Imagine taking a solid piece of aluminum and transforming it into a complex, intricate shape with remarkable precision and minimal waste. Welcome to the world of aluminum extrusion—a fascinating process that combines art, science, and engineering. In this comprehensive guide, we’ll walk you through the step-by-step journey of aluminum extrusion, from preparing the billet to the final cooling and cutting stages. You’ll discover the critical differences between direct and indirect extrusion methods and explore the vast array of applications that make aluminum extrusions indispensable in industries like construction, automotive, and aerospace. Ready to dive into the mechanics and marvels of this versatile process? Let’s get started with the key components and stages that make aluminum extrusion a cornerstone of modern manufacturing.

Aluminum extrusion is a process that shapes aluminum alloy into objects with specific cross-sectional profiles, suitable for a wide range of applications. This method is renowned for its versatility, enabling the creation of complex and precise shapes with high strength-to-weight ratios.

The extrusion die, a specially designed tool, is preheated to 450-500°C. This preheating ensures uniform metal flow and prolongs the die’s lifespan. Concurrently, an aluminum billet, which is a solid block of aluminum alloy, is heated to 400-500°C. This heating makes the aluminum malleable without melting it, ensuring it can be shaped effectively during extrusion.

The heated billet is then placed in the extrusion press, where a hydraulic ram forces it through the die, creating a continuous profile. As the billet is pushed through, it adopts the die’s shape, resulting in a continuous profile.

After extrusion, the profile is cooled using water or air to maintain its shape, and then cut to manageable lengths. The extruded profiles are stretched to correct any distortions and ensure straightness. Following this, they may be aged to achieve specific temper properties such as T5 or T6, enhancing their mechanical characteristics.

Aluminum extrusions are integral to numerous industries, including construction, automotive, aerospace, and consumer goods. Their lightweight, corrosion-resistant, and durable nature makes them suitable for structural components, vehicle parts, and various consumer products.

The extrusion process has evolved to become more sustainable, emphasizing recycling and energy efficiency. Aluminum billets are often produced from recycled material, reducing environmental impact. Innovations in indirect extrusion techniques also help lower energy consumption and enhance process efficiency.

Customization options in aluminum extrusion are vast, allowing for tailored profiles to meet specific requirements. This flexibility is crucial for industries demanding precise and unique components. Advances in die design and extrusion technology continually expand the possibilities for customized aluminum profiles.

Aluminum extrusion involves pushing aluminum alloy through a die to create objects with specific shapes. This method allows the production of complex shapes with high precision, leveraging aluminum’s strength, lightweight nature, and versatility. The process is essential in various industries, including construction, automotive, aerospace, and consumer goods.

An aluminum billet is a cylindrical block of aluminum alloy used as the raw material for the extrusion process. The billet is typically heated before extrusion to make it malleable without melting.

The extrusion die is a precisely machined tool that shapes the aluminum as it is forced through. The die’s design determines the final cross-sectional profile of the extruded product. Dies are made from high-strength steel to withstand the intense pressures and temperatures of the extrusion process.

The first step in the aluminum extrusion process is the preparation of the aluminum billet. The billet is cut to the appropriate length and then preheated in an oven to a temperature of 400-500°C. Preheating makes the billet soft enough to shape without melting.

Once the billet is preheated, it is transferred to the extrusion press. The press chamber is also heated to maintain the billet’s temperature and ensure smooth metal flow. The heating process is crucial as it softens the aluminum, making it easier to shape.

In the extrusion press, a hydraulic ram applies immense pressure to the preheated billet, forcing it through the die. As the aluminum is pushed through the die, it takes on the die’s shape, forming a continuous profile under pressures that can reach up to 15,000 tons.

After the aluminum exits the die, it is immediately cooled to maintain its shape and set its mechanical properties. Cooling can be achieved using a fan or a water bath. Once cooled, the extruded aluminum is cut to the desired lengths using a hot saw. The profiles are then moved to a cooling table where they reach room temperature.

To ensure the extruded profiles are straight and uniform, they undergo a stretching process. The profiles are clamped at both ends and stretched to correct any distortions. This step is crucial for maintaining the structural integrity and dimensional accuracy of the extrusions.

After extrusion and initial cooling, the profiles may undergo various secondary operations to enhance their properties and appearance. These operations include heat treatment, where profiles are oven-aged to achieve specific temper properties like T4, T5, or T6, enhancing their strength and durability. Surface finishing techniques like anodizing, painting, or powder coating improve the corrosion resistance and aesthetic appeal of the extrusions. Additional machining, drilling, or cutting may be performed to customize the profiles for specific applications.

