Imagine a steel that combines exceptional strength, toughness, and versatility, all while being able to withstand intense heat treatments—welcome to the world of 42CrMo4 steel. This comprehensive technical guide delves into the intricate details of 42CrMo4 steel, exploring its unique chemical composition, mechanical properties, and the advanced heat treatment processes that enhance its performance. Whether you’re curious about its widespread applications in industries such as automotive, aerospace, and machinery manufacturing, or you’re interested in the comparative advantages it offers over other alloy steels, this article provides a thorough technical deep dive tailored for intermediate-level enthusiasts and professionals. Ready to uncover the secrets of one of the most resilient and adaptable steels in modern engineering? Let’s dive in and discover what makes 42CrMo4 steel a cornerstone of industrial innovation.

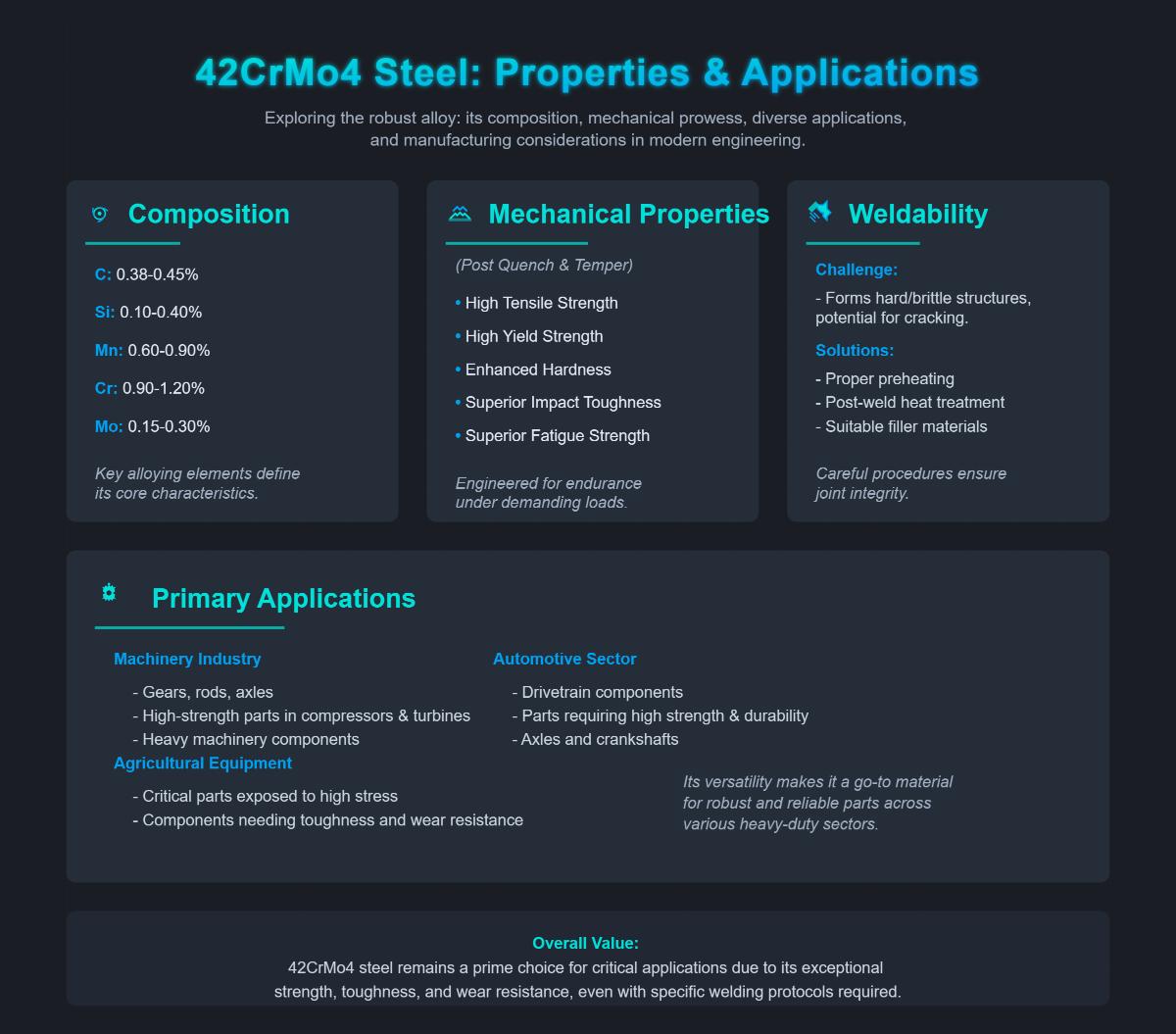

The key elements include Carbon (0.38-0.45%), Silicon (0.17-0.37%), Manganese (0.50-0.80%), Chromium (0.90-1.20%), and Molybdenum (0.15-0.25%). Phosphorus and Sulfur are kept below 0.030%.

42CrMo4 steel exhibits impressive mechanical properties:

42CrMo4 steel is used in a wide range of industries:

42CrMo4 steel has variants like M-treated and BQ-Steel, which offer better machinability and fatigue strength. It is equivalent to international standards such as AISI 4140, 42CD4, and 1.7225, ensuring consistent quality and performance worldwide.

Developed in the early 20th century, 42CrMo4 steel quickly gained importance due to its impressive properties. Early applications primarily involved machinery components, where the steel’s high strength and toughness were crucial. Its ability to withstand mechanical stress and fatigue made it a preferred choice in automotive and aerospace industries.

Advancements in metallurgy and heat treatment techniques have significantly enhanced the quality and performance of 42CrMo4 steel. Innovations like vacuum degassing and precise control over chemical composition increased the steel’s purity and consistency, reducing impurities like sulfur and phosphorus and improving its strength and durability. Traditional methods like quenching and tempering were initially used to enhance its properties. However, more refined techniques such as induction hardening and controlled tempering have since been introduced, allowing for precise adjustments to the steel’s characteristics and tailoring it for specific applications requiring surface hardness and core toughness.

