Imagine a material that offers both strength and flexibility, making it ideal for a wide range of applications. Malleable steel is precisely that, boasting impressive advantages such as corrosion resistance, excellent machinability, and remarkable versatility. However, like any material, it comes with its own set of limitations—low yield strength, susceptibility to wear, and welding challenges, to name a few. This comprehensive guide delves into the intricacies of malleable steel, exploring its benefits, drawbacks, and how it measures up against malleable iron and cast iron. Whether you’re a seasoned professional or just looking to expand your knowledge, this article provides valuable insights into the world of malleable steel. How can understanding these details impact your choice of materials for various applications? Dive in to find out!

Malleable steel is a type of steel known for its exceptional ability to be shaped and bent without breaking. Its composition includes iron, carbon, and small amounts of elements like manganese, silicon, and chromium, which enhance its mechanical properties.

The development of malleable steel dates back to the early 19th century when metallurgists sought to create a material that combined the strength of cast iron with the flexibility of wrought iron. The breakthrough came when metallurgists invented the process of heat-treating white cast iron to produce a more ductile material. This process was refined over the years, leading to the creation of malleable steel with superior properties.

One pivotal moment in the history of malleable steel was the introduction of the annealing process. Annealing involves heating the steel and slowly cooling it, which reduces internal stresses, refines its structure, and improves its flexibility. As a result, malleable steel became a preferred choice for manufacturing components requiring intricate shapes and superior mechanical properties.

Malleable steel is characterized by several key properties that make it a versatile material for various applications:

Due to its unique properties, malleable steel is used in a wide range of industries and applications. Some common uses include:

Malleable steel’s combination of high tensile strength, ductility, and ease of processing makes it an indispensable material in modern manufacturing and construction. Its development marked a significant advancement in metallurgy, providing a material that could be both strong and flexible, meeting the demands of various industrial applications.

