When it comes to selecting the right nuts for your engineering projects, understanding the differences between ASTM A194 and ASTM A563 standards is crucial. Have you ever wondered why ASTM A194 Grade 2H nuts are often compared to ASTM A563 Grade DH nuts? These two grades are commonly used but have distinct differences that can significantly impact your project’s success, especially in high temperature and high pressure environments. In this article, we will dive deep into the material composition, heat treatment processes, and mechanical properties of these nut grades. We’ll also explore their applications and substitution guidelines to help you make informed decisions. So, which nut grade is better suited for your needs? Let’s find out.

ASTM A194 specifies the requirements for heavy hex nuts made from carbon steel, alloy steel, and stainless steel. These nuts are primarily designed for use in high-pressure and high-temperature environments. The standard is particularly relevant in critical sectors such as the oil, gas, and petrochemical industries, where nuts must withstand severe conditions and maintain reliability.

The ASTM A194 standard includes several grades, each with distinct properties to suit different applications. Grade 2H nuts are known for their high hardness and tensile strength; they are heat-treated to endure elevated temperatures and pressures, making them a common choice in high-stress environments. Grade 7 is similar to Grade 2H but is manufactured from alloy steel, offering enhanced performance at both low and high temperatures. Grade 8, made from stainless steel, provides excellent corrosion resistance in addition to high strength, making it suitable for highly corrosive environments.

ASTM A563 specifies the requirements for carbon and alloy steel nuts used mainly in general structural and mechanical applications. These nuts are employed in various structural assemblies, such as steel frames, bridges, and machinery, where high tensile strength is critical but extreme temperature resistance is not a primary concern.

The ASTM A563 standard encompasses a wide range of grades, each tailored for different structural applications. Grade A consists of basic carbon steel nuts used for standard structural applications. Grade B is similar to Grade A but with higher strength requirements. Grades C and C3 are carbon steel nuts with weathering properties, suitable for outdoor applications where resistance to atmospheric corrosion is needed. Grades DH and DH3 are treated to increase strength, but the heat treatment standards are not as strict as those for ASTM A194.

In comparing these two standards, it’s important to note the differences in material types and heat treatment requirements. ASTM A194 primarily includes carbon steel, alloy steel, and stainless steel, while ASTM A563 covers carbon steel and alloy steel with some grades offering weathering properties. ASTM A194 nuts are designed for higher tensile strength and hardness. They perform well under extreme conditions, with rigorous testing to verify mechanical properties, including hardness. On the other hand, ASTM A563 nuts have high tensile strength but are generally designed for structural use rather than high-temperature applications.

ASTM A194 Grade 2H nuts are often substituted for ASTM A563 Grade DH nuts because of their superior strength and availability, particularly in sizes 3/4″ and larger. Understanding the differences between these two standards is crucial for selecting the appropriate nut grade for specific engineering and construction applications.

ASTM A194 nuts are usually made of carbon steel, alloy steel, and stainless steel. These materials are selected to meet the demands of high-pressure and high-temperature environments.

ASTM A563 nuts are primarily made from carbon and alloy steel, focusing on providing high tensile strength for structural and mechanical purposes.

Heat treatment is a controlled process that changes the physical and chemical properties of a material. The objective is to achieve specific mechanical properties such as hardness, strength, and toughness. Common heat treatment processes include annealing, quenching, and tempering.

ASTM A194 nuts undergo stringent heat treatment processes to ensure they can withstand high-pressure and high-temperature environments.

ASTM A563 nuts also undergo heat treatment, but the processes are tailored more towards achieving high tensile strength for structural applications.

Heat treatment is a crucial process in metallurgy that involves carefully heating and cooling metals to change their physical and mechanical properties. This process is essential for achieving desired hardness, strength, and toughness in nuts used in various industrial applications.

ASTM A194 nuts, such as Grade 2H, undergo stringent heat treatment processes, including quenching and tempering, to enhance their mechanical properties, making them suitable for high-pressure and high-temperature environments.

The rigorous heat treatment of ASTM A194 nuts results in high tensile strength and hardness, making them ideal for severe service conditions encountered in industries such as oil, gas, and chemicals.

ASTM A563 nuts, including Grade DH, also undergo quenching and tempering but typically to a lesser degree compared to ASTM A194 nuts. The heat treatment process imparts good mechanical strength and toughness suitable for structural and mechanical applications where the operating temperature is moderate.