The aluminum extrusion industry is placing a greater emphasis on sustainability to minimize its environmental impact. This shift is driven by the need for eco-friendly practices and the growing demand for sustainable materials.

Recycling aluminum saves up to 95% of the energy required to produce new aluminum from raw materials, resulting in a significantly lower carbon footprint and fewer environmental impacts associated with mining and refining bauxite. Additionally, recycling aluminum helps conserve natural resources and reduce waste in landfills.

Innovations in energy management systems and heating techniques are making the aluminum extrusion process more energy-efficient. For instance, the implementation of induction heating, which uses electromagnetic induction to heat the billet, reduces energy consumption and improves process efficiency. Advanced energy management systems monitor and optimize energy use, further boosting sustainability.

Advances in die design and extrusion technology are also contributing to sustainability by minimizing material waste. Improved die designs ensure better metal flow and reduce the amount of scrap produced during extrusion. Efficient systems repurpose waste, ensuring materials are reused rather than discarded.

Customization in aluminum extrusion is becoming increasingly sophisticated, driven by technological advancements and the need for tailored solutions in various industries.

The integration of automation and robotics in the extrusion process has significantly enhanced production efficiency and consistency. Automated systems can handle tasks such as billet loading, extrusion, and quality inspection with high precision, reducing human error and increasing throughput. This level of automation allows for more complex and precise profiles to be produced consistently.

New die technologies enable the creation of more intricate and precise aluminum profiles. Computer-aided design (CAD) and computer-aided manufacturing (CAM) systems are used to design and manufacture dies with high accuracy. These systems allow for the production of complex shapes that meet specific customer requirements, improving die lifespan and performance.

The use of 3D printing for rapid prototyping of extrusion dies is another customization trend. This technology allows for quicker turnaround times and reduced costs in die production. Additive manufacturing techniques can produce profiles with complicated geometries and internal structures that are difficult to achieve with traditional methods, opening up new possibilities for custom applications.

Hybrid extrusion techniques combine conventional methods with cutting-edge processes to create aluminum profiles with enhanced properties. These techniques are particularly beneficial for applications requiring superior strength and formability, such as in the aerospace and automotive sectors. By blending different extrusion methods, manufacturers can achieve the desired mechanical properties and complex shapes required for specific applications.

AI is being used in the extrusion process for predictive maintenance, die design, and corrections. AI systems analyze data from the extrusion process to predict equipment failures, optimize die designs, and make real-time adjustments to improve product quality. This integration enhances efficiency, reduces downtime, and ensures consistent production of high-quality extrusions.

Aluminum extrusion is a versatile manufacturing process used to create objects with specific cross-sectional profiles. Among the different extrusion methods, direct and indirect extrusion are the most prominent, each with distinct characteristics and applications.

Process Overview: In direct extrusion, also known as forward extrusion, a heated aluminum billet is placed into a container. A hydraulic ram then pushes the billet through a stationary die, forcing the aluminum to take the shape of the die’s cross-section.

Advantages:

Disadvantages:

Process Overview: Indirect extrusion, also known as backward extrusion, involves moving the billet and container together while the ram and die remain stationary. A longer stem than the container is used to push the aluminum, reducing friction significantly.

Advantages:

Disadvantages:

Direct extrusion needs more force because of the greater friction as the billet moves through the container. In contrast, indirect extrusion minimizes friction, which reduces the force needed and enhances the longevity of the equipment.

While direct extrusion supports continuous operation and high production volumes, indirect extrusion offers faster production for larger billets due to reduced friction and better heat management.

Direct extrusion is more suitable for producing complex shapes due to its operational flexibility. Indirect extrusion, however, faces limitations in creating intricate designs, making it less ideal for applications requiring detailed profiles.

The choice between direct and indirect extrusion largely depends on the specific application requirements. The complexity of the shape, desired mechanical properties, and production volume are key factors in choosing the right method.

Different aluminum alloys respond differently to extrusion processes. Some alloys may be better suited for direct extrusion due to their ability to form complex shapes, while others may benefit from the reduced friction and better heat control of indirect extrusion.

The availability of equipment and expertise in either direct or indirect extrusion can influence the decision. Manufacturers must consider their existing infrastructure and the expertise of their workforce when choosing the most suitable extrusion method.

By understanding these differences, manufacturers can select the most appropriate method for their needs, ensuring optimal results in terms of product quality, efficiency, and cost-effectiveness.

Aluminum extrusions play a significant role in the construction and architecture sectors due to their unique properties and versatility.

