Steel is the backbone of modern construction and manufacturing, but not all steel is created equal. Two of the most commonly discussed grades in the industry are ASTM A1011 and A36. Understanding the nuances between these two can significantly impact the success of your project. How do their chemical compositions and mechanical properties stack up against each other? Which one offers better formability, and which is superior for structural applications? This comprehensive comparison will delve into the historical development, key properties, and practical applications of ASTM A1011 and A36, providing you with the insights needed to make an informed decision. Ready to uncover the strengths and weaknesses of these steel grades? Let’s dive in.

Steel grades are classifications that define the specific properties and compositions of steel alloys. These classifications help engineers and manufacturers select the right type of steel for a particular application. Each steel grade is identified by a unique set of standards and specifications that outline its chemical composition, mechanical properties, and manufacturing processes.

Choosing the correct steel grade ensures that the material will perform as expected under the required conditions, whether it is for structural applications requiring high tensile strength or automotive components needing excellent formability.

Several factors determine the classification of steel grades:

The chemical composition of steel, including elements like carbon, manganese, phosphorus, and sulfur, significantly impacts its properties. For example, higher carbon content typically increases hardness and strength but can reduce ductility.

Key mechanical properties such as tensile strength, yield strength, hardness, and impact resistance are essential for defining the performance of steel in different applications. These properties are often specified in standards like ASTM (American Society for Testing and Materials) to ensure consistency and reliability.

The method of manufacturing steel, whether it is hot-rolled, cold-rolled, or heat-treated, affects its final characteristics. Each process can alter the grain structure and mechanical properties of the steel, making it suitable for specific uses.

ASTM A1011 is known for its excellent formability and weldability, making it ideal for applications such as automotive parts and sheet metal fabrication. The low carbon content in ASTM A1011 enhances its ability to be shaped and joined without compromising structural integrity.

ASTM A36 is a widely used carbon structural steel. It is known for its high tensile and yield strength, making it ideal for heavy structural applications like construction and machinery. The higher carbon content in ASTM A36 contributes to its robustness and load-bearing capacity, which are critical for structural engineering.

Choosing the appropriate steel grade depends on the specific requirements of the application, such as mechanical load, environmental conditions, and the need for particular mechanical properties. By understanding the differences between various steel grades, such as ASTM A1011 and A36, engineers can make informed decisions that optimize performance and cost-effectiveness in their projects.

ASTM A1011 and ASTM A36 are two key standards in the steel industry, each with distinct development histories and applications.

ASTM A1011, introduced in 2000, is a specification for hot-rolled steel sheet and strip that includes a wide range of grades such as commercial steel (CS), drawing steel (DS), structural steel (SS), high-strength low-alloy steel (HSLAS), HSLAS with improved formability (HSLAS-F), and ultra-high strength steel (UHSS). This standard was developed to meet the needs of industries requiring materials with high formability and ease of fabrication. Its applications include automotive components, sheet metal products, and other manufacturing processes where versatility and adaptability are essential. Over the years, ASTM A1011 has undergone updates, with the latest version reflecting advancements in material performance and industry demands.

ASTM A36 is a long-standing standard for structural steel plates, bars, and shapes, known for its strength, durability, ease of fabrication, and weldability, making it ideal for building frames, bridges, and other heavy-duty structures. This standard has been a cornerstone in construction and structural engineering, offering a reliable and consistent material choice for projects requiring robust performance. Its widespread adoption and consistent use over decades highlight its importance in defining structural norms.

ASTM A1011 focuses on hot-rolled sheet and strip products with a thickness under 0.230 inches, ideal for automotive and sheet metal applications. In contrast, ASTM A36 covers thicker plates, bars, and shapes, making it suitable for structural engineering and construction.

The properties defined by these standards reflect their intended uses: ASTM A1011 emphasizes formability and weldability, while ASTM A36 prioritizes strength and durability. This distinction allows industries to select the appropriate material based on specific project requirements, ensuring optimal performance and efficiency.