The focus of heat treatment for ASTM A563 nuts is primarily on achieving high tensile strength for structural uses rather than optimizing them for high-temperature environments.

The heat treatment processes significantly affect the mechanical properties of ASTM A194 and ASTM A563 nuts, including tensile strength, hardness, and their suitability for different environments.

| Property | ASTM A194 Grade 2H Nuts | ASTM A563 Grade DH Nuts |

|---|---|---|

| Heat Treatment | Quenched and tempered for high hardness and strength suitable for high temperature | Quenched and tempered for structural strength but not specialized for high temperature |

| Tensile Strength | High tensile strength to withstand severe stresses | High tensile strength but generally lower than A194 Grade 2H |

| Hardness | Higher hardness due to stricter heat treatment | Lower hardness compared to A194 Grade 2H |

| High-Temperature Suitability | Excellent; engineered for high-temperature/high-pressure service | Limited; not suitable for high-temperature applications |

| Testing & Certification | Rigorous mechanical property and hardness testing | Standard mechanical testing without high-temperature focus |

Understanding these differences is crucial for selecting the right nut grade for specific engineering and construction applications, ensuring optimal performance and safety in various conditions.

Mechanical properties, including tensile strength, proof load stress, and hardness, are crucial for determining the suitability of nuts in various industrial environments.

Tensile strength measures the maximum stress a material can withstand while being stretched or pulled before breaking. ASTM A194 nuts, such as Grade 2H, exhibit very high tensile strength due to their heat-treated carbon, alloy, and stainless steel composition. This makes them ideal for high-pressure and high-temperature environments where reliability under extreme stress is essential. Conversely, ASTM A563 nuts, including Grade DH, also possess high tensile strength but generally lower than ASTM A194 nuts. While these nuts are heat-treated, their tensile strength requirements are tailored for structural applications with significant—but not extreme—stress levels.

Proof load stress is the maximum stress a nut can endure without permanent deformation. ASTM A194 nuts typically have higher proof load stress, making them suitable for applications involving significant mechanical stress. This ensures the nuts maintain their integrity and resist deformation under pressure, which is vital for safety and performance in high-stress conditions. ASTM A563 nuts also have a high proof load stress but generally lower than ASTM A194 nuts. These nuts are designed to handle substantial loads in structural settings, such as steel constructions and bridges, but are not intended for the more severe conditions where ASTM A194 nuts excel.

Hardness refers to a material’s resistance to deformation, especially surface indentation. ASTM A194 nuts undergo rigorous heat treatment processes—including quenching and tempering—to achieve high hardness. This characteristic is critical for nuts used in high-temperature and high-pressure environments, as it enhances their resistance to wear and deformation under severe conditions. ASTM A563 nuts are also heat-treated; however, their hardness requirements are lower compared to ASTM A194 nuts. The heat treatment for ASTM A563 nuts balances strength and ductility, rendering them suitable for structural applications where extreme hardness is less crucial.

ASTM A194 nuts are subjected to more stringent testing to confirm their suitability for demanding environments. This includes verification of heat treatment, hardness testing, and tensile testing, ensuring reliable performance under high-pressure and high-temperature conditions. In comparison, ASTM A563 nuts undergo less rigorous testing. Although tested for structural strength and mechanical properties, their evaluation does not focus on high-temperature performance, reflecting their broader and less specialized applications.

