From the sleek, aerodynamic frames of modern aircraft to the robust, corrosion-resistant components in automotive engines, aluminium ingots are the unsung heroes behind a multitude of industrial applications. Understanding the different types of aluminium ingots and their specific uses can be a game-changer for anyone working with this versatile metal. This article delves into five distinct types of aluminium ingots—each with unique properties tailored to meet the demands of various industries. Whether you’re an engineer looking to optimize your material choices or a curious mind eager to learn more, this step-by-step guide will provide you with valuable insights into the world of aluminium ingots. So, what makes each type of ingot unique, and how can they be best utilized? Let’s explore these questions and uncover the fascinating details behind this essential material.

Aluminium ingots are essential raw materials in the metal industry and are crucial in many industrial applications. Their significance lies in their versatility and the properties they impart to finished products. Aluminium is known for its lightweight nature, excellent corrosion resistance, and high thermal and electrical conductivity. These characteristics make aluminium ingots highly desirable in industries that require materials with a combination of strength, durability, and efficiency.

In the automotive industry, aluminium ingots are used to manufacture components such as engine blocks, transmission cases, and wheels. Using aluminium helps reduce vehicle weight, improve fuel efficiency, and lower emissions.

The aerospace industry benefits from the use of aluminium ingots due to the metal’s strength and lightness. Aluminium is used in the production of aircraft structures, including fuselage panels, wings, and landing gear components. The reduced weight contributes to better fuel efficiency and performance of aircraft.

In the construction sector, aluminium ingots are transformed into various building materials such as window frames, roofing, and cladding. The corrosion-resistant property of aluminium ensures longevity and minimal maintenance for these structures.

Aluminium’s excellent conductivity makes it ideal for power lines, wiring, and electronic components. This ensures efficient energy transfer and reliability in electrical systems.

There are several types of aluminium ingots, each tailored for specific industrial applications. These include 1000 – Pound Bullion Ingots, known for their high purity and used in high – quality alloys and sanitary ware; Aluminium Slab Ingots, flat rectangular ingots used in manufacturing rolled products like coils and sheets; T – Bar Ingots, made from electrical conductivity alloys, essential for cables and appliances; Billet Ingots, cylindrical ingots used in the extrusion industry for producing tubes, pipes, and structural components; and High – Purity and Secondary Aluminium Ingots, used for die casting complex parts, offering an eco – friendly option through recycling. Understanding the types and applications of aluminium ingots is essential for industries aiming to optimize performance, cost – efficiency, and sustainability. Each type of ingot is engineered to meet specific requirements, ensuring that aluminium remains one of the most widely used metals globally.

Aluminium ingots are widely used in various industries due to their versatile properties and adaptability. They are created by casting molten aluminium into specific shapes, often using the mold chill method. This process allows the aluminium to solidify into ingots that can then be further processed or used directly in manufacturing. Aluminium ingots can be alloyed with other elements to enhance their strength, corrosion resistance, and electrical conductivity.

Aluminium ingots can be alloyed with elements like copper, magnesium, zinc, or silicon to enhance properties such as strength, hardness, and corrosion resistance. Extensively used in automotive, aerospace, construction, packaging, electrical engineering, and more, they are valued for their lightweight, high strength-to-weight ratio, and excellent corrosion resistance.

Aluminium ingots serve as a fundamental raw material for various downstream processes, enabling the production of a wide range of products across multiple industries. Their recyclability and the ability to be produced from secondary materials contribute to their sustainability and environmental advantages.

An aluminium ingot is a block of aluminium cast into a specific shape, such as rectangular, cylindrical, or T-shaped. Aluminium ingots are produced by melting aluminium, which is then poured into molds where it solidifies. This process ensures a uniform composition and structure, making the ingots suitable for further processing into various aluminium products.

Aluminium ingots are lightweight and easy to handle due to their low density, and they form a protective oxide layer that prevents corrosion, making them durable in harsh environments. Additionally, aluminium has high thermal and electrical conductivity, which is crucial for applications in the electrical and electronics industries. Its malleability allows it to be easily shaped and formed into different products through processes like rolling, extrusion, and casting. Moreover, aluminium is highly recyclable, and ingots can be produced from both primary aluminium and recycled aluminium scrap.

Aluminium ingots are foundational in the manufacturing sector due to their versatile properties. They serve as the raw material for a wide range of products across various industries.

In the automotive industry, aluminium ingots are used to produce parts such as engine blocks, transmission cases, and wheels. These components are lightweight, which helps reduce vehicle weight, improving fuel efficiency and lowering emissions.

The aerospace industry extensively uses aluminium ingots to create crucial aircraft parts like fuselage panels, wings, and landing gear. Aluminium’s strength-to-weight ratio enhances aircraft performance and fuel efficiency.

