When it comes to stainless steel, understanding the subtle differences between various grades and specifications can be crucial for making informed decisions in material selection. Have you ever wondered why ASTM A240 and AISI 304 are often mentioned in the same breath, yet they serve distinct purposes? This article delves into the nuances of these two important designations, breaking down their definitions, chemical compositions, mechanical properties, and corrosion resistance. Whether you’re deciding on materials for high-temperature applications, marine environments, or food processing, understanding the key differences between ASTM A240 and AISI 304 stainless steel can lead to better choices and improved outcomes. So, what sets these two apart, and how do their unique properties impact their performance? Let’s explore and find out.

ASTM A240 is a crucial standard developed by the American Society for Testing and Materials (ASTM) that specifies requirements for stainless steel plates, sheets, and strips. It includes various stainless steel grades made of chromium, chromium – nickel, and chromium – manganese – nickel alloys. These materials are primarily intended for pressure vessels and general industrial applications.

ASTM A240 plays a vital role in ensuring that stainless steel products meet stringent quality and performance criteria. The standard outlines specific chemical compositions and mechanical properties for each grade, guaranteeing that materials are suitable for high – stress environments such as pressure vessels. Compliance with ASTM A240 ensures that manufacturers and suppliers provide consistent, high – quality materials, which is essential for maintaining safety and reliability in industrial applications.

Stainless steel products conforming to ASTM A240 are used across various industries due to their excellent corrosion resistance, mechanical properties, and durability. Key applications include:

AISI 304 stainless steel, commonly referred to as 304, is an austenitic stainless steel grade that is widely used for its excellent corrosion resistance, formability, and weldability. Its chemical composition includes chromium and nickel, making it suitable for a variety of industrial applications.

AISI 304 stainless steel is known for its versatile properties, making it a popular choice in numerous industries. Key properties include:

Common uses of AISI 304 include items such as kitchen equipment, food processing equipment, and chemical containers, as well as architectural applications and medical devices.

The main difference between AISI 304 and 304L is their carbon content. AISI 304 contains up to 0.08% carbon, while 304L (the “L” stands for low carbon) contains a maximum of 0.03% carbon. The lower carbon content in 304L minimizes the risk of carbide precipitation during welding. Due to its lower carbon content, 304L is less prone to intergranular corrosion after welding, making it more suitable for welding applications where post-weld annealing is not possible. The mechanical properties of 304 and 304L are similar, though 304L might have slightly lower yield and tensile strength due to its lower carbon content.

304L is particularly advantageous in applications where welding is involved and where the material cannot be subsequently annealed. Examples include:

When it comes to welding, AISI 304 and 304L both offer excellent weldability. However, certain considerations should be taken into account:

Both grades are compatible with various welding techniques such as TIG, MIG, and resistance welding. When welding, it is essential to use filler materials that match the composition of the base metal to maintain corrosion resistance and mechanical properties.

ASTM A240 Grade 304 stainless steel has a well-defined chemical composition, with a maximum carbon content of 0.08%. This low carbon level prevents carbide precipitation during welding, which is essential for maintaining its corrosion resistance. The manganese content is capped at 2.00%, aiding the steel’s hot-working properties. Phosphorus and sulfur are limited to 0.045% and 0.030% respectively, which helps improve ductility and reduces the risk of hot-cracking.

Silicon, present up to 0.75%, enhances the steel’s strength and resistance to oxidation. Chromium, ranging from 18.00% to 20.00%, is crucial for forming a protective oxide layer on the steel’s surface, providing excellent corrosion resistance. Nickel, present at 8.00% to 10.50%, boosts the steel’s toughness, ductility, and corrosion resistance, particularly in acidic environments. Nitrogen has a maximum limit of 0.10%, which can improve the strength and pitting corrosion resistance of the steel.

