When it comes to choosing the right steel for your next project, understanding the nuances between similar alloys can be crucial. Enter 4140 and 4140H steel—two closely related yet distinct materials that often leave engineers and manufacturers deliberating over which to use. Are you wondering about the key differences in their composition and applications? How does each material respond to welding and machining? In this article, we’ll dive deep into the comparative aspects of 4140 and 4140H steel, exploring their chemical makeup, heat treatment effects, and specific industry uses. By the end, you’ll have a clear understanding of which steel is best suited for your needs and why. Ready to uncover the details that set these two steels apart? Let’s get started.

4140 steel is a type of chromium-molybdenum alloy that is well-regarded for its high strength and toughness. It is widely used in industries requiring robust materials capable of withstanding heavy loads and high stress. This steel exhibits good ductility and can be hardened through heat treatment.

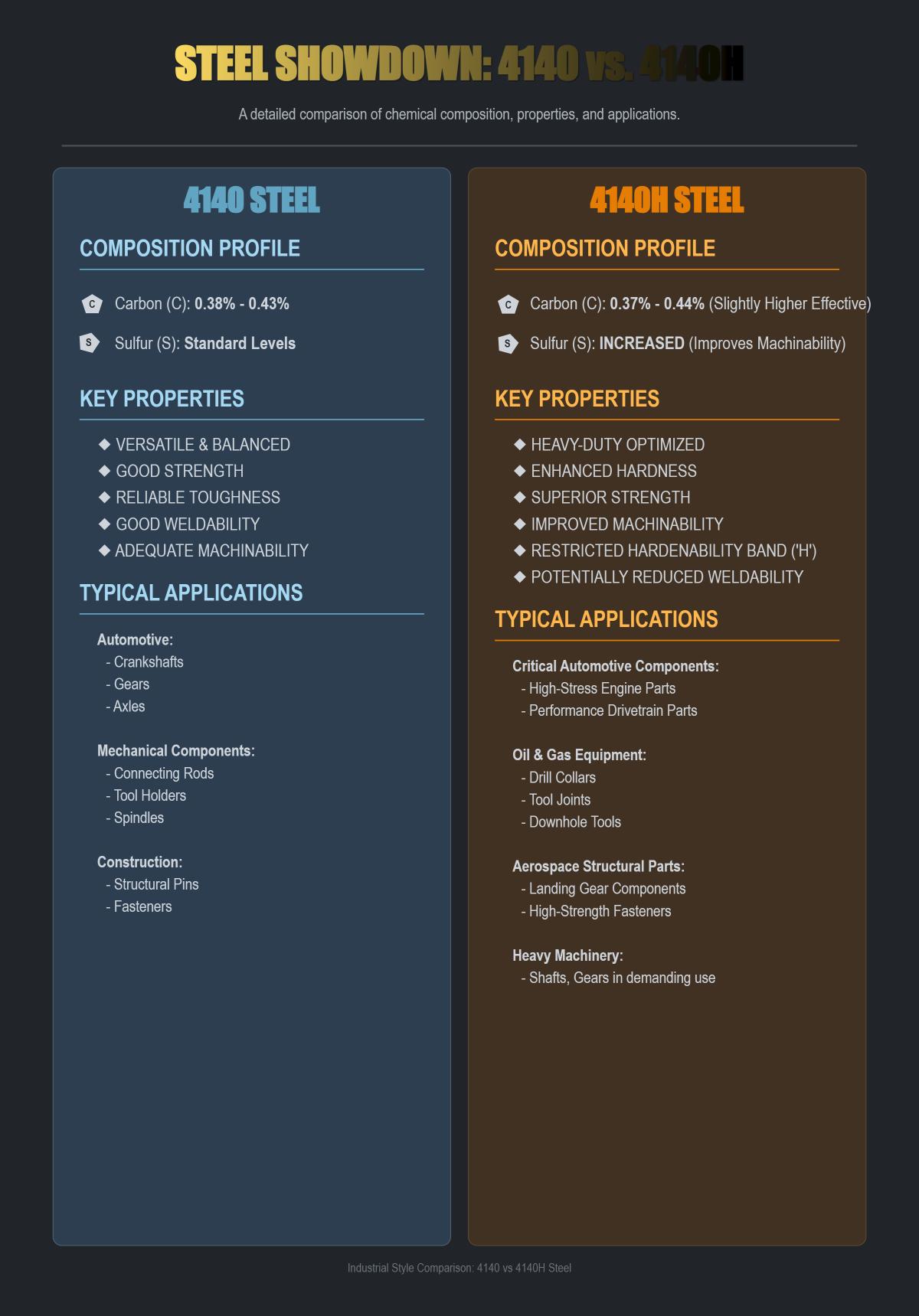

The chemical composition of 4140 steel includes:

4140H steel is a variant of 4140 steel, distinguished by its higher carbon and sulfur content. This modification enhances its hardness and strength, making it suitable for more demanding applications. 4140H also benefits from improved machinability due to the increased sulfur content, although this can affect weldability.