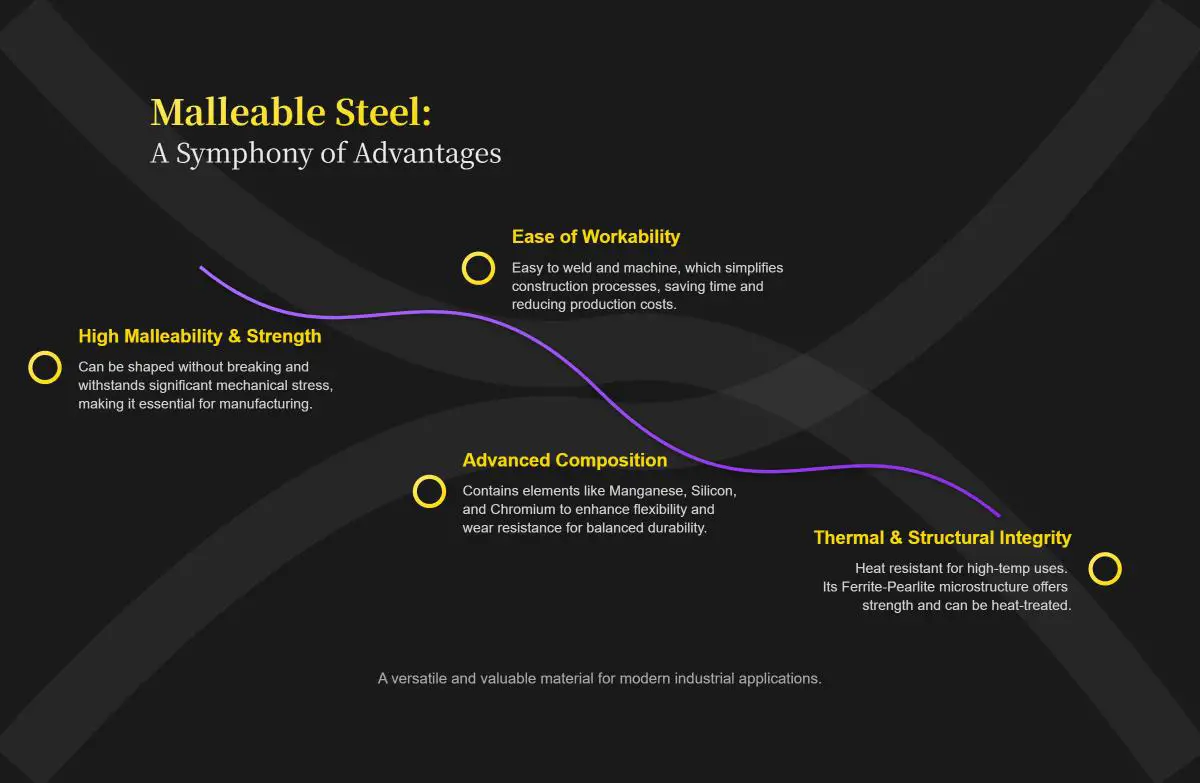

Malleable steel is known for its high malleability and ductility, crucial properties in metalworking and manufacturing. The ability of malleable steel to deform significantly without breaking makes it ideal for applications requiring intricate shapes and designs, allowing it to be formed into thin sheets or drawn into wires for various industrial processes.

One of the primary advantages of malleable steel is its excellent tensile strength. This material can withstand substantial mechanical stress and stretching without breaking, ensuring structural integrity in demanding applications. Its high tensile strength makes it suitable for components that need to endure heavy loads, such as structural elements in construction and machinery parts.

Malleable steel’s ease of welding and machining is another significant advantage. The material can be efficiently welded and shaped, reducing production time and costs. This characteristic is particularly beneficial in construction and manufacturing, where the ability to join and shape components quickly and effectively is crucial. The machinability of malleable steel ensures that it can be precisely cut and shaped to meet specific requirements.

The chemical composition of malleable steel typically includes low to medium carbon content and elements like manganese, silicon, and chromium. These components enhance its flexibility and wear resistance, contributing to the material’s overall strength and durability. This balanced composition allows malleable steel to perform well in various environments and conditions.

Malleable steel exhibits high-temperature resistance and excellent heat conductivity, making it suitable for applications involving heat exposure. Its ability to retain strength at high temperatures is crucial for automotive parts, industrial machinery, and heat exchangers, while excellent heat conductivity ensures efficient thermal management in these environments.

The microstructure of malleable steel, consisting of a mixture of ferrite and pearlite, provides both strength and flexibility. This combination results in a material that can bear significant loads while maintaining its form and function. Heat treatment processes can further refine this microstructure, enhancing the mechanical properties and load-bearing capacity of malleable steel. This flexibility and strength make malleable steel a preferred choice for a wide range of demanding applications.

Malleable steel’s lower yield strength compared to other steel types is a significant drawback. This characteristic limits its ability to withstand deformation under stress before it begins to deform plastically, making it unsuitable for applications requiring high tensile strength and durability, such as heavy machinery parts or structural components.

Malleable steel is softer than high-carbon steels and tool steels, affecting its hardness and wear resistance. The material is more prone to wear and tear, particularly in applications involving continuous motion or abrasive conditions. Additionally, while malleable steel offers some degree of corrosion resistance, it falls short when compared to stainless steel or galvanized steel. Exposure to moisture, saltwater, or harsh chemicals can cause rust and corrosion, leading to degradation over time. These limitations necessitate frequent maintenance or protective coatings, restricting its use in environments demanding high wear and corrosion resistance, such as marine or chemically aggressive settings.

Malleable steel’s performance can be significantly affected by temperature extremes. At high temperatures, the material can become brittle and lose its strength, making it susceptible to cracking or failure. This characteristic limits its use in environments requiring the ability to withstand high temperatures, such as boilers, furnaces, or engine components.

Producing and handling malleable steel requires precise control of heating and cooling to keep its structure intact. Improper handling during these stages can result in defects like cracking, warping, or reduced strength. Additionally, welding malleable steel presents challenges due to the risk of overheating, which can weaken the material or cause localized damage. Skilled workmanship and stringent process controls are essential to avoid such issues, increasing manufacturing complexity and costs.