AISI 304 stainless steel has a chemical composition that is nearly identical to ASTM A240 Grade 304. It also has a maximum carbon content of 0.08%, a manganese limit of 2.00%, and maximum phosphorus and sulfur contents of 0.045% and 0.030% respectively. The silicon content is capped at 0.75%.

The chromium content in AISI 304 is between 18.00% and 20.00%, and the nickel content ranges from 8.00% to 10.50%. These elements work together to provide the steel with its characteristic corrosion resistance and mechanical properties. Nitrogen also has a maximum limit of 0.10%, contributing to the steel’s performance in terms of strength and corrosion resistance.

In both ASTM A240 Grade 304 and AISI 304, the ranges for chromium, nickel, and carbon are the same. The similar chromium and nickel contents ensure that both materials have comparable corrosion-resistant properties, making them suitable for a wide range of applications where resistance to oxidation and corrosion is required. The identical carbon limit helps maintain the weldability and long-term performance of the steel in various environments.

Due to their similar chemical compositions, ASTM A240 Grade 304 and AISI 304 perform similarly in corrosion resistance, mechanical strength, and formability. However, factors like the manufacturing process and heat treatment can still affect their final properties. For instance, variations in the annealing process can influence the grain structure and, consequently, the material’s toughness and ductility.

Tensile strength indicates how well a material can resist pulling forces. Both ASTM A240 Grade 304 and AISI 304 generally have a tensile strength of approximately 75,000 psi (515 MPa). This similarity is due to the fact that AISI 304, when supplied under the ASTM A240 specification, must meet the same stringent mechanical property requirements. Therefore, in practical applications, both materials exhibit comparable performance in terms of tensile strength.

Yield strength, indicating the stress at which a material begins to deform plastically, is another important property. ASTM A240 Grade 304 specifies a minimum yield strength of 30,000 psi (205 MPa), closely aligning with typical values for AISI 304. Both materials also exhibit excellent ductility, with a minimum elongation of about 40%, allowing significant deformation before failure. This high elongation percentage indicates that both materials can undergo significant deformation before breaking, which is advantageous for applications requiring extensive forming and shaping.

Hardness measures how resistant a material is to deformation and wear, usually using the Brinell or Rockwell scales. ASTM A240 Grade 304 specifies a maximum Brinell hardness of approximately 201 HB, which is similar to the typical hardness range for AISI 304. This level of hardness is adequate for many industrial applications, offering a good balance between strength and machinability.

Both ASTM A240 Grade 304 and AISI 304 stainless steels maintain their performance in high-temperature and high-pressure environments. They retain their mechanical properties over a wide temperature range, making them suitable for use in pressure vessels and high-temperature applications. However, it is important to note that prolonged exposure to high temperatures can lead to changes in mechanical properties, such as reduced tensile strength and increased susceptibility to creep.

A key difference between ASTM A240 Grade 304 and its low-carbon variant, ASTM A240 Grade 304L, lies in their carbon content. The lower carbon content in 304L (maximum 0.03%) reduces the risk of carbide precipitation during welding, which can otherwise lead to intergranular corrosion. This makes 304L more suitable for welded structures, where maintaining corrosion resistance in the heat-affected zone is critical. While AISI 304 typically matches the carbon content specified in ASTM A240 304, the presence of 304L as a variant provides additional flexibility in choosing the right material for welding applications.

Both ASTM A240 Grade 304 and AISI 304 harden similarly when worked. Cold working boosts their tensile strength and hardness, and can also make them more magnetic. This change in magnetic properties is due to the transformation of austenite to martensite during deformation, which can be an important consideration in applications where non-magnetic properties are required.

