When it comes to crafting the perfect knife, the choice of steel can make all the difference between a blade that performs admirably and one that falls short. For knife enthusiasts and professionals alike, understanding the nuances between popular steel types such as 420HC and S35VN is crucial. But which one truly stands out for high-performance knives? In this comprehensive comparison, we will delve into the key differences in composition, hardness, edge retention, and corrosion resistance of 420HC and S35VN steel. By the end, you’ll have a clear understanding of which steel type best suits your specific needs and why. Ready to uncover the secrets behind these renowned steels? Let’s dive in.

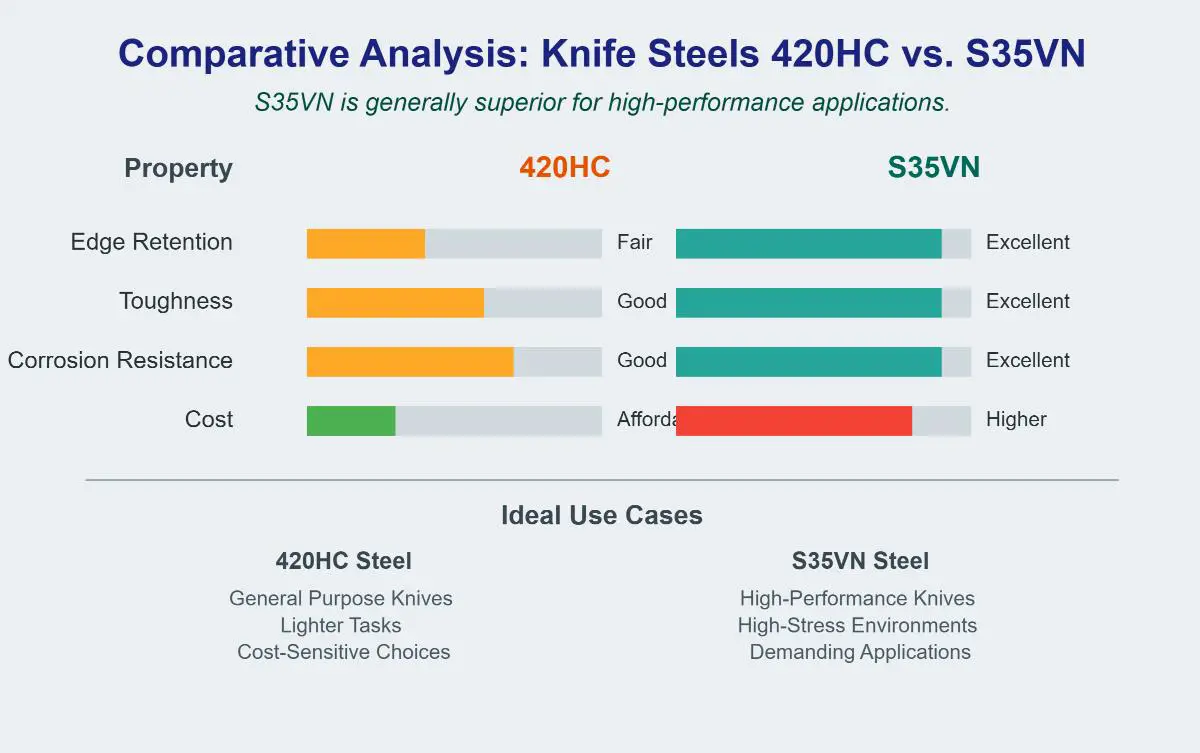

While both 420HC and S35VN steels provide good corrosion resistance, S35VN outperforms 420HC in wear resistance due to its higher hardness and additional elements like vanadium and niobium.

420HC steel is popular in the cutlery industry because it is affordable and has balanced properties. Its moderate hardness and ease of sharpening make it suitable for a variety of knives, such as everyday carry (EDC) knives, hunting knives, and kitchen knives.

420HC steel is tough and resists corrosion, making it ideal for tactical tools. These applications benefit from the steel’s ability to maintain performance under different environmental conditions. It is frequently used in multi-tools and survival knives, which require a balance of toughness and ease of sharpening. It is also often found in rescue tools that demand reliable performance in emergencies.

Many well-known knife manufacturers use 420HC steel, such as Buck Knives and Gerber Gear. Buck Knives are known for their classic hunting and outdoor knives that offer reliable performance and easy maintenance. Gerber Gear utilizes 420HC in various multi-tools and EDC knives, providing a balance of affordability and functionality.

