When it comes to selecting the right aluminium alloy for your engineering project, understanding the nuances between different grades is crucial. Aluminium 5005 and 5052 are two popular choices, each with unique properties that make them suitable for various applications. But how do you decide which one is best for your needs? This article delves into the key differences between Aluminium 5005 and 5052, examining their material properties, corrosion resistance, weldability, and more. Whether you’re working on marine, construction, or automotive projects, we’ll guide you through the comparative aspects to help you make an informed decision. Ready to discover which alloy stands out in your specific application? Let’s dive in.

The chemical composition of Aluminium 5005 and 5052 plays a key role in their properties and applications.

The mechanical properties of these alloys determine their suitability for different uses.

Strength:

Fatigue Strength:

Shear Strength:

Both alloys are known for their corrosion resistance, but there are differences.

The formability and weldability of these alloys are crucial for manufacturing.

The cost and typical applications of these alloys are influenced by their properties.

Applications:

The mechanical properties of Aluminium 5005 and 5052 significantly influence their selection for various applications. Knowing these properties helps in selecting the most suitable alloy for different applications.

The chemical composition of aluminium alloys significantly affects their corrosion resistance. Aluminium 5052 has around 2.5% magnesium and 0.25% chromium, which notably enhances its corrosion resistance, especially in harsh settings like marine environments. In contrast, Aluminium 5005 contains about 0.8% magnesium with less than 1% manganese, which provides moderate corrosion resistance but is generally less effective in highly corrosive environments compared to 5052. The presence of magnesium in these alloys helps form a protective oxide layer on the surface, which acts as a barrier against corrosive elements.

Aluminium 5052 demonstrates excellent corrosion resistance. This makes it a top – choice for applications exposed to seawater or other harsh elements. The high magnesium content in 5052 promotes the formation of a protective oxide layer. This layer offers strong resistance against general atmospheric conditions and marine environments. As a result, Aluminium 5052 is commonly used in marine hardware, shipbuilding, and other applications with frequent exposure to corrosive elements.

Aluminium 5005 offers good corrosion resistance suitable for general atmospheric exposure. It is often employed in architectural applications where environmental conditions are less severe. However, its lower magnesium content makes it less effective in highly corrosive environments compared to 5052. Consequently, Aluminium 5005 is typically used in less demanding applications such as roofing, cladding, and signage.

Both Aluminium 5005 and 5052 can be anodized to further enhance their corrosion resistance. Anodizing Aluminium 5005 forms a dense oxide layer on its surface. This layer acts as a physical barrier, preventing corrosive substances from reaching the underlying metal. Additionally, anodized Aluminium 5005 is known for providing excellent color uniformity, making it a popular choice for architectural applications where appearance is important.

Aluminium 5052 also benefits from anodizing. The anodizing process thickens the natural oxide layer on 5052, enhancing its already superior corrosion resistance. This makes anodized 5052 particularly suitable for applications that require both aesthetic appeal and high durability, such as in marine and industrial environments.

Imagine the harsh, salt – laden air and the constant pounding of waves in a marine environment. In such a challenging setting, Aluminium 5052 stands out as the superior choice. Its higher magnesium content provides better protection against saltwater corrosion. In addition, the presence of chromium in 5052 helps prevent grain boundary precipitation, which can weaken the material and make it more prone to corrosion. Thus, Aluminium 5052 is highly suitable for shipbuilding, marine hardware, and other applications with prolonged exposure to seawater.

Consider the vast expanse of modern buildings with their various facades and structures. For architectural applications, Aluminium 5005 is often the preferred option. It offers good corrosion resistance in general atmospheric conditions. Moreover, its ability to maintain color uniformity when anodized makes it an attractive choice. Also, its lower cost compared to 5052 makes it a cost – effective solution for large – scale architectural projects, such as roofing, cladding, and decorative elements.

Weldability refers to how easily a material can be welded to form a strong and durable joint. Both Aluminium 5005 and 5052 are known for their good weldability, but there are differences that make each alloy suitable for specific applications.