Aluminium ingots are transformed into building materials such as window frames, roofing, and cladding. The metal’s corrosion resistance ensures the longevity and minimal maintenance of these structures.

Aluminium’s excellent conductivity makes ingots ideal for electrical applications, including power lines, wiring, and electronic components. This ensures efficient energy transfer and reliability in electrical systems.

There are several types of aluminium ingots, each tailored for specific industrial applications:

Aluminium ingots are produced using various methods, with the direct chill (DC) casting process being one of the most common. Other methods include smelting and continuous casting.

In the DC casting process, molten aluminium is poured into water-cooled molds, rapidly cooling the aluminium to create a uniform structure and reduce impurities. This method results in high-quality ingots suitable for further processing.

The smelting process involves extracting aluminium from alumina (aluminium oxide) using electrolysis. The extracted aluminium is then cast into ingots, producing primary aluminium ingots known for their high purity.

Alloying elements such as copper, magnesium, zinc, silicon, and manganese are added to aluminium ingots to enhance their mechanical properties. These elements can increase strength, hardness, corrosion resistance, and heat resistance, making the ingots suitable for various demanding applications.

Aluminium ingots play a crucial role in modern manufacturing, providing a versatile and sustainable material that meets the diverse needs of industries worldwide.

Unalloyed ingots consist of pure aluminium. They contain minimal impurities. The aluminium content in unalloyed ingots typically ranges from 98% to 99.999%, with the most common grade being 99.5% aluminium. This high purity is crucial for applications that require excellent electrical conductivity and resistance to corrosion.

Unalloyed ingots are characterized by their high aluminium content, which ensures minimal contamination from other elements. This purity level contributes to their excellent electrical conductivity and makes them suitable for applications where impurities could negatively impact performance.

Their high purity gives unalloyed ingots excellent electrical conductivity. This makes them ideal for manufacturing electrical conductors that efficiently transmit electricity with minimal loss.

Their purity also improves corrosion resistance. Pure aluminium forms a protective oxide layer on its surface, which prevents further oxidation and corrosion, making these ingots suitable for environments where durability is critical.

One of the primary applications of unalloyed ingots is in the production of electrical conductors. The high electrical conductivity of pure aluminium makes these ingots perfect for wiring, power transmission lines, and other electrical components.

Unalloyed ingots are also used in the manufacturing of motor rotors. The purity of the aluminium helps in achieving high performance in terms of electrical conductivity, which is essential for efficient motor operation.

In the packaging industry, unalloyed ingots are used to produce aluminium foil and other packaging materials. The high purity of the ingots ensures that the packaging is safe for food and pharmaceutical products, preventing contamination.

While unalloyed ingots boast high purity, alloyed ingots incorporate other elements such as copper, magnesium, and silicon to enhance specific properties like strength and hardness. This makes alloyed ingots more suitable for applications requiring mechanical robustness.

Unalloyed ingots are preferred in applications where high electrical conductivity and corrosion resistance are paramount. In contrast, alloyed ingots are used in structural applications where enhanced mechanical properties are needed, such as in automotive and aerospace components.

The production of unalloyed ingots often involves more stringent purification processes, which can make them more expensive compared to alloyed ingots. However, their specialized applications justify the cost due to the performance benefits they provide.

Unalloyed ingots are commonly produced through direct chill (DC) casting. In this process, molten aluminium is poured into water-cooled molds, rapidly solidifying the metal and ensuring a uniform structure with minimal impurities.

In continuous casting, molten aluminium is fed into a machine and solidified into long slabs or billets. This method allows for efficient production and consistent quality.

Rich alloy ingots are a specialized form of aluminium ingots that contain significant amounts of alloying elements, typically ranging from less than 1% up to 50%. These elements, such as chromium, copper, iron, magnesium, manganese, nickel, silicon, titanium, and zinc, are added to enhance the properties of aluminium. They allow manufacturers to tailor the mechanical properties, like strength, hardness, and toughness, as well as improve corrosion resistance and other application – specific traits.

Rich alloy ingots act as master alloys or hardeners. When added in controlled quantities to unalloyed aluminium during the production process, they ensure a uniform distribution of alloying elements during melting and casting. This uniform distribution is essential for consistent performance in subsequent processing steps.

In the aerospace industry, components need to be both strong and lightweight. Rich alloy ingots help create alloys that meet these demanding requirements, resulting in better fuel efficiency and In the automotive industry, automotive parts often require durability and corrosion resistance. Rich alloy ingots are used to manufacture engine blocks, transmission cases, and suspension components. The addition of alloying elements helps these parts withstand high stress and harsh environmental conditions, improving the lifespan and reliability of vehicles.

