When it comes to selecting the right steel for your project, understanding the subtle distinctions between various grades can be crucial. AISI 1008 and AISI 1010 are two popular low-carbon steel grades, each with its own set of properties and ideal applications. But what truly sets them apart? From differences in mechanical properties like tensile and yield strength to their specific industrial uses, this article delves deep into the comparative analysis of AISI 1008 and AISI 1010. You’ll discover which grade offers better machinability and weldability, and which one strikes the perfect balance between cost and performance for your needs. Ready to uncover the key differences and make an informed decision? Let’s dive in.

Low-carbon steel, also known as mild steel, contains less than 0.30% carbon, making it a versatile and cost-effective material used across many industries. It offers a great balance of strength, ductility, and affordability, making it widely popular. Its lower carbon content results in increased malleability and ductility, making it easier to form and weld compared to higher carbon steels.

Low-carbon steel exhibits several key characteristics that make it suitable for a wide range of applications:

Two common grades of low-carbon steel are AISI 1008 and AISI 1010. Both of these grades share the general characteristics of low-carbon steel but also have distinct differences that make them suitable for specific applications.

AISI 1008 contains up to 0.10% carbon and 0.30-0.50% manganese, making it ideal for forming and bending into wire products and sheet metal. This composition gives AISI 1008 excellent formability and ductility.

AISI 1010, with 0.08-0.13% carbon and 0.30-0.60% manganese, offers higher strength and hardness, suitable for gears, axles, and structural components. This composition provides AISI 1010 with higher tensile strength and hardness compared to AISI 1008.

While both grades are low-carbon steels, AISI 1008’s lower carbon and manganese content make it more ductile and formable, whereas AISI 1010’s slightly higher carbon and manganese provide greater strength and durability. Understanding these differences helps in selecting the appropriate steel grade for specific projects, ensuring optimal performance and cost-effectiveness.

The carbon content in AISI 1008 is limited to a maximum of 0.10%. This relatively low carbon level contributes to its high ductility and formability, making it suitable for processes like bending and shaping.

AISI 1008 contains manganese in the range of 0.30% to 0.50%. Manganese increases the steel’s strength and hardness while keeping it ductile.

The low sulfur (0.050%) and phosphorus (0.040%) levels ensure AISI 1008 remains ductile and weldable. The majority of the remaining composition is iron, ranging from 99.31% to 99.7%.

AISI 1010 has a carbon content ranging from 0.08% to 0.13%. This higher carbon content compared to AISI 1008 makes AISI 1010 harder and stronger.

AISI 1010 contains manganese in the range of 0.30% to 0.60%. The broader and slightly higher manganese range contributes to better strength and hardenability of this steel grade.

Similar to AISI 1008, AISI 1010 has a maximum sulfur content of 0.050% and a maximum phosphorus content of 0.040%. These low levels also ensure good ductility and weldability. The iron content in AISI 1010 ranges from 99.18% to 99.62%.

The varying carbon and manganese levels in AISI 1008 and AISI 1010 are key to their unique mechanical properties and uses.

