechanical properties ensure that it can handle the stresses and strains of industrial operations.

410 stainless steel is widely used to make cutlery and kitchen utensils. Its corrosion resistance and ability to maintain a sharp edge make it ideal for everyday kitchen tools. Additionally, its ease of fabrication allows manufacturers to produce a variety of shapes and designs.

The use of 410 stainless steel in steam and gas turbine blades is due to its ability to withstand high temperatures and resist corrosion. These blades operate in challenging environments where both heat resistance and strength are crucial for maintaining efficiency and safety.

Fasteners and pump components often utilize 410 stainless steel due to its robustness and moderate corrosion resistance. These parts benefit from the material’s ability to maintain integrity in various environments, ensuring reliability and longevity in service.

420 stainless steel is known for its higher hardness and wear resistance, making it ideal for demanding applications like surgical and dental instruments where durability and sharpness are crucial. The superior hardness and edge retention of 420 stainless steel make it the material of choice for these tools.

420 stainless steel is extensively used in the manufacture of cutting tools and knives. Its ability to achieve high hardness after heat treatment ensures that these tools maintain their sharpness and resist wear over prolonged use. This makes it ideal for both industrial cutting tools and consumer knives.

Certain marine and aerospace components benefit from the high strength and corrosion resistance of 420 stainless steel. In these applications, the material’s ability to withstand harsh environments, including exposure to saltwater and extreme temperatures, is particularly valuable.

Hand tools such as chisels, screwdrivers, and other high-wear tools are often made from 420 stainless steel. The material’s toughness and wear resistance ensure that these tools perform reliably over time, even with frequent use and under heavy loads.

420 stainless steel is selected for applications that demand high hardness and wear resistance. This includes surgical instruments and cutting tools where maintaining a sharp edge is essential. The higher carbon content in 420 stainless steel allows it to achieve greater hardness, making it suitable for these high-performance applications.

410 stainless steel is more appropriate for applications that require a balance of moderate corrosion resistance and ductility. Its lower carbon content makes it more ductile and easier to work with, which is beneficial for applications like automotive parts and industrial machinery that require flexibility and moderate strength.

410 stainless steel is easier to machine and weld compared to 420 stainless steel, making it preferable for applications where extensive fabrication is necessary. The lower carbon content in 410 stainless steel contributes to its better machinability and lower risk of cracking during welding, which is advantageous for manufacturing complex components.

Knowing these differences is essential for choosing the right stainless steel grade for specific performance needs and environmental conditions.

When considering the standards compliance of 410 and 420 stainless steel, their chemical compositions play a crucial role.

The mechanical properties of 410 and 420 stainless steels are influenced by their heat treatment processes, which are also governed by standards to ensure consistency and reliability.

Corrosion resistance is a critical factor for stainless steels, and standards ensure that both 410 and 420 stainless steels meet the necessary criteria for their respective applications.

Various industries have specific standards for 410 and 420 stainless steels to ensure their suitability for different applications.

To understand the cost and market differences between 410 and 420 stainless steel, it’s important to examine their chemical compositions and properties.

| Grade | Chromium Content | Carbon Content | Properties |

|---|---|---|---|

| 410 | 11.5-13.5% | 0.08-0.15% | Ductile, easier machining, good corrosion resistance |

| 420 | 12-14% | 0.15-0.40% | Higher hardness, wear resistance, challenging machining |

410 stainless steel, with its lower carbon content, is easier to machine and offers good ductility, making it a versatile choice for various industries. In contrast, 420 stainless steel has a higher carbon content, providing superior hardness and wear resistance but making it more challenging to machine.

The material costs of 410 stainless steel are generally lower than those of 420 stainless steel. This cost difference is primarily due to the lower chromium and carbon content in 410 stainless steel, which reduces the expense of raw materials required for its production.

Processing costs also vary. 410 stainless steel is cheaper to machine because it’s easier to work with, while 420 stainless steel is more expensive due to its hardness, which wears out tools faster and requires slower machining.

Maintenance costs depend on the operating environment. 410 stainless steel’s better thermal stability can reduce maintenance in high-heat conditions, while 420 stainless steel’s superior corrosion resistance, when properly heat-treated, can lower maintenance in mildly corrosive environments.

410 stainless steel is widely used in food preparation equipment and steam turbine blades due to its cost-effectiveness and moderate corrosion resistance. In contrast, 420 stainless steel is favored in the medical and manufacturing industries for surgical instruments and cutting tools, where high hardness and wear resistance are crucial.

