Imagine a material that not only stands the test of time but also offers an array of vibrant colors and enhanced durability. Welcome to the world of anodized aluminum, a marvel in the realm of metals that combines practicality with aesthetic appeal. But what exactly is anodized aluminum, and why has it become a staple in industries ranging from aerospace to architecture?

In this beginner-friendly guide, we will unravel the mysteries of anodized aluminum step by step. You’ll discover the fascinating process behind anodizing, learn about the benefits this treatment brings, and understand why anodized aluminum is so highly regarded. Whether you’re a hobbyist looking to experiment at home or simply curious about this versatile material, we’ve got everything you need to know right here. Ready to dive in and uncover the secrets of anodized aluminum? Let’s get started!

Anodized aluminum is created through an electrochemical process known as anodizing, which enhances its durability, corrosion resistance, and aesthetic appeal by thickening its natural oxide layer.

Anodized aluminum is highly resistant to corrosion and wear, making it ideal for use in harsh environments and high-stress applications. The thick anodic oxide layer protects the underlying metal, significantly extending its lifespan.

The anodizing process can make aluminum up to three times stronger while keeping it lightweight. This is particularly beneficial in industries such as aerospace and automotive, where the strength-to-weight ratio is crucial.

Anodized aluminum can be dyed in various colors, offering a durable and attractive finish. This makes it a popular choice for consumer goods and architectural applications, where both appearance and longevity are important.

The anodizing process is environmentally friendly, producing no harmful emissions. Additionally, aluminum is fully recyclable, making anodized aluminum a sustainable choice for various applications.

Before anodizing, the aluminum surface undergoes mechanical and chemical treatments to clean and prepare it. This step ensures the surface is free of contaminants that could affect the quality of the anodized layer.

The aluminum is immersed in an electrolytic bath and an electric current is applied. This process forms the anodic oxide layer on the surface of the aluminum, enhancing its properties.

After anodizing, the pores in the oxide layer are sealed to further improve corrosion resistance and provide a more durable finish. This step is crucial for applications where the material will be exposed to harsh conditions.

Anodized aluminum is favored for its strength-to-weight ratio and corrosion resistance, making it suitable for parts and components in industrial machinery and vehicles.

In the aerospace industry, the demand for lightweight and durable materials makes anodized aluminum a top choice for many components.

For building facades and other architectural elements, anodized aluminum offers customizable appearance and long-lasting durability.

High-end products like cookware, electronics, and sporting goods benefit from anodized aluminum’s attractive appearance and durability.

To begin the anodizing process, gather the necessary materials and equipment:

Cleaning: Start by thoroughly cleaning the aluminum parts to remove oils, grease, and other contaminants. Use an alkaline cleaner or a solvent to remove all impurities from the surface.

Etching: After cleaning, apply an acid etchant to smooth the surface. This step not only provides a uniform finish but also helps hide minor defects such as scratches. Eco-friendly acid etchants are recommended for their environmental benefits.

After etching, treat the aluminum with a desmutting solution to remove residual oxides, then rinse thoroughly to eliminate any remaining chemicals.

Setup: Fill the anodizing tank with a sulfuric acid electrolyte solution. Connect the aluminum parts to the power supply, making sure they serve as the positive terminal (anode).

Process: Submerge the cleaned and etched aluminum parts in the electrolyte bath. Apply an electric current through the bath. This electrochemical process thickens the natural oxide layer on the aluminum surface, creating a durable and corrosion-resistant anodic oxide finish.

If you wish to add color to the anodized aluminum, immerse the anodized parts in a dye solution. The porous nature of the anodic layer allows it to absorb colors effectively. You can choose from a variety of colors like black, gold, and other metallic shades to enhance the appearance of your aluminum parts.

After coloring (if applicable), seal the porous anodic layer using hot water or a chemical sealant. This step is essential to increase corrosion resistance and keep the color vibrant over time. Sealing prevents further oxidation and maintains the aesthetic appeal of the anodized surface.