Aluminium 5005:

Aluminium 5052:

Both 5005 and 5052 are compatible with MIG and TIG welding techniques. The choice of filler wire and welding conditions should be carefully considered to avoid defects and ensure strong, visually appealing welds.

| Aluminium 5005 | Aluminium 5052 | |

|---|---|---|

| Strength | Medium strength | Higher strength |

| Weldability | Good weldability with standard techniques | Excellent weldability with all standard methods |

| Corrosion Resistance | Good in atmospheric conditions | Excellent, especially in marine environments |

| Typical Applications | Architectural and decorative applications | Marine components, aircraft parts, high-stress environments |

Both Aluminium 5005 and 5052 offer good weldability, but Aluminium 5052 provides superior performance in terms of weld strength and durability. The choice between these alloys should be based on the specific requirements of the project, considering factors such as strength, weldability, and environmental conditions.

Formability refers to the ability of a material to undergo plastic deformation without being damaged. This property is crucial for manufacturing processes like bending, drawing, and stamping, where materials need to be shaped into complex forms. The formability of Aluminium 5005 and 5052 is influenced by their chemical composition and mechanical properties, making each alloy suitable for different applications.

Aluminium 5005 contains approximately 0.8% magnesium and 0.4% manganese. The magnesium content contributes to its moderate strength and good formability, while manganese improves its resistance to wear and tear. This combination allows 5005 to be easily shaped, especially in softer tempers, making it ideal for applications requiring extensive shaping without high strength.

Aluminium 5052, with about 2.5% magnesium and 0.25% chromium, has a higher magnesium content, which increases its strength but reduces its ductility. The chromium enhances its corrosion resistance. Despite the higher strength, 5052 still offers excellent formability, particularly in the O temper, where it can be bent, drawn, and stamped into intricate shapes with relative ease.

Due to its excellent formability and lower strength, Aluminium 5005 is commonly used in applications where extensive shaping is required without high strength demands. Typical uses include:

Aluminium 5052 is preferred for applications needing a balance of formability and higher strength. It is ideal for:

Both Aluminium 5005 and 5052 can be processed using common forming techniques, but their suitability varies based on specific application requirements.

Aluminium alloys 5005 and 5052 are used across various industries due to their unique properties. This comparison aims to highlight their distinct applications in different sectors.

Aluminium 5005 is widely used in the construction industry for its excellent formability and moderate strength. Applications include:

In construction, Aluminium 5052 is preferred for applications requiring higher strength and better corrosion resistance:

While not the first choice for marine applications, Aluminium 5005 can be used in less demanding marine environments:

Aluminium 5052 is highly favored in the marine industry due to its superior properties:

In the automotive industry, Aluminium 5005 is utilized for components where formability and moderate strength are sufficient:

Aluminium 5052 is used in automotive applications demanding higher strength and better durability:

Aluminium 5005 is used in applications where moderate strength and good corrosion resistance are sufficient:

Aluminium 5052 finds extensive use in the food and beverage industry due to its superior properties:

Aluminium 5005 and 5052 have varying levels of corrosion resistance, which affects their use in marine applications.

While Aluminium 5005 offers good corrosion resistance in general atmospheric conditions, its lower magnesium content (around 0.8%) limits its effectiveness in harsh marine environments. Therefore, it is not the optimal choice for prolonged exposure to seawater, although it can be used in less demanding marine settings.

With approximately 2.5% magnesium and added chromium, Aluminium 5052 offers excellent saltwater corrosion resistance, making it ideal for marine use. The alloy forms a robust oxide layer that protects against the corrosive effects of seawater, making it highly suitable for components exposed to harsh marine conditions.

The mechanical properties of Aluminium 5005 and 5052 play a significant role in their suitability for marine environments.

Aluminium 5005 has a lower tensile strength, ranging from 110 to 230 MPa. This makes it less suitable for structural components that require high mechanical strength. Its lower strength and higher susceptibility to deformation under stress limit its use in demanding marine applications.

Aluminium 5052 exhibits higher tensile strength (190 to 320 MPa), making it more durable and better suited for structural applications in marine environments. Its superior strength ensures that components made from 5052 can withstand the mechanical stresses encountered in marine settings, such as the constant movement and loading of vessels.