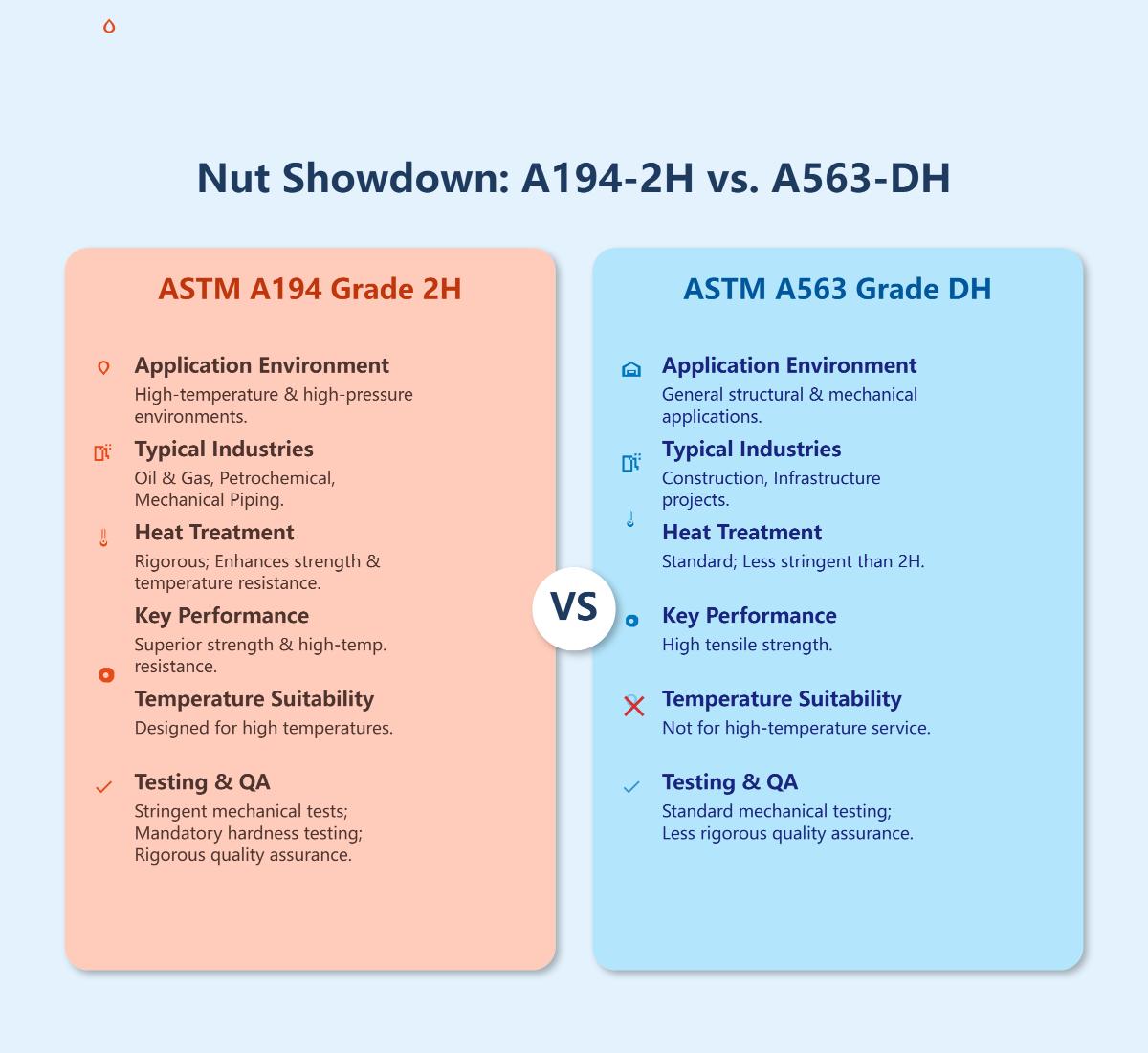

Visual comparison charts are a straightforward way to understand the differences between ASTM A194 and ASTM A563 nuts. These charts highlight critical aspects such as application, material types, grades, heat treatment processes, mechanical properties, suitability for high-temperature environments, testing requirements, bolt compatibility, typical industries, and substitution notes.

| Feature | ASTM A194 Nuts | ASTM A563 Nuts |

|---|---|---|

| Primary Application | High-pressure and high-temperature services (e.g., oil & gas, chemical industries) | General structural and mechanical uses (e.g., steel frames, bridges) |

| Material Types | Carbon steel, alloy steel, stainless steel | Carbon steel, alloy steel |

ASTM A194 nuts are primarily used in high-pressure and high-temperature environments, while ASTM A563 nuts are utilized in general structural and mechanical applications. The material composition for ASTM A194 includes carbon steel, alloy steel, and stainless steel, offering enhanced performance under extreme conditions. ASTM A563 nuts are made from carbon steel and alloy steel, tailored for structural strength.

| Feature | ASTM A194 Nuts | ASTM A563 Nuts |

|---|---|---|

| Grades | Includes 2H, 7, 8 (high strength, heat-treated grades) | Includes A, C, DH, DH3 (varied mechanical properties) |

| Heat Treatment | Required for high strength and hardness; includes quenching and tempering | May include heat treatment but generally less rigorous than A194 |