| Property | ASTM A240 Grade 304 | AISI 304 (Typical) |

|---|---|---|

| Tensile Strength (Ultimate) | Min 75,000 psi (515 MPa) | Approx. 75,000 psi (typical range 515 MPa) |

| Yield Strength (0.2% offset) | Min 30,000 psi (205 MPa) | Approx. 30,000 psi (varies slightly by form) |

| Elongation (%) | Min 40% | Typically around 40% |

| Hardness (Brinell) | Max 201 HB (approx. 92 HRB) | Similar range, typically ≤ 201 HB |

| Work Hardening | Cold working increases tensile strength and magnetic permeability | Similar behavior under cold work |

| Weldability | 304L (lower carbon) preferred for welding due to reduced carbide precipitation risk | Similar for AISI 304L |

Both ASTM A240 Grade 304 and AISI 304 offer robust mechanical properties, making them suitable for a wide range of industrial applications. The choice between them often comes down to specific certification requirements, application needs, and considerations like welding performance.

Both ASTM A240 Type 304 and AISI 304 stainless steel are known for their excellent general corrosion resistance. AISI 304 performs well in various environments, making it popular for food processing, architecture, and household uses due to its protective chromium-nickel oxide layer.

ASTM A240 Type 304 also offers reliable general corrosion resistance. The strict standards of ASTM A240 ensure a consistent protective layer, making it suitable for demanding applications.

ASTM A240 Type 304 typically has superior resistance to intergranular corrosion. The specification imposes strict controls on carbon content and includes testing requirements to prevent carbide precipitation along grain boundaries. This enhances durability, especially in components exposed to high temperatures. While AISI 304 is resistant to intergranular corrosion, it may be more prone if not properly processed or treated, particularly during welding.

In chloride environments, AISI 304 offers robust resistance to oxidizing acids and general corrosion but is moderately susceptible to localized corrosion such as pitting and crevice corrosion. The chloride ions can break down the protective oxide layer, leading to the formation of pits and crevices on the metal surface. While ASTM A240 Type 304 resists chloride environments well, performance varies by grade. For example, ASTM A240 includes grade 316, which has added molybdenum for better chloride resistance.

ASTM A240 Type 304, especially low carbon variants like 304L, resists carbide precipitation during welding, reducing localized corrosion risk. AISI 304 may require additional precautions during welding to avoid carbide precipitation, which can affect the material’s overall corrosion resistance and mechanical properties. When welding AISI 304 stainless steel, it’s important to use low heat input and consider post-weld annealing or using a stabilizing element like titanium or niobium to prevent carbide precipitation.

ASTM A240 is an ideal choice for pressure vessels as it strictly adheres to standards for mechanical properties and corrosion resistance, ensuring safety and durability under high – stress conditions. AISI 304 can serve in pressure vessels with less demanding pressure requirements. However, in high – pressure and high – temperature scenarios, ASTM A240’s wider range of grades and more comprehensive testing make it a more reliable option.

Both ASTM A240 and AISI 304 find wide use in the food processing industry. ASTM A240 suits large – scale food processing equipment and facilities, where its compliance with strict quality and performance criteria is essential. AISI 304 is commonly used in smaller, consumer – facing kitchen appliances like sinks and cooking equipment because its formability and excellent corrosion resistance make it easy to clean and maintain in food – handling environments.

In chemical plants, ASTM A240 excels due to its high corrosion resistance, especially when dealing with corrosive chemicals such as sulfuric acid, hydrochloric acid, and caustic soda at high temperatures. It is used for storage tanks, pipelines, and reaction vessels. AISI 304 can be employed for less corrosive chemical applications or when the aesthetic appearance of the equipment matters. But for handling highly aggressive chemicals, ASTM A240’s specific grade options offer better long – term performance.

ASTM A240, especially some of its low – carbon variants, resists corrosion well in marine environments and can be used in shipbuilding and offshore platforms. AISI 304 has some corrosion resistance, but it’s more prone to pitting (small holes forming on the metal surface due to the breakdown of the protective oxide layer) and crevice corrosion (corrosion occurring in narrow spaces between metal parts) in chloride – rich marine waters. ASTM A240’s ability to resist intergranular corrosion and its wider grade range make it more suitable for long – term use in harsh marine conditions.