The formability and weldability of these alloys are crucial for manufacturing marine components, affecting their ease of shaping and joining.

Aluminium 5005 offers good formability, which is beneficial for creating complex shapes. However, its weldability is slightly inferior compared to 5052, especially in applications where the welded joints need to maintain high strength. Standard welding techniques can be used, but the resulting welds may not be as robust.

Aluminium 5052 is known for its excellent formability and weldability, particularly in the H32 and H34 tempers. It can be easily shaped into complex forms without compromising its strength or corrosion resistance. The alloy’s superior weldability ensures that the joints remain strong and durable, which is crucial for marine applications where structural integrity is paramount.

The specific applications of Aluminium 5005 and 5052 in marine environments highlight their respective strengths and limitations.

Due to its lower corrosion resistance and mechanical strength, Aluminium 5005 is typically used in less critical marine applications. These may include:

Aluminium 5052 is widely used in marine environments due to its superior properties. Common applications include:

The cost of materials can influence the choice between Aluminium 5005 and 5052 for marine applications.

Generally, Aluminium 5005 is less expensive than 5052. This cost advantage makes it an attractive option for projects where budget constraints are a priority, and the high-performance characteristics of 5052 are not necessary.

Aluminium 5052 is more expensive due to its enhanced properties. However, the higher cost is justified in marine applications where the alloy’s superior corrosion resistance and mechanical strength result in longer-lasting and more reliable components.

Aluminium 5005 is widely used in construction for roofing and cladding due to its excellent formability, allowing it to be easily shaped into sheets and panels. Its moderate strength and superior corrosion resistance ensure durability, making it ideal for long-term exposure to various weather conditions. Additionally, its capability to achieve uniform anodized finishes makes it a popular choice for architectural facades where aesthetic appeal is crucial.

In addition to roofing and cladding, Aluminium 5005 is commonly used for architectural elements such as facades, trim, and other decorative features due to its excellent formability and good weldability. This allows for the creation of intricate shapes and designs, enhancing the visual appeal of buildings. The alloy’s good weldability also simplifies the fabrication of complex structures, making it a versatile material for modern architectural applications.

Aluminium 5052 is preferred for structural components in construction due to its higher tensile strength and superior corrosion resistance. This alloy is suitable for applications that require greater mechanical strength and durability. For instance, 5052 is often used in the construction of load-bearing elements and structural frames that must withstand significant stress and deformation.

Aluminium 5052 is ideal for roofing and cladding in coastal areas because of its superior corrosion resistance. Its ability to resist saltwater corrosion ensures that structures remain protected from harsh marine conditions, making it perfect for building exteriors that need to maintain their integrity and appearance over time.

The strength and durability of Aluminium 5052 make it suitable for pressure vessels and storage tanks in various construction projects. These applications require materials that can withstand internal pressures and provide reliable performance over extended periods. The alloy’s resistance to corrosion from stored materials further enhances its suitability for these critical applications.

Aluminium 5005 is generally more cost-effective than 5052, making it an attractive option for large-scale construction projects where budget constraints are a concern. Its lower magnesium content contributes to the reduced cost, providing a balance between performance and affordability.

Although Aluminium 5052 is more expensive due to its higher magnesium content and superior properties, the investment is justified for applications requiring high strength and enhanced corrosion resistance. The long-term benefits of using 5052, such as reduced maintenance and replacement costs, can offset the initial higher expenditure.

Both Aluminium 5005 and 5052 offer unique advantages in construction applications, with the choice depending on specific project requirements like environmental conditions, structural needs, and budget considerations.

| Aluminium 5005 | Aluminium 5052 | |

|---|---|---|

| Formability | Excellent for shaping and bending | Good, especially in softer tempers |

| Strength | Moderate, suitable for non-load-bearing applications | High, ideal for structural components |

| Corrosion Resistance | Good in general atmospheric conditions | Superior, particularly in marine and harsh environments |

| Typical Uses | Roofing, cladding, decorative elements | Structural frames, high-performance roofing, pressure vessels |

Aluminium 5005 and 5052 are popular choices for automotive applications due to their unique properties. Here’s a comparison of their mechanical properties and specific uses.