ASTM A194 nuts include grades such as 2H, 7, and 8, which are heat-treated to achieve high strength and hardness. The heat treatment process involves quenching and tempering, crucial for ensuring performance in high-temperature and high-pressure conditions. ASTM A563 nuts, on the other hand, include grades A, C, DH, and DH3. These nuts may undergo heat treatment but are generally less rigorously processed compared to ASTM A194 nuts.

| Feature | ASTM A194 Nuts | ASTM A563 Nuts |

|---|---|---|

| Mechanical Properties | High tensile strength and hardness; suitable for extreme conditions | High tensile strength but generally lower than A194 nuts |

| Suitability for High-Temperature Applications | Specifically designed and tested for high-temperature environments | Not typically suitable for high-temperature applications |

ASTM A194 nuts have high tensile strength and hardness, making them suitable for extreme conditions. These nuts are specifically designed and tested for high-temperature applications, ensuring reliability in demanding environments. ASTM A563 nuts also possess high tensile strength but are generally lower in strength compared to ASTM A194 nuts. They are not typically suitable for high-temperature applications.

| Feature | ASTM A194 Nuts | ASTM A563 Nuts |

|---|---|---|

| Testing Requirements | Rigorous testing including hardness, tensile strength, and heat resistance | Testing less stringent; focused on structural performance |

| Bolt Compatibility | Compatible with ASTM A193 Grade B7 and other high-strength bolts | Compatible with a variety of bolt grades but not a substitute for A194 in high-temp applications |

ASTM A194 nuts undergo rigorous testing, including hardness, tensile strength, and heat resistance, and are compatible with high-strength bolts like ASTM A193 Grade B7. ASTM A563 nuts have less stringent testing requirements, focusing on structural performance. They are compatible with various bolt grades but should not be substituted for ASTM A194 nuts in high-temperature applications.

| Feature | ASTM A194 Nuts | ASTM A563 Nuts |

|---|---|---|

| Typical Industries | Oil & gas, petrochemical, high-pressure equipment | Construction, general structural engineering |

| Substitution Notes | ASTM A563 DH nuts may substitute A194 2H in some cases but not for high-temp uses | Not acceptable substitute for ASTM A194 nuts in high-temp service |

ASTM A194 nuts are commonly used in industries such as oil & gas, petrochemical, and high-pressure equipment, where high strength and heat resistance are essential. In contrast, ASTM A563 nuts are used in construction and general structural engineering. While ASTM A563 DH nuts may substitute ASTM A194 2H nuts in some cases, they are not suitable for high-temperature applications.

ASTM A194 nuts, especially Grade 2H, are specifically engineered for high-temperature and high-pressure environments. These nuts are commonly used in demanding industries such as oil, gas, petrochemical, and chemical processing, where operational conditions are severe. The material composition and rigorous heat treatment processes, including quenching and tempering, endow these nuts with high tensile strength and hardness, making them suitable for extreme conditions.

ASTM A563 nuts, especially Grade DH, are primarily used in general structural and mechanical applications. These nuts are widely used in construction projects like steel frame structures, bridges, and various machinery assemblies, where high tensile strength is essential but extreme temperature resistance is not a primary concern.

| Feature | ASTM A194 (e.g., Grade 2H) | ASTM A563 (e.g., Grade DH) |

|---|---|---|

| Primary Application | High temperature and high-pressure environments | General structural and mechanical applications |

| Material Types | Carbon, alloy, stainless steel | Carbon and alloy steel |

| Heat Treatment | Rigorous heat treatment including quenching/tempering | Quenched and tempered for some grades (DH) |

| Mechanical Strength | Higher tensile strength and hardness | High tensile strength but generally lower than A194 2H |

| High-Temperature Suitability | Specifically designed for high-temperature use | Not suitable for high-temperature applications |

| Typical Industries | Oil & gas, petrochemical, chemical processing | Construction, structural, general machinery |

To substitute ASTM A194 nuts for ASTM A563 nuts, it’s important to understand the mechanical and performance differences between these grades. ASTM A194 Grade 2H nuts can often replace ASTM A563 Grade DH nuts due to their superior strength, hardness, and rigorous heat treatment processes. However, the reverse substitution is generally not recommended.

