Imagine a material that could withstand the harsh, corrosive conditions of the open sea, all while remaining lightweight and durable. Enter marine grade aluminum, the unsung hero of marine engineering. In this comprehensive guide, we will demystify marine grade aluminum, exploring its unique properties, the reasons behind its remarkable corrosion resistance, and the specific alloys that make it ideal for maritime applications. Whether you’re new to the world of marine materials or looking to expand your knowledge, this step-by-step journey will provide you with a solid understanding of why marine grade aluminum is a top choice for boat hulls, offshore platforms, and beyond. Ready to dive in and discover what makes this material so exceptional? Let’s get started!

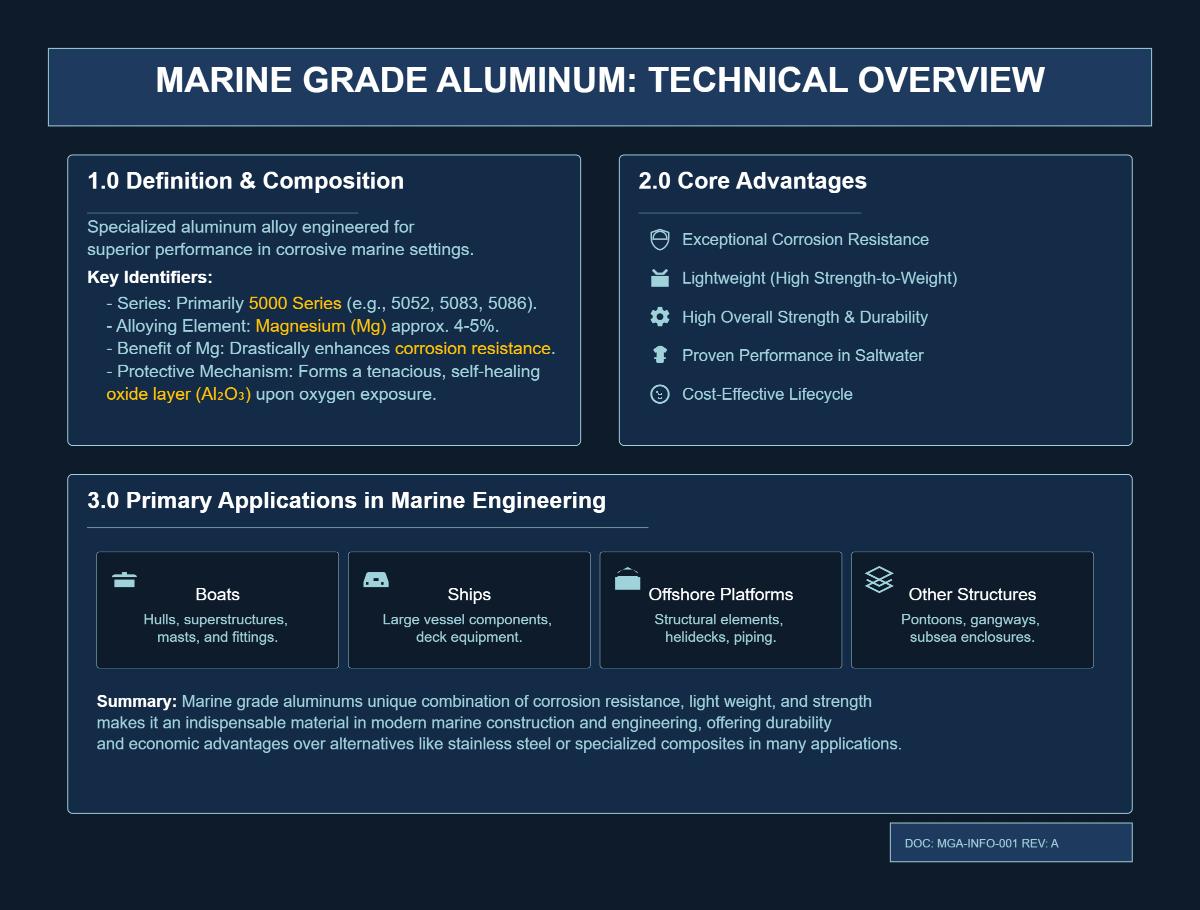

Marine grade aluminum is a type of aluminum alloy specifically designed to endure the harsh conditions of marine environments. These alloys are highly resistant to corrosion, particularly from saltwater and moisture, making them ideal for maritime applications.