Aluminium 5005 offers medium strength, with a tensile strength ranging from 110 to 230 MPa, making it suitable for automotive components that do not require high structural integrity. In contrast, Aluminium 5052 is known for its moderate to high strength, with a tensile strength ranging from 190 to 320 MPa, making it ideal for more demanding automotive environments.

Both alloys resist corrosion well, but Aluminium 5052 performs better in harsh environments. Aluminium 5005 is great for general atmospheric conditions, while Aluminium 5052, due to its higher magnesium content, excels in marine environments.

Formability and weldability are crucial in automotive manufacturing. Aluminium 5005 is easily shaped and bent, making it suitable for components needing extensive shaping. It is also weldable, though not as robust as 5052. Aluminium 5052, on the other hand, is highly formable and weldable, making it ideal for complex shapes and durable joints.

Here’s a concise comparison of Aluminium 5005 and 5052 for automotive use:

When considering Aluminium 5005 and 5052 for various applications, cost and budget are critical factors that influence decision-making. Engineers must balance material properties with cost-effectiveness to ensure optimal performance within budget constraints.

Aluminium 5005 is generally less expensive than 5052. This cost advantage is primarily due to its simpler chemical composition, particularly its lower magnesium content. The lower cost makes Aluminium 5005 an attractive option for applications where high strength and enhanced properties are not critical, thus providing a more budget-friendly solution for general use.

Aluminium 5052 is more expensive because of its higher magnesium content and superior mechanical properties. The cost of 5052 can range significantly, typically between USD 1,900 to USD 3,900 per metric ton, depending on market conditions, sheet thickness, and other factors. The higher price is justified by its increased strength, better corrosion resistance, and improved machinability, making it suitable for more demanding applications.

When choosing between Aluminium 5005 and 5052, it is essential to evaluate the specific needs of the application. Aluminium 5005 offers cost savings but may not provide the necessary strength or durability for all applications. On the other hand, 5052, although pricier, delivers superior performance, which can be crucial for high-stress or corrosive environments.

Investing in Aluminium 5052 can lead to long-term cost savings despite the higher initial expenditure. Its superior corrosion resistance and strength reduce the need for frequent replacements and maintenance, particularly in harsh environments. For projects where longevity and durability are paramount, the higher upfront cost of 5052 can be offset by reduced lifecycle costs.

For architectural and decorative applications, Aluminium 5005 is often preferred due to its excellent formability and lower cost. It is suitable for roofing, cladding, and other non-structural elements where high strength is not necessary. The ability to achieve uniform anodized finishes makes it ideal for aesthetic applications, providing a cost-effective solution without compromising on visual appeal.

In structural and marine applications, the higher cost of Aluminium 5052 is often justified. Its enhanced properties, such as increased tensile strength and superior corrosion resistance, are critical in these environments. For instance, in marine hardware, shipbuilding, and offshore structures, the durability and performance of 5052 are essential, making the investment worthwhile.

The prices of both Aluminium 5005 and 5052 are influenced by global supply and demand dynamics. Fluctuations in raw material availability, manufacturing costs, and market demand can impact the cost of these alloys. Additionally, economic conditions such as inflation, tariffs, and trade policies affect pricing, leading to potential price volatility. Engineers and procurement professionals must stay informed about market trends to make cost-effective purchasing decisions.

Accurate cost estimation is crucial for project planning. Key steps include:

By comparing the total cost of ownership between Aluminium 5005 and 5052, engineers can make informed decisions that align with both performance requirements and budget constraints.

Adopting strategic procurement practices can help manage costs effectively. Bulk purchasing, long-term supplier agreements, and market analysis can lead to cost savings and more predictable pricing. Additionally, working closely with suppliers to understand material availability and lead times can optimize project timelines and budgets.

When selecting between Aluminium 5005 and 5052, it is essential to weigh the cost against the performance requirements of the application. While Aluminium 5005 offers a more economical option, Aluminium 5052 provides enhanced properties that can justify its higher price in demanding environments.