Anodizing is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of aluminum, enhancing its durability, corrosion resistance, and aesthetic appeal.

The process begins with thorough cleaning: degreasing the aluminum to remove oils and contaminants, rinsing with water, etching in a caustic solution to create a uniform texture, and desmutting with an acid solution to eliminate residues.

In this step, the aluminum is placed in a bath of sulfuric acid, where it serves as the positive electrode (anode) while another electrode acts as the negative (cathode). An electric current is then passed through the solution, forming a thick layer of aluminum oxide on the surface.

The anodized aluminum can be dyed in various colors by immersing it in a dye bath, allowing the dye to penetrate the oxide layer’s pores. This step provides a wide range of aesthetic options to suit different applications.

The final step in the anodizing process is sealing the oxide layer to enhance its properties. This can be achieved by immersing the anodized aluminum in boiling water, causing the pores to close and locking in the dye, or by using a chemical sealant to increase corrosion resistance.

There are several anodizing types, each suited to specific needs: Chromic Acid Anodizing (Type I) for high corrosion resistance in aerospace applications; Sulfuric Acid Anodizing (Type II) for good corrosion resistance and easy dyeing, ideal for industrial and consumer products; and Hardcoat Anodizing (Type III) for a thicker, more durable coating used in high-wear applications such as automotive and aerospace components.

Anodizing aluminum offers several significant benefits:

Anodized aluminum is used across various industries due to its enhanced properties:

Electrolytic passivation is a process that enhances the corrosion resistance of metals, including aluminum, by forming a protective oxide layer on the surface. This technique involves an electrochemical reaction that modifies the metal surface to make it less reactive to environmental factors. For aluminum, this is typically achieved through anodization, where an electric current is passed through an electrolytic solution to form a thick and durable oxide layer.

Before passivation, the aluminum surface must be cleaned to remove grease, oils, and contaminants that could affect the oxide layer. This is usually done using an alkaline cleaner, followed by an etching process to smooth the surface.

The cleaned aluminum is then immersed in an electrolytic bath, usually containing sulfuric acid, which conducts the electric current needed for passivation.

An electric current is applied to the aluminum part, serving as the anode in the electrolytic cell. This current causes aluminum ions to migrate outward and react with oxygen ions, forming a thicker aluminum oxide layer.

Electrolytic passivation is integral to the anodizing process because it directly contributes to the formation of the protective oxide layer. This layer not only improves the metal’s resistance to corrosion but also increases its durability and allows for further surface treatments, such as coloring and sealing.

Electrolytic passivation, through the process of anodization, significantly enhances the properties of aluminum, making it a preferred choice in various industrial applications.

Anodizing aluminum requires careful attention to various technical details to achieve a high-quality, durable finish. Understanding these aspects is crucial for achieving consistent and desirable outcomes.

Voltage and current are crucial for the quality and thickness of the oxide layer. The process usually starts with a lower voltage, gradually increasing to 12-18 volts. The specific voltage and current settings depend on the desired thickness of the oxide layer and the type of anodizing being performed.

Achieving consistent results in anodizing requires meticulous control of various factors:

By understanding and controlling these technical aspects, the anodizing process can be optimized to produce high-quality, durable, and aesthetically pleasing anodized aluminum products.

Anodized aluminum is highly resistant to corrosion. The anodizing process creates a thick oxide layer on the surface of the aluminum, which acts as a barrier against environmental factors such as moisture, chemicals, and pollutants. This protective layer prevents the aluminum from reacting with these elements, significantly extending its lifespan. This makes anodized aluminum ideal for outdoor applications and harsh environments where corrosion can be a significant concern.

The anodizing process not only improves corrosion resistance but also significantly enhances the durability of aluminum. The oxide layer formed during anodization is much harder than the base aluminum, providing increased resistance to wear and abrasion. Despite its enhanced durability, anodized aluminum remains lightweight, which is crucial for industries such as aerospace and automotive, where reducing weight can improve fuel efficiency and performance. This characteristic is essential in sectors where both durability and weight are critical factors.

