When it comes to selecting the right material for high-performance applications, the choice between 416R stainless steel and 4140 chromoly can be a perplexing one. Both materials are celebrated for their unique properties and are frequently used in demanding industries such as firearms and aerospace. But what sets them apart? Is one inherently better for high-stress environments, or does corrosion resistance play a pivotal role in your decision? In this article, we will delve into the core differences between 416R stainless steel and 4140 chromoly, comparing their composition, physical properties, and suitability for various applications. By the end, you’ll have a clearer understanding of which material is best suited for your specific needs. So, let’s unravel the mysteries of these two engineering marvels and see how they stack up against each other.

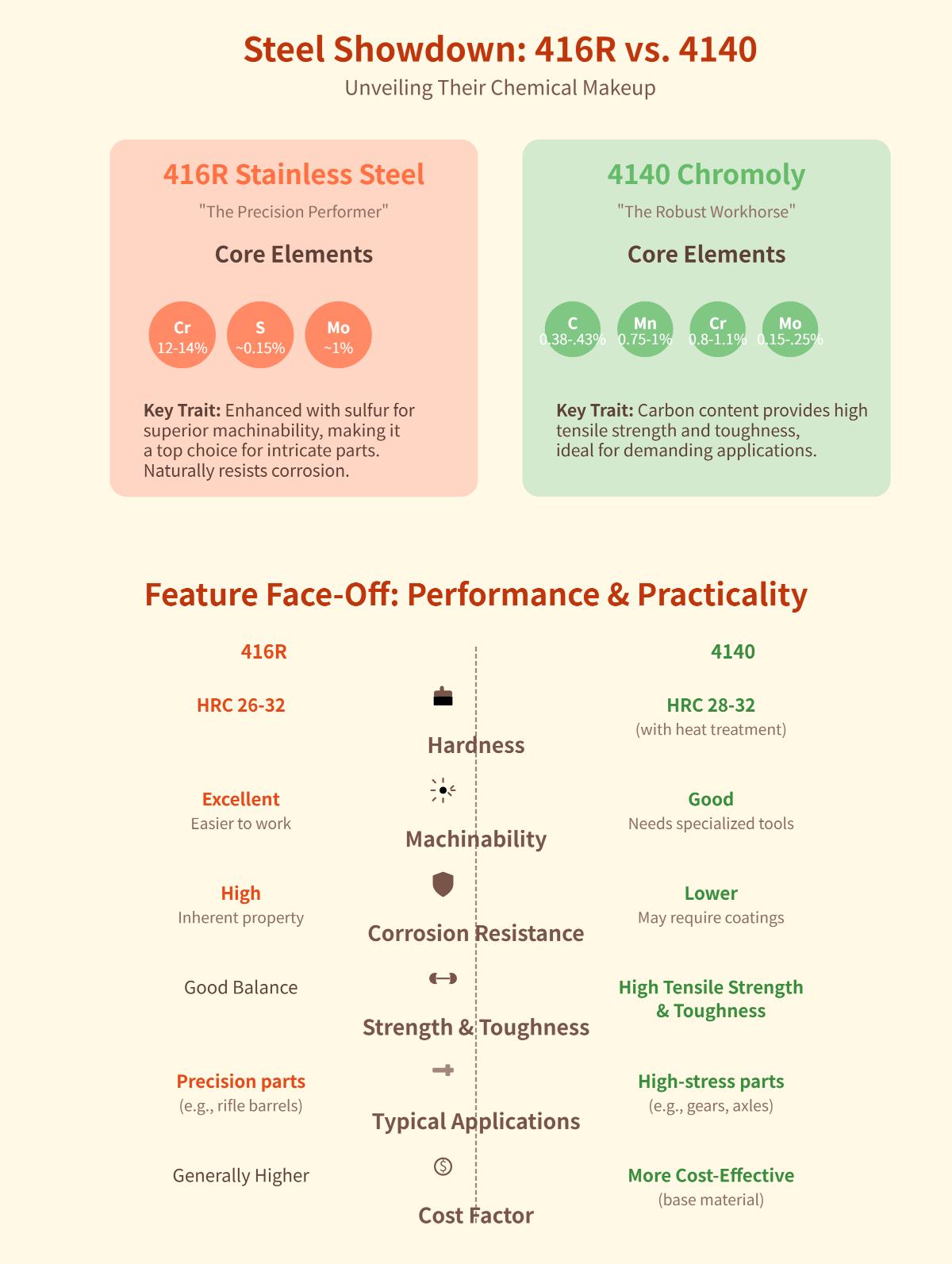

416R stainless steel is a type of martensitic steel that contains 12-14% chromium and 0.15% sulfur. The chromium content provides significant corrosion resistance, making it suitable for environments where moisture and corrosive elements are present. The sulfur content enhances its machinability, which is crucial for precision applications such as rifle barrels. This steel can be heat-treated to a hardness of HRC 26-32, offering a balance between strength and machinability. Additionally, 416R maintains toughness at low temperatures, down to -40°F, which is advantageous for applications in cold environments.

4140 chromoly is an alloy steel made up of 0.38-0.43% carbon, 0.75-1.00% manganese, 0.80-1.10% chromium, and 0.15-0.25% molybdenum. This composition gives it exceptional strength, wear resistance, and toughness. When oil quenched and tempered, 4140 can reach a hardness of HRC 28-32 and a tensile strength of approximately 180,000 psi, making it suitable for high-stress applications. However, it has lower inherent corrosion resistance compared to stainless steel and often requires protective coatings to prevent rust. Its machinability is more challenging due to its higher carbon content, necessitating specialized tools and techniques.

416R stainless steel’s higher chromium content significantly enhances its corrosion resistance compared to 4140 chromoly, which relies on protective coatings to prevent rust. The sulfur in 416R also improves its machinability, making it easier to machine into precise shapes, a critical factor for firearm barrels and other precision components.

In contrast, 4140 chromoly’s higher carbon content and additional alloying elements like molybdenum and manganese provide superior strength and wear resistance. These properties are essential for high-stress applications where failure is not an option.

Both materials have similar densities, with 4140 chromoly being marginally denser. However, the difference is minimal and often negligible in most practical applications. The hardness levels of both materials are comparable, but 4140 chromoly’s slightly higher hardness and tensile strength make it more suitable for applications that demand maximum durability and resistance to mechanical stress.