Both Aluminium 5005 and 5052 are highly recyclable, which is a significant environmental benefit. Recycling aluminium reduces energy consumption by about 95% compared to producing new aluminium. This drastic reduction in energy use leads to lower greenhouse gas emissions, making these alloys a sustainable choice.

Aluminium 5052 outperforms Aluminium 5005 in corrosion resistance, especially in marine environments, which extends its lifespan and reduces the need for frequent replacements. This enhanced durability minimizes waste and lessens the environmental impact associated with production and disposal. In contrast, Aluminium 5005, with its relatively lower corrosion resistance, may need to be replaced more often, leading to more waste.

Producing both alloys uses similar energy. However, because Aluminium 5052 is stronger and more durable, it might require less material for some uses. This reduction in material usage could potentially lower energy consumption over the product’s entire lifecycle.

Aluminium 5052 has more magnesium than 5005. Although this might seem to impact resource usage more, magnesium is abundant and recyclable. This means the environmental impact related to the higher magnesium content in 5052 is minimized. Aluminium 5005, with its lower magnesium content, has a relatively lower demand on magnesium resources.

Both alloys are weldable and formable. Aluminium 5052 offers superior weldability without sacrificing corrosion resistance, making manufacturing processes more efficient and potentially reducing waste and energy consumption. Aluminium 5005 has good formability but is slightly less efficient in welding processes compared to 5052.

Aluminium 5005 is commonly used in architectural applications where high strength is not a critical requirement. Its corrosion resistance is sufficient for these less demanding environments. Aluminium 5052, with its superior strength and weldability, is well-suited for demanding applications such as those in the marine and automotive industries. When used in the right applications, both alloys support sustainable practices effectively.

| Feature | Aluminium 5005 | Aluminium 5052 |

|---|---|---|

| Corrosion Resistance | Excellent in general environments, less in saltwater | Superior in saltwater and marine environments |

| Strength and Durability | Medium strength, softer and less durable | Higher strength, more durable |

| Recyclability | Highly recyclable | Highly recyclable |

| Energy Consumption | Similar to 5052 | Potentially lower due to increased durability |

| Resource Usage | Lower magnesium content | Higher magnesium content |

| Weldability and Formability | Good formability, weldable | Excellent weldability and formability |

In the marine industry, Aluminium 5052 is a preferred choice for boat hulls due to its excellent corrosion resistance and mechanical strength. A case study involving a commercial fishing vessel demonstrated the effectiveness of Aluminium 5052. The vessel, operating in saltwater environments, utilized Aluminium 5052 for its hull construction. After five years, the hull showed minimal corrosion and stayed structurally sound despite constant exposure to harsh marine conditions. This case highlights the alloy’s suitability for marine applications where durability and resistance to saltwater are critical.

Although Aluminium 5005 is less commonly used in marine environments due to its lower corrosion resistance, it finds application in deck equipment where exposure to seawater is limited. A study on small recreational boats revealed that Aluminium 5005 was effectively used for deck rails and other non-structural components. These parts were mainly exposed to the air, not direct seawater. The results showed that Aluminium 5005 provided satisfactory performance, with good formability and sufficient resistance to atmospheric corrosion, making it a cost-effective choice for less demanding marine applications.

In the construction industry, Aluminium 5005 is widely used for architectural cladding due to its excellent formability and aesthetic appeal. A case study on a modern office building demonstrated the advantages of using Aluminium 5005. The building’s exterior was clad with anodized Aluminium 5005 panels, providing a uniform and attractive finish. After a decade, the panels still looked good with minimal maintenance, showing the alloy’s durability and corrosion resistance in urban settings. This case underscores the suitability of Aluminium 5005 for architectural applications where visual appeal and ease of maintenance are essential.

Aluminium 5052 is often selected for structural frames in construction projects requiring higher strength. A notable example is a pedestrian bridge constructed using Aluminium 5052. The bridge, located in a coastal area, needed to withstand both mechanical loads and corrosive marine air. Aluminium 5052 was chosen for its superior strength and corrosion resistance. After several years, inspections revealed that the bridge remained in excellent condition, with no significant signs of corrosion or structural degradation. This case study highlights the effectiveness of Aluminium 5052 in providing long-term durability in demanding construction applications.