In construction, structural elements benefit from the enhanced strength and corrosion resistance provided by rich alloy ingots. These alloys are used in building frames, bridges, and other load – bearing structures, ensuring longevity and reducing maintenance needs.

In the electrical and electronic industries, specific conductivity and thermal characteristics are required. Rich alloy ingots can be used to produce alloys with tailored electrical and thermal properties. They are used in the manufacturing of electrical conductors, heat sinks, and electronic enclosures, ensuring efficient energy transfer and proper functioning of electronic devices.

Casting alloy ingots are aluminium alloys specifically formulated for casting processes. They are a blend of aluminium with various alloying elements, such as silicon, copper, magnesium, and zinc. These elements are carefully selected and combined to enhance the mechanical properties of the ingots, making them suitable for a wide range of applications.

Produced from virgin aluminium, primary casting alloy ingots have tightly controlled impurity levels. They are ideal for high-performance applications requiring consistent quality, as any impurities could affect the product’s integrity.

Made from recycled scrap aluminium, secondary casting alloy ingots have more relaxed impurity limits. They are favored in situations where cost efficiency and sustainability are the main priorities. Recycling scrap aluminium reduces energy consumption and production emissions, making these ingots an environmentally friendly option.

The production of casting alloy ingots often involves recycling large quantities of scrap. The process typically includes the following steps:

In the automotive industry, casting alloy ingots are used to manufacture engine blocks, transmission cases, wheels, and other precision parts. These components require high durability and dimensional accuracy, which the ingots can provide.

They are used in making household goods, motor housings, vacuum cleaner bodies, and other durable consumer products.

Industrial applications that demand wear resistance and strength, such as certain machinery components, also rely on casting alloy ingots.

In die casting, the molten alloy is injected into molds under high pressure. This method is ideal for producing high-precision, medium-sized parts.

Sand casting is suitable for larger or more complex parts needing intricate coring. It offers flexibility in terms of part size and shape.

Permanent mold casting uses reusable molds, which can provide a good surface finish and dimensional control for the cast parts.

An extrusion ingot, also known as an extrusion billet, is a type of aluminum ingot specifically designed for the aluminum extrusion process. These ingots are produced with precise metallurgical properties to facilitate the extrusion of aluminum into various shapes and profiles. Extrusion ingots are typically cylindrical and come in various lengths and diameters, tailored to the requirements of the extrusion process.

The production of extrusion ingots involves several critical steps to achieve the desired properties and quality.

Extrusion ingots are produced using advanced casting methods such as direct chill (DC) casting. In this process, molten aluminum is poured into water-cooled molds, where it solidifies rapidly. This method helps in achieving a fine-grained structure and reduces internal stresses.

After casting, the ingots undergo a homogenization heat treatment. Homogenization helps distribute alloying elements evenly throughout the ingot, enhancing its mechanical properties and making it more suitable for extrusion.

Extrusion is a manufacturing process where the heated extrusion ingot is forced through a die to create a desired cross-sectional shape. This process can produce long, continuous profiles that are cut to specific lengths for various applications.

Extrusion ingots are used in a variety of industries due to their versatility and high-quality properties.

Extruded aluminum profiles are widely used in the construction industry for window frames, door frames, curtain walls, and decorative architectural components due to their strength, corrosion resistance, and finish quality.

In the automotive industry, extruded aluminum profiles contribute to lightweight and strong vehicle components, enhancing fuel efficiency and performance. Typical applications include structural parts, heat exchangers, and trim.

Extruded profiles are also used in engineering and industrial applications, such as precision tubing, structural supports, and specialized components. The ability to create complex shapes with high precision makes extrusion ingots valuable in these sectors.

Household appliances and electronic housings benefit from extruded aluminum profiles due to their aesthetics and thermal properties. Extruded profiles provide durable and attractive solutions for various consumer products.

The choice of alloy significantly impacts the extrudability and performance of the final product. Common alloy series used for extrusion ingots include:

Higher strength alloys like 2024 or 7075 are less frequently used for extrusion due to lower extrudability but are employed where superior strength is essential.

A billet ingot, also known as an aluminium billet, is a semi-finished casting product in the aluminium industry. It usually has a round or square cross-section and is smaller than traditional aluminium ingots. Billets generally have a cross-sectional area of less than 36 square inches along their length. They offer superior mechanical properties such as high strength, toughness, ductility, and malleability compared to standard ingots. This makes them more homogeneous and stress-free, which is essential for precision manufacturing processes.