In the firearms industry, 416R stainless steel is known for being easy to machine and resistant to corrosion. These properties make it an ideal choice for manufacturing precision rifle barrels. The material’s sulfur content enhances its machinability, allowing for intricate and precise machining required in firearm components. Additionally, its high chromium content provides excellent resistance to rust and corrosion, which is crucial for maintaining firearm integrity and performance in various environmental conditions.

The aerospace industry relies on 416R stainless steel for its precise and corrosion-resistant components. Its ability to maintain toughness at low temperatures makes it suitable for parts exposed to extreme conditions, such as bearings and gears. The machinability of 416R also allows for the production of complex shapes and tight tolerances, which are essential in aerospace applications where precision is paramount.

The firearms industry prefers 4140 chromoly for parts that endure heavy stress and wear. Its high tensile strength and hardness make it suitable for components like receivers, bolts, and other structural parts that must withstand significant mechanical forces. Despite its lower corrosion resistance compared to 416R, the application of protective coatings can effectively mitigate rust and corrosion issues, extending the lifespan of the firearm parts.

In aerospace, 4140 chromoly is selected for its outstanding strength and durability. It is commonly used in structural components such as landing gear, where the material must endure substantial loads and impacts. The alloy’s ability to achieve high tensile strength through heat treatment ensures that it can support the rigorous demands of aerospace structures, contributing to the safety and reliability of the aircraft.

For high-stress applications, 4140 chromoly is generally the preferred material due to its superior tensile strength and hardness. Its robustness makes it suitable for components that need to withstand heavy loads, impacts, and wear. Examples include automotive parts like crankshafts and gears, as well as structural components in aerospace and heavy machinery.

When selecting materials for use in corrosive environments, 416R stainless steel is often the better choice. Its higher chromium content provides excellent resistance to rust and corrosion, making it ideal for applications where exposure to moisture or corrosive substances is a concern. This property is particularly beneficial in the marine industry, chemical processing plants, and outdoor environments.

For high-precision applications, 416R stainless steel is ideal because its sulfur content makes machining easier and more accurate. This allows for the creation of complex and precise components, making 416R suitable for precision instruments, medical devices, and any application where tight tolerances and fine details are critical.

