When it comes to protecting your home from the elements, the right roofing trim is essential. Metal roofing trim not only enhances the aesthetic appeal of your roof but also plays a crucial role in safeguarding your home from water damage and ensuring longevity. But with various types of trim available, how do you know which ones are necessary and why they’re used? From eave trim to valley trim, each piece has a specific function that contributes to the overall integrity of your roofing system. In this article, we’ll dive into the five key types of metal roofing trim, exploring their purposes and benefits. Whether you’re curious about how valley trim prevents water damage or the difference between gable trim and eave trim, you’ll find the insights you need to make informed decisions for your roofing project. Ready to uncover the secrets behind these vital components and learn how they can protect your home? Let’s get started.

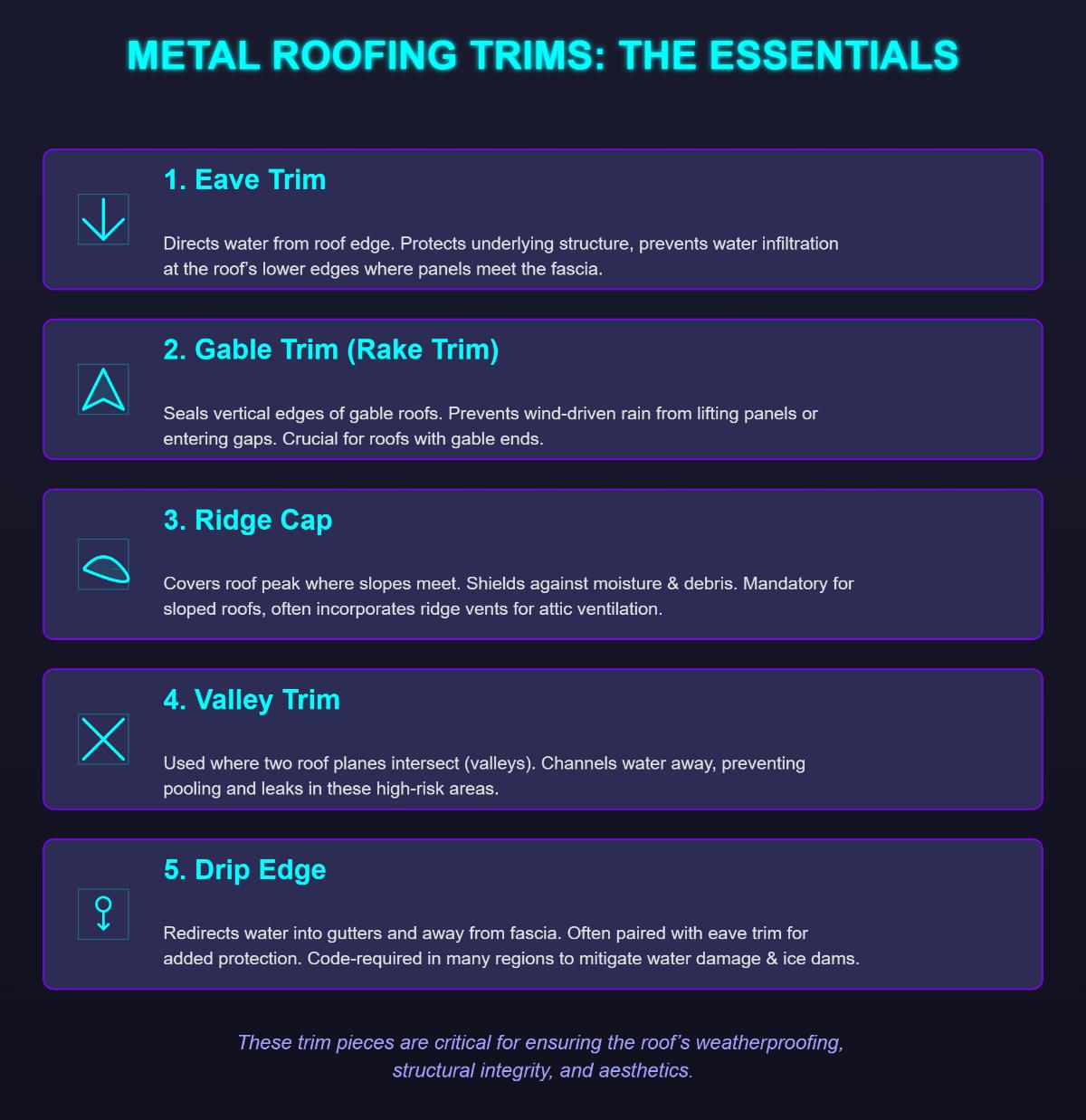

Eave trim is installed along the lower edges of a metal roof, where it meets the gutter or fascia. Its primary function is to direct water away from the roof edges, preventing water from seeping under the roofing panels and damaging the underlying structure. This trim also helps manage water runoff, especially in cases where gutters are not present. By finishing off the roof edge, eave trim enhances the roof’s appearance and provides a clean, polished look.