S35VN steel is preferred for high-performance applications because it retains its edge well and is very durable. Its composition makes it ideal for demanding tasks, such as tactical knives for military and law enforcement personnel, and bushcraft knives used in rigorous outdoor activities.

The high-quality properties of S35VN steel make it a popular choice for premium and custom knife makers. Its excellent edge retention and corrosion resistance enhance the Several high-end knife brands utilize S35VN steel to deliver superior performance. Chris Reeve Knives is renowned for their use of S35VN in models like the Sebenza, known for its exceptional edge retention and craftsmanship. Spyderco incorporates S35VN in various models, offering a combination of cutting-edge technology and high-performance materials.

420HC steel is more affordable due to simpler composition and manufacturing, while S35VN is pricier because of advanced techniques. This makes 420HC an attractive option for budget-conscious consumers needing reliable performance, whereas S35VN appeals to those seeking premium quality.

420HC’s 52-55 HRC is lower than S35VN’s 58-62 HRC, which affects their edge retention differently. This difference means that S35VN retains its edge longer under rigorous use.

420HC provides decent edge retention but may require more frequent sharpening with heavy use. S35VN, known for excellent edge retention, maintains a sharp edge significantly longer, reducing the need for frequent maintenance.

Both 420HC and S35VN offer good corrosion resistance, with S35VN having an edge in harsh environments due to added elements like niobium and vanadium.

420HC offers good toughness and is less prone to chipping under normal use. However, it is generally less durable than S35VN under heavy use. S35VN is known for its high toughness, with elements like niobium enhancing its resistance to chipping and cracking, making it more durable for demanding tasks.

420HC is a breeze to sharpen because of its lower hardness, making it practical for frequent maintenance. S35VN, though tougher to sharpen, needs it less often due to superior edge retention.

420HC is great for entry-level and general tasks, while S35VN shines in high-end and performance-demanding applications. This makes 420HC suitable for everyday carry knives and multi-tools, and S35VN ideal for premium and custom knives, tactical equipment, and high-performance cutting tools.

People know 420HC steel for its ease of sharpening. This is largely due to its lower hardness level of 52-55 HRC. It is an excellent choice for users who prefer a blade that can be quickly and easily restored to sharpness.

Standard sharpening tools, such as whetstones, ceramic rods, and sharpening steels, work effectively with 420HC steel. These tools are widely available and easy to use, making the maintenance process straightforward.

Due to its moderate edge retention, 420HC steel requires more frequent sharpening compared to harder steels. Regular honing can help maintain the edge between sharpening sessions, ensuring consistent performance.

S35VN steel, with its higher hardness range of 58-62 HRC, presents more of a challenge when sharpening. The presence of vanadium and niobium carbides enhances its hardness and wear resistance, but also makes it less responsive to standard sharpening tools.

For sharpening S35VN steel, high-quality sharpening stones or diamond sharpeners are recommended. These tools are designed to handle harder steels, ensuring that the blade can be sharpened effectively. Diamond plates or water stones with a high grit rating (1000 and above) are particularly useful for achieving a fine edge.

Despite the difficulty in sharpening, S35VN steel’s superior edge retention means it requires less frequent maintenance. This makes it ideal for users who prefer a blade that stays sharp for longer periods, reducing the need for regular sharpening.

Regular cleaning is essential for both 420HC and S35VN steel knives to prevent residue buildup and maintain their corrosion resistance. After each use, wash the blade with warm water and mild detergent, then dry thoroughly to avoid moisture retention.

Proper storage is crucial to prevent damage and maintain the integrity of the blade. Store knives in a dry environment, preferably in a knife block or sheath, to protect the edge from accidental nicks and corrosion.

Occasionally applying a rust-inhibiting oil to the blade can help protect against corrosion, especially if the knife is used in humid or wet conditions. This practice is beneficial for both 420HC and S35VN steel knives, ensuring long-term durability.

To maintain sharpness, use 420HC steel knives regularly. Frequent use helps keep the edge aligned and minimizes the need for extensive sharpening sessions.

Avoid cutting through abrasive materials, such as cardboard or hard plastics, which can accelerate edge wear. This is particularly important for 420HC steel due to its moderate edge retention.

Although S35VN steel requires less frequent sharpening, it is important to use the right techniques and tools when maintenance is needed. High-quality sharpening stones or diamond sharpeners are recommended for achieving the best results.