Aluminum extrusions are extensively used in building facades, railings, and canopies. Their high strength-to-weight ratio makes them ideal for applications where minimizing weight while maintaining structural integrity is essential. This is particularly beneficial for constructing high-rise buildings and other large structures that require robust support without adding excessive weight.

These extrusions are durable and require little maintenance, making them ideal for harsh weather conditions. The corrosion resistance of aluminum makes it an excellent choice for outdoor applications such as roofing and fencing. Additionally, aluminum’s lightweight nature simplifies the installation process, reducing labor costs and time.

Aluminum extrusions, used in prefabricated components, enable quick assembly and disassembly on construction sites, making them particularly useful for temporary structures or rapid deployment projects. The extrusions provide a visually appealing and adjustable framework, enhancing both the functionality and aesthetics of the construction.

In the automotive and transportation industries, aluminum extrusions are valued for their contribution to weight reduction and fuel efficiency.

Automakers use aluminum extrusions to manufacture various vehicle components such as cross members, subframes, and trim. These parts benefit from aluminum’s lightweight nature, which helps reduce the overall weight of the vehicle, leading to improved fuel efficiency and reduced emissions.

Aluminum extrusions are ideal for marine and aerospace applications due to their corrosion resistance and lightweight properties. In marine environments, aluminum’s corrosion resistance ensures the longevity of components exposed to saltwater. In aerospace, the material’s light weight is crucial for reducing fuel consumption and enhancing the performance of aircraft.

Aluminum extrusions are widely used in the electrical and electronics industries due to their excellent thermal and electrical conductivity.

Aluminum’s high thermal conductivity makes it an ideal material for heat sinks, which are essential for managing heat in electronic devices. These extrusions efficiently dissipate heat, ensuring the optimal performance and longevity of electronic components. Additionally, aluminum enclosures provide effective protection for sensitive electronic equipment, combining durability with lightweight construction.

Aluminum’s superior electrical conductivity makes it suitable for various electrical applications, including wiring and electrical enclosures. This property is leveraged in both consumer electronics and industrial settings, where efficient electrical transmission is critical.

The industrial and manufacturing sectors utilize aluminum extrusions for their strength, durability, and versatility.

Aluminum extrusions are essential for assembly line equipment like modular T-slot framing systems, offering flexible, durable frameworks for workstations and conveyor systems that can be easily customized and reconfigured as needed.

In manufacturing environments, machine guarding systems made from aluminum extrusions protect both equipment and operators. These systems create safe work areas by segmenting different operational zones, preventing accidents and ensuring compliance with safety regulations.

Aluminum profiles are commonly used in various workstations across different industries. Their adaptability and robustness make them ideal for creating ergonomic and efficient workspaces tailored to specific tasks and workflows.

Aluminum extrusions are prevalent in consumer products due to their aesthetic appeal and functional benefits.

In the consumer goods market, aluminum extrusions are used to manufacture furniture, camping chairs, and household appliances. The material’s combination of strength, light weight, and corrosion resistance makes it an attractive choice for products that require both durability and visual appeal.

Sports equipment, such as bicycles and golf clubs, often incorporates aluminum extrusions. The strength and lightness of aluminum enhance the performance and usability of these products, making them popular choices among consumers and athletes alike.

Aluminum extrusions, with their balance of performance, cost-effectiveness, and versatility, are indispensable in modern manufacturing and design. Their diverse applications across multiple sectors underscore their importance in both industrial and consumer contexts.

In direct extrusion, also known as forward extrusion, the aluminum billet is pushed through the die by a hydraulic ram. This method involves the billet and ram moving in the same direction, with the die remaining stationary.

In indirect extrusion, or backward extrusion, the die is attached to the ram, which moves into the stationary billet. In this method, the container and billet move together while the die stays fixed.

In hydrostatic extrusion, the billet is surrounded by a fluid within the container, and pressure is applied through the fluid to force the billet through the die. Fluid pressure ensures even application, reducing defects and enhancing product quality.

Impact extrusion is a high-speed process where a punch forces the billet into the die cavity, typically used for producing hollow or semi-hollow shapes. This method is commonly applied in the production of aluminum cans and tubes.

Cold extrusion involves extruding aluminum at or near room temperature. This process is suitable for producing parts that require high strength and precision.

Hot extrusion is performed at elevated temperatures, typically between 400-500 degrees Celsius. The high temperature ensures the aluminum is malleable, facilitating the extrusion of complex shapes.