Machinability refers to the ease with which a material can be cut, shaped, or finished using machine tools. It is an important property for materials used in manufacturing precision components, as it affects the efficiency of machining processes, the quality of the finished product, and the lifespan of the cutting tools. High machinability means the material can be machined quickly and efficiently, with minimal wear on tools, while low machinability indicates that the material is more difficult to work with, often requiring specialized tools and techniques.

416R stainless steel is highly machinable, with ratings typically between 85% and 90%. This makes it an excellent choice for precision applications such as rifle barrels.

The high machinability of 416R stainless steel is largely due to sulfur in its composition, forming manganese sulfide inclusions that act as internal lubricants during machining. These inclusions reduce friction between the cutting tool and the material, resulting in less tool wear and allowing for faster machining speeds.

The machinability of 416R stainless steel enables the production of components with smooth finishes and tight tolerances. This is critical for maintaining the accuracy and durability of precision parts, such as those used in firearms and aerospace applications.

4140 chromoly steel has a moderate machinability, generally rated around 70% when in the annealed condition. This makes it less machinable than 416R stainless steel.

The machinability of 4140 chromoly can vary significantly depending on its heat treatment. While annealing improves its machinability, the material often requires additional stress-relieving processes to achieve optimal conditions for machining. This can complicate machining and increase production time and costs.

Machining 4140 chromoly can be challenging. Its higher carbon content contributes to increased tool wear, and the material often requires specialized cutting tools and techniques. These factors can make it less suitable for applications that demand high precision and smooth finishes.

When it comes to precision applications, 416R stainless steel stands out due to its superior machinability. The ease of machining this material allows manufacturers to produce intricate and precise components efficiently, making it the preferred choice for applications such as rifle barrels, where accuracy and surface finish are paramount.

While 4140 chromoly is less machinable, its superior strength and toughness make it more suitable for high-stress applications. This material can endure significant mechanical stress and wear, although it may require additional coatings to protect against corrosion.

The machinability of 416R stainless steel translates to lower tool wear and faster machining speeds compared to 4140 chromoly. This leads to cost savings and higher efficiency, especially in high-volume production.

Corrosion resistance refers to the ability of a material to withstand damage caused by oxidation or other chemical reactions with its environment. This property is critical in applications where the material is exposed to moisture, chemicals, or other corrosive elements that can degrade its structural integrity over time.

416R stainless steel contains approximately 12-14% chromium, which significantly enhances its corrosion resistance. The chromium in the steel forms a thin, stable oxide layer on the surface, known as a passive layer. This layer acts as a barrier, protecting the underlying material from further oxidation and corrosion.

Sulfur in 416R stainless steel enhances machinability while maintaining good corrosion resistance. This balance makes it suitable for precision applications where both ease of machining and resistance to environmental degradation are crucial. However, in highly corrosive environments, 416R may not perform as well as some other stainless steels with higher corrosion resistance.

416R stainless steel is commonly used in the manufacturing of precision firearm components, such as rifle barrels. Its corrosion resistance ensures long-term functionality and accuracy, even in moist environments that promote rust.

4140 chromoly contains about 0.8-1.1% chromium, which provides some level of corrosion resistance, but not to the extent of 416R stainless steel. The lower chromium content means that 4140 is more susceptible to rust and corrosion, especially in environments with high moisture or chemical exposure.

Due to its lower corrosion resistance, 4140 chromoly often needs protective coatings. Techniques such as QPQ (Quench-Polish-Quench) Melonite treatments can significantly enhance the corrosion resistance of chromoly steel, making it more suitable for applications where exposure to corrosive elements is a concern.

4140 chromoly is widely used in high-stress applications where strength and toughness are prioritized. Common uses include aerospace and automotive components, where the material’s mechanical properties are more critical. With appropriate protective coatings, 4140 can also be used in environments where corrosion resistance is necessary.

Tensile strength measures the maximum tensile (pulling or stretching) stress a material can withstand before breaking. It is expressed in units of force per unit area, typically in megapascals (MPa) or pounds per square inch (psi). This property is essential for understanding how materials behave under load and is particularly important in applications involving structural and load-bearing components.

In its annealed state, 416R stainless steel has a tensile strength of approximately 517 MPa (75,000 psi). This is achieved by heating the steel and then cooling it slowly, which relieves internal stresses and increases ductility but reduces tensile strength.

When 416R stainless steel undergoes hardening and tempering, its tensile strength can increase significantly, reaching up to 1405 MPa (204,000 psi). The hardening process involves heating the steel to a high temperature followed by rapid cooling, usually in oil or air. Tempering then adjusts the hardness and reduces brittleness, resulting in a material with high strength and good toughness, making it suitable for high-performance applications like rifle barrels.

