In the vast and intricate world of shipbuilding, welding stands as one of the most crucial elements that ensure the structural integrity and longevity of vessels. Ever wondered how colossal ships withstand the relentless forces of the ocean? The answer lies in the mastery of diverse welding techniques tailored to various materials and applications. This comprehensive guide delves into the five primary welding methods employed in shipbuilding, offering insights into their processes, applications, and the unique advantages each brings to the table. Whether you’re curious about the efficacy of submerged arc welding or the versatility of gas metal arc welding, this article promises a deep dive into the technical nuances that define modern ship construction. Ready to set sail on this technical journey? Let’s explore the welds that keep the maritime world afloat.

Welding is essential in shipbuilding for joining metal parts to form a strong and unified structure. The integrity and durability of a ship heavily depend on the quality of the welds. High-strength and durable welds are crucial to withstand the harsh marine environment, including exposure to saltwater, high winds, and heavy loads.

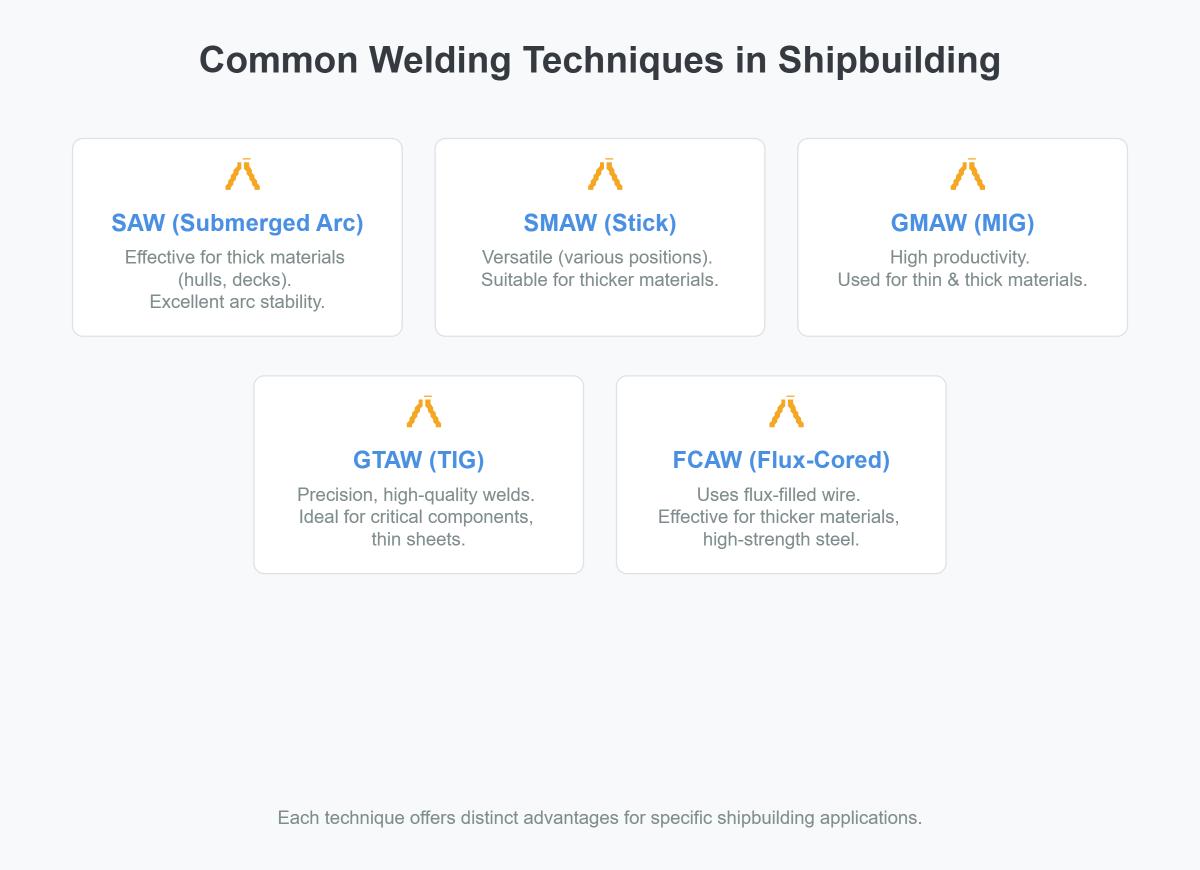

Several welding techniques are commonly used in shipbuilding, each with specific advantages and applications. Understanding these techniques is crucial for selecting the appropriate method for different parts of the ship.

Arc welding is one of the most widely used techniques in shipbuilding due to its efficiency and versatility. It involves creating an electric arc between an electrode and the base material to melt the metals at the welding point. Shielding gas or flux is often used to prevent oxidation and contamination. Arc welding is suitable for various positions and types of metals, making it a go-to method for many shipbuilding applications.

Gas welding, although less common in modern shipbuilding, is still utilized for specific tasks requiring precision. This technique involves using a flame produced by burning a gas (typically acetylene) with oxygen to melt and fuse metals. Gas welding is particularly useful for thin materials and in situations where portability is essential.

Resistance welding involves generating heat through the resistance to an electric current passed through the metal pieces being joined. This method is less prevalent in shipbuilding but is used for specific applications where high-speed production and repeatability are required. It is commonly used for welding thin sheets of metal and small components.

Selecting the appropriate welding technique for shipbuilding involves several considerations:

Different materials require specific welding techniques for optimal results. For instance, aluminum and stainless steel have different thermal properties, necessitating techniques like Gas Metal Arc Welding (GMAW) for aluminum and Gas Tungsten Arc Welding (GTAW) for stainless steel. The structural integrity of ship components also dictates the welding method. Critical parts like the keel, framing, and plating need robust techniques such as Submerged Arc Welding (SAW) to ensure high-strength welds.

The working environment influences the choice of welding technique. For example, Flux-Cored Arc Welding (FCAW) is preferred outdoors due to its ability to perform well without shielding gas, making it less affected by wind.

Shipbuilding is a time-sensitive process, and the efficiency of welding techniques plays a significant role. Techniques like GMAW are favored for their speed and ability to maintain high productivity levels while ensuring quality.

Submerged Arc Welding (SAW) is ideal for welding thick structural steel due to its high deposition rates and minimal contamination, making it crucial for ship framing and girders. Similarly, Gas Metal Arc Welding (GMAW), known for its speed and efficiency, is useful for welding aluminum and stainless steel, with pulsed MIG welding offering improved penetration and productivity.

FCAW offers high deposition rates and is effective for thick structural steel, often used in outdoor conditions without shielding gas. This technique is valued for its robustness and versatility in different shipbuilding scenarios.

GTAW provides high precision and quality, ideal for thin materials and complex joints. This technique is crucial for tasks requiring meticulous control and high-quality welds.

Laser welding offers minimum heat input, reducing distortion and is ideal for advanced shipbuilding applications. It is increasingly used for precise and high-quality welds in critical areas.

Friction Stir Welding (FSW) uses friction to create welds, which reduces distortion. This technique is increasingly popular for joining aluminum structures in naval applications due to its ability to produce high-strength, defect-free welds.

Combining the benefits of laser and arc welding, HLAW provides reduced distortion and improved efficiency. This hybrid technique is gaining popularity for its ability to deliver high-quality welds with enhanced productivity.

Flux-Cored Arc Welding (FCAW) is a welding technique that uses a wire filled with flux to create an electric arc, melting the wire and the base material to form a weld. The flux within the wire provides shielding from atmospheric contamination and helps stabilize the arc, enhancing the weld quality.

There are two main types of FCAW: Self-Shielded FCAW (FCAW-S), which uses flux within the wire for shielding gas, making it ideal for outdoor use; and Gas-Shielded FCAW (FCAW-G), which uses an external shielding gas to enhance weld quality in controlled environments.