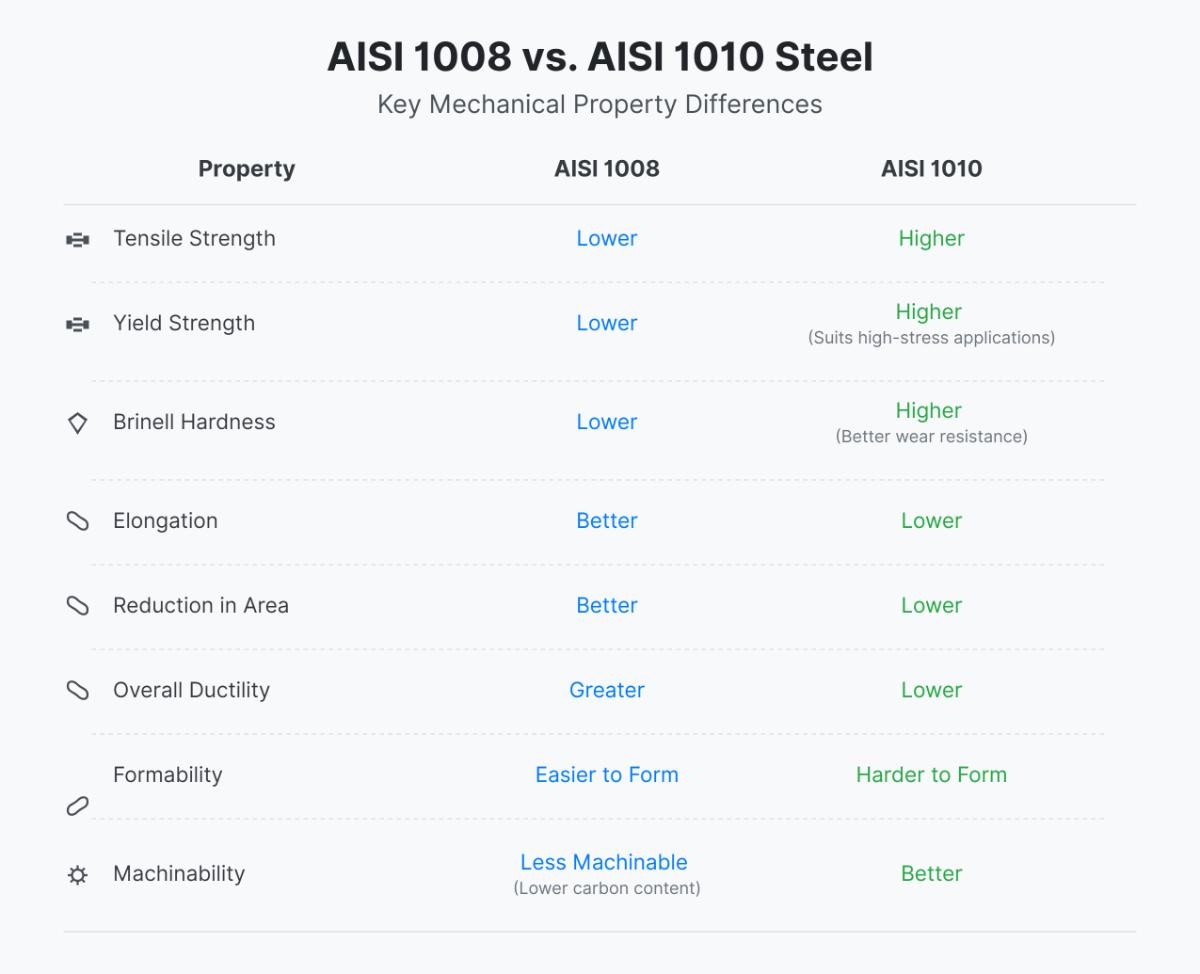

The tensile strengths of AISI 1008 and AISI 1010 vary based on how they are manufactured. In the cold-drawn state, AISI 1010 has an approximate tensile strength of 53,000 psi (366 MPa), which is higher than AISI 1008’s tensile strength of about 49,000 psi (338 MPa). When hot-rolled, AISI 1010 still maintains an edge with about 47,000 psi (324 MPa), compared to AISI 1008’s 44,000 psi (303 MPa). This indicates that AISI 1010 can withstand greater pulling forces before breaking. It is, therefore, more suitable for applications requiring high tensile strength.

Yield strength is another critical mechanical property. For cold-drawn samples, AISI 1010 has a yield strength of about 44,000 psi (303 MPa), while AISI 1008 has a yield strength of approximately 41,500 psi (286 MPa). In the hot-rolled condition, AISI 1010’s yield strength is around 26,000 psi (179 MPa), higher than AISI 1008’s 24,500 psi (169 MPa). A higher yield strength means that AISI 1010 can endure more stress without undergoing permanent deformation, making it a better choice for components that need to maintain their shape under load.

AISI 1008 has a higher elongation at break, ranging from 20% to 30%, while AISI 1010 ranges from 20% to 28%. This greater ability to stretch before breaking indicates that AISI 1008 is more ductile and can be more easily formed into various shapes without fracturing.

The reduction in area also reflects ductility. AISI 1008 has a reduction in area of 45% to 55%, while AISI 1010 has a range of 40% to 50%. A higher reduction in area for AISI 1008 further demonstrates its superior ductility, making it ideal for applications involving extensive deformation.

AISI 1008 has a Brinell hardness of 86 to 95, whereas AISI 1010 ranges from 95 to 105. AISI 1010’s higher hardness implies greater resistance to indentation and wear, which is beneficial for applications where the material needs to withstand abrasive forces.

AISI 1008 is commonly used in the automotive industry for body panels due to its high formability and ductility. Its excellent weldability also makes it ideal for parts assembled through welding, like door frames and structural elements.

AISI 1010 is preferred for high-strength components like gears, axles, and crankshafts, which endure significant stress and wear. The higher tensile and yield strength of AISI 1010 ensure these components can withstand significant operational loads without deforming.

AISI 1008 is often used for wire products and reinforcing bars due to its flexibility and ease of fabrication. The ability to easily bend and shape AISI 1008 without compromising its integrity makes it a valuable material for construction projects.

AISI 1010 is employed for structural beams, columns, and other load-bearing components that require greater strength and rigidity. These properties ensure the material can support significant weights and resist deformation, making it a reliable choice for critical structural elements.