Shrinkage during cooling can complicate manufacturing, causing problems with dimensions and assembly. This physical property must be accounted for during the design and production stages to ensure the final product meets required specifications, adding another layer of complexity to the manufacturing process.

At elevated temperatures, malleable steel can exhibit brittleness, compromising its structural integrity. This brittleness makes the material more prone to cracking and failure under thermal stress, which is a significant drawback for applications involving high heat. The material’s brittleness at high temperatures limits its use in environments such as industrial furnaces, heat exchangers, and other high-temperature applications where reliability and durability are critical.

To compare the strength of malleable steel, malleable iron, and cast iron, we need to look at their tensile strengths and structural properties.

Malleable steel exhibits high tensile strength, making it capable of withstanding significant mechanical stress without breaking. This property makes it suitable for structural applications that require both strength and flexibility.

Malleable iron, produced by heat-treating white cast iron, offers moderate tensile strength. It is less strong than malleable steel but provides better ductility and impact resistance. This balance of strength and flexibility makes it suitable for components that need to absorb shock and withstand moderate stress, such as pipe fittings and brackets.

Cast iron, with its high carbon content, is known for its compressive strength but is generally brittle and less capable of withstanding tensile stress. This makes cast iron strong under compression but more prone to cracking under tensile loads.

Ductility is the ability of a material to deform under stress.

Malleable steel is highly ductile, allowing it to be shaped and bent without breaking. This property is advantageous in applications that require extensive machining or forming processes.

Malleable iron also offers good ductility, though not as high as malleable steel. Its ability to be machined into intricate designs makes it suitable for various industrial applications where flexibility and moderate strength are needed.

Cast iron is much less ductile compared to malleable steel and malleable iron. Its brittleness limits its use to applications where high compressive strength is more critical than flexibility.

The suitability of malleable steel, malleable iron, and cast iron for different uses depends on their mechanical properties and performance in specific conditions.

Due to its high tensile strength, ductility, and heat resistance, malleable steel is widely used in automotive parts, construction, and industrial machinery. It is ideal for components that require intricate shapes and the ability to withstand mechanical stress and high temperatures.

Malleable iron is suitable for applications that require good machinability and moderate strength. It is commonly used in pipe fittings, brackets, and housings where impact resistance and ductility are important.

Cast iron’s strength under compression and cost-effectiveness make it suitable for applications like engine blocks, pipes, and heavy machinery bases. However, its brittleness limits its use in applications that require tensile strength or flexibility.

Cost is an important factor when choosing materials for different uses.

Malleable steel tends to be more expensive than malleable iron and cast iron due to its superior mechanical properties and versatility. The added cost is justified in applications where high strength and ductility are critical.

Malleable iron is generally more affordable than malleable steel but more expensive than cast iron. Its cost-effectiveness, combined with good machinability and moderate strength, makes it a practical choice for many industrial components.

Cast iron is typically the least expensive of the three materials. Its low melting point and ease of production contribute to its cost-effectiveness, making it a preferred choice for applications where budget constraints are a primary concern and high tensile strength is not required.

To provide a clear comparison, the following table summarizes the key differences between malleable steel, malleable iron, and cast iron:

| Feature | Malleable Steel | Malleable Iron | Cast Iron |

|---|---|---|---|

| Tensile Strength | High | Moderate | Low |

| Ductility | High | Moderate | Low |

| Cost | High | Moderate | Low |

| Suitability | Automotive, construction, industrial machinery | Pipe fittings, brackets, housings | Engine blocks, pipes, heavy machinery bases |

| Brittleness | Low | Low | High |

This table highlights the primary attributes and application suitability of each material, providing a comprehensive overview for material selection based on specific project requirements.

Heat treatment is essential for improving the malleability of steel. The key technique involves annealing, where steel is heated to a specific temperature and then cooled slowly, altering the microstructure and reducing internal stresses to make the steel more ductile. Other heat treatment methods, such as normalizing and tempering, can also be applied to achieve the desired properties.