Anodized aluminum is highly valued for its aesthetic versatility. The anodizing process allows the aluminum to be dyed in a wide range of colors, providing a durable and attractive finish. The oxide layer’s porous nature means it can absorb dyes effectively, resulting in vibrant and long-lasting colors that do not fade over time. This makes anodized aluminum popular in building projects and everyday products, where both appearance and longevity are important.

An interesting benefit of anodized aluminum is its electrical insulation properties. The anodized layer is non-conductive, making it suitable for use in electrical components where minimizing conductivity is essential. This property is particularly useful in the electronics and automotive industries, where insulating materials are required to prevent electrical shorts and ensure safety.

The porous surface of anodized aluminum enhances adhesion for coatings and paints, making it easier to apply and maintain finishes. This property is beneficial in industries such as automotive and aerospace, where additional layers of protection or decoration are often required. Additionally, the porous nature of the anodic layer allows it to retain lubricants better, which can be advantageous in mechanical applications where reduced friction is desired.

Anodized aluminum is environmentally friendly and safe for health. The anodizing process does not involve harmful chemicals, and the resulting anodized aluminum is non-toxic and completely recyclable. This aligns with sustainability goals and makes anodized aluminum a responsible choice for environmentally conscious applications.

Anodized aluminum exhibits increased resistance to high temperatures, making it suitable for use in heat-intensive environments. The anodized layer can withstand higher temperatures without degrading, which is beneficial in applications such as automotive and aerospace components that are exposed to extreme heat.

The aerospace and defense industries extensively use anodized aluminum because it is lightweight and has a high strength-to-weight ratio. Common applications include aircraft interior components like seats and overhead bins, which benefit from its durability and corrosion resistance, and structural parts such as wings and fuselage elements that ensure long-term durability and safety. Additionally, anodized aluminum is used in various military equipment due to its resilience and ability to withstand harsh conditions.

The automotive industry favors anodized aluminum for its lightweight and durable properties, which enhance vehicle performance and fuel efficiency. Applications include wheels that are not only lightweight but also resistant to corrosion and wear, exterior and interior trim parts like door handles and decorative strips that benefit from its aesthetic appeal and durability, and performance parts such as engine components and suspension parts that reduce weight and enhance strength.

Anodized aluminum is a popular material in the consumer electronics industry due to its sleek appearance and durability. It is used in smartphone housings for a durable and scratch-resistant surface, laptops and tablets for a premium look and feel while protecting them from everyday wear and tear, and high-end audio equipment for both aesthetic appeal and robust properties.

The medical field uses anodized aluminum for various devices due to its hygiene and durability. Applications include surgical instruments that are easy to sterilize and maintain, diagnostic equipment housings and components that ensure longevity and reliability, and hospital furniture like bed frames and operating tables that benefit from its durability and cleanliness.

In architecture and construction, anodized aluminum is valued for its aesthetic versatility and resistance to the elements. Common uses include window frames that are corrosion-resistant and can be colored to match any design, exterior cladding for building facades that offer a modern look and durability against weather conditions, and railings and balustrades that withstand outdoor environments.

Anodized aluminum is a popular choice in kitchenware due to its resistance to corrosion and scratches. Applications include pots and pans with a hard, non-reactive surface ideal for cooking and easy cleaning, and food preparation equipment like mixers and food processors that use anodized aluminum parts for durability and ease of maintenance.

In the optical industry, anodized aluminum is used to minimize light reflection and improve performance. Applications include binoculars with housings that reduce glare and protect internal optics, and night vision devices with non-reflective surfaces that help maintain functionality.

Because anodized aluminum is fully recyclable and the anodizing process produces no hazardous waste, it is an environmentally friendly choice. This sustainability aspect is particularly important in industries aiming to reduce their environmental footprint.