AISI 1008 is used in various industrial applications beyond automotive and construction. Its excellent formability and weldability make it suitable for manufacturing appliances, industrial equipment, and other products requiring complex shapes and reliable welding.

AISI 1010 is ideal for precision components like gears, shafts, and pins, where strength and machinability are crucial. Additionally, it is used in the production of structural components in industrial settings, where its strength and hardness are essential for maintaining the integrity of the structure under various operating conditions.

Machinability is a critical factor when selecting steel for applications that involve extensive machining processes, such as turning, drilling, and milling. The machinability of a material influences the ease with which it can be cut, the surface finish quality, and the tool life.

AISI 1008 is known for its good machinability, though it has slightly lower machinability than AISI 1010. The low – carbon AISI 1008 is softer and more ductile. This helps in forming but can cause machining problems. The ductility of AISI 1008 can lead to issues such as chip formation and increased tool wear. However, with the right machining parameters and tools, AISI 1008 can still be effectively machined to achieve the desired surface finish and dimensional accuracy.

AISI 1010 offers better machinability compared to AISI 1008. The slightly higher carbon content in AISI 1010 enhances its hardness and strength, making it easier to form chips during machining. This leads to smoother cutting and less tool wear. AISI 1010 is preferred for applications that require precise machining and forming operations, as it can maintain tighter tolerances and provide a better surface finish. The improved machinability of AISI 1010 makes it a suitable choice for components requiring intricate shapes and high dimensional accuracy.

Weldability is another crucial consideration when selecting steel grades for applications involving welding. Good weldability ensures that the material can be joined effectively without defects such as cracking or porosity. AISI 1008 is highly regarded for its excellent weldability. The low carbon content in AISI 1008 minimizes the risk of weld cracking and other defects, making it suitable for various welding processes, including resistance welding and arc welding. The material’s ductility allows for smooth welding operations and strong, reliable weld joints. AISI 1008 is often used in applications where welding is a primary method of assembly, such as in the automotive and construction industries. In contrast, AISI 1010 also offers good weldability, but it is slightly more challenging to weld compared to AISI 1008. The higher carbon content in AISI 1010 increases the risk of weld cracking and requires more careful control of welding parameters. Preheating and post – weld heat treatment might be needed to prevent cracking and ensure weld joint integrity. Despite these additional precautions, AISI 1010 can still be effectively welded and is used in applications where higher strength and hardness are required in the welded components.

AISI 1008 generally costs less than AISI 1010 due to its lower carbon content. The reduced carbon and manganese content result in lower material costs, making AISI 1008 a more budget-friendly option for projects where cost minimization is crucial.

AISI 1008’s high formability and ductility reduce processing costs. Its ease of bending, shaping, and welding allows for efficient manufacturing processes, leading to lower labor and equipment costs.

AISI 1008’s excellent formability and ductility make it ideal for applications requiring extensive shaping and bending. These properties are particularly beneficial for manufacturing complex components and intricate designs.

AISI 1008’s superior weldability, resulting from its low carbon content, ensures strong and reliable weld joints with minimal risk of cracking. This makes it suitable for welded assemblies in various industries, including automotive and construction.

AISI 1008’s balanced mechanical properties and cost-effectiveness make it a versatile choice for numerous low-stress applications, such as automotive body panels, wire products, and appliances.

AISI 1010 is typically more expensive than AISI 1008 due to its higher carbon and manganese content. These elements enhance the steel’s mechanical properties but also increase the raw material costs.

While AISI 1010 offers better machinability, the need for more precise welding techniques can increase processing costs. Additional requirements for preheating and post-weld heat treatments to prevent cracking can also add to the expenses.

The higher carbon content in AISI 1010 provides greater strength and hardness compared to AISI 1008. This makes AISI 1010 suitable for high-stress applications, such as gears, axles, and structural components that demand durability and resistance to wear.

AISI 1010’s improved machinability allows for more efficient and precise machining processes. This results in better surface finishes and tighter dimensional tolerances, which are essential for components requiring high precision.

The enhanced mechanical properties of AISI 1010 ensure better structural integrity for load-bearing applications. Its higher tensile and yield strengths make it a reliable choice for critical components that must maintain their shape under significant loads.

The choice between AISI 1008 and AISI 1010 depends largely on the specific requirements of the application. For projects prioritizing cost-efficiency, formability, and weldability, AISI 1008 is the better option. However, applications demanding higher strength, hardness, and machinability will benefit more from AISI 1010.

For budget-conscious projects, AISI 1008 offers a more cost-effective solution due to its lower material and processing costs. However, the long-term benefits of AISI 1010’s superior mechanical properties might justify its higher initial cost for applications where performance and durability are paramount.