The technical specifications of 42CrMo4 have continually been refined to meet evolving industry standards. Improvements in chemical composition control have led to enhanced mechanical properties, such as tensile and yield strength. The steel’s high hardenability through various heat treatment processes has expanded its use in demanding applications, including heavy-duty gears and high-stress mechanical components.

42CrMo4 steel’s versatility has led to its adoption in many industries. Its initial use in machinery components paved the way for broader applications in aerospace, automotive, and industrial machinery sectors. The steel’s high fatigue strength and wear resistance make it ideal for manufacturing components subjected to high stress and repetitive loads, such as gears, shafts, and crankshafts.

Recent manufacturing advancements have created new variants of 42CrMo4, like M-Steel and BQ-Steel. These variants offer improved machinability and cleanliness, reducing wear on machining tools and enhancing the steel’s fatigue strength. These developments streamline manufacturing processes and expand the material’s application range, making it even more valuable in modern engineering and industrial contexts.

The ongoing evolution of 42CrMo4 steel reflects the dynamic nature of material science and engineering. As new manufacturing techniques and metallurgical advancements emerge, the steel continues to adapt, meeting increasingly complex demands of modern engineering applications. This continual refinement ensures that 42CrMo4 remains a cornerstone material in various industries, providing reliable performance and durability in critical applications.

The chemical composition of 42CrMo4 steel is meticulously balanced to provide its unique mechanical properties and high performance in various applications. The proportions of alloying elements play a crucial role in determining the steel’s characteristics.

42CrMo4 steel is renowned for its impressive mechanical properties, which are enhanced through various heat treatment processes. These properties make it suitable for high-stress applications in demanding industries.

The tensile strength of 42CrMo4 steel ranges from 900 to 1100 MPa when quenched and tempered. This high tensile strength allows the steel to withstand significant forces without breaking or deforming, making it ideal for manufacturing components like gears and shafts.