FCAW is widely used in shipbuilding because it works well with metals like carbon steel and stainless steel, which are common in ships. Its high deposition rate makes it perfect for large projects. Key applications include welding the large steel plates that form the ship’s hull, fabricating and assembling internal structures such as bulkheads and frames, and performing on-site repairs and maintenance, especially in outdoor conditions.

FCAW is versatile, works in various positions, and is portable, especially the self-shielded type, which doesn’t need external gas. It’s also more tolerant of surface contamination, which is useful in shipbuilding. The high deposition rate increases productivity, making it ideal for large-scale projects.

FCAW generates significant fumes and slag, necessitating proper ventilation and post-weld cleanup. The specialized equipment and consumables can be more expensive than those for other welding methods. While relatively easy to learn, achieving consistent high-quality welds requires skilled operators.

To get the best results with FCAW in shipbuilding, set up your equipment correctly, use proper welding techniques, clean the workpiece, wear safety gear, ensure good ventilation, and regularly inspect welds to meet quality standards.

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding, is widely used in shipbuilding. It involves the use of a consumable wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. The wire is continuously fed through a welding gun, where it melts and joins the base materials, while the shielding gas, usually argon or a mixture of argon and carbon dioxide, ensures a clean and stable arc.

GMAW is particularly favored in shipbuilding for its versatility and efficiency. It is employed in various applications, including:

GMAW is widely used to make and repair structural parts of ships, such as decks, hulls, and bulkheads, thanks to its strong, high-quality welds with minimal distortion.

This welding technique is effective for joining metal sheets commonly found in superstructures and other parts of the ship. The process’s speed and adaptability allow for efficient assembly and repairs, enhancing construction timelines and reducing overall labor costs.

Ensuring clean and smooth joint surfaces is vital for achieving strong and durable welds. Removing any contaminants such as oil, rust, or dirt can significantly improve weld quality.

Correctly setting voltage, current, and travel speed is crucial for optimal weld quality. Adjusting these parameters based on the material type and thickness ensures consistent and defect-free welds.

Choosing the appropriate shielding gas composition is essential for protecting the weld pool and stabilizing the arc. For example, a mixture of argon and carbon dioxide is commonly used for welding steel, while pure argon is preferred for aluminum.

Using techniques like stringer beads and weave patterns ensures consistent weld quality and better control over the weld pool, especially useful for thicker materials and complex joints.

Regular inspection of welds and maintenance of welding equipment are necessary to ensure high-quality outcomes. Identifying and addressing any issues promptly can prevent defects and enhance Following these best practices allows shipbuilders to fully leverage GMAW, creating ships that meet strict industry standards and withstand tough maritime conditions. Continuous training and adherence to safety guidelines are essential for optimizing welding efficiency and quality in shipbuilding.

Submerged Arc Welding (SAW) is a highly efficient welding process widely used in shipbuilding. It uses an arc created between a consumable electrode and the workpiece, all covered by a layer of granular flux. This flux serves multiple purposes, including shielding the weld zone from atmospheric contamination, stabilizing the arc, and adding alloying elements to the weld pool. The SAW process is renowned for producing high-quality, uniform welds with deep penetration and minimal spatter.

SAW is particularly suited for heavy-duty welding tasks in shipbuilding, such as:

Proper handling and storage of the flux are essential to prevent contamination and moisture absorption, which can adversely affect weld quality. The flux should be kept dry and free from impurities.

Setting the correct welding parameters, including voltage, current, travel speed, and electrode extension, is crucial for achieving optimal weld quality. These parameters should be tailored to the specific material thickness and joint configuration.

It’s essential to keep the workpiece clean and free from contaminants like oil, rust, and paint to prevent weld defects. Proper joint preparation, such as beveling and aligning, improves weld penetration and fusion.