Welding malleable steel is challenging because of its composition and the risk of overheating. Proper welding techniques must be employed to avoid weakening the material or causing localized damage. Preheating the steel before welding and maintaining controlled cooling rates can help mitigate these issues. Additionally, using appropriate filler materials that match the steel’s properties is essential to ensure a strong weld.

Shrinkage during cooling can commonly affect the size and integrity of malleable steel parts. To address this, precise control over the cooling rate is necessary. Implementing gradual and uniform cooling processes can help minimize shrinkage and prevent defects such as warping or cracking. Design adjustments may also be required to compensate for anticipated shrinkage.

Malleable steel’s machinability is one of its advantages, but it requires specific best practices to optimize the process. Sharp, high-quality cutting tools and proper cutting speeds improve machining performance. Lubrication and cooling fluids should be employed to reduce friction and heat buildup, which can affect the material’s surface finish and dimensional accuracy.

Manufacturers must be prepared to address common issues that arise during the production of malleable steel components. Regular inspections and quality control measures can help identify and rectify problems early. For instance, if cracking or brittleness is observed, reviewing the heat treatment parameters and welding techniques can pinpoint the root cause. Employing advanced diagnostic tools such as ultrasonic testing can also aid in detecting internal defects.

By understanding and implementing these manufacturing considerations, producers can effectively work with malleable steel, ensuring high-quality and reliable components for various industrial applications.

Malleable steel is prized for its strength, flexibility, and ease of machining, making it ideal for many industrial uses.

In the automotive sector, malleable steel is used for manufacturing components that require both durability and the ability to withstand dynamic loads and vibrations. These components must endure constant stress and impact, with malleable steel’s ductility allowing them to absorb shocks and vibrations effectively. Key applications include:

Malleable steel is widely used in construction because it can bear heavy loads and resist bending. Applications include:

The plumbing industry uses malleable steel to make strong, durable pipe fittings. Key applications are:

Malleable steel’s strength and machinability make it ideal for manufacturing parts in industrial machinery. Applications include:

In electrical systems, malleable steel is used to produce fittings and connectors that require precision and robustness. Applications include:

While malleable steel offers numerous advantages, there are certain applications where it may not be the best choice due to its limitations.

For applications requiring extremely high tensile strength and durability, such as heavy machinery parts or critical load-bearing structures, materials like high-strength steel or ductile iron may be more suitable. Malleable steel’s lower yield strength can limit its performance under intense stress.

Despite its moderate corrosion resistance, malleable steel is not ideal for environments with high exposure to moisture, saltwater, or aggressive chemicals. Stainless steel or galvanized steel, which offer superior corrosion resistance, are better suited for these conditions.

Malleable steel can become brittle at elevated temperatures, compromising its structural integrity. Boilers, furnaces, and engine parts exposed to high heat are better made from materials designed to handle extreme temperatures.

In a case study involving automotive manufacturing, malleable steel was used to produce suspension brackets and engine mounts. The material’s ability to absorb shocks and vibrations while maintaining strength ensured the components’ reliability and performance.

In a large-scale construction project, malleable steel was utilized for structural supports and reinforcement bars. The material’s high tensile strength and flexibility provided the necessary support for the building’s framework, ensuring stability and safety.

A plumbing company employed malleable steel for manufacturing pipe fittings used in a gas distribution network. The fittings’ resistance to cracking and ability to withstand high pressures ensured the safe and efficient transport of gas throughout the system.

Below are answers to some frequently asked questions:

Malleable steel offers several advantages that make it highly suitable for a variety of industrial applications. Firstly, its high malleability and ductility allow it to be shaped and formed without breaking, which is essential in metalworking and manufacturing processes. Additionally, malleable steel exhibits high tensile strength, enabling it to withstand significant mechanical stress without failure.

Another key advantage is its ease of welding and machining. This property simplifies construction and manufacturing processes, reducing both time and costs. The chemical composition of malleable steel, which includes elements like manganese, silicon, and chromium, enhances its flexibility and resistance to wear, thereby balancing strength and durability.