Yield strength, which is the stress at which the steel begins to deform plastically, is typically between 650 and 930 MPa for 42CrMo4 steel. This high yield strength ensures the material can endure substantial loads while maintaining its structural integrity.

Elongation measures the steel’s ability to stretch before breaking, indicating its ductility. 42CrMo4 steel generally exhibits an elongation of more than 12%, which allows it to absorb impacts and stresses without fracturing, enhancing its suitability for dynamic applications.

Hardness is a measure of the steel’s resistance to deformation and wear. In the quenched and tempered state, 42CrMo4 steel typically has a hardness between 270 and 320 HB (Brinell Hardness). After induction hardening, the surface hardness can exceed 53 HRC (Rockwell Hardness), providing exceptional wear resistance for components subjected to high abrasion.

Impact toughness indicates the steel’s ability to absorb energy during sudden impacts. 42CrMo4 steel demonstrates an impact toughness of over 35 Joules at room temperature, ensuring that it can withstand shocks and dynamic loads without failing, making it suitable for critical mechanical components.

The mechanical properties of 42CrMo4 steel are significantly influenced by heat treatment processes such as quenching and tempering. These treatments alter the steel’s microstructure, enhancing its strength, hardness, and toughness.

Quenching involves heating the steel to high temperatures (typically between 840-880°C) and then rapidly cooling it in oil or water. This process transforms the steel’s microstructure to martensite, increasing its hardness and strength.

Tempering follows quenching and involves reheating the steel to lower temperatures (540-680°C) and then cooling it slowly. This process reduces brittleness and enhances toughness, providing a balanced combination of strength and ductility.

Induction hardening is used to increase the surface hardness of 42CrMo4 steel. This process involves heating the steel’s surface using electromagnetic induction and then rapidly cooling it. Induction hardening achieves a surface hardness of at least 53 HRC, making the steel highly resistant to wear and ideal for components like gears and axles.

Heat treatment is a critical process for enhancing the mechanical properties of 42CrMo4 steel, including its strength, hardness, and toughness. Through various heat treatment techniques, the steel’s microstructure can be modified to achieve specific performance characteristics suitable for demanding applications.

Quenching involves heating 42CrMo4 steel to a high temperature, typically between 840°C and 880°C, and then rapidly cooling it in oil or water. This rapid cooling transforms the steel’s microstructure to martensite, a hard and brittle phase that significantly increases its hardness and tensile strength.

Following quenching, tempering is performed to reduce brittleness and enhance toughness. The steel is reheated to a lower temperature range, typically between 540°C and 680°C, and then cooled slowly, altering the martensite structure to balance hardness with improved ductility and impact resistance.

Normalizing involves heating the steel to about 913°C and then letting it cool in the air. This refines the grain structure, relieves internal stresses, and improves mechanical properties.

Annealing is a heat treatment process used to soften 42CrMo4 steel for machining and to reduce hardness. The steel is heated to a temperature range of 680°C to 720°C and then slowly cooled to 600°C. This process makes the steel softer and easier to machine, while also reducing residual stresses.

Stress relief annealing is performed to relieve internal stresses that may have developed during machining or welding. The steel is heated to a temperature range of 450°C to 650°C and then air-cooled. This process helps prevent deformation and cracking during subsequent processing.

Induction hardening uses electromagnetic induction to heat the surface of the steel, which is then rapidly cooled to increase surface hardness while keeping the core tough. This method enhances the surface hardness while maintaining core toughness, making it ideal for components subjected to high wear.

The choice of heat treatment for 42CrMo4 steel depends on the intended application and desired properties. Components requiring high strength and toughness, such as gears, shafts, and crankshafts, often undergo quenching and tempering. Surface-hardening techniques like induction hardening are used for parts needing enhanced wear resistance, such as axles and bearings.

Understanding the specific heat treatment processes and their effects on 42CrMo4 steel’s properties is essential for optimizing its performance in various industrial applications.