ASTM A1011 is a standard developed by the American Society for Testing and Materials (ASTM) for hot-rolled steel sheet and strip. This specification covers various steel grades, including carbon, structural, high-strength low-alloy (HSLA), and ultra-high-strength steels, detailing their chemical composition, mechanical properties, and manufacturing processes.

ASTM A1011 steel is widely used in various industries due to its excellent formability and weldability. Some of the common applications include:

ASTM A1011 steel is known for several key properties that make it suitable for the aforementioned applications:

ASTM A1011 steel typically has a yield strength of 24 to 36 ksi and a tensile strength of around 41 ksi, depending on the grade.

One of the standout features of ASTM A1011 steel is its excellent formability. The lower carbon content in this steel improves its ability to be shaped into complex forms without cracking or other issues. This makes it ideal for applications requiring intricate shapes and designs. Additionally, ASTM A1011 steel exhibits outstanding weldability, allowing for efficient and reliable joining processes.

The chemical composition of ASTM A1011 steel includes elements such as carbon, manganese, phosphorus, sulfur, and sometimes small amounts of alloying elements like titanium, nickel, and molybdenum. These elements are carefully controlled to enhance the steel’s mechanical properties and resistance to corrosion.

Compared to ASTM A36, ASTM A1011 has better formability due to its lower carbon content and specific alloying elements, making it ideal for applications needing intricate shapes and designs. While ASTM A1011 offers good strength for many applications, ASTM A36 typically provides higher tensile and yield strengths, making it more suitable for heavy structural applications. ASTM A1011 is preferred for applications where ease of fabrication and shaping is critical, whereas ASTM A36 is used in construction and infrastructure projects requiring higher strength and durability.

ASTM A36 is a widely recognized standard for carbon structural steel established by ASTM International. It is one of the most commonly used grades of steel, valued for its versatility and cost-effectiveness in structural applications.

ASTM A36 steel primarily consists of up to 0.26% carbon, 0.60-1.20% manganese, up to 0.04% phosphorus, up to 0.05% sulfur, and up to 0.40% silicon, with the balance being mostly iron. This combination results in a material that is both strong and ductile, suitable for a wide range of construction and industrial uses.

ASTM A36 is commonly used in constructing buildings, bridges, and other structures requiring strength and durability. Its reliability and adaptability make it a preferred material in infrastructure projects and heavy equipment manufacturing, where load-bearing capacity is crucial.

The steel exhibits excellent mechanical properties that strike a balance between strength and ductility:

These properties make ASTM A36 ideal for applications requiring structural integrity under various conditions.

ASTM A36 is highly regarded for its ease of fabrication and welding, and it can be welded using various methods such as SMAW, GMAW, and oxyacetylene welding. Its composition allows for strong welds without the need for preheating or post-weld heat treatment in most cases, simplifying manufacturing processes.

While ASTM A36 is ideal for structural applications due to its high strength and durability, ASTM A1011 is preferred for applications requiring excellent formability, such as automotive parts and sheet metal fabrication. ASTM A1011 features lower carbon content and added alloying elements, enhancing its suitability for shaping and forming processes. Each grade serves distinct purposes, and the choice depends on the specific requirements of the project or industry.

Carbon content in steel affects its strength, ductility, and weldability.

Manganese is another critical element that influences the strength and toughness of steel.

Phosphorus and sulfur are typically kept to low levels in steel to prevent brittleness and ensure ductility.

The presence of additional alloying elements can enhance specific properties of steel.

The differences in chemical composition between ASTM A1011 and ASTM A36 result in distinct practical implications for their use in various applications.

Yield strength measures the stress a material can handle before it permanently deforms.

Tensile strength indicates the maximum stress a material can withstand before it breaks.

Ductility reflects a material’s ability to deform under tensile stress, often measured by elongation percentage.

Hardness and toughness are important for understanding a material’s resistance to wear and its ability to absorb energy without fracturing.

Impact resistance determines a material’s ability to absorb energy during sudden loading.