The chemical composition of 4140H steel includes:

| Element | 4140 Content (%) | 4140H Content (%) |

|---|---|---|

| Carbon | 0.380 – 0.430 | Higher than 4140 |

| Chromium | 0.80 – 1.10 | 0.80 – 1.10 |

| Manganese | 0.75 – 1.0 | 0.75 – 1.0 |

| Silicon | 0.15 – 0.30 | 0.15 – 0.30 |

| Molybdenum | 0.15 – 0.25 | 0.15 – 0.25 |

| Sulfur | 0.040 | Higher than 4140 |

| Phosphorus | 0.035 | 0.035 |

4140 steel is commonly used to make bolts, nuts, screws, and other high-strength components in construction, automotive, and manufacturing industries.

4140H steel is preferred for heavy-duty applications requiring high strength and toughness. It is commonly used in the automotive and aerospace industries for components like gears, crankshafts, axles, and structural parts where consistent hardenability is crucial.

The compositional differences between 4140 and 4140H steel greatly influence their performance in different applications. While 4140 steel offers better weldability and versatility, 4140H steel provides superior strength and hardness, making it ideal for more demanding and critical applications.

Heat treatment is a critical process used to alter the physical and mechanical properties of metals such as 4140 and 4140H steels. This process involves heating the metal to specific temperatures, maintaining those temperatures for a set period, and then cooling it at controlled rates. The primary goals are to improve hardness, strength, toughness, and wear resistance.

Several heat treatment methods are commonly applied to 4140 and 4140H steels to achieve the desired properties:

Heat treatment greatly impacts the mechanical properties of 4140 steel. After quenching and tempering, its tensile strength is typically 115-135 ksi, yield strength is about 95 ksi, hardness is Rockwell C 28-32, and elongation is around 12%.

For 4140 steel, a common heat treatment cycle involves:

This cycle provides a good balance between hardness and ductility, making 4140 steel suitable for various applications, including gears, bolts, and machine parts.

4140H steel, due to its controlled composition and guaranteed hardenability, exhibits superior mechanical properties after heat treatment. The tensile strength typically ranges from 140-165 ksi, with a yield strength of around 130 ksi. The hardness of 4140H steel after heat treatment is generally between Rockwell C 32-36, and the elongation is approximately 10%.

The heat treatment cycle for 4140H steel often includes:

This cycle ensures that 4140H steel achieves high strength and hardness while maintaining sufficient toughness, making it ideal for heavy-duty applications such as crankshafts and structural components in the automotive and aerospace industries.

| Property | 4140 Steel | 4140H Steel |

|---|---|---|

| Tensile Strength (ksi) | 115-135 | 140-165 |

| Yield Strength (ksi) | 95 | 130 |

| Hardness (Rockwell C) | 28-32 | 32-36 |

| Elongation (%) | 12 | 10 |

The comparison shows that 4140H steel generally has higher tensile and yield strengths, greater hardness, and slightly less elongation compared to 4140 steel. This makes 4140H steel better suited for high-stress applications where higher performance and reliability are needed.

4140 steel is a versatile material used across various industries due to its balanced combination of strength, hardness, and ductility.

In the automotive sector, 4140 steel is commonly used for manufacturing critical components such as gears, crankshafts, and connecting rods. It is ideal for high-performance applications due to its ability to withstand high stress and wear.

The oil and gas industry uses 4140 steel for wellhead components, pipeline fittings, and drill collars. The steel’s durability and resistance to fatigue under cyclic loads are crucial in these demanding environments.

4140 steel is also prevalent in the construction and heavy machinery industries. It is used for high-strength fasteners, bolts, and machine parts that need toughness and can handle significant mechanical loads.

4140H steel, with its enhanced hardenability and strength, is tailored for more demanding applications where higher performance is essential.

In the aerospace industry, 4140H steel is used for components such as landing gear, shafts, and structural parts. The steel’s high strength and hardness, coupled with its ability to maintain these properties under extreme conditions, make it suitable for aerospace applications.

4140H steel finds extensive use in the construction and heavy equipment industries. It is employed in the manufacture of hydraulic machinery, heavy-duty axles, and other structural components that require superior strength and wear resistance.

In the energy sector, particularly in wind turbine manufacturing, 4140H steel is used for critical components like shafts and gears. The steel’s reliability under high stress and its resistance to fatigue are vital for the long-term operation of energy-producing equipment.