ASTM A194 Grade 2H nuts have higher tensile strength and hardness compared to ASTM A563 Grade DH nuts, making them suitable for high-pressure and high-temperature environments. However, ASTM A563 Grade DH nuts are not designed for such severe conditions and lack the necessary heat treatment, making them unsuitable for substitution in place of ASTM A194 Grade 2H nuts.

Following these substitution guidelines ensures you choose the right fasteners, maintaining safety and performance in different industrial applications.

The intended application significantly influences the cost and availability of ASTM A194 and ASTM A563 nuts.

ASTM A194 nuts are specifically designed for high-pressure and high-temperature environments, such as those found in the oil, gas, and petrochemical industries. These nuts undergo rigorous heat treatment, hardness testing, and other stringent quality controls to ensure they can withstand extreme conditions, which increases the manufacturing complexity and cost. For instance, ASTM A194 Grade 2H nuts are heat-treated to perform exceptionally well at elevated temperatures, making them more expensive but necessary for demanding applications.

ASTM A563 nuts are mainly used in general structural and mechanical applications where high tensile strength is needed but extreme temperature resistance is not. Commonly found in construction, steel framing, and bridge building, these nuts are more economical due to less rigorous testing and heat treatment requirements. They offer a broad range of grades, providing flexibility for various structural needs without the premium cost associated with high-temperature service nuts.

| Feature | ASTM A194 (e.g., Grade 2H) | ASTM A563 (e.g., Grade DH) |

|---|---|---|

| Material | Carbon, alloy, and stainless steel | Carbon and alloy steel |

| Mechanical Strength | Higher proof load; suitable for high temp/pressure | High tensile strength but lower than A194 in heat resistance |

| Heat Treatment | Required (quenching and tempering) | Required for some grades but less stringent |

| Testing Requirements | More rigorous (including hardness testing) | Less rigorous compared to A194 |

| Suitable Environments | High temperature, high pressure (oil & gas) | Structural, mechanical, non-extreme temperature |

| Typical Cost | Higher due to processing and testing | Lower, more common in construction and general use |

ASTM A194 Grade 2H nuts have higher proof load and are suitable for high temperature and pressure environments, while ASTM A563 Grade DH nuts offer high tensile strength but are less resistant to heat. The superior mechanical properties and rigorous testing of ASTM A194 nuts make them more expensive but essential for high-stress environments.

ASTM A563 nuts are generally more widely available due to their broad usage in construction and mechanical applications. This broad usage translates to higher manufacturing volumes and widespread distribution, making these nuts easier to source. In contrast, ASTM A194 nuts, which are specialized for high-temperature and pressure environments, may have more limited availability and longer lead times, especially for specific grades or sizes required in critical industries. This specialization can affect both the ease of procurement and the cost.

ASTM A194 Grade 2H nuts can sometimes replace ASTM A563 Grade DH nuts due to their superior strength, but ASTM A563 nuts are not suitable for high-temperature applications that require ASTM A194 nuts.

| Aspect | ASTM A194 Nuts | ASTM A563 Nuts |

|---|---|---|

| Cost | Higher due to heat treatment, testing, and material | Lower, suitable for general structural use |

| Availability | More specialized, potentially limited availability | Broadly available due to general use |

| Application Suitability | High temperature, high pressure environments | Structural, mechanical, non-extreme temperature |

| Substitution Flexibility | Can substitute A563 Grade DH nuts in some cases | Not suitable to substitute A194 nuts in high-temp applications |

Choosing between ASTM A194 and ASTM A563 nuts involves weighing cost against performance and availability. ASTM A194 nuts command a premium due to their stringent manufacturing processes and suitability for harsh environments. Conversely, ASTM A563 nuts offer a cost-effective and widely available option for structural and mechanical applications where extreme conditions are not a concern.

ASTM A194 nuts are crafted for use in high-pressure and high-temperature settings, ideal for industries like oil, gas, and petrochemicals. Conversely, ASTM A563 nuts are intended for general structural and mechanical applications, commonly found in construction projects, machinery assemblies, and steel frameworks where extreme temperature resistance is not a primary concern.