Below are answers to some frequently asked questions:

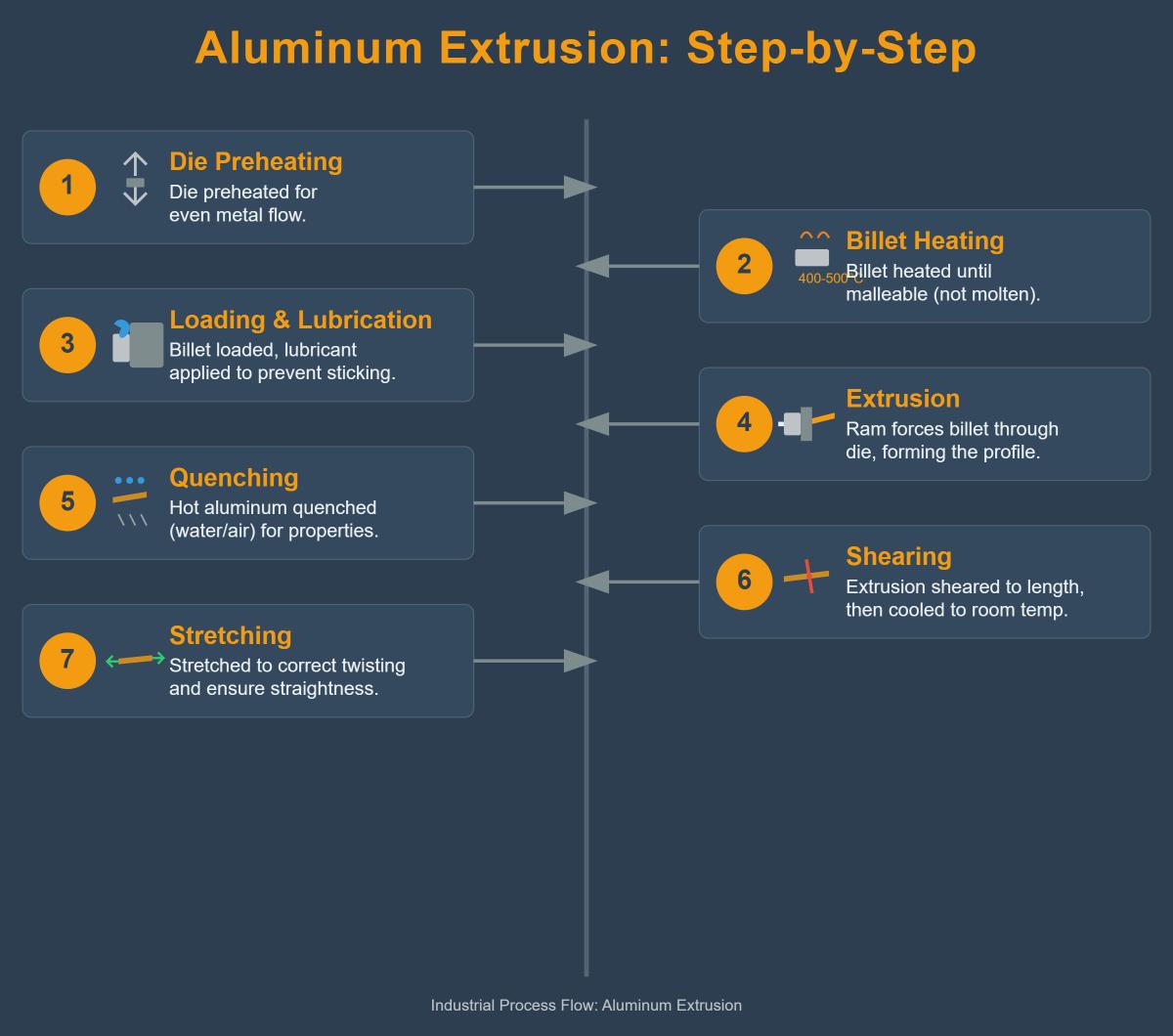

The aluminum extrusion process involves several key steps to transform aluminum billets into desired profiles. First, the extrusion die is preheated to ensure even metal flow. Next, the aluminum billet is heated to around 400°C to 500°C to make it malleable without melting. The preheated billet is then loaded into the extrusion press, where a lubricant is applied to prevent sticking.

The extrusion process begins as the ram applies pressure, forcing the billet through the die openings to form the desired profile. Once extruded, the hot aluminum is quenched using water or air to control cooling rates and achieve specific mechanical properties. After quenching, the extrusion is sheared to table length and allowed to cool to room temperature.

Subsequently, the extrusion is stretched to correct any twisting and ensure straightness.

Direct and indirect aluminum extrusion are two primary methods used in the manufacturing process, each with unique characteristics.