Regular inspection and testing of the welds, such as visual inspection, ultrasonic testing, and radiographic testing, help identify any defects or discontinuities that need to be addressed. This ensures the structural integrity of the welded components.

By adhering to these best practices, shipbuilders can maximize the benefits of SAW, producing high-quality welds that meet stringent industry standards and contribute to the durability and safety of maritime vessels.

Shielded Metal Arc Welding (SMAW), also known as stick welding, is a common and versatile welding method used in shipbuilding. It creates an electric arc between a flux-coated consumable electrode and the workpiece, generating heat that melts both the electrode and the base material to form a weld pool. The flux coating decomposes to produce a gas shield that protects the molten weld pool from atmospheric contamination and forms a layer of slag to cover the weld bead.

SMAW is highly versatile and can weld various metals, including steel, stainless steel, and cast iron. This makes it ideal for shipbuilding, where different metal types are used for various components.

SMAW can be performed in all positions—flat, horizontal, vertical, and overhead—making it highly adaptable for shipbuilding, where welds may need to be made in confined spaces or at difficult angles.

SMAW is extensively used for repair and maintenance in shipbuilding due to its portability and simplicity. The minimal equipment requirements make it ideal for on-site repairs, allowing for quick and effective welding without extensive setup.

SMAW equipment is compact and portable, making it easy to use in different locations within a shipyard or for on-site repairs. It’s cost-effective due to minimal setup and equipment needs, and it can be used on a wide range of materials in all welding positions. Additionally, the flux coating protects the weld from environmental factors, making it suitable for outdoor work.

Achieving high-quality welds with SMAW requires a skilled operator. The manual nature of the process means that welder technique significantly affects the outcome. The slag formed during welding must be removed after each pass, which can be time-consuming and labor-intensive. Furthermore, SMAW produces a significant amount of fumes and smoke, necessitating proper ventilation and safety measures to protect the welder’s health.

Choosing the appropriate electrode is crucial for achieving high-quality welds. Common electrodes used in shipbuilding include:

Proper control of welding parameters such as current, voltage, electrode angle, and travel speed is essential for quality welds. Higher currents increase penetration but require careful management to avoid excessive weld pool size.

Employing specific techniques can improve weld quality:

Safety is critical in welding. Essential safety equipment includes a welding helmet with a filter lens to protect the eyes, gloves and protective clothing to shield from heat and sparks, ear protection against noise, and proper ventilation to reduce exposure to fumes and gases.

Maintaining high weld quality involves regular inspection and adherence to best practices:

By adhering to these best practices, shipbuilders can maximize the effectiveness of SMAW, ensuring durable and high-quality welds essential for the structural integrity and longevity of maritime vessels.

Gas Tungsten Arc Welding (GTAW), or Tungsten Inert Gas (TIG) welding, uses a non-consumable tungsten electrode to create precise welds. This process is characterized by the use of an inert shielding gas, typically argon or helium, to protect the weld area from atmospheric contamination, and the high melting point and excellent electrical conductivity of tungsten create a stable arc crucial for high-quality welds.

In shipbuilding, GTAW is prized for producing clean, high-quality welds with minimal spatter and distortion. Key applications include:

Advantages

Limitations

Proper Preparation

Equipment and Setup

Welding Technique

Safety Precautions

By adhering to these best practices, shipbuilders can leverage the advantages of GTAW to produce high-quality, durable welds essential for the integrity and safety of maritime vessels.

Each material used in shipbuilding needs specific welding techniques to guarantee performance, durability, and structural integrity. The selection of the appropriate welding method is crucial for achieving high-quality welds that meet the stringent demands of maritime applications.

High-strength steel is commonly used in the construction of ship hulls and structural components due to its excellent mechanical properties and resistance to impact. Submerged Arc Welding (SAW) is preferred for high-strength steel, especially for welding thick plates. It provides deep penetration and high deposition rates, making it suitable for long, continuous welds required in hull construction. Flux-Cored Arc Welding (FCAW) works well for thick structural steel, even in challenging positions like vertical and overhead. The self-shielded variant (FCAW-S) is particularly useful for outdoor applications where shielding gas is impractical.