ASTM A194 nuts come in carbon steel, alloy steel, and stainless steel, ensuring they meet the demands of high-stress environments. They include grades such as 2H, 7, and 8, each with unique properties. Grade 2H, for instance, is known for its high strength and heat treatment. On the other hand, ASTM A563 nuts, made primarily from carbon steel and alloy steel, focus on structural strength and include grades like A, C, DH, and DH3, with Grade DH being the strongest.

ASTM A194 nuts have higher tensile strength and hardness due to rigorous heat treatment, which is crucial for high-pressure and temperature applications. While ASTM A563 nuts also have good tensile strength, their hardness is generally lower, making them suitable for structural but not high-temperature uses.

Heat treatment is essential for ASTM A194 nuts, especially grades like 2H, to withstand high temperatures and pressures through processes like quenching and tempering. ASTM A563 nuts also undergo heat treatment, but it’s less stringent, focusing on achieving structural strength.

ASTM A194 Grade 2H nuts can replace ASTM A563 Grade DH nuts due to their superior strength and heat treatment. However, using A563 Grade DH nuts in place of A194 Grade 2H nuts in high-temperature applications is not recommended, as A563 nuts lack the necessary heat treatment and strength.

Below are answers to some frequently asked questions:

ASTM A194 Grade 2H and ASTM A563 Grade DH nuts have distinct differences that cater to their specific applications. ASTM A194 Grade 2H nuts are designed for high-temperature and high-pressure environments, such as those found in the oil and gas, petrochemical, and mechanical piping industries. These nuts undergo rigorous heat treatment processes to enhance their strength and temperature resistance, and they must meet stringent mechanical property requirements, including mandatory hardness testing.

In contrast, ASTM A563 Grade DH nuts are intended for general structural and mechanical applications, such as construction and infrastructure projects. While they also require heat treatment, the standards are less stringent compared to A194 Grade 2H nuts. A563 Grade DH nuts provide high tensile strength but are not designed for high-temperature service. They undergo standard mechanical testing but do not have the same rigorous quality assurance protocols as A194 Grade 2H nuts.

Yes, ASTM A194 Grade 2H nuts can be substituted for ASTM A563 Grade DH nuts. This substitution is permitted and aligns with industry standards and practices. ASTM A194 Grade 2H nuts are designed for high-pressure and high-temperature applications, such as those found in the petroleum and chemical industries, and they undergo more rigorous heat treatment and testing to ensure their performance in such conditions. Consequently, they possess higher tensile strength and superior hardness compared to ASTM A563 Grade DH nuts, which are primarily used for structural applications.

Substituting ASTM A194 Grade 2H nuts for ASTM A563 Grade DH nuts ensures that the mechanical properties and performance requirements are met or exceeded. However, the reverse substitution (using ASTM A563 Grade DH nuts in place of ASTM A194 Grade 2H nuts) is not recommended because A563 DH nuts do not meet the high-temperature and high-pressure performance standards required for applications where A194 Grade 2H nuts are specified.

For high-temperature and high-pressure applications, ASTM A194 Grade 2H nuts are the superior choice. These nuts are specifically designed for such demanding conditions, featuring enhanced mechanical properties through rigorous heat treatment processes. This makes them highly suitable for industries like oil, gas, and petrochemicals, where both high strength and resistance to elevated temperatures are critical. In contrast, ASTM A563 nuts, including Grade DH, are primarily intended for general structural applications and do not offer the same level of performance in high-temperature environments. Therefore, ASTM A194 Grade 2H nuts are recommended for ensuring reliability and safety in high-temperature and high-pressure scenarios.

ASTM A194 and ASTM A563 nuts differ primarily in their mechanical properties due to their intended applications and material specifications. ASTM A194 nuts, such as Grade 2H, are designed for high-pressure and high-temperature environments, typically found in industries like oil and gas. These nuts are made from carbon, alloy, and stainless steel and undergo rigorous testing processes, including heat treating and hardness testing, to ensure high tensile strength and hardness. Conversely, ASTM A563 nuts, including Grade DH, are intended for general structural and mechanical uses. These nuts, made from carbon and alloy steel, undergo a quenching and tempering process, providing high load-bearing capacity suitable for structural applications but lacking the specific high-temperature capabilities of A194 nuts. In summary, ASTM A194 nuts offer superior mechanical properties for high-stress, high-temperature applications, while ASTM A563 nuts are more suited for general structural uses.