The dominant method for producing billet ingots is continuous casting. In this process, molten aluminium is poured into a casting machine that continuously shapes the molten metal into billets, ensuring consistent size, shape, and quality. This method allows for high production efficiency and ensures each billet has similar properties. Centrifugal casting is an alternative method used for producing seamless pipes or components that require enhanced structural integrity. Here, the molten aluminium is poured into a rotating mold, and the centrifugal force distributes the metal evenly, creating a more uniform and dense structure.

After casting, billets are often reheated before extrusion, forging, or rolling processes. Reheating to the appropriate temperature improves the workability of the billet and helps achieve the desired final product properties.

Billet ingots serve as the primary raw material for extrusion processes. In construction, aluminium extrusions from billets are used for window frames and curtain walls. In the automotive industry, they are employed to create pipes, bars, rods, and complex profiles, contributing to vehicle structures and components. The aerospace sector also utilizes these products for various structural and mechanical applications.

Due to their homogeneity and low internal stress, billets are ideal for machining high-precision parts. In the aerospace industry, billets are used to make landing gear and engine components. The automotive industry relies on them for shafts, gears, and axles. Medical devices also benefit from the high-precision parts machined from billets.

Billets are used to manufacture beams, columns, and other structural elements. Their excellent strength-to-weight ratio and corrosion resistance make them suitable for these applications, providing long-lasting support while reducing the overall weight of the structure.

In rolled ring forging, a heated billet is formed into rings. These rings are used in applications requiring high strength and durability, such as bearings or flanges. The rolled ring forging process from billets produces components with excellent mechanical properties and precise dimensions.

T-bar ingots are a specialized form of aluminium ingot, predominantly composed of a high-purity Electrical Conductivity (E.C.) alloy. This alloy is meticulously formulated to maximize electrical conductivity, which is crucial for applications in the electrical and electronics industries. The distinctive “T” shape of these ingots makes casting, handling, and processing more efficient.

The E.C. alloy used in T-bar ingots ensures minimal impurities, which enhances their electrical conductivity. This high level of purity is essential for applications where efficient electrical transmission is critical.

The T-shaped cross-section of these ingots is not merely a design choice but a functional aspect that aids in easier handling and processing. This shape allows for more uniform cooling during casting, reducing the likelihood of internal stresses and defects.

T-bar ingots are primarily used in industries that require high electrical conductivity and reliability. Their applications span several sectors, including electrical conductors and cables, home appliances, electronics, and the power industry.

Their high conductivity makes T-bar ingots ideal for manufacturing power lines, wiring, and cables, ensuring efficient electrical transmission and system safety.

T-bar ingots are commonly used in home appliances for components like motors, heating elements, and connectors, requiring reliable electrical performance.

In the electronics sector, the need for materials with minimal electrical resistance is paramount. T-bar ingots provide the necessary properties for manufacturing electronic components that demand high performance and reliability. This includes parts for computers, mobile devices, and other electronic equipment.

The power industry relies heavily on T-bar ingots for the production of electrical conductors used in power distribution and transmission systems. The ingots’ high conductivity and purity ensure that power is transmitted efficiently over long distances with minimal energy loss.

One of the most significant advantages of T-bar ingots is their high electrical conductivity. This property is a direct result of the E.C. alloy composition, which guarantees efficient electrical performance crucial for various applications.

The high purity of T-bar ingots ensures consistent quality, which is vital for sensitive electrical applications. This consistency reduces the risk of defects and improves the reliability of the final products made from these ingots.

The T-bar shape simplifies remelting and casting into finished products. This ease of processing helps manufacturers produce high-quality electrical conductors and other components efficiently.

While T-bar ingots are specifically designed for high electrical conductivity applications, other types of aluminium ingots serve different purposes based on their composition and shape.

Billet ingots are typically used for extrusion processes to create structural components. They are cylindrical or square and are more focused on mechanical properties rather than electrical conductivity.

Aluminium slabs are used to produce flat-rolled products such as coils, sheets, and belts, primarily for construction and packaging industries. These slabs are characterized by their large, flat rectangular shape.

These bullion ingots vary in size and purity. The 50-pound bullion ingots are manageable and versatile, used extensively in the automotive industry. In contrast, the 1000-pound bullion ingots are known for their high purity and are used in high-quality alloys, sanitary ware, and medical equipment.

T-bar ingots are produced by casting molten aluminium alloy into specifically designed steel molds. The alloying elements, such as copper, magnesium, zinc, or silicon, may be added to tailor the mechanical and chemical properties of the ingots. The focus on electrical conductivity means that the alloy used in T-bar ingots is purer compared to those used for other types of ingots that prioritize mechanical strength or formability.