A prominent automotive manufacturer employed 4140 steel for engine crankshafts. The steel’s balance of strength and ductility provided the necessary performance while maintaining cost-effectiveness. Conversely, 4140H steel was used in high-performance racing cars’ drive shafts, where the enhanced strength and hardness were critical for reliability under extreme stress.

In aerospace, 4140H steel was used for landing gear components. The high hardenability ensured that the steel maintained its strength and toughness, even after extensive use and exposure to varying temperatures and mechanical loads.

Industry professionals highlight the importance of choosing the right material based on the specific requirements of the application. According to a leading metallurgist, “While 4140 steel offers a great balance for general engineering uses, 4140H steel’s enhanced properties make it indispensable for high-stress applications, where failure is not an option.”

This nuanced understanding of the different applications and the properties of 4140 and 4140H steels helps engineers and manufacturers optimize their material choices to ensure performance, reliability, and cost-effectiveness.

When comparing the cost of 4140 and 4140H steel, it’s important to note that 4140H generally comes at a higher price point. This is mainly because its higher carbon content requires more refining and stricter heat treatment. These additional steps enhance the mechanical properties of 4140H, making it suitable for more demanding applications. The higher cost reflects the improved strength and hardness of 4140H steel, which is critical in heavy-duty applications such as automotive and aerospace components.

Both 4140 and 4140H steels are widely available in the market. Suppliers like Eaton Steel Bar Company offer these materials in various forms, including bars and rods. However, the availability of specific sizes and shapes may vary based on regional demand and supplier capacity. 4140H steel bars, for instance, are commonly stocked in sizes ranging from 2½ inches to 15 inches to cater to diverse industrial requirements. This widespread availability ensures that both 4140 and 4140H steels can be sourced relatively easily for various applications.

The production of both 4140 and 4140H steels is energy-intensive, but 4140H requires more energy due to its higher carbon content, potentially leading to a larger carbon footprint. The additional refining and stringent heat treatment processes for 4140H steel contribute to this increased energy consumption.

Both 4140 and 4140H steels are recyclable, which can help mitigate their environmental impact. Recycling these materials reduces waste and conserves raw materials, contributing to more sustainable manufacturing practices. The recyclability of these steels is a significant advantage, allowing industries to reuse materials and reduce their carbon footprint.

Understanding these differences helps in selecting the appropriate material for specific applications, balancing the need for mechanical performance, cost, and environmental considerations.

Machinability refers to how easily a material can be cut, shaped, or machined to meet desired specifications. This property is crucial for manufacturing processes, as it directly impacts production efficiency, tooling costs, and the quality of the final product.

4140 steel is easier to machine than 4140H steel. This is largely due to its lower carbon and sulfur content, which results in reduced hardness and brittleness. The machinability of 4140 steel allows for faster machining speeds and less wear on cutting tools, making it more convenient for a variety of manufacturing processes.

Key Points:

4140H steel presents more challenges in machining due to its higher carbon and sulfur content. These elements make the material harder and more brittle, requiring sharper tools and slower speeds to avoid damage. Specialized machining techniques are required to manage the increased wear on tools and to achieve precise cuts.

Key Points:

Weldability is the ability of a material to be welded under specified conditions to perform satisfactorily in the intended service. It involves various factors, including the material’s chemical composition, its thermal properties, and the welding process used.

4140 steel offers better weldability and can be welded using standard techniques. However, it often requires careful preheating and post-weld heat treatment to avoid issues such as hydrogen-induced cracking. These precautions help maintain the integrity and performance of the welded joints.

Key Points:

Welding 4140H steel is more challenging due to its higher carbon content, which increases the risk of hardening and cracking during the welding process. This requires stricter preheating and post-weld treatments to ensure weld quality. Specialized welding processes are often required to achieve satisfactory results.

Key Points:

When comparing the machinability and weldability of 4140 and 4140H steels, it’s evident that each has distinct advantages and limitations based on their chemical compositions and intended applications.

4140 steel is suitable for a wide range of applications where machinability and weldability are important. These include bolts, nuts, screws, and general machinery components used in industries such as automotive, construction, and machinery manufacturing.

4140H steel is ideal for heavy-duty applications requiring superior strength and hardness. It is commonly used in the automotive and aerospace sectors for components such as gears, crankshafts, and axles, where high stress and performance are critical.

Knowing these differences helps choose the right steel for projects, balancing machinability, weldability, and performance.

Below are answers to some frequently asked questions:

4140 steel and 4140H steel differ primarily in their chemical composition and specific applications. 4140 steel has a carbon content ranging from 0.38% to 0.43%, while 4140H has a slightly higher carbon range of 0.37% to 0.44%, enhancing its hardness and strength. Additionally, 4140H contains more sulfur, improving machinability but potentially reducing weldability.

