Imagine embarking on a construction project only to realize that your fasteners are failing to hold. The secret to a secure and durable structure often lies in the often-overlooked component: masonry anchors. Whether you’re hanging heavy artwork on a brick wall or securing shelving in a concrete garage, choosing the right masonry anchor is crucial. In this comprehensive guide, we delve into the seven types of masonry anchors and their specific uses, helping you navigate the selection process with confidence. You’ll discover the distinct advantages of both mechanical and chemical anchors and learn how to choose the best option for your unique project needs. Ready to ensure your next project is built to last? Let’s explore the world of masonry anchors and unlock the secrets to their effective application.

Masonry anchors are essential components in construction and engineering, designed to provide secure attachment points for various fixtures and structures on masonry surfaces such as brick, concrete, and stone. Understanding the purpose, types, and applications of these anchors is crucial for ensuring the stability and safety of any masonry-related project.

Masonry anchors work by gripping or expanding within the masonry, creating strong and reliable connections. This anchoring mechanism ensures that fixtures remain securely attached, distributing loads effectively and preventing pull-out or loosening over time. The fundamental steps in using masonry anchors include:

There are various types of masonry anchors, each designed for specific materials, loads, and applications. The most common categories include:

These anchors rely on mechanical expansion to hold tightly to the masonry. Common types include:

Concrete screws are self-tapping fasteners that create their own threads in pre-drilled holes. They offer a quick and efficient fastening solution for medium-duty attachments and are ideal for projects that require frequent removals or adjustments.

Plastic plugs expand inside drilled holes when a screw is inserted. They are suitable for lighter loads and less dense masonry materials such as brick or hollow blocks. These are often used in DIY projects, such as hanging pictures or installing light fixtures.

Anchor bolts are embedded in concrete to provide a fixed point for structural connections, while lag shields are tubular metal inserts that expand to hold lag screws in masonry. These anchors are typically employed in heavy structural or mechanical fixings.

Choosing the correct masonry anchor involves several factors, including:

Masonry anchors are used across a wide range of applications, from simple home improvement projects to complex industrial installations. They provide secure attachment points for:

Expansion anchors securely grip masonry by expanding within a pre-drilled hole. This expansion mechanism ensures a strong and stable connection, making them ideal for various heavy-duty applications.

Wedge anchors, known for their high holding power, consist of a threaded stud, a nut, and an expansion clip. When the nut is tightened, the expansion clip is pulled up the cone-shaped end, causing it to expand and grip the walls of the hole.

Applications:

Advantages:

Considerations:

Sleeve anchors have a split sleeve that expands as the bolt is tightened. They are suitable for use in a variety of masonry materials, including concrete, brick, and block.

Applications:

Advantages:

Considerations:

Concrete screws, or threaded anchors, are self-tapping screws made for masonry. They cut threads into the walls of a pre-drilled hole, creating a secure hold without the need for expansion.

Applications:

Advantages:

Considerations:

Epoxy anchors use a resin that hardens, bonding the anchor to the masonry. This type of anchor provides an exceptionally strong hold, even in weak or cracked masonry.

Applications:

Advantages:

Considerations:

Anchor bolts are metal rods embedded in masonry or concrete, with one end projecting to secure structural or non-structural components. They are often used in foundational applications.

Applications:

Advantages:

Considerations:

Wall plugs are tubular inserts that expand when a screw is driven in, gripping the masonry to provide a secure hold. They are commonly used for lighter loads and DIY projects.

Applications:

Advantages:

Considerations:

Mechanical expansion anchors are specialized fasteners used in masonry that expand within a pre-drilled hole to provide a strong and reliable hold. This expansion mechanism ensures a secure attachment in various masonry materials, making them ideal for diverse construction and engineering applications.

Wedge anchors consist of a threaded rod, an expansion wedge, and a nut. Tightening the nut pulls the wedge into the anchor body, causing it to expand and grip the hole’s walls.

Applications and Advantages:

Installation:

Sleeve anchors are versatile mechanical expansion anchors suitable for light to medium-duty applications. They consist of a threaded bolt, an expansion sleeve, and a nut or washer. As the nut is tightened, the sleeve expands, creating a secure hold within the masonry.

