When it comes to selecting the right material for engineering applications, understanding the subtle yet significant differences between A216 and A105 is crucial. Both materials are widely used in industries such as oil and gas and chemical processing, but each brings unique properties and advantages to the table. Are you wondering which material offers superior mechanical properties, or which is more cost-effective for your specific application? This article dives deep into the comparative analysis of A216 and A105, examining their definitions, characteristics, manufacturing processes, and performance metrics. By the end, you’ll have a clear understanding of how these materials stack up against each other and which might be the better choice for your next project. Ready to uncover the key distinctions between A216 and A105? Let’s explore the intricate details that make these materials stand out.

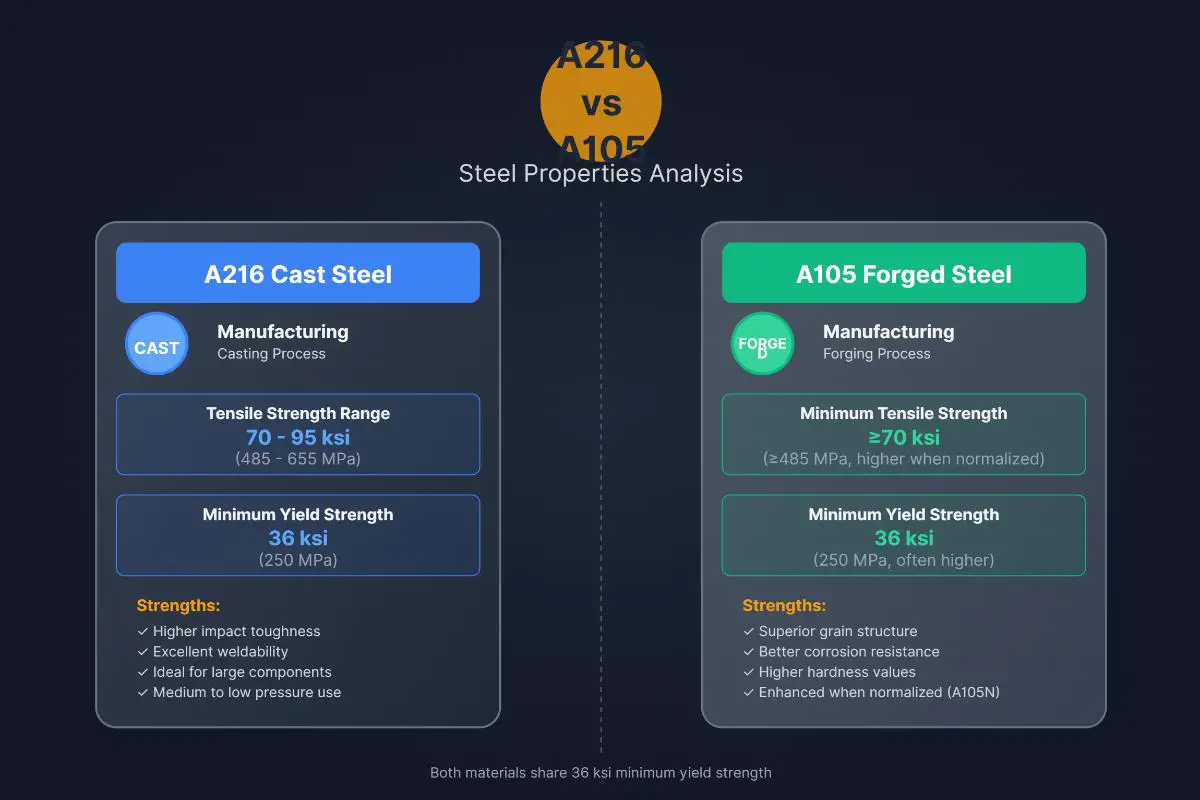

ASTM A216 is a versatile cast carbon steel material widely used in various industries. Its lower carbon content contributes to good weldability, while the silicon enhances corrosion resistance. With a tensile strength ranging from 70–95 ksi (485–655 MPa) and a minimum yield strength of 36 ksi (250 MPa), it offers reliable mechanical performance.