Electric arc furnace (EAF) smelting is an efficient method for producing small batches of 42CrMo4 steel by melting scrap steel with high-power electric arcs. Secondary refining and vacuum degassing are employed to remove impurities and ensure a high-quality steel composition. The presence of scrap steel significantly influences the final chemical composition of the molten steel.

For large-scale production, converter steelmaking followed by continuous casting is preferred. This method yields higher purity molten steel by lowering energy use and speeding up the smelting process. Continuous casting ensures uniformity and consistency in the final steel product, making it ideal for mass production.

42CrMo4 steel is typically forged at temperatures ranging from 900°C to 1100°C. The hot forging process involves shaping the steel by applying compressive forces, often producing complex shapes. After forging, the steel is slowly cooled in still air or sand to prevent the formation of undesirable microstructures.

Normalizing involves heating the steel to 850°C to 880°C, then cooling it in air. This refines the grain structure, improves mechanical properties, and relieves internal stresses.

Soft annealing involves heating the steel to 680°C to 720°C and then cooling it slowly in a furnace. This treatment reduces hardness, making the steel easier to machine and enhancing its ductility.

Stress relief annealing is conducted at 450°C to 650°C and then cooled in air. This process alleviates internal stresses that may have developed during previous manufacturing steps, reducing the risk of deformation and cracking.

To harden the steel, it is heated to 820°C to 880°C and then quenched in oil or water. Tempering at 540°C to 680°C follows, enhancing toughness while maintaining strength.

42CrMo4 steel exhibits good machinability in the annealed condition, allowing for precise and efficient machining operations. However, machining becomes challenging in the hardened state due to increased hardness and reduced ductility. Techniques such as M-Steel treatment can be applied to control non-metallic inclusions, improving machinability and reducing tool wear.

Induction hardening is a surface hardening technique that uses electromagnetic induction to heat the steel’s surface, followed by rapid cooling. This method achieves a surface hardness exceeding 53 HRC, significantly enhancing wear resistance.

Nitriding is another surface hardening process that introduces nitrogen into the steel’s surface, creating a hard, wear-resistant layer. This treatment can achieve a surface hardness of up to 700 HV, making it suitable for components exposed to high wear conditions.

Machining 42CrMo4 steel demands careful handling due to its high strength and toughness. The machining processes involve techniques that can manage the material’s hardness while maintaining precision and efficiency.

Turning operations for 42CrMo4 steel involve optimizing parameters such as cutting speed, feed rate, and depth of cut. Advanced tool inserts, such as Cubic Boron Nitride (CBN) and Poly-crystalline Diamond (PCD), enhance wear resistance and improve the material removal rate (MRR), while flood cooling, preferred over dry machining, effectively dissipates heat, thus increasing MRR and prolonging tool life.

High-feed milling (HFM) effectively machines 42CrMo4 steel using face cutters with small angles, typically between 10° and 20°. The small entering angle directs most of the cutting force axially, leveraging the tool’s stiffness to handle high loads and allowing for high feed rates. This method improves efficiency despite limitations in axial depth of cut.

Surface treatments for 42CrMo4 steel are crucial for enhancing its wear resistance, corrosion resistance, and overall mechanical properties. Common surface treatments include carburizing, nitriding, and induction hardening.

Heat treatments like quenching and tempering improve 42CrMo4 steel’s mechanical properties. Quenching rapidly cools heated steel to harden it, while tempering reheats it to balance hardness and toughness. Induction hardening and nitriding are additional surface hardening techniques used to further enhance wear resistance.

Shot blasting is a surface treatment process that improves surface roughness and helps prevent corrosion by removing surface imperfections. This treatment is particularly useful for components exposed to harsh environmental conditions, ensuring better performance and longevity.

42CrMo4 steel has poor weldability due to its high carbon content. To minimize the risk of cracking, preheating and post-weld heat treatment are necessary. These steps help reduce residual stresses and improve the microstructure of the welded joint.

Although 42CrMo4 steel has some corrosion resistance from its chromium content, extra surface treatments might be needed for certain environments. Methods like nitriding and shot blasting offer additional protection against corrosion.