A crucial property of marine grade aluminum is its exceptional resistance to corrosion. When aluminum interacts with oxygen, it forms a protective oxide layer that serves as a barrier against further oxidation. This feature is particularly beneficial in marine settings, where exposure to saltwater can cause rapid corrosion in other materials.

Marine grade aluminum is known for its impressive strength-to-weight ratio. It is both lightweight and strong, making it ideal for building durable marine vessels and structures without adding unnecessary weight. This quality enhances fuel efficiency and performance in maritime applications.

The addition of magnesium to marine grade aluminum alloys significantly boosts their corrosion resistance and strength. Magnesium aids in creating a more robust protective layer, preventing issues like pitting and crevice corrosion common in saltwater environments. This makes magnesium a crucial component in these alloys.

Marine grade aluminum is widely used in constructing boat hulls, decks, and various marine vessels, as well as in offshore structures and platforms due to its durability. Its versatility makes it suitable for a range of applications, from small recreational boats to large commercial ships and offshore drilling rigs.

Choosing marine grade aluminum for maritime applications offers several advantages. Its resistance to corrosion results in lower maintenance costs and a longer lifespan compared to other materials like steel. Additionally, the lightweight nature of aluminum contributes to better handling and fuel efficiency in marine vessels. Furthermore, marine grade aluminum is recyclable, supporting sustainable practices in marine engineering.

Marine grade aluminum is widely recognized for its outstanding ability to resist corrosion, a vital feature for materials used in marine settings. This resistance arises from the formation of a protective oxide layer when aluminum interacts with oxygen. This layer serves as a barrier, preventing further oxidation and effectively combating the corrosive effects of saltwater. Such resilience is essential in maritime environments, where exposure to harsh conditions can lead to rapid material degradation.

Marine grade aluminum not only resists corrosion but also boasts remarkable strength and durability. Despite its lightweight nature, aluminum alloys used in marine settings provide significant tensile strength, essential for building robust and reliable marine vessels and structures. The high strength-to-weight ratio allows for the creation of durable designs without compromising performance or safety, while also enhancing fuel efficiency due to reduced structural weight.

Magnesium plays a crucial role in enhancing the properties of marine grade aluminum. By forming a stronger oxide layer, it boosts the alloy’s strength and resistance to the types of corrosion often seen in salty marine conditions, making it ideal for use in marine applications. Magnesium is a key component in many marine aluminum alloys, like those in the 5000 series, designed specifically to endure harsh marine conditions.

Aluminum alloys are crucial in the marine industry because of their lightweight nature, strength, and excellent resistance to corrosion. These alloys are created by combining aluminum with other elements, such as magnesium, silicon, and zinc, to enhance their performance in harsh marine environments.

The 5000 series, especially, is popular in marine settings due to its high magnesium content, which boosts corrosion resistance. This series includes alloys such as 5083 and 5086, both favored for their durability and strength in marine settings.

The 5083-H116 alloy is particularly noteworthy due to its exceptional resistance to saltwater corrosion and robust mechanical properties. It is commonly employed in the construction of marine vessels and structures. The H116 temper means the alloy is strain-hardened and stabilized, which helps prevent cracking and deformation.

For aluminum alloys to be used effectively in marine applications, they must comply with specific standards that ensure their suitability and safety. These standards govern the composition, mechanical properties, and corrosion resistance of the alloys. The American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) are two key bodies that provide guidelines for marine-grade aluminum.

These standards ensure aluminum alloys used in marine environments can endure saltwater and other corrosive elements. Compliance is essential for maintaining vessel integrity and performance, preventing failures, and extending their operational lifespan.

By choosing the right aluminum alloys and adhering to standards, manufacturers can ensure their marine applications are safe, durable, and efficient.

Marine grade aluminum plays a crucial role in constructing various types of marine vessels, from small boats to large ships.

Marine grade aluminum is a preferred material for constructing offshore structures, where durability and corrosion resistance are paramount.