Aluminum alloys are lightweight and corrosion-resistant, making them suitable for superstructures, deckhouses, and other non-structural components. Gas Metal Arc Welding (GMAW) efficiently welds aluminum. It provides a stable arc and minimal distortion, which is essential for maintaining the integrity of thin aluminum sheets. Friction Stir Welding (FSW) is a solid-state process that joins aluminum components without melting, reducing distortion and improving weld quality. It is particularly effective for long, continuous welds in aluminum structures.

Stainless steel is used in shipbuilding for its corrosion resistance and strength, particularly in areas exposed to harsh marine environments. Gas Tungsten Arc Welding (GTAW) is preferred for welding stainless steel due to its precision and ability to produce high-quality welds with minimal contamination. It is ideal for thin materials and complex joints. Gas Metal Arc Welding (GMAW) can also be used for welding stainless steel, offering higher productivity and ease of use. It is suitable for thicker sections and less critical applications.

Carbon steel is widely used in shipbuilding for its strength, affordability, and ease of welding. Shielded Metal Arc Welding (SMAW), or stick welding, is versatile and effective for welding carbon steel in various positions and environments. It is widely used for repairs and on-site work due to its portability. Flux-Cored Arc Welding (FCAW) is suitable for welding thicker carbon steel sections, providing high deposition rates and good penetration. The process is effective in both indoor and outdoor environments.

The performance of different welding techniques can be compared based on several criteria, including weld quality, productivity, ease of use, and suitability for specific materials and applications.

Gas Tungsten Arc Welding (GTAW) provides the highest weld quality with minimal defects, making it ideal for critical and high-precision applications. Submerged Arc Welding (SAW) produces high-quality welds with deep penetration, suitable for thick structural components. Gas Metal Arc Welding (GMAW) offers good weld quality with minimal spatter, effective for a range of materials including aluminum and stainless steel. Flux-Cored Arc Welding (FCAW) provides robust welds with good penetration, but requires proper slag removal and ventilation.

Submerged Arc Welding (SAW) boasts high deposition rates and automation capabilities, making it the most productive for large-scale applications. Gas Metal Arc Welding (GMAW) continuous wire feed and high welding speeds contribute to high productivity, especially for long, straight welds. Flux-Cored Arc Welding (FCAW) offers high deposition rates and is effective in various positions, enhancing productivity in diverse applications.

Shielded Metal Arc Welding (SMAW) is simple and portable, suitable for repairs and on-site work, but requires skilled operators for consistent quality. Gas Metal Arc Welding (GMAW) is relatively easy to learn and operate, making it accessible for various skill levels. Gas Tungsten Arc Welding (GTAW) requires high skill and precision, best suited for experienced welders.

Submerged Arc Welding (SAW) is best for high-strength steel and thick materials. Gas Metal Arc Welding (GMAW) is versatile for aluminum, stainless steel, and carbon steel. Gas Tungsten Arc Welding (GTAW) is ideal for thin materials and high-precision applications. Flux-Cored Arc Welding (FCAW) is effective for thick structural steel and carbon steel.

A major shipyard used SAW to construct a new fleet of cargo ships, achieving deep penetration and high deposition rates to ensure durable hulls that withstand harsh maritime conditions. A naval shipbuilder utilized FSW to join aluminum components for a series of patrol boats. The solid-state welding process minimized distortion and defects, resulting in lightweight and high-strength superstructures that enhanced the vessels’ performance and fuel efficiency. A luxury yacht manufacturer used GTAW to weld the stainless steel piping systems on its latest model. The precision and high weld quality achieved with GTAW ensured leak-free and corrosion-resistant joints, critical for the yacht’s operational reliability and longevity. During the maintenance of a commercial vessel, SMAW was extensively used to repair the carbon steel structures. The portability and versatility of SMAW allowed the repair team to address various issues quickly and effectively, ensuring the vessel’s timely return to service.