Applications and Advantages:

Installation:

Drop-in anchors are designed for flush mounting in solid concrete. They consist of a metal sleeve with an internal expansion plug. When a setting tool is used, the plug is driven into the sleeve, causing it to expand and grip the concrete.

Applications and Advantages:

Installation:

When selecting mechanical expansion anchors, consider the following factors:

Proper installation and safety practices are crucial:

By understanding the various types of mechanical expansion anchors and their applications, you can select the most appropriate anchor for your specific needs, ensuring a safe and durable installation.

Chemical anchors, also known as adhesive anchors, are highly valued for their strength and versatility. These anchors use chemical adhesives to securely bond to various substrates, making them ideal for a wide range of applications.

Epoxy anchors are renowned for their high strength and excellent resistance to chemicals and environmental factors. The epoxy resin used in these anchors creates a strong bond with the substrate, making them ideal for applications that require long-term durability and stability.

Applications:

Advantages:

Polyester anchors are more cost-effective and easier to install compared to epoxy anchors. However, they offer lower strength and durability, making them suitable for lighter-duty applications where budget constraints are a priority.

Applications:

Advantages:

Epoxy acrylate anchors provide a blend of strength and flexibility, suitable for dynamic environments. Hybrid systems further enhance performance by combining properties of different chemical anchors to meet specific application requirements.

Applications:

Advantages:

Vinyl chemical anchors are high-performance solutions designed for demanding applications in both solid and hollow substrates. They offer high resistance to traction, vibrations, and fire, making them suitable for structural applications.

Applications:

Advantages:

Chemical anchors provide several benefits over traditional mechanical anchors, making them a preferred choice in many applications.

Chemical anchors offer superior bond strength compared to mechanical anchors. This makes them ideal for high-stress environments where heavy loads and structural integrity are critical.

These anchors are highly resistant to vibration and shock loads, which enhances their durability and performance in dynamic conditions. This characteristic is particularly beneficial in applications where the substrate is subject to frequent movement or impact.

Chemical anchors exhibit excellent resistance to corrosion and chemical attacks, ensuring a longer lifespan even in harsh environments. This makes them suitable for outdoor applications and areas exposed to chemicals.

Unlike mechanical anchors, chemical anchors provide more flexibility in load distribution. The adhesive used allows for better stress distribution across the substrate, reducing the risk of material failure.

To install chemical anchors:

Consider the following when choosing chemical anchors:

Chemical anchors are widely used in various sectors, such as:

Choosing the right masonry anchor is crucial for ensuring the safety, stability, and longevity of fixtures attached to masonry surfaces. Several factors must be considered to select the appropriate anchor for a specific application.

The type of masonry material plays a crucial role in determining the appropriate anchor. Solid materials like concrete, stone, and solid brick require different anchors than hollow or less dense materials like hollow brick or block. For instance, wedge anchors and drop-in anchors are well-suited for solid concrete due to their high holding power and expansion mechanisms. In contrast, sleeve anchors and plastic wall plugs are more versatile and can be used in both solid and hollow masonry, provided they are correctly sized and installed.

Understanding the load requirements is essential for selecting an anchor with adequate holding capacity. Heavy-duty applications, such as anchoring structural supports or heavy machinery, typically require high-strength anchors like wedge or epoxy chemical anchors, which provide robust and reliable holding power essential for safety-critical installations. For medium to light-duty applications, such as attaching handrails, shelving, or light fixtures, sleeve anchors, concrete screws, and plastic wall plugs may be sufficient.

The environment in which the anchor will be used also plays a critical role in the selection process. Factors such as exposure to moisture, chemicals, and temperature fluctuations can affect the anchor’s performance and longevity. Stainless steel or coated anchors are recommended for outdoor or corrosive environments to prevent rust and deterioration. Chemical anchors, especially those made from epoxy, offer excellent resistance to harsh environmental conditions, making them suitable for outdoor and industrial applications.

The anchor’s length and diameter are determined by the type and thickness of the fixture being attached. Adjustable anchors, such as sleeve anchors, can accommodate various fixture thicknesses, making them versatile for different applications. Drop-in anchors are ideal for flush mounting fixtures, providing a clean finish and reliable internal threading for bolts or rods. It is crucial to match the anchor size to the fixture’s requirements to ensure a secure and stable connection.