In terms of applications, 4140 steel is versatile and commonly used in automotive parts (e.g., crankshafts, gears), mechanical components (e.g., connecting rods, tool holders), and construction due to its good balance of strength, toughness, and weldability. On the other hand, 4140H steel is suited for heavy-duty applications requiring higher strength and hardness, such as critical automotive components, oil and gas equipment, and aerospace structural parts.

The welding and machining properties of 4140 and 4140H steel differ primarily due to variations in their carbon content and chemical compositions.

4140 steel generally has better weldability compared to 4140H steel. This is because 4140 has a lower carbon content, which results in a more stable composition during welding. The lower carbon content reduces the risk of cracking and makes it easier to perform complex fabrications and repairs. In contrast, 4140H steel, with its higher carbon content, tends to be harder and more prone to cracking during welding. This makes it less suitable for extensive welding applications.

When it comes to machining, 4140 steel is relatively easier to work with. Its lower carbon and sulfur content contribute to better machinability, allowing for efficient processing with standard cutting tools and parameters. On the other hand, 4140H steel, with higher carbon and sulfur levels, is more challenging to machine. It requires specialized tools, slower cutting speeds, and lower feed rates to prevent excessive tool wear and material damage due to its increased hardness and brittleness.

4140 steel is commonly used in the automotive industry for manufacturing gears, shafts, and axles due to its balance of strength, toughness, and wear resistance. In construction and machinery, it is employed in heavy-duty components like beams, columns, spindles, and jigs. The oil and gas industry utilizes 4140 for drill collars and pipes, benefiting from its high strength and toughness. Though less common, it can also be used in aerospace for specific applications.

4140H steel, with its enhanced hardenability, is preferred in the automotive sector for critical components like crankshafts and gears. It is also ideal for the oil and gas industry, used in pipelines and valve components. In aerospace, 4140H is favored for landing gear and engine parts due to its excellent strength-to-weight ratio and fatigue resistance. Additionally, 4140H is suitable for heavy machinery, including mining equipment and industrial gear systems, where higher hardness and strength are required.

For heavy-duty applications requiring high strength and hardness, 4140H steel is the better choice. As discussed earlier, 4140H steel has a higher carbon content and increased sulfur concentration, which significantly enhances its mechanical properties. Specifically, 4140H offers superior tensile strength (140-165 ksi), yield strength (130 ksi), and hardness (Rockwell C 32-36) compared to 4140 steel. These characteristics make 4140H ideal for critical components such as crankshafts, gears, and structural parts used in demanding environments like automotive and aerospace sectors. However, it’s important to consider that 4140H’s enhanced properties come with higher costs and reduced weldability, necessitating specialized machining techniques and tools. Therefore, if the application demands maximum strength and hardness, 4140H steel should be selected despite its higher cost and machining challenges.

The cost and availability differences between 4140 and 4140H steel primarily stem from their composition and intended applications.

4140 steel is generally less expensive due to its lower carbon content and less stringent manufacturing requirements. It is widely used across various industries for general-purpose components, making it more readily available from numerous suppliers globally. This widespread availability and lower cost make 4140 steel suitable for projects where budget constraints are a significant factor and extreme strength is not necessary.

On the other hand, 4140H steel, with its higher carbon content and guaranteed hardenability (as indicated by the “H” suffix per ASTM A304 standards), undergoes specialized heat treatment processes. These factors contribute to its higher cost. The enhanced mechanical properties of 4140H steel, such as superior strength, hardness, and impact resistance, justify its higher price, making it ideal for critical applications in demanding industries like aerospace and oil and gas. However, this also means that 4140H steel is typically available from specialized suppliers who can meet these stringent requirements, potentially making it less readily available than standard 4140 steel.

Heat treatment significantly impacts the properties of both 4140 and 4140H steel, primarily through processes like annealing, normalizing, quenching, and tempering.

For 4140 steel, heat treatment enhances its strength, toughness, and wear resistance. Annealing at 1450-1600°F softens the steel, making it easier to machine, while normalizing at 1600-1700°F refines its grain structure, improving toughness. Quenching, typically between 1550-1600°F, transforms the microstructure into martensite, significantly increasing hardness and strength. Subsequent tempering at 400-1300°F reduces brittleness and balances hardness with toughness, resulting in a final hardness range of 28-48 HRC.

4140H steel, while similar in composition to 4140, is often tailored for specific hardness levels. The “H” designation indicates a focus on higher hardness requirements, achieved through precise heat treatment adjustments. The process for 4140H generally mirrors that of 4140 but is optimized to meet specific application needs.

In summary, heat treatment processes enhance the mechanical properties of both 4140 and 4140H steel, with 4140H potentially being adjusted for higher hardness and specialized applications.