The mechanical differences between ASTM A1011 and ASTM A36 have significant implications for their applications:

Formability is a key property in materials science that describes how well a material can be plastically deformed without being damaged. This property is particularly important in manufacturing processes that involve bending, stretching, or molding materials into complex shapes. High formability ensures the material can be manipulated without cracking or breaking, which is essential for applications requiring intricate designs and detailed shapes.

ASTM A1011 is a hot-rolled steel known for its excellent formability, making it easy to shape into complex forms. Its lower carbon content (up to 0.15%) and the hot-rolling process contribute to its high ductility and ability to withstand significant deformation. With a yield strength ranging from 24 to 36 ksi, ASTM A1011 can endure substantial shaping before yielding, making it suitable for applications requiring extensive bending and forming.

These characteristics make ASTM A1011 ideal for use in the automotive industry, sheet metal products, and other manufacturing processes where high formability is crucial.

ASTM A36, a carbon structural steel, also offers good formability but is less pliable than ASTM A1011 due to its higher carbon content (0.25% to 0.29%). Its yield strength of at least 36 ksi requires more force to shape, making it better suited for structural applications. While ASTM A36 provides sufficient formability, its primary advantage lies in its strength, making it more appropriate for structural uses rather than intricate shaping.

The formability differences between ASTM A1011 and ASTM A36 have practical implications for their use in manufacturing:

Choosing between ASTM A1011 and ASTM A36 depends on the specific requirements of the application. ASTM A1011 is preferred for its high formability in detailed shaping tasks, while ASTM A36 is favored for its strength in robust structural projects.

Weldability is the ability of a material to be welded under certain conditions while achieving a joint with desired properties like strength, ductility, and toughness. Factors affecting weldability include the material’s composition, properties, and the welding method used.

ASTM A1011 steel is known for its excellent weldability, primarily due to its lower carbon content, which typically ranges from 0.08% to 0.15%. This lower carbon content reduces the risk of weld cracking and enhances the material’s ability to be joined without defects. The steel’s good formability also contributes to its weldability, making it suitable for applications requiring complex shapes and consistent weld quality.

ASTM A36 steel also exhibits good weldability, although it has a higher carbon content, up to 0.29%, compared to ASTM A1011. Although the higher carbon content can increase the risk of weld cracking, it also enhances the steel’s strength and integrity. Despite this, ASTM A36 is widely used in construction due to its balance of weldability and mechanical properties.

Both ASTM A1011 and ASTM A36 support various welding methods, but the choice of steel and technique should match the project’s specific needs:

In structural engineering, ASTM A36 is widely used for its high tensile and yield strengths. This makes it suitable for constructing buildings, bridges, and other infrastructure where durability and load-bearing capacity are essential. The robust mechanical properties of ASTM A36 allow it to withstand significant stress and strain, making it a reliable choice for foundational elements like beams, columns, and girders.

In contrast, ASTM A1011, with its superior formability, is less common in heavy structural applications but useful in secondary structural components where intricate shapes and ease of fabrication are needed.

The automotive industry benefits significantly from the use of ASTM A1011 due to its excellent formability and weldability. It’s ideal for making automotive body panels, frames, and other components with complex shapes and precise dimensions. The ability to easily form and weld ASTM A1011 makes it a preferred choice for applications where flexibility in design and manufacturing efficiency are critical.

While ASTM A36 is not typically used for automotive body parts, its higher strength makes it suitable for manufacturing heavy-duty vehicle components, such as chassis and structural frames, where high load-bearing capacity is necessary.

In the metalworking and fabrication sectors, both ASTM A1011 and A36 have their distinct applications based on their properties. ASTM A1011 is favored for sheet metal work due to its formability, which allows for intricate designs and shapes. This makes it ideal for producing appliances, HVAC systems, and other consumer goods that require detailed fabrication.

ASTM A36, on the other hand, is preferred for fabrication projects that demand higher strength and durability. It is commonly used in the production of industrial equipment, machinery parts, and other heavy-duty components that must endure substantial mechanical stress.