Installation constraints, including access to both sides of the masonry and the availability of installation tools, must be considered. Anchors like wedge and sleeve types need specific tools, such as wrenches or setting tools, for installation. Others, like concrete screws, offer easier installation with standard tools and do not require expansion mechanisms. Additionally, some anchors, such as anchor bolts, may need to be embedded during the masonry work, making them less suitable for retrofit applications without additional steps like using epoxy.

Carefully considering these factors and following the selection steps ensures you choose the right masonry anchor, leading to a secure and durable installation.

In an automotive assembly facility, the precision and stability of heavy machinery are paramount. Wedge anchor bolts were employed to secure heavy machinery, ensuring precise alignment and reducing downtime under dynamic loads. This application highlighted the anchors’ ability to handle the vibrations and movements typical in high-volume manufacturing environments, enhancing overall operational efficiency.

For a highway overpass project, 7/8-inch concrete anchor bolts were essential in reinforcing the bridge supports. These anchors demonstrated exceptional load-bearing capacity, ensuring the structural integrity of the overpass under heavy traffic conditions. The success of this application underscores the importance of selecting anchors with adequate strength for infrastructure projects.

In data centers, anchor bolts stabilized server racks and network cabinets, preventing displacement from vibrations and ensuring the security of critical data infrastructure. This application ensured the stability of crucial systems, minimizing the risk of operational disruptions and data loss.

In multistory commercial buildings and coastal residential areas, adhesive anchor bolts and 7/8-inch bolts were utilized to secure steel columns and foundations. These anchors provided superior tension and shear resistance, ensuring long-term structural integrity and resistance to earthquakes and strong winds. The corrosion-resistant properties of these anchors made them ideal for humid and saltwater-exposed environments, ensuring the durability and safety of the structures.

In historic building retrofits, specialty anchors stabilized aging terra cotta masonry, while helical anchors reinforced a partially collapsed 20-story warehouse. These solutions ensured structural integrity without compromising aesthetics. The use of tailored anchoring solutions in these contexts demonstrates the effectiveness of preserving historic structures while maintaining their architectural integrity.

The DryFix system was employed to repair the stucco façades of Broderick Tower, a historic landmark in Detroit. This non-invasive approach preserved the building’s architectural integrity, avoiding the need for full replacement. The success of this project illustrates the advantages of innovative anchoring systems in preserving historic buildings.

In coastal residential foundations, 7/8-inch bolts with high corrosion resistance ensured structural stability and longevity despite humidity and saltwater exposure. These anchors were crucial for maintaining the integrity of structures in challenging environmental conditions, making them ideal for coastal construction projects.

The Helifix system addressed cracking in exterior stucco by reinforcing the material rather than replacing it. This solution was particularly effective in moisture-prone environments, providing a durable and cost-effective method for preserving the appearance and integrity of stucco façades.

Different applications highlight the importance of selecting anchors based on load requirements, material compatibility, and environmental factors. For example, wedge anchors are ideal for securing heavy machinery, while adhesive anchors are better suited for structural columns. Choosing anchors that are compatible with specific materials is crucial, as demonstrated by the use of specialty anchors for terra cotta in historic preservation projects and helical anchors for compromised masonry. Anchors with corrosion-resistant coatings are essential for coastal and industrial settings, as evidenced by their application in residential foundations and moisture-prone environments.

Below are answers to some frequently asked questions:

Masonry anchors are essential components in construction and DIY projects for securing items to masonry surfaces like concrete, brick, block, and CMU (Concrete Masonry Unit). Various types of masonry anchors are designed for specific applications and weight capacities.