Rapid technological advancements in the shipbuilding industry are enhancing efficiency, safety, and environmental sustainability. Innovations such as digital twin technology create virtual replicas of ships, enabling real-time monitoring and predictive maintenance. Automation and robotics are also improving the precision and speed of construction processes.

Stricter environmental regulations are shaping the shipbuilding industry, driving the adoption of greener technologies. The International Maritime Organization (IMO) has implemented regulations to reduce sulfur emissions and greenhouse gases. This has prompted shipbuilders to explore alternative fuels such as liquefied natural gas (LNG) and hydrogen. Energy-efficient designs and propulsion systems are becoming increasingly important as well.

Supply chain disruptions, worsened by the COVID-19 pandemic, have significantly challenged the shipbuilding industry. Delays in the delivery of critical components, fluctuating material costs, and labor shortages have impacted production schedules and increased operational costs. Shipbuilders are focusing on enhancing supply chain resilience through strategic sourcing and improved inventory management.

Welding techniques play a crucial role in the economic efficiency of shipbuilding projects. Advanced welding processes like Submerged Arc Welding (SAW) and Gas Metal Arc Welding (GMAW) offer high deposition rates and automation capabilities, reducing labor costs and production time. Adopting efficient welding methods directly impacts the cost-effectiveness and competitiveness of shipyards.

The environmental impact of welding techniques is a growing concern within the shipbuilding industry. Traditional welding processes can generate significant fumes, gases, and waste materials. To mitigate these effects, shipbuilders are increasingly adopting eco-friendly welding technologies, such as laser welding and friction stir welding, which produce minimal emissions and waste. The use of corrosion-resistant materials and advanced welding techniques also helps extend the lifespan of vessels, reducing the frequency of repairs and replacements.

Countries such as China, South Korea, and Japan dominate the global shipbuilding market, accounting for a significant share of new vessel deliveries. These nations benefit from advanced infrastructure, skilled labor, and supportive government policies. European countries like Germany and Italy are also notable players, particularly in the construction of specialized vessels and luxury yachts.

The demand for new ships is influenced by various factors, including global trade volumes, fleet renewal programs, and technological advancements. The increasing focus on sustainability and energy efficiency is driving the development of eco-friendly ships. Moreover, the growth of offshore wind energy projects is creating new opportunities for shipbuilders to construct specialized vessels for the installation and maintenance of wind farms.

The shipbuilding industry is highly competitive, with shipyards striving to differentiate themselves through technological innovation, quality, and cost-effectiveness. Strategic partnerships and collaborations with technology providers, material suppliers, and research institutions are essential for staying ahead in this dynamic market. The ability to adapt to changing market demands and regulatory requirements is crucial for long-term success.

Ongoing investment in research and development, along with the use of advanced manufacturing techniques, will be crucial for staying competitive and tackling future maritime challenges.

Hybrid Laser Arc Welding (HLAW) is revolutionizing shipbuilding by combining the precision of laser welding with the robustness of arc welding. This innovative method reduces distortion and boosts efficiency, especially with thinner steel plates. By integrating these two technologies, HLAW achieves high-quality welds with enhanced productivity, making it ideal for critical shipbuilding applications.

Friction Stir Welding (FSW), developed by The Welding Institute in England, is a solid-state welding process that joins materials without melting them. FSW is especially advantageous for aluminum structures. It provides defect-free welds with minimal distortion. This technique is increasingly used in shipbuilding for applications such as fishing boats and U.S. Navy ships, where high-strength, lightweight welds are required.

Explosion Welding uses controlled explosive force to bond dissimilar metals, like aluminum to steel. This technique simplifies the joining process, previously done with thousands of nuts and bolts, and enhances structural integrity while reducing labor. Explosion welding is valuable in shipbuilding for creating strong, durable connections between different materials.