Below are answers to some frequently asked questions:

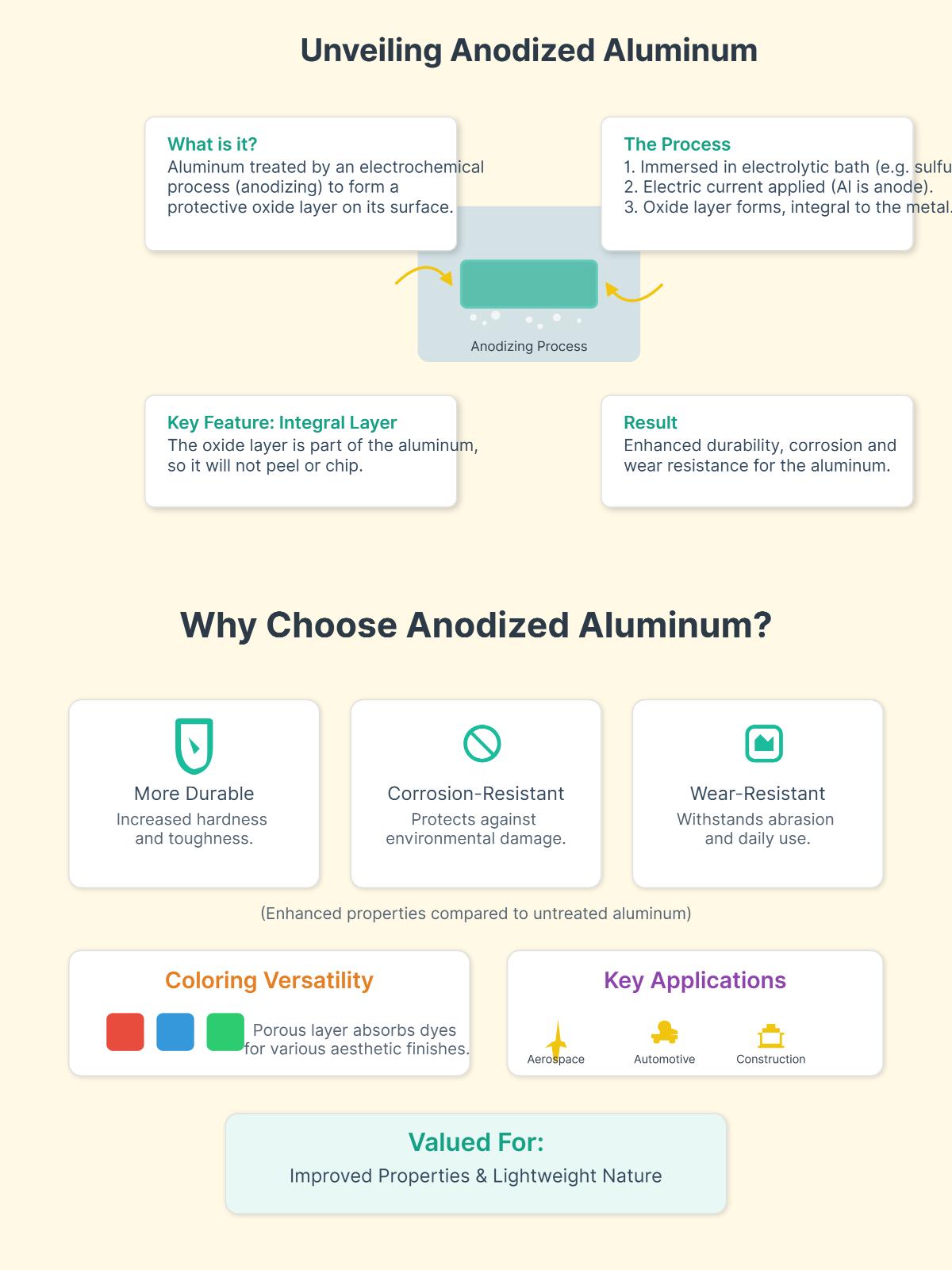

Anodized aluminum is aluminum that has undergone an electrochemical process called anodizing. This process involves immersing the aluminum in an electrolytic bath, typically containing sulfuric acid, and applying an electric current. The aluminum acts as the anode, and this causes an oxide layer to form on its surface. This oxide layer is integral to the aluminum, which means it will not peel or chip.