Moreover, malleable steel is heat resistant, making it suitable for applications that involve high temperatures, such as automotive parts and industrial machinery. Its microstructure, consisting of ferrite and pearlite, contributes to its strength and flexibility, and can be further refined through heat treatment to enhance its mechanical properties. These combined characteristics make malleable steel a versatile and valuable material for many industrial uses.

Malleable steel, while highly adaptable and easy to fabricate, comes with several disadvantages and limitations. It has a lower yield strength compared to many high-strength steels and alloys, making it prone to deformation under stress. Its lower hardness and wear resistance mean it is susceptible to wear and tear, limiting its use in parts exposed to regular friction or abrasive conditions. Processing malleable steel requires precise control over heating and cooling to avoid defects such as cracking or warping. Welding can be particularly challenging due to the risk of overheating and localized damage. Moreover, malleable steel has moderate mechanical properties, making it unsuitable for applications demanding high strength or durability, such as aerospace or large-scale construction. Its corrosion resistance is limited compared to stainless or galvanized steels, necessitating protective coatings or regular maintenance, which increases long-term costs. Additionally, malleable steel tends to be more expensive and requires more maintenance than some alternatives, further impacting its suitability for cost-sensitive projects.

Malleable steel generally offers superior ductility and tensile strength compared to malleable iron and cast iron, making it highly suitable for applications requiring significant deformation without failure. Malleable iron, which undergoes a heat treatment process to convert brittle iron carbide into more ductile forms, provides better machinability and shock resistance than traditional cast iron but remains less ductile than malleable steel. Cast iron, characterized by its high carbon content and graphite microstructure, excels in compressive strength and castability but is more brittle and prone to cracking under tensile stress. Hence, malleable steel is often preferred for high-stress, load-bearing applications, while malleable iron is chosen for components needing a balance of strength and ductility, and cast iron is used where compressive strength and ease of casting are paramount.

Malleable steel is unsuitable for several applications due to its inherent limitations. Firstly, it is not recommended for high mechanical load-bearing applications, such as structural components in construction or heavy machinery, because it has a lower yield strength and deforms more easily under stress compared to high-carbon or tool steel. Secondly, it is unsuitable for aerospace and other high-stress industries, where materials must withstand extreme stress and impact. Its moderate mechanical properties do not meet the rigorous demands of these sectors. Additionally, malleable steel is not ideal for highly corrosive environments, such as those involving moisture, saltwater, or harsh chemicals, since it requires protective coatings and regular maintenance to prevent rust. Furthermore, it is less hard than some other alloys, making it prone to wear and tear in high friction and abrasive conditions, such as cutting tools or machinery parts. Finally, malleable steel presents challenges in welding and fabrication, as it must be handled with precision to avoid defects like cracking or warping. These factors collectively limit the suitability of malleable steel for applications requiring high strength, durability, corrosion resistance, and ease of fabrication.

When manufacturing malleable steel, several important considerations must be addressed to ensure the material meets the required properties for its intended applications. Firstly, the selection of raw materials is crucial. High-purity iron ore, scrap, and additives should be used to minimize impurities that could affect ductility. Primary steelmaking methods such as Basic Oxygen Furnace (BOF) or Electric Arc Furnace (EAF) are employed to produce crude steel, with EAF being preferred for better control over alloying elements.

Secondary steelmaking processes like Ladle Furnace (LF) and Vacuum Oxygen Decarburization (VOD) are then used to refine the steel further, removing impurities and adjusting the chemical composition to enhance malleability. Controlled casting techniques, including continuous or ingot casting, are necessary to shape the molten steel into desired forms.

Hot rolling is used to form semi-finished products while the steel is still hot, improving internal structure and workability. Cold forming and finishing processes, such as cold rolling and machining, are employed to achieve precise dimensions and surface quality. Heat treatment, including annealing or normalizing, is critical to relieve internal stresses, improve grain structure, and enhance malleability.

Quality assurance is essential, involving regular chemical analysis and mechanical testing to ensure the steel meets specifications for ductility and other mechanical properties. Surface treatments, like galvanizing, may be applied to protect against corrosion. These steps ensure that the steel maintains the necessary balance between strength and formability for its intended use.