The integration of collaborative robots, or cobots, in shipbuilding is transforming welding operations. Cobots handle repetitive tasks, freeing skilled welders to focus on complex jobs, thus improving productivity, reducing errors, and boosting overall efficiency.

Innovations in laser sensing technologies are revolutionizing welding quality control. These advanced sensors provide real-time data analysis, enabling immediate detection and correction of weld defects. The implementation of such technologies ensures consistent weld quality and significantly reduces the likelihood of errors.

Virtual and augmented reality training programs are becoming essential tools in shipbuilding. These immersive technologies provide realistic training environments for welders, reducing the risk and cost associated with traditional training methods. Enhanced skill levels and improved safety are direct benefits of adopting VR and AR in welding education.

Inverter power supplies are crucial for modern shipbuilding, providing compact and portable welding solutions. These advanced power supplies enhance productivity and ease of use, allowing welders to work efficiently in various shipyard environments.

High-power multi-process welders are increasingly utilized in shipbuilding, supporting techniques such as MIG, TIG, and SAW. These versatile machines enable flexible and efficient operation, catering to the diverse welding needs of ship construction and repair.

Submerged Arc Welding (SAW) remains a staple in shipbuilding for thick structural steel applications. Its high deposition rates and superior weld quality make it indispensable for welding ship frames and structural members. The evolution of SAW continues to enhance productivity and weld integrity in shipbuilding.

Flux-Cored Arc Welding (FCAW) and MIG Welding are highly productive techniques widely used in shipbuilding. FCAW provides deeper penetration, making it suitable for thick steel sections, while MIG Welding offers ease of use, particularly for aluminum welding. Both techniques contribute significantly to the efficiency of ship construction processes.

The use of thinner, higher-strength steel plates in shipbuilding presents both challenges and advantages. While these materials can reduce heat-induced distortion and improve efficiency, they require advanced welding techniques to ensure structural integrity and performance.

Integrating aluminum superstructures with steel hulls necessitates sophisticated welding methods to achieve strong, lightweight constructions. Advanced techniques such as FSW and HLAW are crucial for creating durable hybrid structures that meet the stringent demands of modern shipbuilding.

Below are answers to some frequently asked questions:

The most common welding techniques used in shipbuilding are Submerged Arc Welding (SAW), Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Flux-Cored Arc Welding (FCAW). SAW is highly effective for welding thick materials such as hulls and decks, offering excellent arc stability. SMAW, also known as stick welding, is versatile and suitable for various positions and thicker materials. GMAW, or MIG welding, is known for its high productivity and is used for both thin and thick materials. GTAW, or TIG welding, is prized for its precision and high-quality welds, ideal for critical components and thin sheets. FCAW is similar to GMAW but uses a flux-filled wire, making it effective for thicker materials and high-strength steel. Each technique offers distinct advantages, making them suitable for different applications in shipbuilding.

In shipbuilding, different welding techniques are chosen based on the materials used and the specific requirements of the application. For thick structural steel, methods like Flux-Cored Arc Welding (FCAW) and Submerged Arc Welding (SAW) are preferred due to their high deposition rates and deep penetration capabilities. Shielded Metal Arc Welding (SMAW) is versatile and effective for welding in various positions and challenging conditions, making it suitable for thick materials.

For aluminum alloys, commonly used in high-speed vessels to reduce weight, Gas Metal Arc Welding (GMAW) or MIG welding is ideal due to its speed and efficiency. Gas Tungsten Arc Welding (GTAW), or TIG welding, is used for its precision and quality, making it suitable for thin materials and complex joints, which are crucial for maintaining structural integrity in critical areas.

Stainless steel, known for its corrosion resistance, often requires TIG welding for high-quality, precise welds. Carbon steel, a common material in shipbuilding, can be welded using various techniques depending on the specific application, balancing strength and flexibility.