T-bar ingots can be produced from recycled aluminium scrap, significantly reducing energy consumption and environmental impact compared to primary aluminium extraction. This makes them an environmentally friendly option for manufacturers.

Primary ingots, derived from raw bauxite ore, are highly pure and suited for high-quality applications, while secondary ingots from recycled materials offer cost and sustainability benefits for various industries.

Primary aluminium ingots are produced from bauxite ore. The production process has two main stages: the Bayer process and the Hall-Héroult process.

This method results in high-purity aluminium ingots, typically exceeding 99.7% aluminium content. However, it is energy-intensive, requiring approximately 15,000 kWh of electricity per ton of aluminium produced.

Secondary aluminium ingots, made from recycled aluminium scrap, are not only cost-effective but also environmentally friendly. The production process includes:

Secondary aluminium production consumes significantly less energy, around 700 kWh per ton, which is about 95% less than primary production. This makes it a more sustainable option.

Primary aluminium ingots boast a high level of purity, typically greater than 99.7% aluminium. The low impurity levels make these ingots ideal for applications requiring superior material properties such as high electrical conductivity, excellent corrosion resistance, and high strength-to-weight ratios. Industries like aerospace, automotive, and electronics often use primary aluminium ingots due to these stringent quality requirements.

The purity of secondary aluminium ingots varies depending on the quality of the recycled material and the refining processes used. While secondary ingots can achieve high purity levels, they generally contain more impurities and alloying elements than primary ingots. This variability necessitates stricter quality control during production, especially for applications where precise material properties are critical.

The production of primary aluminium ingots involves significant costs due to mining, refining, and high energy consumption. Consequently, primary ingots are more expensive than secondary ingots. However, their high purity and consistent quality often justify the higher price in applications requiring these attributes.

Secondary aluminium ingots are more cost-effective as they utilize recycled materials and require less energy for production. The lower production costs make secondary ingots an attractive option for industries where cost efficiency is a priority, such as construction and consumer goods manufacturing.

The production of primary aluminium ingots has a substantial environmental impact due to the energy-intensive processes involved. The high energy consumption contributes to a significant carbon footprint, with considerable greenhouse gas emissions.

Secondary aluminium ingots offer substantial environmental benefits. The recycling process conserves natural resources, reduces landfill waste, and significantly lowers energy consumption, resulting in reduced CO₂ emissions. Recycling aluminium can avoid approximately 2.5 tons of CO₂ emissions per ton of aluminium, making secondary ingots a more sustainable choice.

Primary aluminium ingots are used in high-performance applications where material purity and consistency are paramount. Key industries include:

Secondary aluminium ingots are widely used in applications where cost efficiency and sustainability are more critical than maximum purity. Common applications include:

Bauxite, the primary raw material for aluminium production, is usually found in large surface deposits. Miners extract bauxite using open-pit mining methods. After extraction, the bauxite is transported to refineries for further processing.

At the refinery, the bauxite is processed into alumina (aluminium oxide) using the Bayer process. In this process, the bauxite is crushed and mixed with a hot solution of caustic soda. The mixture is then heated under pressure, dissolving the aluminium oxide in the bauxite while leaving behind impurities. After filtering to remove the impurities, the solution is cooled, causing pure alumina to precipitate out.

The alumina is then converted into liquid aluminium via the Hall–Héroult process. Alumina is dissolved in molten cryolite, a substance that lowers the melting point and reduces energy use. A high electrical current is passed through the molten mixture. This electrolytic process causes the aluminium ions in the alumina to gain electrons and be reduced to pure aluminium metal, which collects at the bottom of the electrolytic cell as a liquid.

The molten aluminium obtained from electrolysis may still contain impurities that need to be removed. Various techniques, such as fluxing or filtering, are employed to purify the metal. Once purified, the molten aluminium is cast into ingots using different casting machines. Vertical and horizontal casting machines are commonly used, where the molten metal is poured into molds and left to solidify into the desired ingot shape.

Primary aluminium ingots are produced directly from alumina through smelting. They typically have a very high purity level, often around 99.8%. This high purity makes them suitable for applications requiring superior material properties, such as high electrical conductivity, excellent corrosion resistance, and high strength-to-weight ratios. Industries like aerospace, automotive, and electronics often rely on primary aluminium ingots for their stringent quality needs.

Secondary aluminium ingots are made from recycled aluminium scrap, and their purity varies depending on the quality of the recycled material and the refining processes used. Generally, they contain more impurities and alloying elements compared to primary ingots. However, they offer significant environmental benefits by reducing energy consumption and supporting sustainability. They are widely used in applications where cost-efficiency and environmental friendliness are more important than maximum purity, such as in construction and consumer goods manufacturing.