ASTM A240 covers a wide range of stainless steel grades, each tailored for specific uses. These include austenitic, ferritic, martensitic, duplex, and superduplex stainless steels. Common grades include:

AISI 304, also known as UNS S30400, is one of the most commonly used stainless steel grades. Part of the 300 series, these austenitic stainless steels are renowned for high corrosion resistance and excellent formability. AISI 304 is often used interchangeably with ASTM A240 Type 304 but is specified under different standards. It features:

ASTM A240 specifies rigorous certification and testing protocols to ensure material quality and performance, including:

While AISI 304 does not have a formal certification process like ASTM A240, materials are often supplied with mill test reports (MTRs) that provide:

The stringent requirements and comprehensive testing of ASTM A240 make it a preferred choice for critical applications where reliability and performance are paramount. Industries benefiting include:

AISI 304’s versatility and excellent corrosion resistance make it suitable for a wide range of less demanding applications, such as:

To choose between ASTM A240 and AISI 304 stainless steel, it’s essential to understand their specifications and definitions.

ASTM A240 is a specification standard for chromium and chromium-nickel stainless steel plates, sheets, and strips, primarily used in pressure vessels and general industrial applications. It includes a variety of grades, such as 304 and 316, each tailored for specific performance criteria.

AISI 304 is a specific grade of austenitic stainless steel, composed of approximately 18% chromium and 8% nickel. It is known for its excellent corrosion resistance, formability, and weldability, making it suitable for a wide range of applications.

Both ASTM A240 and AISI 304 have similar chemical compositions, typically containing 18% chromium and 8% nickel, though the ASTM A240 specification can include slight variations depending on the specific grade.

ASTM A240 Type 304 typically has a minimum tensile strength of 75 ksi (515 MPa) and a minimum yield strength of 30 ksi (205 MPa). AISI 304 generally exhibits comparable mechanical properties but may have slight variations depending on the manufacturing process.

Both ASTM A240 Type 304 and AISI 304 offer excellent general corrosion resistance due to their high chromium content, which forms a protective oxide layer on the surface.

In high-chloride environments, AISI 304 is more prone to pitting and crevice corrosion compared to ASTM A240 grades like 316, which contain molybdenum for better resistance. ASTM A240 Type 304 is particularly noted for its superior intergranular corrosion resistance, making it suitable for high-stress applications.

ASTM A240 is widely used in high-stress environments such as pressure vessels, chemical processing, and food processing due to its strength and corrosion resistance. It is also suitable for marine environments where enhanced durability against chloride-induced corrosion is required.

AISI 304 is preferred in applications requiring general corrosion resistance, hygiene, and aesthetic appeal, such as food processing equipment, architectural components, and household appliances.

ASTM A240 stainless steels can withstand higher temperatures than AISI 304, making them ideal for applications requiring thermal stability, like pressure vessels and high-temperature chemical processing.

AISI 304 is highly formable and weldable, making it versatile for various industrial uses. Its excellent formability allows it to be shaped into complex structures without the need for intermediate annealing.

AISI 304 is generally more affordable due to its widespread use and economic production processes. This makes it a cost-effective choice for general applications.

Both ASTM A240 and AISI 304 are widely available, but ASTM A240 products may require specific tailoring to meet detailed application requirements, especially in high-stress or high-temperature environments.

Below are answers to some frequently asked questions:

