Imagine your product standing the test of time, resisting wear and tear, and maintaining its quality despite constant use. This durability is often determined by a critical process known as abrasion resistance testing. Whether you’re a beginner in the field or simply looking to understand the basics, this guide will walk you through the essentials of performing abrasion resistance tests. From understanding the fundamental concepts and various types of tests, such as the Taber, Wyzenbeek, and Martindale methods, to setting up the necessary equipment and interpreting the results, we’ve got you covered. Ready to ensure your products can withstand the rigors of daily use? Let’s dive into the step-by-step process of abrasion resistance testing.

Abrasion resistance testing measures how well a material withstands friction or rubbing. This property is crucial for materials used in environments where wear and tear are common, such as flooring, protective coatings, and textiles.

Abrasion resistance is crucial for a material’s longevity and performance, helping manufacturers select the best materials for various applications. It also plays a vital role in quality control, ensuring that products meet industry standards and perform well under expected conditions. Common applications include:

The Taber abrasion test is one of the most widely used methods for assessing abrasion resistance. It involves a rotating turntable with a grinding wheel that simulates wear. Key parameters include:

After testing, abrasion resistance is assessed by checking weight loss, abrasion depth, or visually inspecting the material.

The Wyzenbeek test is primarily used for textiles. In this method, a sample is rubbed back and forth against an abrasive surface. Parameters include:

The Wyzenbeek test offers important insights into fabric durability, aiding manufacturers in choosing long-lasting materials.

The Martindale test is another common method for testing textiles. It involves a sample being rubbed in a figure-eight pattern against an abrasive fabric. Key parameters include:

The Martindale test is particularly useful for evaluating upholstery and clothing fabrics.

Abrasion testers are specialized machines designed to simulate wear conditions. They vary in design based on the testing method being used, but all serve the purpose of applying controlled abrasion to a sample. Common types include:

To guarantee consistency and reliability, abrasion resistance testing must adhere to industry standards. The most common standards include:

These standards help manufacturers and researchers compare results across different materials and applications, ensuring that products meet the required performance criteria.

The Taber test uses a machine featuring a rotating table with two abrasive wheels that rub against the material’s surface as the table turns, simulating wear conditions. The test measures the mass loss of the material after a set number of cycles, providing a quantitative assessment of abrasion resistance.

This test is versatile and can be applied to a wide range of materials, including plastics, metals, coatings, and textiles. It is particularly useful for assessing the durability of flooring materials, automotive interiors, and protective coatings.

Primarily used for textile materials, the Wyzenbeek test involves rubbing a fabric sample back and forth against an abrasive surface, counting the number of rubs the fabric can withstand before showing signs of wear, simulating real-world conditions.

Commonly used in the textile industry, this test helps evaluate the durability of fabrics used in clothing, upholstery, and automotive interiors. It assists manufacturers in choosing fabrics that will endure prolonged use.

The Martindale test rubs a fabric sample in a figure-eight pattern against an abrasive material, measuring how many cycles the fabric can endure before showing wear.

This method is widely used for testing textiles, especially those used in upholstery and clothing. It provides valuable insights into the wear resistance of fabrics subjected to continuous friction.

This test uses a mixture of sand and liquid to simulate harsh conditions, abrading the material’s surface to mimic wear experienced in environments like mining or construction.

Materials used in pipelines, construction machinery, and mining equipment benefit from this test. It helps assess their durability in abrasive environments, ensuring they can withstand extreme conditions.

This test uses a rubber wheel and dry sand to simulate wear conditions similar to those in desert environments, where materials face sand and dust exposure.

Ideal for outdoor applications, this test is used for materials such as coatings, paints, and surface treatments that need to endure sandy conditions. It is particularly useful for evaluating the durability of products used in desert regions.

The pin-on-disc test uses a pin (or ball) that rubs against a rotating disc. This setup allows for controlled assessment of wear resistance under specific conditions. The test measures the wear rate and friction coefficient of the material.

Commonly used in the automotive and aerospace industries, this test evaluates the wear resistance of moving parts such as bearings, gears, and coatings. It helps ensure that components will perform reliably under operational stresses.

The wet scrub abrasion test uses a wet abrasive material to simulate conditions encountered during cleaning or painting processes. The test measures the material’s resistance to wear caused by scrubbing.

Often used in the coatings and architectural paints industry, this test evaluates the durability of surfaces exposed to frequent cleaning. It helps manufacturers develop products that can withstand repeated scrubbing without degrading.

Properly setting up abrasion testing equipment is essential for achieving accurate and reliable results. Follow these steps to ensure everything is in order:

Adhering to industry standards is vital for ensuring that abrasion resistance testing is consistent and reliable. Here are the key standards to follow:

Understanding the various abrasion testing methods is essential for selecting the most appropriate test for specific materials and applications. Each method has unique characteristics and advantages that make it suitable for different types of wear resistance assessments.