4140 chromoly steel, in its annealed condition, typically has a tensile strength ranging from 690 MPa (100,000 psi) to 900 MPa (130,000 psi). The annealing process involves heating and slow cooling to reduce hardness and improve machinability. This state is often used for preliminary machining operations before final heat treatments are applied.

Upon hardening and tempering, 4140 chromoly steel can achieve a tensile strength of up to 979 MPa (142,000 psi). The hardening process heats the steel and quenches it in oil or water. Tempering then adjusts the hardness and reduces brittleness, creating a material that balances strength, toughness, and wear resistance. This makes 4140 chromoly suitable for high-stress applications such as automotive and aerospace components.

In their annealed states, 4140 chromoly generally has higher tensile strength than 416R stainless steel, making it better for applications where initial strength is crucial before further heat treatment.

Both materials can achieve high tensile strengths through heat treatment, but 416R stainless steel can reach slightly higher levels than 4140 chromoly under specific conditions. This makes 416R advantageous for applications requiring the highest possible tensile strength combined with other properties like machinability and corrosion resistance.

Choosing between 416R stainless steel and 4140 chromoly depends on the application: 416R is ideal for precision applications requiring easy machining and high tensile strength, like firearm barrels. 4140 chromoly suits high-stress environments due to its superior initial strength and hardenability, making it perfect for automotive and aerospace components.

416R stainless steel tends to be more costly because of its unique composition and the complex processes required to produce it. The higher chromium content, which enhances corrosion resistance, and the inclusion of sulfur for improved machinability contribute to the elevated cost. Additionally, proprietary production methods for achieving precise properties further increase its price.

4140 chromoly steel is more cost-effective compared to 416R stainless steel. Its simpler composition and lower production costs make it a popular choice for budget-conscious applications. The alloy’s manufacturing processes are less complex, contributing to its affordability.

In high-precision applications like rifle barrels, the higher cost of 416R stainless steel is justified by its superior machinability, allowing for the production of intricate and precise components.

In high-stress applications where strength is paramount, 4140 chromoly steel’s cost-effectiveness becomes more appealing. Its high tensile strength and toughness make it suitable for demanding environments, and the lower material costs can provide significant savings.

416R stainless steel’s natural corrosion resistance reduces the need for protective coatings, lowering long-term maintenance costs. However, under certain conditions, its barrel life may be shorter compared to chromoly steel. The reduced need for maintenance can offset the initial higher cost.

4140 chromoly steel requires additional coatings, such as QPQ Melonite, to enhance its corrosion resistance, adding to its overall cost. However, it is known for its excellent strength and durability, making it a popular choice for high-stress applications.

When deciding between 416R stainless steel and 4140 chromoly steel, consider the following factors:

416R Stainless Steel: The high chromium content provides significant corrosion resistance, ideal for environments with moisture or corrosive elements.

4140 Chromoly: Lower chromium content results in lower corrosion resistance, necessitating protective coatings for prolonged use in corrosive environments.

416R Stainless Steel: High machinability due to sulfur content, allowing for efficient machining of precision components.

4140 Chromoly: Moderate machinability, which may require specialized tools and increase machining costs.

416R Stainless Steel: Achieves high tensile strength through heat treatment, making it suitable for precision applications that need both strength and machinability.

4140 Chromoly: Offers high tensile strength even in untreated form, making it ideal for high-stress applications where maximum durability is essential.

416R Stainless Steel: Less flexible, which can crack under dynamic loads.

4140 Chromoly: More flexible and maintains better ductility at low temperatures, suitable for applications involving dynamic or impact loads.

416R Stainless Steel: Expands less with heat, which is helpful for keeping precise dimensions.

4140 Chromoly: Superior heat resistance, making it suitable for high-temperature applications and continuous fire scenarios.

416R Stainless Steel: Its higher cost is justified by superior machinability and corrosion resistance, making it ideal for precision rifle barrels and high-accuracy components.

4140 Chromoly: More cost-effective for general use, suitable for high-stress parts in firearms, automotive, and aerospace industries.

Below are answers to some frequently asked questions:

The primary differences between 416R stainless steel and 4140 chromoly lie in their composition, properties, and suitability for various applications.