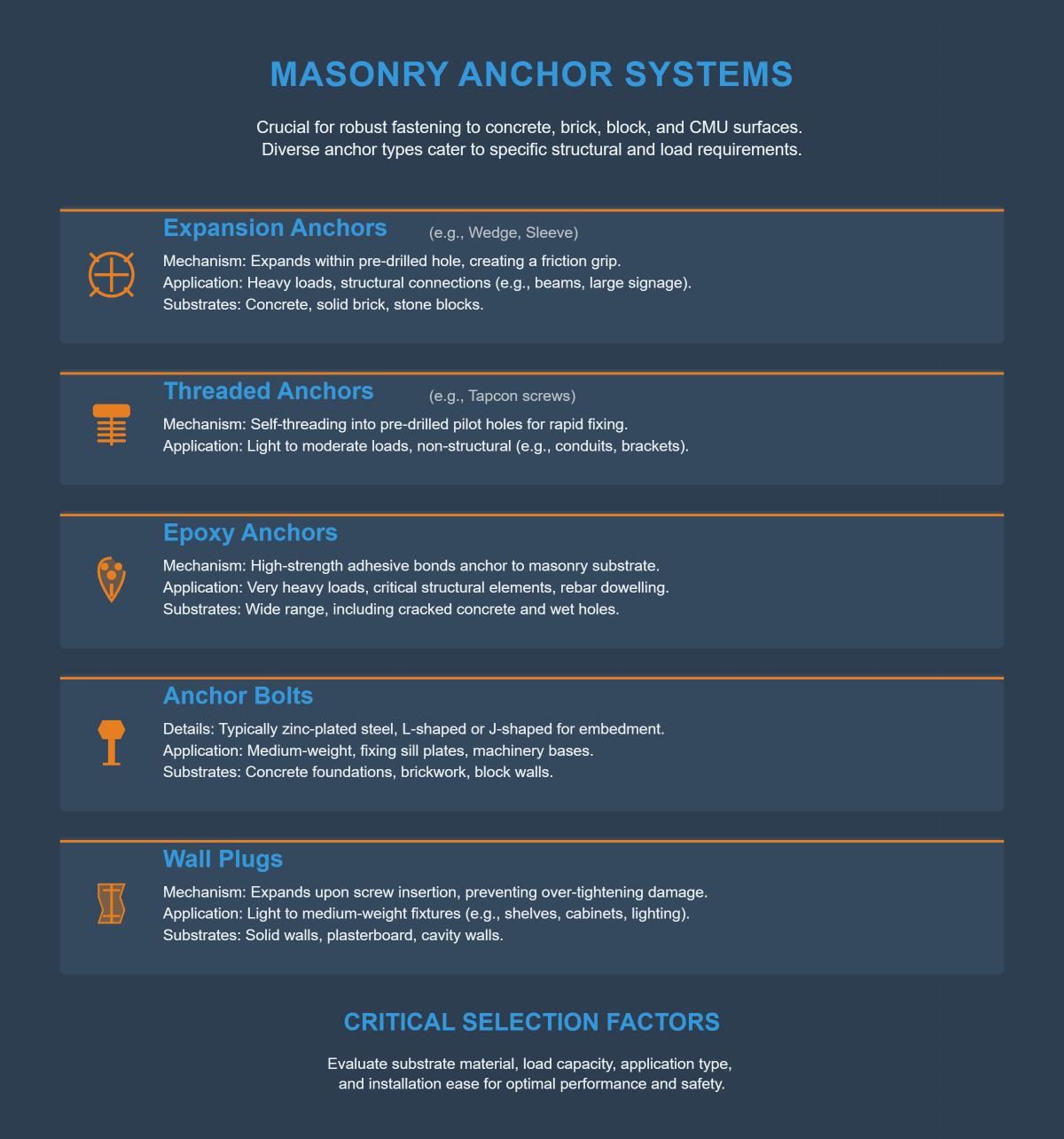

Expansion anchors, such as wedge anchors and sleeve anchors, expand within a drilled hole in the masonry material to create a secure grip. They are commonly used for heavy loads like structural elements or large signs in concrete, brick, and block.

Threaded anchors, including Tapcon masonry screws, are inserted into pre-drilled holes and provide immediate holding power. They are suitable for lighter loads like furring strips, shelf brackets, and other non-structural components.

Epoxy anchors use a strong adhesive epoxy to fill the hole around the anchor, offering exceptional holding power in various masonry materials. They are ideal for heavy-duty applications requiring high load-bearing capacity, such as securing large machinery or structural elements.

Anchor bolts, typically made from zinc-plated steel, are versatile and used in medium-weight applications to fix both structural and non-structural components to brick, block, and hard masonry.