Advancements in machining techniques, such as high-feed milling and innovative hard machining approaches with flood cooling, continue to improve efficiency and material removal rates for 42CrMo4 steel. Ongoing research into new tool materials and optimization of machining parameters will further enhance the manufacturing process, making it more efficient and cost-effective.

42CrMo4 steel is widely used in the automotive industry due to its high strength, toughness, and wear resistance. Its high strength, toughness, and wear resistance make it ideal for manufacturing components that endure heavy loads and dynamic forces. Key applications in this sector include:

In the aerospace sector, 42CrMo4 steel’s combination of lightweight and high strength is essential for performance under extreme conditions. Applications include:

The construction industry benefits from 42CrMo4 steel’s excellent strength-to-weight ratio, which ensures structural integrity while bearing significant loads. Typical applications include:

42CrMo4 steel is crucial in the oil and gas industry, where components must resist harsh environments and wear. Applications include:

The heavy machinery and manufacturing industries rely on 42CrMo4 steel for components that handle heavy loads and resist wear. Key applications include:

Recent advancements have expanded the use of 42CrMo4 steel in heavy-duty gear manufacturing. Its balance of strength and toughness makes it suitable for large modulus gears, offering a cost-effective solution compared to other materials like 40CrNiMo. Innovations in heat treatment processes, such as precise control of quenching and tempering, have further enhanced the steel’s performance in demanding applications.

42CrMo4 is a high-strength alloy steel, favored for its outstanding mechanical properties in challenging applications. To understand its relative advantages and limitations, it is essential to compare it with other commonly used alloy steels, such as AISI 4140, 42CrMo, and 40CrNiMo.

AISI 4140 is widely used in applications requiring a good balance of toughness, strength, and wear resistance. It is commonly utilized in the manufacturing of crankshafts, gears, and fasteners. AISI 4140 offers slightly lower tensile and yield strengths but greater elongation, providing better ductility and formability.

42CrMo steel is often used in heavy-duty applications similar to 42CrMo4, such as in the production of high-stress mechanical parts, including gears, shafts, and axles. Though 42CrMo4 and 42CrMo have similar compositions, 42CrMo4’s higher tensile and yield strengths make it better for high-strength applications.

40CrNiMo steel is used in high-strength applications such as large modulus gears, heavy-duty shafts, and high-stress machinery components. While 40CrNiMo has similar tensile strength and hardness to 42CrMo4, 42CrMo4’s unique chromium and molybdenum balance enhances wear resistance and toughness, ideal for high-wear and dynamic applications.

42CrMo4 stands out among alloy steels like AISI 4140, 42CrMo, and 40CrNiMo for its superior tensile and yield strengths, essential for high-stress uses. Its enhanced mechanical properties and wear resistance make it the preferred choice for demanding applications in automotive, aerospace, and heavy machinery industries. Additionally, the specific alloying elements in 42CrMo4 provide an optimal balance of strength, toughness, and machinability, ensuring its continued relevance in modern engineering applications.

Improved heat treatment and machining processes have made the production of 42CrMo4 steel components much more efficient. These advancements not only improve the steel’s mechanical properties but also reduce energy consumption, contributing to both cost savings and environmental sustainability. By optimizing the heat treatment process, manufacturers can achieve desired hardness and strength levels more quickly and with less energy input. Enhanced machining techniques also allow for more precise and faster production, reducing waste and the need for rework.

Enhanced machinability of 42CrMo4 steel, due to its uniform hardness and microstructural stability, results in reduced tool wear and material waste during manufacturing. Techniques like M-Steel treatment, which controls non-metallic inclusions, further improve machinability, leading to more efficient material usage and less scrap production. This reduction in waste lowers production costs and minimizes the environmental impact of manufacturing processes.

Although steel production impacts the environment, using 42CrMo4 steel for critical components can result in lighter constructions. This reduction in weight can lead to several benefits, including improved fuel efficiency in automotive and aerospace applications, reduced material usage, and lower transportation costs.