Advanced methods like laser welding and friction stir welding (FSW) are also emerging, offering precision and minimal distortion, especially beneficial for delicate structures and vertical joints in aluminum superstructures.

Submerged Arc Welding (SAW) offers several advantages in shipbuilding, making it a preferred method for many large-scale projects. Firstly, SAW provides a high deposition rate, which significantly enhances productivity. This is particularly beneficial in shipbuilding, where large volumes of weld metal are required. The continuous feed of the electrode wire allows for uninterrupted welds, reducing downtime.

Secondly, SAW produces high-quality welds with deep penetration, essential for the thick steel plates commonly used in shipbuilding. This results in strong, durable welds with excellent mechanical properties, such as enhanced toughness and strength.

Additionally, the flux layer in SAW minimizes exposure to harmful fumes and UV radiation, creating a safer working environment. It also reduces spatter, further enhancing safety and cleanliness.

SAW is often automated, ensuring consistent weld quality and reducing labor costs. The process is also cost-effective due to the elimination of shielding gases and the straightforward setup.

In shipbuilding welding, several standards and regulations must be followed to ensure the structural integrity and safety of vessels. Key regulations include those set by classification societies such as the International Association of Classification Societies (IACS), Lloyds Register, Det Norske Veritas (DNV), and the American Bureau of Shipping (ABS). These organizations provide detailed rules for welding procedures, welder qualifications, and material selection.

Welding procedures must be supported by a Welding Procedure Qualification Record (WPQR) and adhere to standards like ISO 15614-1, ASME IX, and ANSI/AWS D1.1. Welders themselves must be certified according to standards such as EN 287, ISO 9606, and ASME Section IX.

Welding operations should be properly supervised, with approved materials and consumables used, all meeting specific standards for structural integrity. Additionally, safety and health regulations, such as those provided by OSHA in the United States, must be followed to ensure safe working conditions. Adherence to these standards ensures high-quality welds and the safety of the workers involved.

To optimize welding efficiency in shipbuilding, several strategies can be employed. Firstly, utilizing advanced welding processes such as MIG, TIG, and Submerged Arc Welding (SAW) can significantly enhance productivity and quality. These methods offer high deposition rates, precision, and are well-suited for various shipbuilding materials.

Incorporating modern technologies like laser welding, electron beam welding, and friction welding can further boost efficiency by providing precise, high-speed welds with minimal distortion. Automation and AI integration play a crucial role in optimizing welding tasks, as AI can plan weld sequences and manage heat inputs effectively, reducing lead times and errors.

Ensuring the use of reliable equipment and specialized welding materials tailored for shipbuilding, such as high-strength low-alloy steel, is essential. Additionally, a skilled workforce with proper certification and knowledge of safety standards is critical for maintaining efficiency and quality.

Continuous process optimization, leveraging new technologies, and regularly assessing welding operations can help in adapting to advancements and improving overall productivity.

Several successful shipbuilding projects have utilized advanced welding techniques to achieve superior structural integrity and efficiency. One notable example is the use of Friction Stir Welding (FSW) for welding aluminum extrusions in the construction of integrally stiffened panels, essential for decks, bulkheads, and helicopter landing platforms. This technique enhances strength and corrosion resistance while reducing production time and costs.

Another example is the application of Submerged Arc Welding (SAW) and Flux-Cored Arc Welding (FCAW) in constructing and repairing ship hulls. SAW is particularly effective for large-scale applications due to minimal atmospheric contamination, whereas FCAW efficiently handles high-strength steel.

MIG welding, including pulsed MIG, has been employed for welding aluminum in high-speed vessels like coastguard boats, offering improved penetration and deposition rates.

Gas Tungsten Arc Welding (GTAW), including orbital TIG, has been used for precise welding of complex systems such as hydraulic lines in sophisticated vessels like FPSOs, ensuring high weld quality and precision.

These techniques have significantly contributed to the durability, safety, and operational efficiency of modern ships, demonstrating the critical role of advanced welding in the shipbuilding industry.