In the automotive industry, Aluminium 5005 is utilized for various interior components due to its formability and corrosion resistance. A case study involving a luxury car manufacturer showed the benefits of using Aluminium 5005 for dashboard panels and trim. The alloy’s ease of shaping and anodizing enabled the creation of attractive and durable interior parts. Over the vehicle’s lifecycle, the components retained their finish and resisted wear, demonstrating Aluminium 5005’s effectiveness for automotive interiors where appearance and longevity are important.

Aluminium 5052’s superior corrosion resistance and strength make it ideal for automotive fuel tanks. A case study on a fleet of commercial trucks highlighted the performance of Aluminium 5052 fuel tanks. The tanks were subjected to various fuels and environmental conditions over several years. The study found that Aluminium 5052 tanks had no corrosion or leaks, ensuring the fuel system’s safety and reliability. This case illustrates the alloy’s suitability for critical automotive components that require high durability and resistance to corrosive elements.

Below are answers to some frequently asked questions:

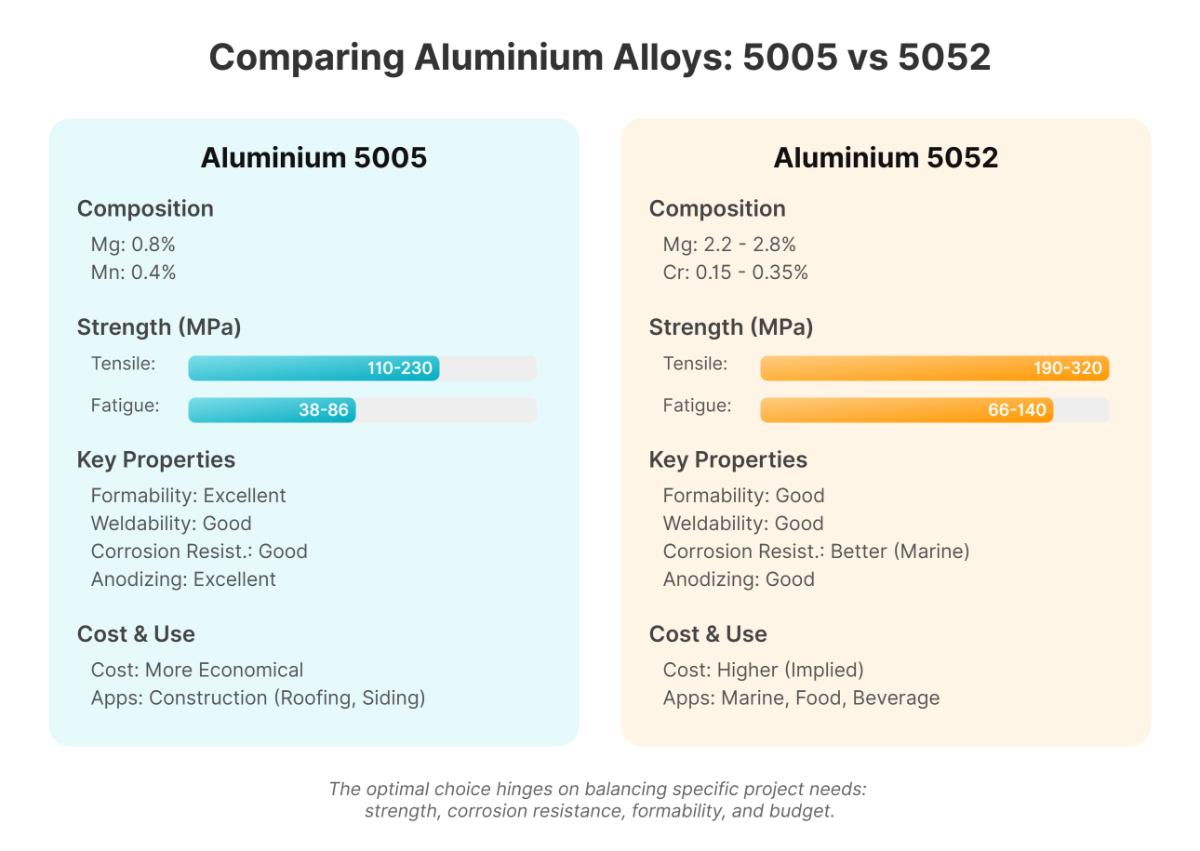

The key differences between Aluminium 5005 and 5052 lie primarily in their chemical composition, mechanical properties, and applications. Aluminium 5005 contains 0.8% magnesium and 0.4% manganese, making it a non-heat treatable alloy with excellent formability and good weldability, especially when anodized. In contrast, Aluminium 5052 has a higher magnesium content (2.2% to 2.8%) and 0.15% to 0.35% chromium, which provides it with superior strength, higher tensile strength (190-320 MPa vs. 110-230 MPa for 5005), and better corrosion resistance, particularly in marine environments.

Additionally, 5052’s higher fatigue strength (66-140 MPa vs. 38-86 MPa for 5005) makes it suitable for applications involving cyclic loading. Aluminium 5005 is generally more economical due to its lower magnesium content, making it ideal for construction projects like roofing and siding. On the other hand, 5052’s enhanced properties are preferred for demanding applications in the food, beverage, and marine industries. The choice between these alloys depends on specific project requirements, including strength, corrosion resistance, formability, and cost considerations.

For marine applications, Aluminium 5052 is generally the better choice. It has a high magnesium content (nearly 3%), which gives it superior corrosion resistance in saltwater environments. It also offers higher tensile strength and excellent weldability, and can be readily welded without compromising its properties. In contrast, Aluminium 5005 has less magnesium, lower strength, and is less resistant to saltwater corrosion, making it less suitable for harsh marine conditions.