Recycling 42CrMo4 steel is crucial for sustainability, as it reduces the need for new raw materials and minimizes waste. Steel is inherently recyclable, and 42CrMo4 is no exception. Recycled steel retains the same properties as newly produced steel, ensuring that 42CrMo4 can be reused in various applications without compromising performance.

The development of advanced machining tools, such as solid carbide drills, has enhanced the machining efficiency of 42CrMo4 steel. These high-performance tools increase tool life and reduce production costs by improving the precision and speed of machining operations. Additionally, process optimization techniques, such as composite heat treatment (e.g., carburizing followed by quenching and tempering), improve the surface hardness and wear resistance of 42CrMo4 components, extending their lifespan and reducing maintenance needs.

M-Steel treatment is one approach that improves the machinability of 42CrMo4 steel by controlling non-metallic inclusions. This treatment not only enhances manufacturing efficiency but also reduces tool wear, further lowering production costs. Additionally, BQ-Steel variants, which have restricted impurities, improve fatigue strength, making them ideal for applications requiring high durability and reliability.

Although 42CrMo4 steel has excellent mechanical properties, its poor weldability can cause cracking during welding. This poses a significant challenge in applications requiring structural integrity post-welding. Research into novel heat treatment methods or alloy modifications could improve weldability while maintaining the steel’s strength and toughness.

The continued use of 42CrMo4 steel in high-performance gears, including those for wind turbines and mining machinery, underscores its versatility and adaptability to high-stress environments. As industries evolve, the development of new applications and improved production techniques will ensure that 42CrMo4 steel remains a valuable material in various engineering and manufacturing contexts.

Below are answers to some frequently asked questions:

42CrMo4 steel is an alloy steel known for its excellent combination of strength and toughness, making it highly suitable for engineering applications. The steel’s chemical composition includes carbon (0.38-0.45%), silicon (0.10-0.40%), manganese (0.60-0.90%), chromium (0.90-1.20%), and molybdenum (0.15-0.30%), which contribute to its robust mechanical properties. When subjected to quenching and tempering processes, 42CrMo4 achieves high tensile and yield strength, enhanced hardness, and superior impact toughness and fatigue strength.

The primary applications of 42CrMo4 steel are in the machinery and automotive industries. It is commonly used for manufacturing gears, rods, and axles due to its mechanical properties and hardness. In compressors and turbines, it is utilized for high-strength parts, and in the automotive sector, it is employed for components requiring high strength and durability. Additionally, 42CrMo4 is ideal for heavy machinery and agricultural equipment parts, where its strength and toughness are crucial.

Despite its advantageous properties, 42CrMo4 steel presents challenges in weldability, as it tends to form hard and brittle structures during welding, leading to potential cracking. Nonetheless, its high strength, toughness, and wear resistance make it a popular choice for critical components in the automotive and machinery industries. Proper preheating, post-weld heat treatment, and the use of suitable filler materials can mitigate some of the welding issues, ensuring the integrity and performance of the welded joints.

Heat treatment is crucial in enhancing the properties of 42CrMo4 steel, a versatile alloy widely used in engineering applications. The primary heat treatment processes include quenching, tempering, normalizing, soft annealing, stress relieving, and induction hardening.

Quenching involves heating the steel to 820-860°C and then rapidly cooling it in oil, transforming its microstructure into martensite to increase hardness. Tempering follows quenching, typically at 540-680°C, to relieve stresses and adjust hardness, enhancing toughness. Normalizing at 840-880°C with air cooling refines the grain structure for uniform mechanical properties and better machinability. Soft annealing at 680-720°C reduces hardness for easier machining. Stress relieving at 450-650°C reduces residual stresses from previous processing, maintaining dimensional stability. Induction hardening heats the surface rapidly using electromagnetic induction followed by quenching, resulting in a hard surface layer with a tougher core.

These heat treatments optimize 42CrMo4 steel’s balance between hardness, strength, and toughness, making it ideal for high-stress applications.