The resulting anodized aluminum has several enhanced properties: it is more durable, corrosion-resistant, and wear-resistant compared to untreated aluminum. Additionally, the porous nature of the oxide layer allows for the absorption of dyes, enabling the aluminum to be colored in various shades for aesthetic purposes. Anodized aluminum is commonly used in industries such as aerospace, automotive, and construction due to its improved properties and lightweight nature.

Aluminum is anodized through an electrochemical process that enhances its natural oxide layer, improving durability, corrosion resistance, and aesthetics. The process begins with surface preparation, where the aluminum parts are thoroughly cleaned and etched to remove impurities. Next, the parts are immersed in an electrolyte bath, typically containing sulfuric acid. An electric current is then applied, making the aluminum part the anode. This causes aluminum ions to migrate and form a thick, porous oxide layer. The properties of this layer can be controlled by adjusting the electrolyte composition, temperature, and current density. Optionally, the oxide layer can be dyed for color and sealed to enhance corrosion resistance. This process is widely used in industries such as aerospace, automotive, and construction.

Anodized aluminum offers several benefits, making it highly valued in various industries. Firstly, anodizing enhances the durability of aluminum by increasing its surface hardness, making it more resistant to abrasion and wear. This durability ensures that components maintain their integrity under heavy usage. Additionally, anodized aluminum has improved corrosion resistance due to the protective oxide layer formed during the process, which acts as a barrier against moisture, salt, and chemicals.

Aesthetically, anodizing allows for the addition of vibrant colors and a smooth, uniform finish, which is ideal for products where appearance is important. The process is also cost-effective and environmentally friendly, as aluminum is fully recyclable and the anodizing process itself does not emit harmful chemicals. Moreover, anodized aluminum improves adhesion for coatings and adhesives due to its porous nature, and it provides electrical insulation, beneficial in applications requiring controlled conductivity.

Yes, you can anodize aluminum at home. The process involves using some specialized materials and equipment, but it is feasible with careful attention to safety and procedure. First, thoroughly clean and degrease the aluminum part. Then, prepare an anodizing bath by mixing sulfuric acid and water in a plastic or glass container. Suspend the aluminum part in the bath using an aluminum wire, ensuring it does not touch the container sides. Attach a DC power supply, with the positive lead connected to the aluminum part and the negative lead to a piece of aluminum foil in the bath. Apply a voltage of 12-20 volts for 30 minutes to 2 hours. After anodizing, rinse the part with distilled water, optionally dye it, and then seal the anodized layer by boiling it in water. Always wear protective gear and ensure proper ventilation. Following these steps will enhance the durability and aesthetic of your aluminum parts.

Anodized aluminum is widely used in various industries due to its enhanced durability, corrosion resistance, and aesthetic appeal. In the kitchenware and appliances sector, it is popular for items like lunch boxes, kettles, and pots because of its excellent scratch resistance. In consumer electronics, it is valued for its attractive appearance and is often used in smartphone components. Building and construction materials benefit from its corrosion resistance and aesthetic qualities, making it suitable for carport columns, metal posts, and window frames. In the transportation industry, anodized aluminum is used for automotive parts like wheels, as well as aircraft and rail car panels due to its lightweight and durable properties. Aerospace and defense applications rely on its corrosion resistance and strength for components such as panels and military equipment. Medical equipment uses anodized aluminum for its hygienic surface and durability. It is also used in optical components to minimize light reflection, semiconductor components for insulation and heat dissipation, lighting fixtures for decorative quality and heat management, and nameplates and decorative panels for color versatility and durability.

Anodizing aluminum has both environmental benefits and challenges.

Benefits:

Challenges:

Innovations such as Plasma Electrolytic Oxidation (PEO) are improving the sustainability of anodizing by reducing toxic waste and enhancing energy efficiency.