In the automotive industry, aluminium ingots are crucial for manufacturing lightweight and strong components. Aluminium ingots are used to produce engine blocks, cylinder heads, and pistons, which reduce vehicle weight and improve fuel efficiency. Similarly, body panels, doors, hoods, and trunk lids benefit from aluminium’s lightweight yet durable properties, enhancing vehicle performance, handling, and safety. Aluminium alloy wheels, being lighter than steel, reduce unsprung weight, thus improving handling and fuel efficiency while offering long-lasting corrosion resistance.

The aerospace industry uses aluminium ingots for aircraft structures and engine parts due to their strength, light weight, and corrosion resistance. Critical components such as fuselage panels, wing sections, and landing gear are manufactured from aluminium ingots, contributing to better fuel efficiency and payload capacity. Aluminium’s high thermal conductivity and strength make it ideal for engine parts like turbine blades and casings, ensuring reliable performance under high temperatures and stress.

Aluminium ingots are ideal for structural components like beams and columns, as well as facades and cladding, due to their strength, durability, and weather resistance. These materials are used in high-rise buildings and large infrastructure projects, providing both aesthetic appeal and functional benefits. Aluminium window and door frames maximize glass area, improving natural lighting while maintaining structural integrity.

The electrical and electronics industries rely on aluminium ingots for their excellent electrical conductivity. Aluminium ingots are used to produce electrical conductors and power cables, ensuring efficient power transmission with minimal energy loss. In electronics, aluminium is utilized for heat sinks, casings, and components requiring effective thermal management, aiding in the performance and longevity of electronic devices.

Aluminium ingots are processed into packaging materials like foil, containers, and cans, which are lightweight, durable, and recyclable. These materials provide excellent barrier properties to protect contents from light, oxygen, and moisture, ensuring product freshness and safety. Aluminium cans, widely used for beverages, offer an environmentally friendly packaging option due to their recyclability.

Aluminium ingots are used in the production of household appliances and everyday goods, leveraging the metal’s thermal conductivity, strength, and aesthetic appeal. Cookware such as pots, pans, and baking sheets benefit from aluminium’s even heating properties, enhancing cooking performance. Household appliances like refrigerators, washing machines, and microwaves incorporate aluminium components for efficiency and durability. Aluminium furniture and fixtures, including chairs, tables, and lighting, combine functionality with stylish design, owing to the metal’s strength and resistance to corrosion.

Primary aluminium ingots are produced from bauxite ore. This involves a series of processes, including refining and electrolysis. The production method is highly energy – intensive. The main reason is the large amount of electricity needed for the electrolysis process. On average, producing one metric ton of primary aluminium results in approximately 8,940 kg of CO₂ emissions. The smelting process uses carbon anodes. These anodes release CO₂ and other pollutants into the atmosphere. Despite these environmental challenges, the aluminium industry has made significant progress. Since 1995, there has been about a 37% reduction in the carbon emissions linked to primary aluminium production. This is due to improvements in energy efficiency and advancements in smelting technology.

Secondary aluminium ingots are made by recycling aluminium scrap, like used beverage cans and other discarded aluminium products. This recycling process is much more energy – efficient compared to primary production. It only requires about 8 – 10% of the energy needed for primary aluminium production. As a result, recycling aluminium can save around 2.5 tons of CO₂ emissions per ton of aluminium produced.

Beyond energy savings, recycling aluminium also offers other environmental benefits. By recycling, the need for bauxite mining is reduced. This conserves natural resources and lessens the environmental degradation associated with mining activities. Additionally, secondary aluminium production leads to fewer impurities and less dross during the melting process, which enhances product quality and production efficiency.

One of the key sustainability advantages of aluminium is its recyclability. Aluminium can be recycled an infinite number of times without losing its quality. This makes it a highly sustainable material and supports circular economy practices. In a circular economy, materials are reused and recycled to minimize waste and cut down the demand for virgin raw materials.

The energy efficiency of secondary aluminium production is a major sustainability benefit. By using only a small fraction of the energy required for primary production, secondary aluminium significantly reduces the overall environmental impact. This process not only conserves natural resources but also decreases greenhouse gas emissions, contributing to a more sustainable and eco-friendly industry.

Industries can optimize performance and minimize environmental impact by choosing the right aluminium ingot for specific applications. The strong, lightweight, and corrosion – resistant properties of aluminium also lead to energy savings in downstream applications. For example, lighter vehicles made with aluminium improve fuel efficiency and reduce emissions.

The aluminium industry is constantly innovating in sustainable practices to further reduce the environmental impact of aluminium production. In recycling technology, advanced sorting systems are being developed. These systems can more accurately separate different types of aluminium alloys from mixed scrap, increasing the quality and quantity of recycled aluminium. New melting techniques are also being explored. These techniques can reduce energy consumption during the recycling process by using more efficient heat transfer methods.