Both grades offer good corrosion resistance in mildly corrosive environments. However, they differ in their ability to withstand more severe conditions. 410 stainless steel performs better in chloride-rich environments, whereas 420 stainless steel requires proper heat treatment to optimize its corrosion resistance. This heat treatment is crucial for achieving the desired balance of hardness and corrosion resistance in 420 stainless steel.

The primary distinction between 410 and 420 stainless steel lies in their chemical composition. 410 stainless steel contains 11.5-13.5% chromium and 0.08-0.15% carbon, resulting in a softer and more ductile material. On the other hand, 420 stainless steel has a higher carbon content of 0.15-0.40% and 12-14% chromium. This increased carbon content significantly enhances its hardness and durability, making 420 stainless steel ideal for high-stress applications.

When it comes to mechanical properties, 410 stainless steel exhibits a tensile strength of 700-950 MPa and a yield strength of around 450 MPa. Its Rockwell hardness ranges from 20-28 HRC in the annealed state and can be hardened to 35 HRC. This makes it suitable for applications requiring moderate strength and good machinability.

In contrast, 420 stainless steel offers a tensile strength of 620-750 MPa and a yield strength between 345-415 MPa. With heat treatment, 420 can reach a Rockwell hardness of 48-56 HRC, making it perfect for cutting tools and high-stress applications.

Both 410 and 420 stainless steels offer moderate corrosion resistance, with performance varying by environment. 410 stainless steel performs well in typical environments such as food preparation and sports equipment due to its chromium content. It is also more resistant to chloride-induced corrosion compared to 420 stainless steel.

420 stainless steel, while having slightly higher chromium content, is more susceptible to corrosion in humid or acidic conditions unless properly heat-treated. It performs adequately in atmospheric conditions and mild chemicals, but its higher carbon content can sometimes compromise its corrosion resistance.

410 stainless steel is commonly used in automotive parts, fasteners, cutlery, pump shafts, and valve stems due to its moderate corrosion resistance and mechanical strength. Its properties make it a versatile material for various industrial applications.

On the other hand, 420 stainless steel is best suited for applications requiring high hardness and wear resistance, such as surgical instruments, cutting tools, and industrial tools. Its enhanced hardness makes it particularly suitable for applications that endure high stress and demand durability.

In terms of machinability and weldability, 410 stainless steel is easier to machine and weld due to its lower carbon content. This makes it a preferred choice for applications involving extensive machining and welding operations.

420 stainless steel, however, is more challenging to machine and weld. Its increased hardness and carbon content demand precise operations, potentially raising tooling costs. This necessitates careful consideration during manufacturing processes to ensure optimal performance.

From a cost perspective, 410 stainless steel generally has lower material costs and machining expenses compared to 420 stainless steel. While 420 may incur higher initial costs and processing expenses, it offers long-term benefits through enhanced durability in specific applications.

The choice between 410 and 420 stainless steel depends on the specific requirements of the application. If cost is a primary concern and the application does not demand high resistance to wear and corrosion, 410 stainless steel may be the more economical choice.

largely depends on the requirements and priorities of the specific application at hand. For instance, 410 stainless steel, with its superior machinability and lower cost, is often preferred for applications where cost-efficiency and ease of manufacturing are critical. It is commonly used in the production of components such as bolts, screws, and fasteners, where mechanical properties are sufficient for the intended use.

On the other hand, 420 stainless steel, which can be hardened through heat treatment, offers higher strength and better wear resistance. This makes it an excellent choice for applications that demand greater durability and resistance to abrasion, such as in the manufacturing of cutlery, surgical instruments, and various tools.

Below are answers to some frequently asked questions:

The main differences between 410 and 420 stainless steel lie in their chemical composition, mechanical properties, corrosion resistance, machinability, and applications.

410 stainless steel has a chromium content of 11.5-13.5% and a lower carbon content of 0.08-0.15%, which results in better ductility and easier machinability. It achieves a moderate tensile strength (700-950 MPa) and can be hardened to a Rockwell hardness of up to 35 HRC. It offers moderate corrosion resistance, suitable for general use in environments like air and mild chemicals.

In contrast, 420 stainless steel contains 12-14% chromium and a higher carbon content of 0.15-0.40%, enhancing its hardness and wear resistance. Its tensile strength ranges from 620-750 MPa, and it can be hardened to a significantly higher Rockwell hardness of 48-56 HRC. However, its higher carbon content makes it more prone to corrosion in harsh environments, although this can be mitigated through polishing and tempering.

For machining, 410 stainless steel is easier to work with due to its lower hardness, while 420 requires more precise operations and increased tooling costs. In terms of applications, 410 is commonly used in automotive parts, fasteners, and cutlery, whereas 420 is ideal for surgical instruments and industrial tools due to its exceptional hardness and wear resistance.