Aluminium 5005 is generally more economical than Aluminium 5052. This cost difference is primarily due to the lower magnesium content in 5005, which typically ranges between 0.5% to 1.1%, compared to the 2.2% to 2.8% found in 5052. The reduced magnesium content not only affects its mechanical properties and corrosion resistance but also reduces production costs. Consequently, Aluminium 5005 is often preferred for applications where budget is a significant consideration without the need for the enhanced strength and corrosion resistance provided by 5052.

In contrast, Aluminium 5052 commands a higher price due to its enhanced properties, making it suitable for more demanding environments such as marine and aerospace applications. The higher magnesium content in 5052 improves its strength and corrosion resistance, justifying the additional cost. Therefore, the choice between these alloys should be based on the specific requirements of the project, balancing cost with the needed performance characteristics.

Aluminium 5005 is typically used in building and construction for roofing, cladding, and architectural components, as well as in signage and name plates due to its corrosion resistance and anodizing properties. It’s also used in food and chemical equipment, furniture, HVAC, and packaging, and is well – suited for decorative anodizing in architectural fittings and electronics. Aluminium 5052 is mainly used in marine applications like boat hulls and coastal structures because of its high corrosion resistance. It’s also found in aircraft and automotive parts, and used to manufacture pressure vessels and food containers due to its formability and strength.

Aluminium 5005 and 5052 both offer good general corrosion resistance. Aluminium 5005 contains about 0.8% magnesium and 0.4% manganese, providing decent corrosion protection, suitable for architectural applications. However, in harsh environments like marine settings, its performance is less effective. Aluminium 5052, with 2.5% magnesium and 0.25% chromium, has superior corrosion resistance, especially in marine atmospheres and slightly alkaline conditions, making it a top choice for marine applications.

Both Aluminium 5005 and 5052 are relatively easy to weld. Aluminium 5005 has good weldability and can be welded using standard techniques. A 5356 filler wire is often recommended to achieve good color uniformity, though some discoloration may occur. On the other hand, Aluminium 5052 is renowned for its excellent weldability. Its low melting point and lower magnesium content reduce the risk of cracking during welding. Common techniques like TIG and MIG can be easily used, and 5356 or 4043 filler wires are recommended. Overall, 5052 stands out with superior weldability and lower defect risk.