ASTM A1011’s application in automotive body panels showcases its formability and ease of welding. The steel’s ability to be shaped into complex curves and its compatibility with various welding techniques ensure high-quality, durable automotive parts. This application highlights the material’s suitability for products that require both flexibility and strength.

ASTM A36’s use in construction projects, such as bridges and buildings, demonstrates its strength and reliability, making it an excellent choice for load-bearing beams and columns. These properties ensure the structural integrity and longevity of large-scale construction projects.

In the HVAC industry, ASTM A1011 is used to manufacture ductwork and other components due to its formability and lighter weight. The ease of shaping ASTM A1011 into various configurations without compromising strength is crucial for efficient HVAC system performance.

Each steel grade, ASTM A1011 and A36, serves specific purposes based on their unique properties, making them valuable in different industrial applications. The choice between them depends on the specific requirements of the project, whether it be formability, strength, or a combination of both.

The environmental impact of ASTM A1011 and A36 steels is shaped by their composition and manufacturing processes, affecting energy use, emissions, and material efficiency.

Both ASTM A1011 and A36 are highly recyclable, making them sustainable options in terms of material reuse. However, their distinct properties influence how efficiently they can be utilized during the manufacturing process.

The energy required to produce and process these steels plays a crucial role in their environmental footprint.

The sustainability of ASTM A1011 and A36 extends beyond production to their performance in various applications.

Cost-effectiveness is another factor that ties directly to environmental sustainability.