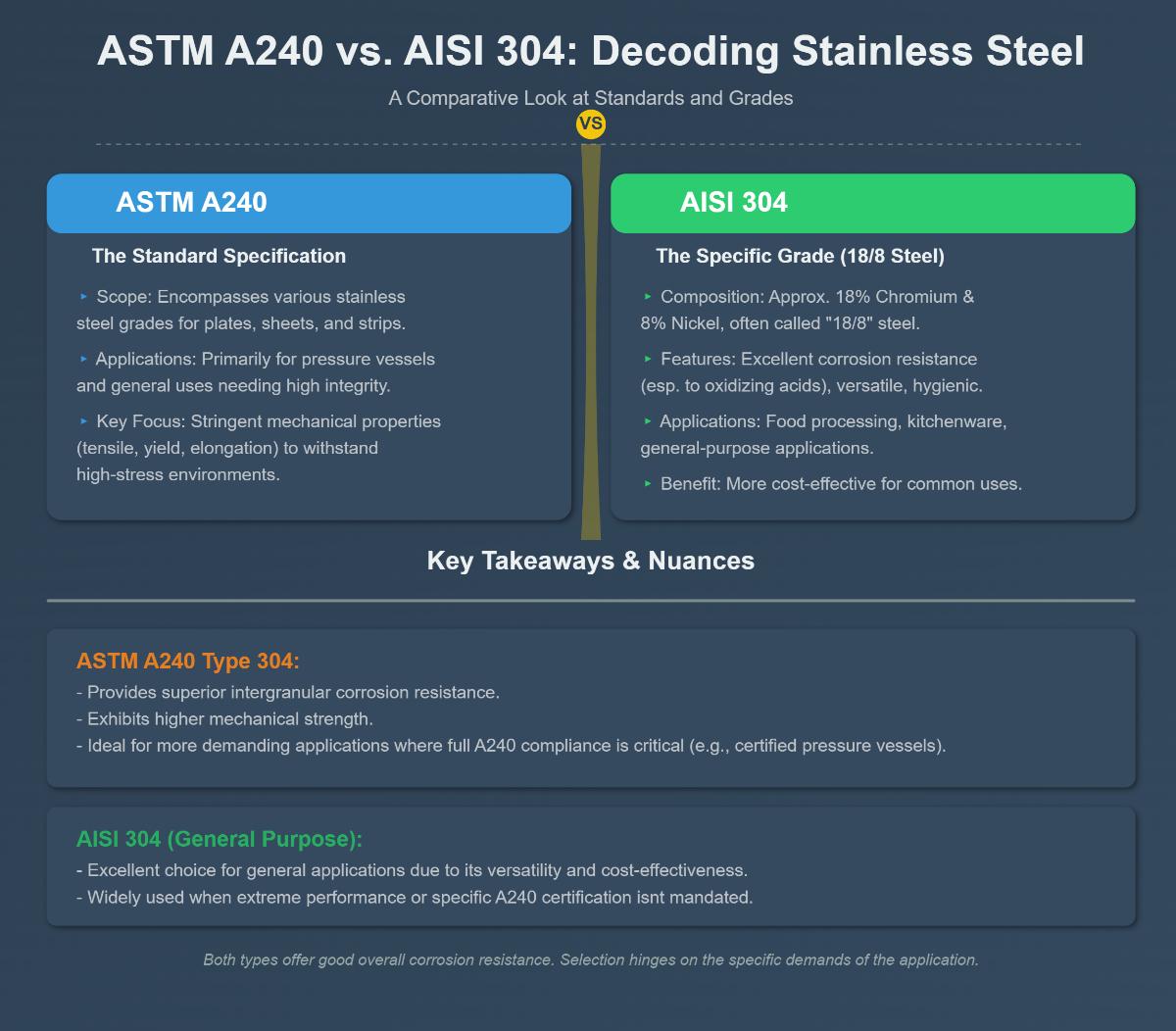

The main difference between ASTM A240 and AISI 304 stainless steel lies in their scope and application. ASTM A240 is a standard specification that encompasses a variety of stainless steel grades used for plates, sheets, and strips in pressure vessels and general-purpose applications. It sets stringent requirements for mechanical properties, including tensile strength, yield strength, and elongation, ensuring materials can withstand high-stress environments.

In contrast, AISI 304 is a specific grade within the ASTM A240 specification, known for its excellent corrosion resistance, particularly against oxidizing acids, and its versatility in various applications. AISI 304, often referred to as “18/8” stainless steel due to its approximate 18% chromium and 8% nickel content, is widely used for its ease of cleaning and hygiene in the food processing industry.