While S35VN steel is highly durable and suitable for heavy-duty tasks, it should still be handled with care to avoid unnecessary stress. Avoid using the knife for prying or cutting through extremely hard materials, which can compromise the blade’s integrity.

Below are answers to some frequently asked questions:

For high-performance knives, S35VN steel is generally considered superior to 420HC steel. S35VN offers significantly better edge retention, toughness, and On the other hand, 420HC steel, while being more affordable and providing good corrosion resistance, does not match the performance of S35VN in high-stress environments. It is more suitable for general-purpose knives where the cost is a significant factor, and the knife will be used for lighter tasks.

The key differences in composition and properties between 420HC and S35VN steel significantly influence their performance in knife blades.

Composition: 420HC steel contains 0.45-0.54% carbon, 13% chromium, and small amounts of manganese, silicon, nickel, and molybdenum, which contribute to its moderate hardness and good corrosion resistance. S35VN steel, a premium-grade tool steel, has a higher carbon content of 1.4% and 14% chromium, with notable additions of vanadium (3%), molybdenum (2%), niobium (0.5%), and cobalt (0.5%). These elements enhance its hardness, edge retention, and wear resistance.

Properties: S35VN has a higher Rockwell hardness (58-62 HRC) compared to 420HC (40-55 HRC), leading to superior edge retention and durability. Both steels offer excellent corrosion resistance due to their chromium content, but S35VN’s niobium addition provides a slight advantage in harsh environments. S35VN is also tougher and more wear-resistant than 420HC, making it less prone to chipping and cracking.

Cost and Applications: 420HC is more cost-effective and suitable for budget-friendly applications, while S35VN, being more expensive, is preferred for high-end knives and tactical equipment where superior performance is required.

To maintain a 420HC steel knife blade, follow these steps to ensure its longevity and optimal performance. Firstly, clean the blade after each use with regular dish soap and hot water, then dry it thoroughly by hand to prevent rust. Avoid using dishwashers as they can damage the knife.

Sharpening 420HC steel is relatively easy compared to harder steels. Use standard sharpening tools like Arkansas whetstones or ceramic rods for best results. Regular touch-ups are necessary to maintain the edge, as 420HC requires more frequent sharpening due to its moderate hardness.

For storage, keep the knife in a dry environment and apply a light layer of oil to the blade to protect against corrosion. This is particularly important since 420HC, while offering good corrosion resistance, benefits from additional protection in high-moisture conditions.

By adhering to these maintenance practices, you can keep your 420HC steel knife in excellent condition, ensuring it remains a reliable tool for everyday use.

Yes, S35VN steel is worth the extra cost for a knife blade. This premium steel, composed of 1.4% carbon, 3% vanadium, 0.5% niobium, 2% molybdenum, and 14% chromium, offers superior properties that justify its higher price. S35VN steel provides exceptional edge retention with a Rockwell hardness of 58-62 HRC, meaning it stays sharp longer and requires less frequent sharpening compared to 420HC steel. Its high toughness and fracture resistance make it ideal for demanding applications, ensuring durability and minimizing the risk of chipping and cracking. Additionally, the high chromium content contributes to excellent corrosion resistance, making it suitable for various environments, including outdoor and kitchen use. For users prioritizing long-term performance, durability, and minimal maintenance, investing in S35VN steel is a wise choice. Conversely, for budget-conscious consumers or those needing a knife for casual use, 420HC steel remains a cost-effective and adequate option.

Both 420HC and S35VN steels offer unique advantages in knife performance, making them popular choices for various applications.

420HC steel is widely appreciated for its ease of sharpening and maintenance. It is an economical choice, often used in mass-produced knives, providing a good balance of hardness, toughness, and corrosion resistance suitable for general-purpose tasks. A notable example of 420HC steel performance is the Buck 110 Folding Hunter, which is reliable for everyday use and general cutting tasks.

On the other hand, S35VN steel is favored for high-performance knives due to its superior edge retention, toughness, and corrosion resistance. Its advanced composition, including vanadium and niobium, enhances its wear resistance, making it more durable under heavy use. The Benchmade Griptilian is a prime example of a knife that utilizes S35VN steel, demonstrating its capability to maintain a sharp edge in demanding environments.

Sharpening S35VN steel requires specific techniques due to its high hardness and superior edge retention properties. Here are some practical tips:

By following these steps, you can effectively maintain the sharpness and performance of your S35VN steel knife.