Direct extrusion, also known as forward extrusion, involves pushing a heated aluminum billet through a stationary die using a ram. The billet and ram move in the same direction, creating high pressure. This method is straightforward and flexible, allowing for the production of complex shapes and profiles with excellent surface quality. However, it involves significant friction between the billet and container, leading to higher energy consumption and faster die wear.

Indirect extrusion, on the other hand, involves moving the billet and container together while the ram and die remain stationary. This setup reduces friction and heat generation, resulting in consistent product quality and lower energy consumption. Indirect extrusion is efficient, particularly suitable for high-strength alloys, and leads to less die wear. However, it is more complex to operate and less versatile in producing a wide range of shapes and sizes compared to direct extrusion.

The choice between these methods depends on the specific requirements of the product, including shape complexity, material properties, and desired surface finish.

Aluminum extrusions are extensively utilized across various industries due to their versatility, lightweight nature, and corrosion resistance. In construction and architecture, they are used for railings, building facades, and canopies, providing strength and durability. The automotive and transportation sectors benefit from aluminum extrusions in components like subframes and trim, contributing to reduced vehicle weight and enhanced performance. In electrical and electronics applications, aluminum extrusions are favored for busbars, enclosures, and heat sinks due to their high electrical conductivity. Consumer products such as furniture, bicycles, and cookware also leverage the advantages of aluminum extrusions, including lightweight and corrosion resistance. Additionally, industrial and manufacturing processes use aluminum extrusions for assembly lines and equipment mounting, offering modular design and durability. Solar and renewable energy systems utilize aluminum extrusions for photovoltaic panel supports, ensuring strength and low weight. Clean rooms and workstations benefit from aluminum extrusions for their ease of cleaning and ergonomic design. These diverse applications underscore the critical role of aluminum extrusions in modern industry.

Aluminum extrusion significantly contributes to sustainability through several key features. Firstly, aluminum is 100% recyclable, allowing it to be reused indefinitely without losing its properties. This reduces the need for raw material extraction, which in turn lowers energy consumption and greenhouse gas emissions. Secondly, aluminum’s high strength-to-weight ratio enables the creation of lighter structures, which reduces energy requirements in transportation and construction. This also improves fuel efficiency in vehicles and energy efficiency in buildings.

Additionally, aluminum’s natural corrosion resistance extends the lifespan of products, minimizing the need for replacements and conserving resources. The material’s excellent thermal conductivity further supports energy efficiency in building applications, such as thermal breaks in windows and doors, which enhance insulation.

Using recycled aluminum in extrusion processes also cuts down on the energy required compared to producing new aluminum, thus reducing carbon emissions. The high recycled content in aluminum products ensures continuous material reuse, reducing waste and environmental impact. These features make aluminum extrusion a crucial component in sustainable practices across various industries, including construction, automotive, and renewable energy sectors.

Aluminum extrusion offers numerous customization options, making it highly adaptable for various applications. Design flexibility is a major benefit, as extrusions can be tailored to a vast array of shapes and sizes, including complex and intricate designs that are difficult to achieve with standard methods. Material selection is another key aspect, with various aluminum grades and alloys available, such as 6061, 6063, and 6005/6005A, each providing unique properties and finishes.

Finishing options are extensive, including anodizing for enhanced corrosion resistance and color variety, painting and powder coating for precise color matching and durability, and mechanical finishing techniques like deburring and polishing for a smooth surface. Secondary operations further customize extrusions through cutting, bending, machining, and assembly processes like welding, drilling, and punching.

Performance optimization is achievable by designing extrusions to meet specific strength, weight, and corrosion resistance requirements, which is particularly beneficial in industries like construction, automotive, aerospace, and electronics. These customization options enable manufacturers to produce high-quality aluminum extrusions that meet precise project specifications, enhancing both functionality and aesthetic appeal.

Aluminum extrusions offer several advantages across various industries due to their unique properties. One of the primary benefits is their lightweight nature combined with high strength, making them ideal for applications in aerospace and automotive industries where weight reduction is crucial. They are cost-effective, as aluminum is generally less expensive than other metals, and the extrusion process minimizes material waste and energy consumption.

Aluminum’s natural corrosion resistance reduces maintenance costs and extends the lifespan of components, which is beneficial in marine and construction applications. Additionally, aluminum’s malleability allows for the creation of complex shapes, catering to customized solutions in different sectors. Its excellent thermal and electrical conductivity makes it suitable for heat exchangers and electrical connectors.

Furthermore, aluminum is highly recyclable, supporting sustainability efforts. The extrusion process also enables high precision and quality surface finishes, which are essential for mass production. Finally, the faster lead times of aluminum extrusions facilitate rapid design iterations and prototype development, making them a preferred choice in industries requiring quick turnaround times.