When selecting between AISI 1008 and AISI 1010, consider the manufacturing processes involved. AISI 1008’s ease of forming and welding can simplify production and reduce costs. In contrast, AISI 1010’s machinability and strength make it ideal for precision components and high-stress environments, albeit with potentially higher processing expenses.

By carefully evaluating these factors, engineers and manufacturers can make informed decisions that balance cost, performance, and suitability for their specific applications.

Below are answers to some frequently asked questions:

AISI 1008 and AISI 1010 are low-carbon steels with distinct mechanical properties. AISI 1010 has higher tensile and yield strength, making it suitable for high-stress applications. Its Brinell hardness is also higher, providing better wear resistance. In contrast, AISI 1008 offers better elongation and reduction in area, indicating greater ductility. AISI 1008 is more ductile and easier to form but less machinable due to its lower carbon content, while AISI 1010 offers better machinability.

AISI 1008 and AISI 1010 steel grades are suited to different applications based on their properties. AISI 1008, with its lower carbon content, is highly ductile and formable, making it ideal for low-stress applications. It is commonly used in automotive body panels, construction, appliances, and industrial equipment. Its excellent malleability also makes it suitable for wire products and cold-headed parts.

On the other hand, AISI 1010 has a slightly higher carbon content, providing greater tensile strength and yield strength. This makes it better suited for higher-stress applications requiring moderate strength and durability. Typical uses include precision machining for gears, shafts, pins, and various structural components. It is widely employed in the automotive industry for parts such as axles and crankshafts.

Both AISI 1008 and AISI 1010 have comparable machinability and weldability, but there are nuanced differences due to their carbon content. AISI 1008, with a maximum carbon content of 0.10%, is generally easier to weld. Its lower carbon content reduces the risk of weld cracking, making it more suitable for applications requiring reliable and defect-free welding.

On the other hand, AISI 1010, which has a slightly higher carbon content (0.08-0.13%), offers marginally better machinability. The higher carbon content aids in chip formation during machining, which can lead to a smoother machining process and less tool wear. However, AISI 1010 can be more prone to weld defects compared to AISI 1008.

AISI 1008 and AISI 1010 are both categorized as low-carbon steels, which are steels with a carbon content typically less than 0.30%. These grades are known for their excellent ductility, formability, and weldability, making them suitable for various applications.

AISI 1008 has a maximum carbon content of 0.10%, while AISI 1010 contains slightly more carbon, ranging from 0.08% to 0.13%. This slight difference in carbon content affects their mechanical properties. AISI 1008 is more ductile and easier to form, making it ideal for applications requiring flexibility and low stress. In contrast, AISI 1010, with its higher carbon content, offers greater strength and hardness, making it better suited for higher-stress applications.

Both grades contain manganese, with AISI 1008 ranging from 0.30% to 0.50% and AISI 1010 from 0.30% to 0.60%, which further influences their strength and hardenability.

For a comprehensive cost-benefit analysis of AISI 1008 and AISI 1010 steel in different industries, it’s essential to consider their unique properties and how these affect their performance and costs in various applications.

In the automotive industry, AISI 1008 is favored for parts requiring excellent formability and weldability, such as body panels and other complex shapes. Its lower cost and high ductility enhance manufacturing efficiency and reduce waste. However, its lower tensile strength means additional reinforcement might be necessary in high-stress areas, potentially increasing costs.

AISI 1010, with higher tensile and yield strengths, is better suited for components that endure greater stress, such as engine parts and structural elements. While its higher carbon content enhances durability, it may also complicate welding, potentially increasing manufacturing costs. Nonetheless, the improved strength and durability can lead to lower maintenance and replacement expenses over time.

In construction, AISI 1008 is ideal for applications like building frames and sheet metal roofing, where formability and ease of welding are critical. Its lower material and labor costs can speed up construction and reduce on-site labor. Conversely, AISI 1010 may be over-specified for standard construction unless specific high-strength requirements are necessary, potentially leading to higher costs without significant benefits.

For manufacturing and machinery, AISI 1008’s high ductility and weldability make it suitable for low-stress applications like wire mesh and small machinery parts. Its lower material costs and simpler manufacturing processes contribute to faster production times and reduced waste. AISI 1010, on the other hand, is advantageous for machinery requiring higher strength, such as gears and axles, despite its slightly higher material and machining costs. The increased durability of AISI 1010 components can result in a longer lifespan and reduced maintenance costs.

When choosing between AISI 1008 and AISI 1010 for a project, several cost-benefit factors should be considered:

In summary, the choice between AISI 1008 and AISI 1010 depends on the specific requirements of the project, including strength, formability, machinability, weldability, and budget constraints.