Different abrasion tests are tailored to evaluate specific types of materials:

Each test employs distinct motion patterns: the Taber test uses a circular motion with rotating abrasive wheels, the Wyzenbeek test mimics back-and-forth rubbing, and the Martindale test uses a figure-eight pattern for comprehensive assessment.

Abrasion tests are quantified using various metrics: the Taber test measures mass or volume loss, the Wyzenbeek test counts double rubs, and the Martindale test tracks cycles before wear appears.

The Taber test is versatile and provides detailed wear data but may be too aggressive for delicate fabrics. The Wyzenbeek test is ideal for textiles and simulates realistic conditions, though it requires consistent pressure. The Martindale test is thorough for fabrics, assessing wear in multiple directions, but is primarily limited to textiles.

To select the right abrasion test, first identify the material type. Consider the application to understand the wear conditions the material will face. Choose a test that simulates these conditions and ensure it complies with relevant industry standards for reliable results.

Understanding the results of abrasion resistance tests involves examining several key indicators. These indicators help determine how well a material can withstand wear and tear in practical applications.

Weight loss is a primary metric in abrasion resistance testing, measured by weighing the material sample before and after the test. A smaller weight loss indicates better abrasion resistance, as the material has retained more of its original mass.

Abrasion depth refers to the thickness of the material that has been worn away during the test. This can be measured using precise instruments that gauge the depth of wear marks on the material’s surface. Minimal abrasion depth signifies that the material can resist wear effectively, maintaining its structural integrity.

The abrasion resistance index compares the material’s performance against a standard reference material, calculated based on the mass or volume loss of the test material relative to the reference. A higher index value indicates superior abrasion resistance, showing that the material performs better under abrasive conditions.

Interpreting the data from abrasion resistance tests involves several steps to ensure accurate and meaningful results.

Proper sample preparation is crucial for reliable test results. Ensure the material sample is correctly sized and fixed according to the test method guidelines. Conditioning the sample under controlled temperature and humidity conditions can also help stabilize its properties.

Run the abrasion resistance test under the specified conditions, such as load, rotation speed, and number of cycles. It is important to monitor the test closely to ensure that it proceeds without any issues that could affect the accuracy of the results.

After completing the test, collect the necessary data by measuring the weight loss, abrasion depth, or other relevant indicators. Accurate data collection is essential for meaningful analysis.

Compare the test results to standard materials or benchmarks to evaluate the material’s abrasion resistance. This comparison helps determine if the material meets the required performance criteria for its intended application. Use statistical tools and methods to analyze the data and draw conclusions about the material’s durability and wear resistance.

Understanding abrasion resistance test results is crucial for product development and quality control, helping manufacturers make informed decisions about material selection and product design. By understanding how a material performs under abrasive conditions, manufacturers can ensure that the final products meet the desired durability standards and perform reliably in their intended applications.

Below are answers to some frequently asked questions:

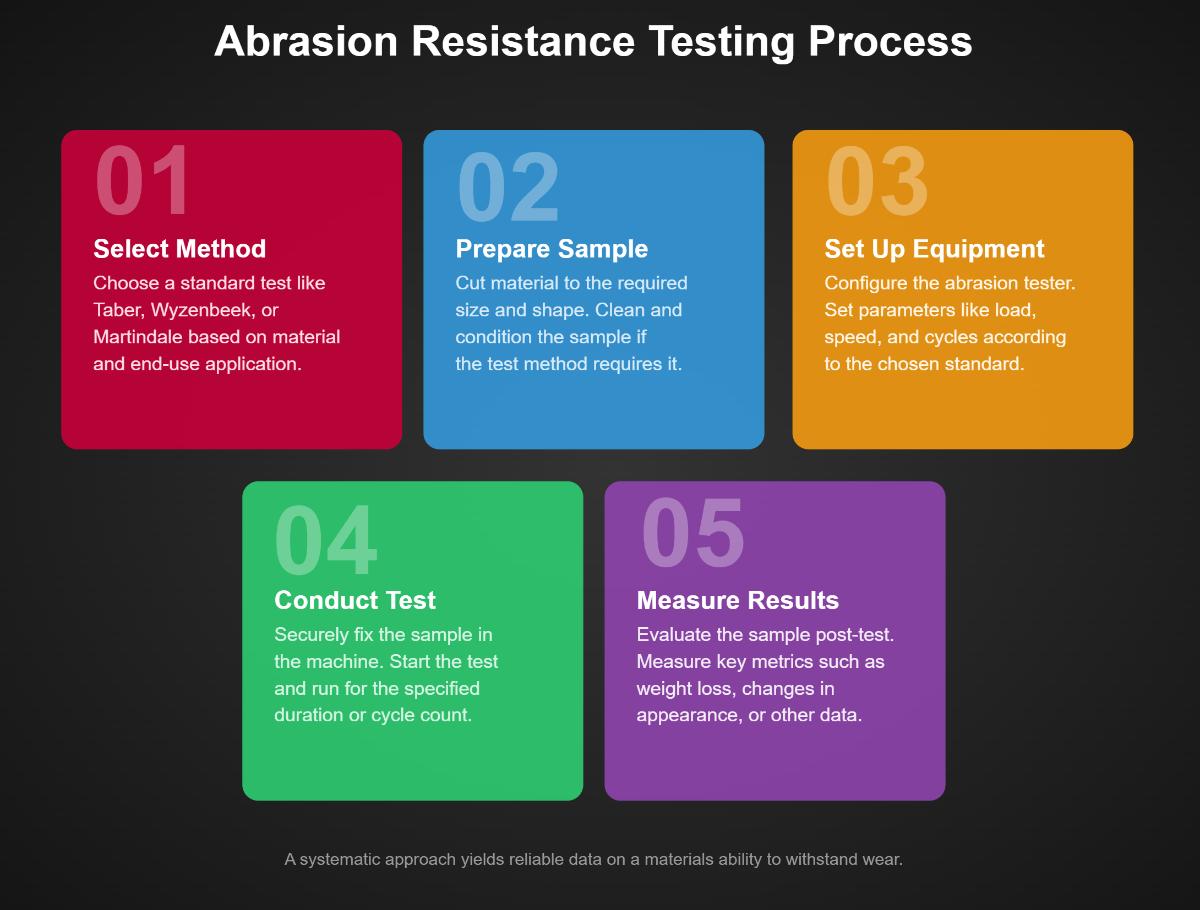

To perform abrasion resistance testing, you need to follow a systematic approach to evaluate how well a material can withstand wear caused by mechanical contact with abrasive surfaces. Here’s a basic guide:

By carefully following these steps and adhering to standard procedures, you can effectively assess the abrasion resistance of different materials.

Abrasion resistance testing evaluates how well materials withstand wear and tear caused by friction. Various standardized tests are used in the industry, each tailored to specific materials and applications. The main types of abrasion tests are:

These tests help determine the durability of materials in various applications, ensuring they meet industry standards and perform well under real-life conditions.

Abrasion testing requires specialized equipment designed to simulate wear and tear on materials. Key equipment includes general abrasion testers, scrub abrasion and washability testers, rubber abrasion testers, and Böhme abrasion testers. These machines typically feature rotating wheels, abrasive materials like white corundum sand, specimen holders, and loading devices to apply controlled forces. To perform an abrasion test, you need to select the appropriate tester, prepare the test specimen, set testing parameters, conduct the test, and measure the abrasion effect. This setup ensures consistent and accurate evaluation of a material’s resistance to abrasion, adhering to standards like ASTM and ISO.

Interpreting the results of an abrasion test involves understanding the data provided by specific testing methods and what they signify about the material’s durability. For instance, in the Martindale Test, the number of cycles a fabric can endure before significant wear (such as thread breaks) indicates its abrasion resistance. Higher cycle counts mean better durability, with decorative fabrics typically rated between 6,000 to 10,000 cycles, while heavy-duty materials can exceed 30,000 cycles.

Similarly, the Wyzenbeek Test measures the number of double rubs a fabric can withstand before showing wear. More double rubs suggest greater durability. However, it’s important to note that results can vary significantly, sometimes up to 60%, due to factors like test conditions and fabric properties. While these tests provide a general idea of material durability, real-world performance can differ based on usage and environmental conditions. Therefore, consider both test ratings and practical application when selecting materials.

Choosing the right abrasion test method for your product depends on several factors, including the type of material and its intended use.

For versatile applications, the Taber Abrasion Test is widely recommended. It uses a rotary platform to simulate wear patterns and is suitable for various materials like coatings, plastics, and textiles. This test is straightforward to perform and cost-effective.

If your product experiences linear wear, such as flooring or surfaces subjected to directional forces, the Linear Abrasion Test might be more appropriate. This test applies abrasion in a linear motion, matching real-world wear conditions.

For products exposed to harsh environments with abrasive particles like sand or gravel, the Dry Sand/Rubber Wheel Abrasion Test is ideal. It replicates conditions where materials encounter abrasive particles.

For precise measurements of wear on thin layers or coatings, consider the Micro-abrasion Test. This method uses a rotating ball with an abrasive slurry to evaluate fine wear.

For abrasion resistance testing, several standards are commonly followed to ensure accuracy and consistency in evaluating material durability under friction. Key standards include:

These standards help ensure that abrasion resistance testing is performed consistently and accurately, providing reliable data for material performance evaluation.