Marine infrastructure projects often incorporate marine grade aluminum due to its ability to withstand marine conditions with minimal upkeep.

The versatility of marine grade aluminum extends to recreational equipment, enhancing performance and user experience.

Marine grade aluminum is frequently used in the production of various marine hardware and accessories, ensuring reliability and durability.

Marine grade aluminum is highly valued for its corrosion resistance, lightweight strength, and durability in harsh saltwater environments.

Marine grade aluminum naturally forms a protective oxide layer that shields it from the corrosive effects of seawater. In comparison, while stainless steel resists rust, it can pit in salty conditions unless treated. Carbon steel rusts quickly without protective coatings, and although fiberglass is corrosion-proof, it can degrade with UV exposure.

Marine grade aluminum is strong yet lightweight, reducing vessel weight and improving fuel efficiency. In contrast, steel is heavy, requiring reinforced structures that increase fuel consumption. Wood, while lightweight, lacks consistency in strength, and composites, though strong and light, can be costly to repair.

With marine grade aluminum, you can enjoy reduced maintenance demands, unlike stainless steel, which requires regular cleaning to prevent corrosion. Wood is prone to rot and requires frequent treatment, while fiberglass needs repairs for cracks and UV protection.

Although marine grade aluminum costs more upfront, it saves money over time because it requires less maintenance and lasts longer. Carbon steel is initially cheaper but incurs high maintenance costs. Fiberglass has moderate initial costs, but repair expenses can rise with damage.

Marine grade aluminum is a sustainable choice due to its recyclability, offering a lower carbon footprint compared to steel production. Steel is energy-intensive to produce and recycle, while wood, though renewable, raises concerns about deforestation. Fiberglass is difficult to recycle, often ending up in landfills.

Marine grade aluminum is versatile, used in hulls, superstructures, docks, offshore wind turbines, and marine hardware. Stainless steel is common in fasteners and railings, fiberglass is favored for recreational boats, and wood remains in traditional boatbuilding and decorative uses.

Regular cleaning is essential for extending the life of marine grade aluminum. After each use, particularly in saltwater environments, rinse the aluminum surface with freshwater to remove salt deposits and other contaminants. This step is crucial in preventing oxidation, which can lead to corrosion over time. Specialized aluminum cleaners, such as Captain’s Fury Aluminum Boat Cleaner, effectively remove stubborn stains while preserving the surface integrity.

To protect marine grade aluminum, apply a marine-grade polish or wax after cleaning to create a barrier against saltwater and UV damage. Regularly inspect the surface for any scratches, as these can become focal points for corrosion. Address any damage promptly with touch-up paint or sealant to maintain the protective layer.

For minor damage like small holes, clean the area well and use a marine-grade epoxy. Allow it to cure fully before putting the material back into use. For more extensive repairs that require welding, ensure the area is clean and free from oxide layers, using compatible filler materials to maintain structural integrity. Regular inspections are vital; look for stress cracks, loose fasteners, and signs of corrosion, particularly around joints and welds.

If your marine grade aluminum equipment is used with a trailer, ensure the wheel bearings are greased annually and checked for wear, especially after exposure to saltwater. Check tire pressure and tread depth regularly to avoid blowouts while transporting. It’s also important to test trailer lights frequently to ensure they are functioning correctly and meet safety standards.

Storing your marine grade aluminum equipment properly is crucial for its longevity. Keep the boat or trailer dry, covered, and elevated to minimize moisture exposure. Regularly inspect and replace sacrificial anodes, which help protect against galvanic corrosion. Applying a marine-grade primer and paint can further enhance the durability of aluminum surfaces, providing an additional layer of defense against the elements.

Below are answers to some frequently asked questions:

Marine grade aluminum is a specially formulated aluminum alloy designed to endure the harsh conditions of marine environments, such as exposure to water, saltwater, and moisture. This type of aluminum typically belongs to the 5000 series, which includes alloys with about 4-5% magnesium. The addition of magnesium significantly enhances the alloy’s corrosion resistance, making it ideal for marine applications. When exposed to oxygen, marine grade aluminum forms a protective oxide layer on its surface, preventing further corrosion.