42CrMo4 steel, known for its high strength, toughness, and wear resistance, is widely used in various industries. In the automotive industry, it is commonly used for gears, axles, crankshafts, and shafts due to its ability to withstand heavy loads and dynamic stresses. In aerospace, it is employed in landing gear, engine mounts, and structural components, where its strength and lightweight properties enhance aircraft performance. The construction industry utilizes 42CrMo4 steel for beams, supports, and other structural elements, benefiting from its excellent strength-to-weight ratio. In the oil and gas industry, it is used in drill pipes, valves, and fittings, offering wear and corrosion resistance essential in harsh environments. Additionally, heavy machinery components like excavator arms and hydraulic cylinders leverage its durability and performance under heavy loads. These applications highlight the versatility and reliability of 42CrMo4 steel across multiple sectors.

To achieve optimal machining results for 42CrMo4 steel, several best practices should be followed. This steel, known for its excellent machinability, can benefit from various machining methods such as turning, milling, drilling, cutting, polishing, and boring. Ensuring the material is properly annealed before machining is crucial, as this enhances its machinability by providing uniform hardness and microstructural stability.

Selecting high-quality cutting tools designed for alloys with similar properties to 42CrMo4 is essential. Tool coatings and geometries tailored to reduce wear can significantly improve performance. Regular inspection and maintenance of tools are necessary to prevent premature wear and maintain consistent results.

Optimizing machining parameters, including cutting speed, feed rate, and depth of cut, is important. Experimenting with these parameters can help minimize tool wear and improve surface finish. Additionally, monitoring the machining process closely, potentially with real-time systems, allows for adjustments to maintain optimal conditions.

Surface treatment techniques, such as M-Steel treatment, can enhance chip control and further reduce tool wear. Considering the impact of heat treatment on the material’s properties during and after machining ensures the retention or enhancement of desired mechanical characteristics. By integrating these practices, manufacturers can achieve high-quality finished products efficiently and cost-effectively.

42CrMo4 steel is a versatile alloy steel known for its high strength, toughness, and wear resistance. To enhance its surface properties, several surface treatment techniques are recommended.

Nitriding is a common method that involves heating the steel in a nitrogen-rich environment, creating a hard, wear-resistant layer with surface hardness levels between 550 to 700 HV. Flame hardening uses a flame to heat the surface, followed by rapid cooling, achieving a minimum surface hardness of 53 HRC. Induction hardening employs electromagnetic induction for rapid heating and cooling, resulting in a surface hardness of 50-55 HRC. Laser surface hardening and melting provide precise control over the treated area, creating a martensitic layer that enhances wear resistance without significantly altering the bulk properties.

Selecting the appropriate surface treatment depends on application requirements, material properties, cost, and precision needs. These treatments optimize 42CrMo4 steel for high-performance applications in automotive, aerospace, and mechanical engineering industries.

42CrMo4 steel is renowned for its impressive performance characteristics, especially when compared to other alloy steels. This medium-carbon alloy steel, containing chromium and molybdenum, provides excellent hardenability and strength, making it suitable for demanding applications.

In terms of mechanical properties, 42CrMo4 offers a tensile strength ranging from 900 to 1200 MPa, which is comparable to or superior to many other alloy steels, such as AISI 4140. Its yield strength exceeds 770 MPa, indicating its high load-bearing capacity, making it ideal for components like axles and crankshafts. Additionally, 42CrMo4 demonstrates good impact toughness with energy absorption values exceeding 35 J, surpassing many lower alloy steels.

Heat treatment processes, including quenching and tempering, enhance 42CrMo4’s performance. Quenching achieves surface hardness levels of 54-59 HRC, providing resistance to abrasive wear. Tempering refines the microstructure, balancing strength and toughness, an advantage over traditional steels like 35HM.

Overall, 42CrMo4’s combination of strength, toughness, and machinability positions it favorably against alternatives such as AISI 4140 and other medium-carbon steels, making it a preferred choice in industries requiring high-performance materials.