In energy – efficient smelting processes, some companies are experimenting with new anode materials. These materials can reduce the amount of CO₂ emissions during the electrolysis process. Additionally, improvements in furnace design are being made to better capture and reuse waste heat, further enhancing energy efficiency. These innovations not only make aluminium production more sustainable but also support the industry’s shift towards a more circular and low – carbon economy. As global sustainability goals become stricter, the role of aluminium as a versatile and sustainable material is likely to grow.

Below are answers to some frequently asked questions:

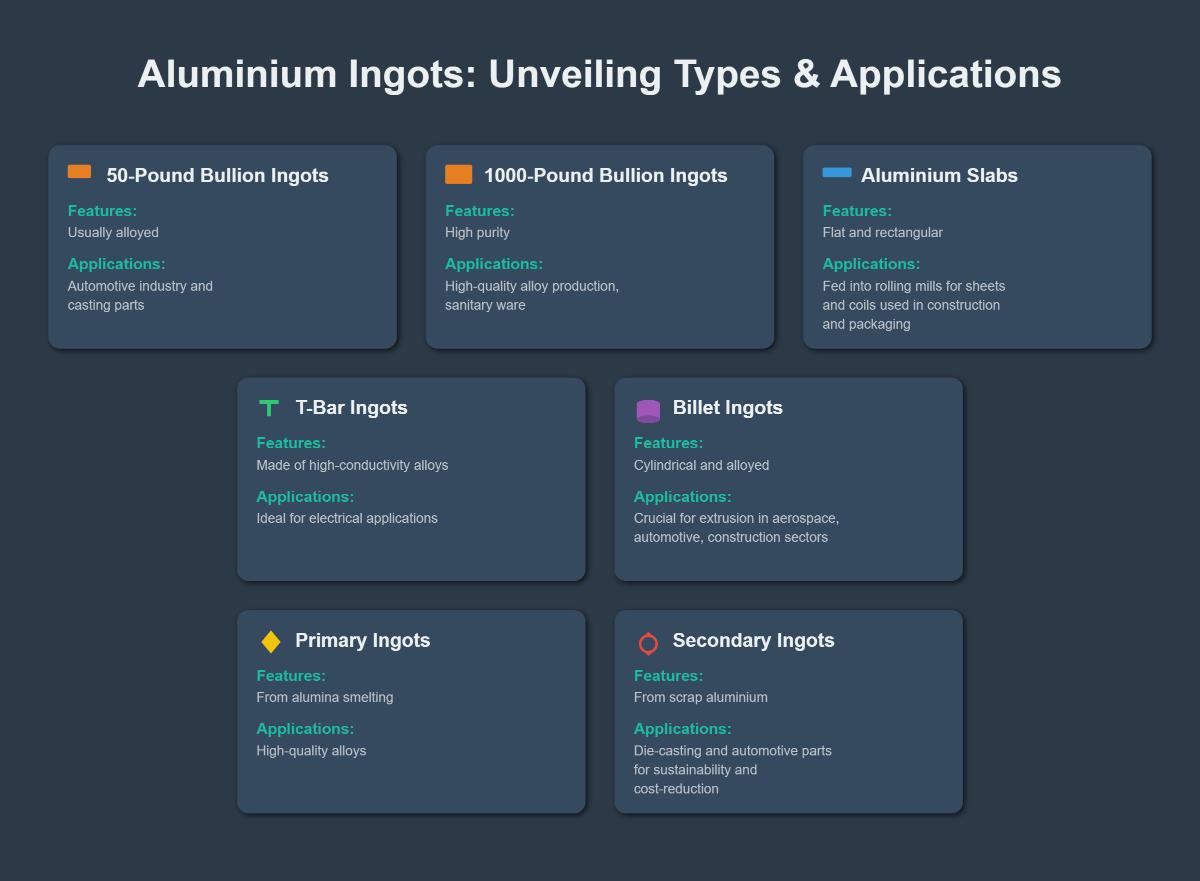

Aluminium ingots are essential raw materials for manufacturing various aluminium products. The main types and their uses include: 50 – Pound Bullion Ingots, usually alloyed, are used in the automotive industry and casting parts; 1000 – Pound Bullion Ingots, with high purity, are for high – quality alloy production, sanitary ware, etc.; Aluminium Slabs, flat and rectangular, are fed into rolling mills for sheets and coils used in construction and packaging; T – Bar Ingots, made of high – conductivity alloys, are ideal for electrical applications; Billet Ingots, cylindrical and alloyed, are crucial for extrusion in aerospace, automotive, and construction sectors. Additionally, primary ingots from alumina smelting are for high – quality alloys, while secondary ingots from scrap aluminium are used in die – casting and automotive parts for sustainability and cost – reduction.