It is used primarily because of its excellent corrosion resistance, lightweight nature, and high strength. These properties make marine grade aluminum a preferred material for constructing boats, ships, offshore platforms, and other marine structures. Its durability in saltwater conditions and cost-effectiveness compared to other materials like stainless steel or composites contribute to its widespread use in marine engineering.

Marine grade aluminum is known for its exceptional corrosion resistance, which is crucial for its use in harsh marine environments. This resistance is primarily due to two factors: the formation of a natural oxide layer and the alloying process.

When aluminum is exposed to air or moisture, it naturally forms a thin oxide layer on its surface. This layer acts as a barrier, preventing further corrosion by blocking oxygen and water from reaching the metal beneath. This self-healing feature is a key component of aluminum’s corrosion resistance.

Additionally, marine grade aluminum is often alloyed with elements such as magnesium, silicon, manganese, and chromium. These elements enhance its resistance to corrosion, particularly in saltwater environments, which are highly corrosive. For instance, the 5083 alloy includes magnesium, which significantly boosts its strength and corrosion resistance.

Marine-grade aluminum alloys are specially formulated to withstand the corrosive marine environment, offering excellent strength and durability. The most recommended alloys for marine applications are from the 5000 series, particularly 5083, 5086, and 5052.

5083 aluminum is highly favored for its exceptional strength and corrosion resistance, making it ideal for boat hulls and offshore structures. It is composed of magnesium and manganese, enhancing its suitability for extreme marine conditions. 5086 aluminum shares similar properties but is slightly more formable, which is beneficial for complex components such as gangways and superstructures.

5052 aluminum offers moderate strength with excellent resistance to saltwater corrosion, making it suitable for hull plating and fuel tanks. For structural components like railings and masts, 6061 aluminum is often used due to its good mechanical strength and versatility, although it is less corrosion-resistant compared to 5xxx series alloys.

Marine grade aluminum is often favored over steel in marine applications due to its advantageous strength-to-weight ratio. While both materials are strong, aluminum is significantly lighter, weighing about one-third of steel. This weight difference allows marine vessels made from aluminum to be more fuel-efficient and capable of carrying larger payloads. For example, the 5083-H116 aluminum alloy is commonly used in marine settings because it provides a good balance of strength and lightness.

Steel, on the other hand, is known for its high absolute strength, which can be beneficial in applications where maximum durability is necessary. However, its heavier weight can lead to increased fuel consumption and operational costs. Additionally, marine grade aluminum offers superior corrosion resistance, which is crucial in harsh saltwater environments, whereas steel requires additional coatings or treatments to resist corrosion effectively.

Marine aluminum must comply with specific standards to ensure its suitability for use in harsh marine environments. One key standard is ASTM B928/B928M-15, which sets requirements for high magnesium aluminum-alloy products, focusing on corrosion resistance, strength, and material quality. This specification covers flat sheet, coiled sheet, and plate materials, emphasizing resistance to intergranular corrosion.

Marine-grade aluminum typically involves alloys from the 5000 series, like 5083 and 5086, known for their high magnesium content that boosts corrosion resistance in seawater. Compliance also includes rigorous corrosion testing to verify durability, such as ensuring minimal weight loss during saltwater exposure.

Additionally, inspection and quality control processes are vital, involving metallographic examinations to confirm the microstructure meets standards. Products must be certified and marked with essential information for traceability and compliance, ensuring they meet the necessary performance and durability requirements for marine applications.

To maintain marine grade aluminum and ensure its longevity, regular care and protection are essential. Begin by cleaning the aluminum with aluminum-friendly cleaners and non-abrasive brushes to remove salt, dirt, and grime. This prevents corrosive substances from accumulating. Protect the aluminum from UV exposure by applying specialized UV protectants to prevent fading and surface weakening. Regularly inspect the aluminum for any signs of damage, such as cracks or corrosion, and address these promptly to maintain structural integrity.

Using cathodic protection, such as installing sacrificial anodes, can help prevent corrosion by allowing the anodes to corrode instead of the aluminum. Additionally, applying protective coatings like anodizing enhances corrosion resistance by creating a thicker oxide layer. Rinse aluminum components with fresh water after exposure to saltwater to further prevent corrosion. By following these practices, marine grade aluminum can remain durable and functional in marine environments for an extended period.