410 stainless steel is best suited for applications requiring moderate corrosion resistance and good ductility. Common uses include automotive parts, fasteners, cutlery, and industrial machinery components like pumps and valves. Its lower carbon content makes it easier to machine and weld, offering flexibility and toughness without extreme hardness.

On the other hand, 420 stainless steel is ideal for applications where high hardness and wear resistance are crucial. This makes it suitable for cutting tools, surgical instruments, industrial components like gears and pump shafts, aerospace parts, and food processing equipment. The higher carbon content in 420 stainless steel allows for greater hardness and edge retention after heat treatment, but it requires proper maintenance to prevent rust in harsh environments.

410 and 420 stainless steel differ primarily in their hardness and corrosion resistance due to variations in their chemical composition and heat treatment capabilities.

Hardness: 410 stainless steel offers moderate hardness, typically around 20-28 HRC in its annealed state, and can be hardened up to 35 HRC through heat treatment. This makes it more ductile and suitable for applications requiring some flexibility. On the other hand, 420 stainless steel, with its higher carbon content, can achieve significantly higher hardness levels, ranging from 48-56 HRC after proper heat treatment. This high hardness makes 420 ideal for cutting tools and surgical instruments but less ductile and more challenging to machine.

Corrosion Resistance: 410 stainless steel, containing 11.5-13.5% chromium, provides moderate corrosion resistance, performing well in everyday environments like air and mild chemicals but not in harsh conditions. 420 stainless steel, with slightly higher chromium content (12-14%), might suggest better corrosion resistance, but its higher carbon content makes it more prone to corrosion in severe environments. Proper heat treatment can enhance its corrosion resistance, but it is generally less resilient than 410 in harsh conditions.

410 and 420 stainless steels are governed by specific standards that ensure their appropriate use in various applications. For 410 stainless steel, compliance is primarily with ASTM standards such as UNS S41000, which define its chemical composition and mechanical properties. It also aligns with EN standards (EN 10088-1 and EN 10088-3) and DIN standards (DIN 1.4006), ensuring consistency in its properties and delivery conditions.

420 stainless steel adheres to ASTM specifications like ASTM A276 and ASTM A314. These standards outline its chemical composition, which includes 12-14% chromium and 0.15-0.40% carbon, mechanical properties, and heat treatment processes. While 420 provides moderate corrosion resistance and can achieve high hardness (up to 50 HRC) after heat treatment, it is less resistant to harsh environments compared to austenitic grades.

Heat treatment processes, including hardening, tempering, and annealing, significantly impact the properties of both 410 and 420 stainless steel.

For 420 stainless steel, hardening is achieved by heating to 1742–1922°F (950–1050°C) followed by quenching in oil or air. This process increases hardness and wear resistance. Tempering at 300–1292°F (150–700°C) adjusts the balance between hardness and toughness, with lower temperatures increasing hardness and higher temperatures enhancing toughness. Annealing at 1550/1650°F (843/900°C) provides maximum softness, improving machinability.

Similarly, 410 stainless steel is hardened by heating to 1700–1850°F (925–1010°C) and quenching. Tempering between 392–1112°F (200–600°C) optimizes hardness and strength while relieving internal stresses. Pre-machining annealing enhances workability.

When machining 410 and 420 stainless steel, differences in carbon content and resulting hardness play a significant role. 410 stainless steel, with lower carbon content, is easier to machine, especially in its annealed condition. It allows for higher cutting speeds and less tool wear, making it suitable for moderate strength applications. In contrast, 420 stainless steel, with higher carbon content, is more challenging to machine due to its increased hardness. Precision tools like high-speed steel or carbide are necessary to prevent work hardening and premature tool wear. Sharp cutting edges and controlled feed rates are essential for minimizing damage.

Welding considerations also vary between the two. 410 stainless steel is easier to weld because of its lower carbon content. Preheating between 300°F and 500°F is recommended to minimize thermal shock and cracking, with post-weld heat treatment to restore mechanical properties and relieve stresses. Conversely, welding 420 stainless steel is more challenging due to its higher carbon content, increasing the risk of cracking. Preheating to 300°F to 400°F can help reduce this risk, and post-weld tempering is crucial to mitigate brittleness. The use of low hydrogen electrodes and proper cooling techniques is also recommended for 420 stainless steel.

Overall, the choice between 410 and 420 stainless steel for machining and welding should be guided by the specific requirements of the application, considering the differences in machinability, weldability, strength, and corrosion resistance.