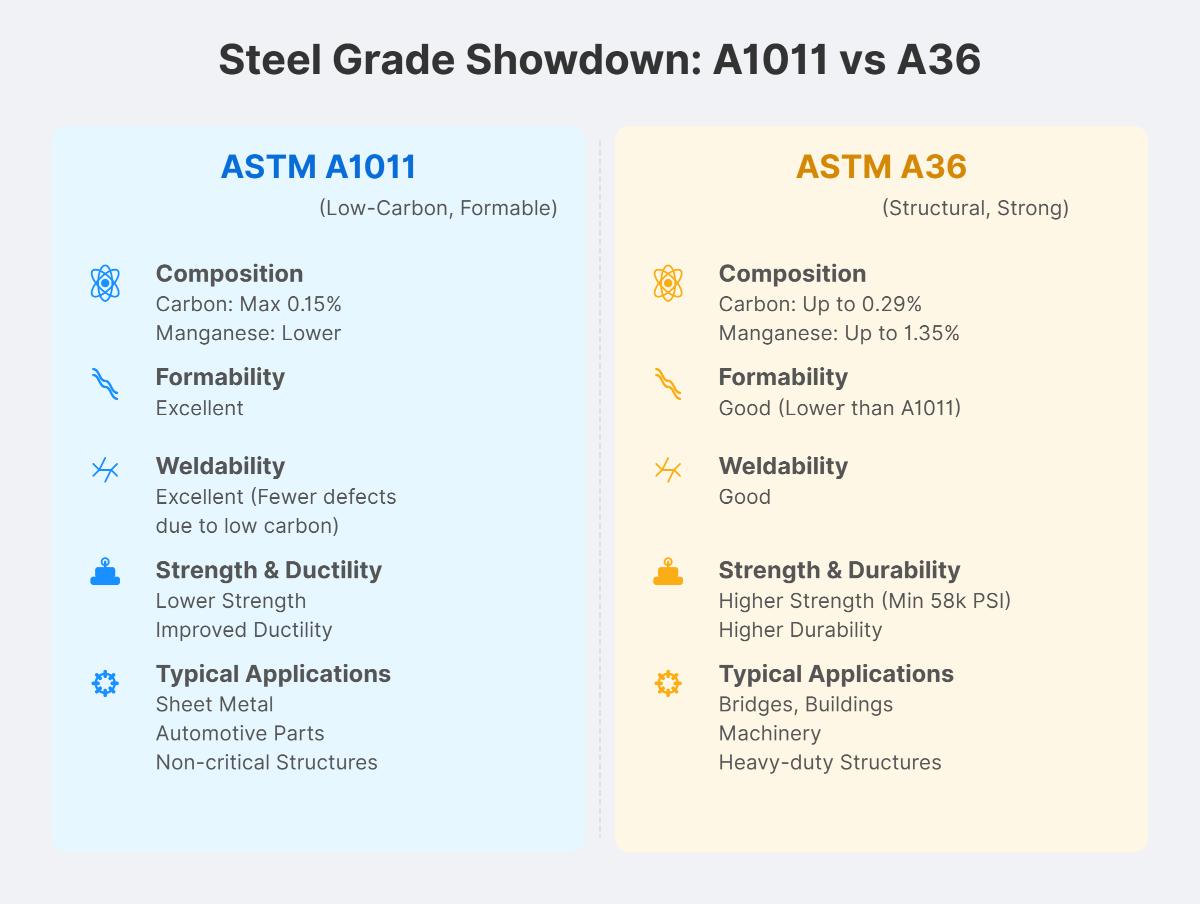

To clearly illustrate the key differences between ASTM A1011 and ASTM A36, the following table summarizes their main properties and characteristics:

| Property | ASTM A1011 | ASTM A36 |

|---|---|---|

| Carbon Content | 0.08% to 0.15% | 0.25% to 0.29% |

| Manganese Content | Up to 0.60% | Up to 1.35% |

| Yield Strength | 24,000 to 36,000 psi (165 to 248 MPa) | Minimum 36,000 psi (248 MPa) |

| Tensile Strength | 41,000 psi (283 MPa) | 58,000 to 80,000 psi (400 to 552 MPa) |

| Formability | Excellent | Good |

| Weldability | Excellent | Good |

| Main Applications | Automotive parts, appliances, HVAC systems | Structural engineering, bridges, machinery |

| Manufacturing Process | Hot-rolled | Furnace and cooling |

| Impact Resistance | Moderate | High |

ASTM A1011 generally has a lower carbon content (0.08% to 0.15%) compared to ASTM A36 (0.25% to 0.29%), improving its formability and weldability. The lower carbon content in ASTM A1011 makes it easier to shape and weld without the risk of cracking. Additionally, ASTM A1011 may include trace elements like titanium and molybdenum, which can improve specific properties like corrosion resistance.

ASTM A36, on the other hand, has a higher manganese content (up to 1.35%) which increases its strength and toughness. The higher carbon content in ASTM A36 enhances its strength but reduces its formability compared to ASTM A1011.

The mechanical properties of ASTM A1011 and ASTM A36 vary significantly:

Due to its lower carbon content, ASTM A1011 is highly formable, making it ideal for applications that require intricate shapes and designs, such as automotive body panels and HVAC components. Its excellent weldability allows for efficient and reliable joining processes.

ASTM A36, while also formable, is less pliable than ASTM A1011 and is better suited for structural applications due to its higher strength. Its good weldability makes it suitable for structural components like building frames and bridges, where strong and durable joints are essential.

ASTM A1011 is preferred for automotive parts and HVAC systems, while ASTM A36 is widely used in structural engineering and heavy machinery.

Each steel grade serves specific purposes based on its unique properties, and the choice between ASTM A1011 and A36 depends on the requirements of the application, such as the need for formability, strength, or weldability.

Below are answers to some frequently asked questions:

ASTM A1011 and ASTM A36 are distinct steel grades with specific differences suited for various applications. ASTM A1011 is a hot-rolled, low-carbon steel known for its excellent formability and weldability, making it ideal for applications like sheet metal, automotive parts, and non-critical structural components. It typically has a maximum carbon content of 0.15% and lower manganese levels, resulting in lower strength but improved ductility and ease of processing.

ASTM A36, on the other hand, is a structural steel grade with higher strength and durability. Its carbon content can reach up to 0.29%, with manganese levels up to 1.35%, providing a minimum tensile strength of 58,000 PSI and superior performance in heavy-duty applications like bridges, buildings, and machinery.