The standard grade (WCB) can be used up to 425°C, while WC6/WC9 grades are suitable for up to 550°C, and the WCC grade can be used in cryogenic (-50°C) service. A216 is commonly used in chemical processing plants and power generation. Its applications include cast valve bodies, flanges, and low-temperature fittings, where its casting process allows for the production of large-diameter components for medium/low-pressure systems.

ASTM A105 is a forged carbon steel. A105 has higher carbon (up to 0.35%) and manganese, which improves its strength and properties. It has a minimum tensile strength of 70 ksi (485 MPa) and a minimum yield strength of 36 ksi (250 MPa), similar to A216 in yield strength but with a more defined minimum in tensile strength.

A105 shows better corrosion resistance than A216 in rust-prone environments, especially in its normalized A105N form. It is generally used for high-temperature applications but is not inherently suitable for low-temperature use unless normalized. A105 is preferred for small-size, high-pressure valves and precision components. It is commonly used in high-pressure pipelines, oil/gas systems, and for making forged flanges, fittings, and small valves.

Carbon steel is a broad category that includes both A216 and A105. General carbon steel can vary widely in its properties depending on its composition and manufacturing process.

The casting process of A216 allows for the production of large and complex shapes, making it ideal for medium/low-pressure systems. Its relatively lower carbon content makes it more weldable compared to some high-carbon general carbon steels. A105, on the other hand, due to its forging process, has a more uniform grain structure, which can result in better mechanical properties in high-stress applications.

In terms of applications, general carbon steel can be used in a wide range of industries, but A216 is more specialized for medium/low-pressure large-scale applications in chemical and power industries. A105 is designed for high-pressure, small-size applications, particularly in the oil and gas sectors.

Forging is a manufacturing process that shapes metal by applying compressive forces, typically at high temperatures to make the metal more malleable. The primary steps in forging include heating the metal to a ductile state, placing it between dies, and applying compressive forces through hammering or pressing.

Casting is a manufacturing process where molten metal is poured into a mold to form a desired shape. The key steps in casting include melting the metal in a furnace, pouring the molten metal into a mold cavity, allowing it to cool and solidify, and removing the solidified metal part from the mold.

Understanding the mechanical properties of ASTM A216 and ASTM A105 is essential for determining their suitability in various applications. Here, we’ll compare their tensile strength, yield strength, and other relevant mechanical characteristics.

Cost is a crucial factor in selecting materials for industrial applications, considering both initial expenses and long-term savings.

To further understand the cost and performance dynamics, let’s look at the specific applications in the oil and gas and chemical processing industries.

In the oil and gas industry, the selection between ASTM A216 and ASTM A105 materials is critical due to the demanding operational environments. Let’s explore a specific case study to highlight the considerations and outcomes.

An offshore drilling platform required a high-pressure pipeline system capable of handling extreme pressures and temperatures.

The engineering team compared ASTM A216 and ASTM A105 based on the criteria above:

The choice was based on A105’s ability to endure harsh conditions, its superior strength, and long-term reliability, which reduced maintenance costs and downtime.

In the chemical processing industry, material selection is influenced by the need to handle various chemicals, temperature fluctuations, and mechanical stresses. The following case study demonstrates the selection process for a chemical plant’s valve system.

A chemical processing plant required new valve systems for its high-temperature reactors. The valves needed to handle temperatures up to 500°C and moderate pressures, while also being resistant to chemical corrosion.

The engineering team evaluated ASTM A216 and ASTM A105:

The project selected ASTM A216 for the valve systems. The material’s ability to withstand high temperatures, its adequate mechanical properties, and its cost-effectiveness made it the preferred choice for the chemical processing plant’s requirements. The casting process also facilitated the production of the complex valve shapes needed for the reactors.

Below are answers to some frequently asked questions:

The primary differences in mechanical properties between ASTM A216 and ASTM A105 stem from their manufacturing processes—casting for A216 and forging for A105. ASTM A216, a cast carbon steel, typically exhibits good toughness and weldability, making it suitable for large, medium, and low-pressure components. It offers tensile strength ranging from 70 to 95 ksi (485 to 655 MPa) and a minimum yield strength of 36 ksi (250 MPa). Its impact toughness is generally higher in its standard form.