Wall plugs are designed to expand into the wall, providing a secure grip without the risk of over-tightening. They are commonly used for attaching light to medium-weight items like shelves and cabinets to solid and cavity walls.

Selecting the right masonry anchor involves considering the material type, load capacity, application, and ease of installation. This ensures secure and effective attachment based on the specific needs of the project.

Choosing the right masonry anchor for your project involves evaluating several key factors: the masonry material, the load requirements, the anchor’s diameter and embedment depth, and the installation environment.

First, identify the type of masonry material you are working with—whether it’s concrete, brick, or block. For solid concrete, wedge anchors or sleeve anchors are typically the best choice due to their strong holding power. For brick or block, sleeve anchors or lag shields are suitable because they accommodate the hollow or porous nature of these materials. For softer masonry, plastic wall plugs or anchors designed for light loads may be necessary.

Next, assess the load requirements by determining the weight and type of load the anchor must support, including static, dynamic, shear, and tension forces. Larger diameter anchors generally provide higher holding power, with deeper embedment offering better strength.

Consider the installation environment and conditions, ensuring the anchor material is corrosion-resistant if used in outdoor or humid environments. Follow manufacturer guidelines for hole size, cleaning, and installation to ensure optimal performance.

By systematically evaluating these factors, you can select an anchor that meets your project’s structural and load needs while ensuring reliable performance in the given conditions.

Chemical masonry anchors offer several benefits over mechanical anchors. First, they provide a higher load-bearing capacity due to the bonding of resin with metal, which covers a larger area and fills substrate holes, enhancing their ability to withstand significant loads. Second, chemical anchors are versatile and can be used with various masonry types, including softer materials like hollow brick and block, without risking damage or dislodging. They do not expand within the substrate, preventing cracks and maintaining structural integrity. Additionally, chemical anchors allow for close-edge anchoring and are suitable for wet and underwater applications. They also offer better resistance to environmental factors such as chemicals, heat, and corrosion due to specially formulated resins. Lastly, chemical anchors provide maximum user safety and reliability in high-stress applications due to their strong bonding and resistance to vibration and shock loads.

However, it’s important to note that chemical anchors require more preparation and installation time and are generally more expensive compared to mechanical anchors. They are also more sensitive to installer technique, necessitating proper training and adherence to installation guidelines to ensure optimal results.

To install different types of masonry anchors, follow these general steps tailored to each anchor type:

For wedge anchors:

For sleeve anchors:

For drop-in anchors:

For plastic or nylon anchors:

Ensure proper preparation, such as using a hammer drill with appropriate bits and cleaning the holes, to achieve maximum holding power and safety.

When using masonry anchors, several safety standards should be considered to ensure structural integrity and safety. Firstly, the load capacity and safety factors are crucial. Masonry anchors must handle significant tension and compression loads, typically supporting around 400 pounds with a safety factor of 4 to account for material and workmanship uncertainties. Installation practices are also important; torque control is essential to avoid over-torquing, which can reduce holding power, and anchors should be spaced at least 10 diameters apart to prevent interference.

Material considerations and edge distances must be taken into account, with a recommended safety factor of at least 4:1 for variations in base materials and workmanship. Maintaining a minimum edge distance, particularly for expansion anchors, is necessary to prevent cracking. Regulatory and approval standards, such as UL, FM, ICBO, and GSA, are required for specific safety applications, emphasizing adherence to strict performance criteria.

Masonry anchors are specifically designed for use in masonry materials such as brick, block, concrete, and stone. They are not universally suitable for all building materials. The effectiveness of masonry anchors depends on the type of anchor, the properties of the substrate, and the load requirements. For example, wedge anchors are ideal for solid concrete and heavy loads, while wall plugs are better suited for light to medium loads in materials like plasterboard and cavity walls. However, standard masonry anchors may not perform well in hollow or low-density substrates like aerated concrete or hollow blocks unless specifically designed for such applications. Additionally, masonry anchors generally lack certifications for use in non-masonry materials such as wood, metal, or engineered composites unless explicitly stated by the manufacturer. Therefore, it is crucial to select the appropriate type of anchor based on the specific building material and application requirements.