While both grades are weldable, A1011’s lower carbon content reduces weld defects.

When it comes to structural applications, ASTM A36 is generally the better choice compared to ASTM A1011. This is primarily due to its higher strength and load-bearing capacity. A36 has a minimum yield strength of 36,000 PSI and tensile strength ranging from 58,000 to 80,000 PSI, making it more suitable for construction projects that require robustness and durability. These properties are essential for structural components such as beams, columns, and bridges.

In contrast, ASTM A1011, with a yield strength typically ranging from 30,000 to 36,000 PSI and tensile strength around 41,000 PSI, is more often used in applications that benefit from its excellent formability and weldability, such as automotive components and sheet metal fabrication. While A1011’s lower carbon content enhances its ductility and ease of shaping, it does not offer the same level of strength as A36, which is crucial for structural integrity in construction.

Therefore, for structural applications where strength and durability are critical, ASTM A36 is the preferred steel grade.

The formability of ASTM A1011 is superior compared to ASTM A36. Formability refers to the ability of a material to be easily shaped or deformed without breaking, which is crucial for applications requiring complex shapes. ASTM A1011, with its lower carbon content (max 0.15%) and the presence of alloying elements like titanium, nickel, and molybdenum, allows it to be formed into intricate shapes while maintaining durability. This makes ASTM A1011 ideal for industries such as automotive, appliances, and HVAC, where easy shaping is essential.

On the other hand, ASTM A36, with a higher carbon content (max 0.29%) and greater manganese levels, offers good formability but not to the extent of ASTM A1011. The increased carbon content enhances the strength but limits the ability to form complex shapes. ASTM A36 is typically used in construction and infrastructure projects where structural strength is more critical than formability, such as in structural beams, columns, and plates.

ASTM A1011 has specific advantages over A36 in certain applications, primarily due to its superior formability and weldability. ASTM A1011 excels in applications requiring complex shapes and ease of fabrication, such as automotive body parts, sheet metal products, and HVAC systems. Its lower carbon content and the potential inclusion of alloying elements like titanium, nickel, and molybdenum enhance its formability and reduce weld defects, making it highly suitable for manufacturing processes that involve extensive shaping and joining.

In contrast, ASTM A36 is more suited for structural applications where higher strength and durability are critical, such as in construction and heavy-duty frames. While both steels are versatile, A1011’s advantages in formability and weldability make it preferable for applications where ease of manufacturing and efficient welding are essential.

Both ASTM A1011 and A36 are well-suited for welding, but their specific properties guide the selection of techniques. ASTM A1011, with its lower carbon content (typically ≤0.15%), offers excellent weldability and is less prone to weld defects. Common techniques like Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Gas Tungsten Arc Welding (GTAW) are effective for producing clean, strong welds in applications requiring high formability, such as automotive parts and sheet metal.

ASTM A36, while also highly weldable, has a slightly higher carbon content (up to 0.29%) and combines strength with ductility. It supports the same welding techniques—SMAW, GMAW, and GTAW—and is particularly favored for structural applications like bridges and building frames where strength is critical.

ASTM A1011 and A36 impact their use in the automotive industry primarily through their mechanical properties. ASTM A1011, with its lower yield strength (30,000–36,000 PSI) and higher formability, is ideal for lightweight, intricate automotive components such as body panels and equipment parts. Its excellent weldability and lower carbon content streamline manufacturing processes, making it highly suited for modern vehicle designs focused on fuel efficiency and reduced weight.

Conversely, ASTM A36, with a higher yield strength (minimum 36,000 PSI) and tensile strength (up to 80,000 PSI), is better suited for heavy-duty applications requiring durability and strength. However, its moderate formability limits its use in complex automotive designs, making it less common for lightweight vehicle components. In summary, ASTM A1011 is preferred for flexible, lightweight automotive applications, while ASTM A36 is more applicable to heavy structural needs outside the automotive sector.