In contrast, ASTM A105 is a forged carbon steel, known for higher mechanical strength and better grain structure uniformity. It has a minimum tensile strength of 70 ksi (485 MPa), which can be higher when normalized (A105N), and the same minimum yield strength of 36 ksi (250 MPa) but often higher in normalized conditions. A105 also exhibits better corrosion resistance and higher hardness due to the forging process.

When evaluating the cost-effectiveness of ASTM A216 versus ASTM A105 for specific applications, several factors come into play. Generally, A216 is more cost-effective for medium- to low-pressure applications due to its simpler casting process and lower carbon content, which results in a lower initial cost. This makes it suitable for applications such as large-diameter valves, flanges, and fittings in chemical processing plants, refineries, and power generation facilities where high mechanical strength is not critical.

On the other hand, A105, being a forged carbon steel, has a higher initial cost due to its superior mechanical properties, including higher tensile and yield strength. This makes it ideal for high-pressure and high-temperature environments, such as pipelines and small-size valves. Despite the higher upfront cost, A105 can offer long-term savings by reducing the need for frequent replacements or repairs, thus proving to be more cost-effective over time in demanding applications.

A216 and A105 differ significantly in terms of manufacturing processes and applications. A216 is produced through a casting process, where molten metal is poured into molds, allowing for the creation of complex shapes and large parts. This method is cost-effective for producing medium to low-pressure components used in industries such as automotive, consumer goods, and medical sectors. However, casting can result in a more random grain structure and potential defects like porosity, which may reduce mechanical strength.

On the other hand, A105 is manufactured using a forging process, which involves shaping metal in its solid state through compressive forces. This process aligns the grain structure, enhancing the material’s tensile strength, yield strength, and fatigue resistance. Forged A105 components are commonly used in high-pressure and high-temperature applications, particularly in the aerospace, construction, and oil and gas industries. Despite a higher initial cost, A105’s superior mechanical properties and longer service life can make it a more cost-effective choice for critical applications.

In real-world industrial applications, A216 and A105 serve distinct purposes. A216, made through casting, is used in high-temperature, medium to low-pressure scenarios. It’s common in industrial boilers, pressure vessels, chemical processing plants, and power generation facilities. For example, it’s suitable for large – diameter valves in these settings. On the other hand, A105, produced by forging, is used in high – temperature and high – pressure applications. In the oil and gas industry, it’s used for high – pressure valves and fittings, crucial for upstream drilling and processing facilities. In chemical processing plants, A216 offers thermal stability, while A105 is preferred for components needing high mechanical strength under high pressure.

When comparing the long-term cost-benefit of A216 and A105, several factors must be considered. A105, being a forged carbon steel, has a higher initial cost due to its manufacturing process and superior mechanical properties. This material is known for its high tensile and yield strength, making it suitable for high-pressure and high-temperature applications such as pipelines, valves, and flanges. Its durability often translates into lower long-term maintenance costs and fewer replacements, resulting in cost savings over time.

On the other hand, A216, a cast carbon steel, is generally more affordable initially due to the simpler casting process. It is often used in lower to moderate pressure environments, such as chemical processing plants and refineries. However, A216 may require more frequent maintenance and have a shorter lifespan in demanding conditions, potentially leading to higher long-term costs.

Real-world case studies demonstrate the selection between ASTM A216 and ASTM A105 by highlighting their specific advantages in different industrial applications. For instance, in the oil and gas industry, A105 forged steel is preferred for high-pressure and high-temperature environments, such as upstream extraction and downstream refining, where mechanical reliability is crucial. Its superior tensile strength and fatigue resistance make it ideal for critical components like valve bodies and pipeline segments.

Conversely, A216 cast steel is often chosen for medium to low-pressure applications where complex geometries and larger sizes are necessary, such as in industrial boilers and chemical processing plants. The ability to cast large, intricate shapes economically suits A216 for valve bodies and pressure vessels, particularly in moderate temperature and pressure conditions.

Case studies also reveal that A216 grades like WCC are preferred in corrosive or low-temperature environments due to their better impact toughness and corrosion resistance. In terms of cost-benefit analysis, A105 components, despite their higher initial cost, offer longer service life and reduced maintenance in high-stress environments, while A216 components provide cost-effective solutions for less demanding applications. This strategic selection ensures optimal performance and cost management in engineering projects.