While both materials offer good corrosion resistance, ASTM A240 Type 304 provides superior intergranular corrosion resistance and higher mechanical strength, making it suitable for more demanding applications. AISI 304, however, is more cost-effective and commonly used for general-purpose applications where extremely high performance is not critical.

The chemical compositions of ASTM A240 and AISI 304 stainless steel are fundamentally aligned, as ASTM A240 encompasses the standards for products made from AISI 304 alloy. Both specifications denote austenitic stainless steel, typically containing approximately 18% chromium and 8% nickel, which are crucial for corrosion resistance and maintaining the austenitic structure.

In detail, ASTM A240 Grade 304 specifies:

AISI 304 typically adheres to similar ranges:

The key difference lies in the scope: ASTM A240 provides comprehensive guidelines for the production, mechanical properties, and testing of stainless steel products, ensuring consistency and quality for industrial applications. Variants such as 304L (with ≤ 0.03% carbon for better weldability) and 304H (with higher carbon content for high-temperature strength) are also specified under ASTM A240, offering tailored solutions for specific application needs.

For high temperature and pressure applications, ASTM A240 Type 304 stainless steel is the superior choice compared to AISI 304. ASTM A240 is a specification standard that includes stringent requirements for chemical composition, mechanical properties, and testing protocols, ensuring materials can withstand high stress, temperature, and corrosive conditions. This makes it particularly suited for demanding environments such as pressure vessels and high-temperature industrial equipment.

AISI 304, while sharing a similar chemical composition with ASTM A240 Type 304, does not inherently require the same rigorous standards for mechanical testing and certifications. Consequently, ASTM A240 materials typically offer higher tensile and yield strengths, providing better structural integrity under high pressure. Additionally, ASTM A240 Type 304 has enhanced temperature resistance and superior intergranular corrosion resistance due to stricter impurity limits and controlled heat treatments.

The main difference in corrosion resistance between ASTM A240 and AISI 304 lies in the scope and specificity of each term. ASTM A240 is a broad specification that covers various stainless steel grades, including AISI 304, ensuring that these materials meet stringent corrosion resistance criteria. It defines the chemical composition, mechanical properties, and quality control measures necessary for stainless steels to perform reliably in corrosive environments.

AISI 304, a specific grade under ASTM A240, is known for its excellent corrosion resistance due to its chromium (approximately 18%) and nickel (around 8-10.5%) content. This composition allows it to form a stable, passive oxide layer that protects against oxidation and general corrosion in many environments, including atmospheric and mild chemical conditions.

However, in applications involving welding, 304L (a low-carbon variant of 304) is preferred due to its reduced carbon content, which minimizes the risk of intergranular corrosion around welds. While both ASTM A240 and AISI 304 provide high corrosion resistance, ASTM A240 encompasses a wider range of stainless steel grades, each tailored for specific environments, including those requiring enhanced resistance to pitting and crevice corrosion.

ASTM A240 and AISI 304 are both valued for their corrosion resistance and durability, but they have different application focuses. ASTM A240, a standard specification for various stainless – steel products, is used in pressure vessels, chemical processing, food processing, construction, automotive, medical equipment, and petrochemical industries. AISI 304, a specific grade under ASTM A240, is popular in home and commercial appliances, food processing industries, pharmaceutical and medical fields, automotive and aerospace for structural parts, and architectural trim.

The significance of ASTM A240 certification lies in its role as a comprehensive standard that ensures the quality, chemical composition, mechanical properties, and performance of stainless steel materials, specifically plates, sheets, and strips. This certification is crucial for several reasons:

In summary, ASTM A240 certification guarantees that stainless steel materials, including AISI 304, meet the necessary standards for quality, performance, and durability, making it indispensable for various industrial applications.