416R stainless steel contains 12-14% chromium, 0.15% sulfur, and 1% molybdenum, making it highly machinable and resistant to corrosion. It achieves a hardness of HRC 26-32, which balances strength and machinability, and is ideal for precision applications like rifle barrels.

4140 chromoly, on the other hand, features 0.38-0.43% carbon, 0.75-1.00% manganese, 0.80-1.10% chromium, and 0.15-0.25% molybdenum. This composition provides high tensile strength and toughness, suitable for high-stress applications. It can achieve a hardness of HRC 28-32 with proper heat treatment but has lower inherent corrosion resistance compared to 416R.

In terms of machinability, 416R is easier to work with, making it preferable for precision manufacturing, whereas 4140 requires specialized tools. Cost-wise, 4140 chromoly is generally more cost-effective but may need additional coatings for corrosion resistance.

For high-stress applications, 4140 Chromoly Steel is generally the better choice compared to 416R Stainless Steel. This preference is due to 4140 Chromoly’s superior tensile strength, which can reach up to 142,000 psi when properly hardened and tempered. It also offers excellent fatigue resistance and durability under mechanical stress, making it suitable for components that endure significant loads and dynamic forces, such as landing gear and engine parts in aerospace applications.

While 416R Stainless Steel provides good machinability and moderate strength, it does not match the high tensile strength and durability of 4140 Chromoly. Additionally, 4140 Chromoly can maintain its properties at lower temperatures and is less prone to deformation, further cementing its suitability for high-stress environments.

In terms of corrosion resistance, 416R stainless steel and 4140 chromoly steel exhibit notable differences. 416R stainless steel, with its higher chromium content (12% to 14%), offers moderate to good inherent corrosion resistance. The chromium in 416R forms a passive oxide layer that protects against corrosion, making it suitable for environments with moisture or mildly corrosive elements.

Conversely, 4140 chromoly steel, containing about 0.80% to 1.10% chromium and molybdenum, has lower inherent corrosion resistance. However, its corrosion resistance can be significantly improved through protective coatings such as QPQ Melonite. These treatments enhance its suitability for high-stress applications where untreated chromoly might degrade.

416R stainless steel and 4140 chromoly have distinct applications in manufacturing due to their unique properties.

416R stainless steel, known for its excellent machinability and good corrosion resistance, is primarily used in precision applications. It is ideal for manufacturing rifle barrels, where high precision is crucial. Additionally, it finds use in aerospace components like bearings and gears, as well as automotive parts such as fuel injectors and valve components. Its moderate corrosion resistance makes it suitable for general environments.

On the other hand, 4140 chromoly, characterized by its superior tensile and yield strength, is suitable for high-stress applications. This material is widely used in the aerospace industry for parts like landing gear, in automotive manufacturing for components such as crankshafts and gears, and in firearms for various structural components. While it has lower inherent corrosion resistance compared to 416R, it can be enhanced with appropriate coatings.

When comparing the costs of 416R Stainless Steel and 4140 Chromoly, 416R Stainless Steel is generally more expensive. This higher cost is attributed to its specialized composition, which includes a higher chromium content that enhances its corrosion resistance and machinability. These properties make it particularly suitable for precision applications, like rifle barrels, where long-term durability and ease of manufacturing are critical.

On the other hand, 4140 Chromoly is more cost-effective due to its lower chromium content and simpler production process. However, it may require additional protective coatings to improve its corrosion resistance, potentially adding to the The choice between these materials should be based on specific application requirements, including performance needs, maintenance considerations, and budget constraints.

Yes, there are significant differences in machinability between 416R stainless steel and 4140 chromoly. 416R stainless steel is known for its high machinability, typically rated between 85% and 90%. This is primarily due to its high sulfur content, which forms manganese sulfide inclusions that act as internal lubricants, reducing tool wear and enabling faster machining speeds. This makes 416R stainless steel ideal for precision applications requiring smooth surface finishes, such as rifle barrels.

In contrast, 4140 chromoly steel has moderate machinability, generally around 70% when annealed. Its machinability is influenced by heat treatment processes, necessitating more stress-relieving steps compared to 416R stainless steel. While it is less machinable, 4140 chromoly offers better ductility and toughness at low temperatures, making it suitable for high-stress and cold weather applications.

Ultimately, the choice depends on the specific requirements of the application, with 416R stainless steel favored for high-precision machining and 4140 chromoly preferred for its versatility and strength in demanding conditions.