Primary aluminium ingots are produced directly from raw bauxite ore through a multi-step process involving the Bayer process and the Hall–Héroult electrolytic process. This method results in aluminium of very high purity and consistency, making it suitable for applications that require exacting material standards, such as aerospace and high-end automotive manufacturing.

Secondary aluminium ingots, on the other hand, are made by recycling aluminium scrap. The scrap is melted, cleaned, and often alloyed with other elements to achieve desired properties. This recycling process significantly reduces energy consumption and environmental impact compared to primary production, making secondary aluminium a cost-effective and sustainable option. However, secondary ingots may contain higher levels of impurities due to the heterogeneous nature of the scrap feedstock.

Aluminium ingots are produced through a series of intricate processes starting from raw material extraction to final casting. The production begins with the extraction of bauxite, the primary ore for aluminium, which is mined predominantly from tropical and sub-tropical regions. The bauxite undergoes the Bayer Process, where it is crushed and treated with sodium hydroxide to extract alumina (aluminium oxide). This involves grinding, digestion, settling, and precipitation to purify the alumina.

Next, the purified alumina is subjected to the Hall-Héroult Process, a method of electrolysis, where high electrical currents pass through a mixture of molten cryolite and alumina to separate pure aluminium from oxygen. The resulting molten aluminium is then cast into ingots through methods such as semi-continuous vertical direct-chill casting or horizontal casting.

These processes ensure the production of various types of aluminium ingots, such as primary ingots made from alumina and secondary ingots derived from recycled aluminium. Each type of ingot serves specific industrial applications, leveraging aluminium’s properties like lightweight, strength, and corrosion resistance.

Aluminium ingots are widely used across various industries due to their unique properties such as lightweight, corrosion resistance, and excellent conductivity. In the automotive industry, they are primarily used for engine blocks, transmission cases, and body panels, with billet ingots being particularly favored for their structural integrity and suitability for extrusion processes. The aerospace industry utilizes high-purity bullion ingots for aircraft structures, fuselage, and wings, benefiting from their high strength-to-weight ratio and corrosion resistance. In the construction industry, aluminium slabs are used for window frames, roofing, and structural components due to their durability and aesthetic appeal. The electrical and electronics industry employs T-bar ingots for wiring, conductors, and heat sinks, leveraging their excellent conductivity and non-magnetic properties. Additionally, the packaging industry uses aluminium slabs to produce cans, foils, and wrappers, capitalizing on their lightweight and recyclability. Lastly, household appliances often incorporate recycled aluminium ingots for cookware and heating elements, highlighting the material’s thermal conductivity and cost-effectiveness.

Secondary aluminium ingots, produced by recycling aluminium scrap, offer significant environmental benefits compared to primary aluminium ingots made from raw bauxite ore. One of the primary advantages is the dramatic reduction in energy consumption. Producing secondary aluminium ingots requires about 95% less energy than the energy-intensive processes involved in mining and refining bauxite for primary aluminium production. This substantial energy saving directly correlates with a lower carbon footprint, as secondary ingot production emits significantly fewer greenhouse gases.

Additionally, recycling aluminium reduces the need for bauxite mining, conserving natural resources and mitigating the environmental degradation associated with mining activities, such as habitat destruction and biodiversity loss. Aluminium’s property of being infinitely recyclable without losing its essential qualities supports a closed-loop circular economy, minimizing waste and promoting sustainable resource use.

Moreover, using recycled aluminium helps decrease landfill waste, as it diverts scrap aluminium from waste streams and reprocesses it into valuable secondary ingots. This not only aids in sustainable waste management but also reduces environmental contamination.

Alloying elements significantly influence the properties of aluminium ingots, tailoring them for specific industrial applications. Copper (Cu) enhances strength and hardness but may reduce corrosion resistance, making Al-Cu alloys suitable for high-strength applications like aerospace. Magnesium (Mg) improves strength, ductility, and corrosion resistance, ideal for marine and structural uses. Silicon (Si) boosts castability and mechanical properties, commonly used in automotive and electrical industries. Zinc (Zn), especially when combined with magnesium, significantly increases tensile and yield strength but may increase stress corrosion cracking risks. Manganese (Mn) refines grain structures, prevents recrystallization, and enhances corrosion resistance, often complementing magnesium’s effects. Understanding these modifications allows manufacturers to optimize aluminium ingots for varied industrial needs, balancing mechanical strength, corrosion resistance, and other critical properties.