Gable trim, also known as rake trim, is used along the sloping edges of the roof that form the gable ends. This trim creates a clean, finished edge along the roof’s sides and protects the roof panels and the underlying structure from wind-driven rain and other weather elements. Gable trim not only safeguards the roof but also adds to the aesthetic appeal by creating a smooth transition between the roof and the gable walls.

The ridge cap is a crucial component installed at the peak or ridge of a metal roof where two roof slopes meet. Its primary purpose is to seal the ridge, preventing moisture, debris, and pests from entering the roof system through the ridge gap. Some ridge caps also allow for ventilation, reducing attic heat buildup and extending the roof’s lifespan.

Valley trim is installed in the valleys where two roof slopes meet, forming a V-shaped channel. This trim plays a vital role in directing water off the roof and into the gutters or downspouts, preventing water buildup and leaks at these critical points. By efficiently managing water flow, valley trim helps protect the roof structure from water damage and extends the durability of the roofing system.

Sidewall flashing is used where a metal roof intersects with a vertical wall, such as where a roof meets an upper story or a chimney. This trim seals the gap between the roof and the wall, preventing water from seeping in. Sidewall flashing is essential for channeling water away from these intersections and adding a clean, finished look to the roof’s perimeter.

Drip edge trim is installed along the roof’s edges to direct water away from the fascia and into the gutters. By preventing water from dripping down the sides of the building, drip edge protects the underlying structure from water damage and decay. This trim also helps maintain the integrity of the roof’s edge by reinforcing it against wind uplift and weathering, contributing to the roof’s overall longevity and performance.

When choosing metal roofing trim materials, comparing options based on durability, corrosion resistance, and ideal use cases is essential. Understanding these properties ensures an informed decision for specific roofing environments.

Aluminum: Aluminum is known for being lightweight yet strong, ensuring that the roofing trim doesn’t add significant weight to the structure while maintaining durability. Its properties make it less prone to physical damage and deformation under stress, ensuring longevity even in challenging conditions.

Galvalume: Galvalume is a steel substrate coated with a zinc-aluminum alloy, offering enhanced durability over traditional galvanized steel. The coating provides a protective barrier that significantly increases the material’s lifespan. It combines the strength of steel with the corrosion resistance of aluminum, making it a durable choice for various environmental conditions.

Aluminum: One of aluminum’s standout features is its excellent corrosion resistance. It naturally forms an oxide layer when exposed to the elements, protecting it from further corrosion. This property makes aluminum an ideal choice for coastal areas or regions with high humidity, where salt and moisture can accelerate corrosion in other metals.

Galvalume: Galvalume’s zinc-aluminum coating offers superior corrosion resistance compared to galvanized steel. The aluminum in the coating enhances the material’s ability to resist corrosion, while the zinc offers sacrificial protection, slowing down the rusting process. It performs exceptionally well in both rural and industrial environments, making it versatile for various applications.

Aluminum: Aluminum’s high corrosion resistance makes it ideal for coastal regions, as it withstands salty air and moisture, ensuring a longer lifespan with minimal maintenance. It is also suitable for inland climates, providing consistent performance and durability across different weather conditions.

Galvalume: Galvalume is highly effective in inland regions where the risk of salt corrosion is lower. Its strength and corrosion resistance make it a reliable option for areas with varied weather patterns, including heavy rain and snow. Although Galvalume offers good corrosion resistance, it may not perform as well as aluminum in extremely salty environments. However, it can still be a viable option with proper maintenance and protective coatings.

Consider the environmental conditions, structural requirements, and long-term maintenance needs when choosing between aluminum and Galvalume for your metal roofing trim. Assess the specific environmental conditions of the installation site, the weight-bearing capacity of the building structure, and the long-term maintenance requirements and lifespan of the material. By understanding the unique properties and advantages of aluminum and Galvalume, you can make an informed decision that ensures the longevity and performance of your metal roofing system.

Installing metal roofing trim correctly is essential for creating a strong, leak-proof roof. Here are the general steps to follow:

Optimal placement of each trim type is essential for effective roof protection and water management.

Considerations for different climates can influence the installation process and material choice.

Valley trim is crucial in managing water flow on metal roofs, especially where two roof slopes meet. Proper installation of valley trim ensures that water is directed efficiently into gutters, preventing water buildup and leaks.

Valley trim forms a V-shaped channel that directs water away from the roof, minimizing the risk of pooling and damage. The trim’s design allows for the seamless flow of water, which is particularly important during heavy rainfall. It also helps prevent debris from accumulating in the valley, which can obstruct water flow and cause leaks.

Flashing is vital for waterproofing various roof intersections and penetrations. Properly installed flashing prevents water from seeping into the roof structure, protecting against leaks and damage.

Proper installation of metal roofing trim is critical for preventing water infiltration. Avoiding common mistakes can significantly enhance the roof’s performance and longevity.

Regular maintenance of metal roofing trim is essential for ensuring its longevity and effectiveness in preventing water infiltration.

By following these guidelines and regularly maintaining metal roofing trim, you can effectively prevent water infiltration and extend the life of your roofing system.

Below are answers to some frequently asked questions:

For a basic metal roofing installation, the essential trim pieces are:

These trim pieces are critical for ensuring the roof’s weatherproofing, structural integrity, and aesthetics.

Valley trim is essential in preventing water damage by managing the flow of water in the internal angles where two roof planes meet, forming a valley. These areas are particularly susceptible to water accumulation during rainstorms. Valley trim creates a waterproof channel that directs runoff towards the gutters, ensuring that water does not pool in these critical areas. This effectively reduces the risk of leaks and potential water damage to the interior of the home.

Additionally, valley trim is typically made from durable metal materials that can withstand harsh weather conditions, further enhancing its ability to prevent water seepage. Proper installation is crucial; the trim must be securely fastened and correctly overlapped with surrounding roofing materials to ensure it remains watertight. By creating a secure channel for water runoff, valley trim helps maintain the overall integrity of the roof and extends its lifespan. Regular inspection and maintenance of the valley trim can also help identify and address any potential issues before they lead to significant damage.

Gable trim and eave trim are both essential components in metal roofing but serve distinct purposes and are installed in different locations.

Gable trim is used at the edges of the roof where it meets the endwall panels, particularly at the gable ends of a building. Its primary function is to prevent water and debris from entering the roof system, thereby protecting against heavy winds and rain. Additionally, gable trim contributes to the roof’s aesthetic by providing a clean, finished look.

Eave trim, also known as eave drip, is installed along the lower edges of the roof, specifically where the fascia board is located. Its main role is to redirect rainwater away from the roof’s perimeter and into the gutter system, thus preventing water from running down the walls and causing potential damage. Eave trim is crucial for managing rainwater flow, especially in homes without gutters.

The key differences between the two lie in their installation locations and specific functions. Gable trim addresses the gable ends of the roof, while eave trim manages water flow at the roof’s lower edges. Both trims enhance the roof’s durability and appearance but serve different protective roles.

When choosing between Aluminum and Galvalume for your roofing trim, consider several key factors including environmental conditions, budget, and specific project requirements. Galvalume, a steel product coated with a zinc-aluminum alloy, is known for its strength, durability, and cost-effectiveness. It is particularly suitable for non-coastal areas where saltwater corrosion is minimal. Its zinc-aluminum coating offers good corrosion resistance for typical weather conditions, while its steel core provides superior mechanical strength, making it ideal for applications requiring robustness.

Aluminum, on the other hand, excels in environments where corrosion resistance is critical, such as coastal or marine areas. It naturally resists rust and saltwater-induced corrosion far better than Galvalume, whose coating can degrade in high salt exposure. Aluminum’s lighter weight also simplifies handling and installation, reducing the load on the roof structure. Additionally, aluminum’s malleability allows for more intricate and customized trim designs, enhancing aesthetic appeal.

Metal roofing trim should be maintained through biannual inspections, typically in the spring and fall, to check for signs of damage, rust, corrosion, loose fasteners, and degraded sealants. Annual cleaning is essential to remove dirt, debris, and leaves that can cause moisture buildup and potentially lead to rust or corrosion. Additionally, re-sealing joints and seams as needed will help maintain watertight barriers. After severe weather events, conduct extra inspections to identify any immediate damage, such as dents or dislodged trim pieces.

Replacement of metal roofing trim is necessary if there is significant corrosion, structural damage, or failure of protective coatings. Persistent leaks or extensive rust that compromise the integrity of the metal indicate it’s time for replacement. With regular maintenance, metal roofing trim can last many years, often matching the lifespan of the metal roof panels. Neglecting maintenance can accelerate wear and shorten the trim’s effective lifespan.

Yes, metal roofing trim can be installed in all climates. The versatility and durability of metal roofing trim make it suitable for a wide range of environmental conditions, from hot and dry regions to humid and coastal areas, as well as cold and snowy climates. For hot climates, materials like galvanized steel and aluminum are preferred for their heat resistance. In humid and coastal regions, corrosion-resistant materials such as aluminum and zinc-coated steel are ideal due to their ability to withstand salty air and moisture. In cold and snowy environments, metal roofing trim effectively manages snow and withstands low temperatures. Additionally, secure fastening methods ensure that metal trim remains in place in wind-prone areas. Proper material selection and installation techniques are crucial for ensuring the trim’s performance and longevity across different climates.