Steel is the backbone of many industries, serving as the fundamental material for construction, manufacturing, and engineering projects. Among the myriad of steel grades available, ASTM A29 and ASTM A36 stand out for their distinct properties and applications. But what sets these two apart, and how do you determine which one is best suited for your needs? In this article, we will dive deep into the key differences between ASTM A29 and ASTM A36, comparing their chemical compositions, mechanical properties, and suitability for various applications. Whether you’re dealing with high-strength requirements, weldability, or machinability concerns, understanding these differences is crucial for making an informed decision. So, which steel grade will emerge as the better option for your next project? Read on to find out.

ASTM A29 and ASTM A36 are two important steel standards, each used for different applications. Understanding these standards is essential for professionals in fields such as construction, engineering, and manufacturing. This section provides a detailed introduction to both standards, highlighting their significance and the rationale behind comparing them.

Choosing the right steel standard can significantly impact a project’s durability, performance, and cost, making it crucial to understand the differences between ASTM A29 and ASTM A36. Each standard serves different purposes, and knowing their distinct characteristics helps in making informed decisions. For instance, while ASTM A29 is typically used for steel bars in various industrial applications, ASTM A36 is primarily used for structural steel in construction.

This comparison aims to highlight the differences in chemical compositions, mechanical properties, and applications, helping professionals select the most suitable steel grade. By examining these aspects, this article provides a comprehensive understanding that will aid in choosing the right material for specific needs, especially in projects requiring high-strength materials or specific structural characteristics.

ASTM A29 and ASTM A36 hold significant positions in the steel industry. ASTM A29 is used for a variety of industrial applications involving hot-wrought and cold-finished carbon and alloy steel bars, while ASTM A36 is known for its weldability and strength, making it ideal for structural components in construction.

Understanding these standards not only helps in selecting the right material but also ensures compliance with industry norms, enhancing the safety and efficiency of engineering projects.

The carbon content in ASTM A29 and ASTM A36 steels significantly influences their properties and applications.

ASTM A29 includes a variety of carbon steel and alloy steel grades. For example, carbon steel grades like 1020 and 1045 have carbon content ranging from 0.20% to 0.45%, balancing hardness and ductility. Alloy steel grades such as 4140 and 4340 typically have carbon levels around 0.38-0.43%, which, combined with alloying elements, enhance their strength and toughness.

ASTM A36 steel features a more uniform and relatively lower carbon content, usually around 0.25% to 0.29%. This lower carbon content makes ASTM A36 more malleable and easier to weld, form, and machine, which is advantageous for general structural applications.

Manganese improves the strength and hardness of steel while also enhancing its toughness and wear resistance.

In ASTM A29 steels, manganese levels vary by grade. Carbon steel grades typically have 0.30% to 1.00%, while alloy steels like 4140 include 0.75-1.00%.

ASTM A36 steel contains about 1.03% manganese, enhancing its strength and weldability for structural applications.

Silicon is added to steel to improve its strength and deoxidize the material during production.

The silicon content in ASTM A29 steels can vary, especially in alloy steels. For instance, alloy steel grades like 4140 may contain silicon levels up to 0.35%, which helps in improving the steel’s overall strength and hardness. Silicon acts as a deoxidizing agent during the steel-making process, which helps reduce the presence of oxygen and improve the quality of the steel.

ASTM A36 steel includes 0.280-0.40% silicon, which helps deoxidize the steel during production and improves its strength.

Apart from carbon, manganese, and silicon, other elements play a significant role in defining the properties of ASTM A29 and ASTM A36 steels.

Depending on the grade, ASTM A29 steels may include additional elements such as:

ASTM A36 steel also contains small amounts of phosphorus, sulfur, and copper, which improve machinability and corrosion resistance.

These differences in chemical composition between ASTM A29 and ASTM A36 steels are crucial as they directly impact the mechanical properties and suitability of these steels for various applications.

ASTM A29 steel grades offer a wide range of tensile strengths, with some high-strength alloys reaching up to 95000 psi (655 MPa). This variability allows ASTM A29 steels to be tailored for specific applications requiring different levels of tensile strength.

ASTM A36 steel has a tensile strength range of 58000 to 79800 psi (400 to 550 MPa). This range is generally lower than that of ASTM A29, making ASTM A36 more suitable for applications where moderate tensile strength is sufficient.

The yield strength of ASTM A29 steels varies significantly based on the specific grade. For example, specific grades may offer yield strengths around 60200 psi (415 MPa). This adaptability makes ASTM A29 suitable for applications demanding precise yield strength specifications.

ASTM A36 steel has a minimum yield strength of 36300 psi (250 MPa), which is lower compared to many ASTM A29 grades. This lower yield strength is ideal for structural applications where ductility and ease of fabrication are more critical than high yield strength.

The elongation properties of ASTM A29 steel grades vary, with some grades offering up to 25.70% elongation. Higher elongation indicates better ductility, making these steels suitable for applications where the material needs to withstand deformation without breaking.

ASTM A36 steel provides at least 20% elongation in 200 mm and 23% in 50 mm. These values indicate good ductility, which is advantageous for structural components that need to absorb energy and deform under load without fracturing.

Hardness in ASTM A29 steels can be quite high, with certain grades reaching up to 197 Brinell hardness. This high hardness level is beneficial for wear-resistant applications and components that require a hard surface to extend their lifespan.

ASTM A36 typically has a hardness around 83 Rockwell, which is lower than many ASTM A29 grades. The lower hardness of ASTM A36 makes it easier to machine and weld, though it may be less suitable for applications requiring high surface hardness.

The elastic modulus of ASTM A29 steels ranges between 190-210 GPa, indicating their stiffness and resistance to deformation under load. This range is beneficial for applications requiring high rigidity and minimal deflection.

ASTM A36 steel has an elastic modulus of approximately 200 GPa, which is comparable to many ASTM A29 grades. This similarity ensures that both standards provide adequate stiffness for structural applications.

ASTM A29 steels exhibit a shear modulus of about 80 GPa, which reflects their resistance to shear deformation. This property is particularly important for components subjected to shear forces.

ASTM A36 steel has a shear modulus of around 79.3 GPa, similar to ASTM A29. This ensures that ASTM A36 steel can also handle shear forces effectively, making it suitable for various structural applications.

| Property | ASTM A29 | ASTM A36 |

|---|---|---|

| Tensile Strength | Up to 95000 psi (655 MPa) | 58000 to 79800 psi (400 to 550 MPa) |

| Yield Strength | Around 60200 psi (415 MPa) | Minimum 36300 psi (250 MPa) |

| Elongation | Up to 25.70% | At least 20% in 200 mm |

| Hardness | Up to 197 Brinell | Around 83 Rockwell |

| Elastic Modulus | 190-210 GPa | Approximately 200 GPa |

| Shear Modulus | Approximately 80 GPa | About 79.3 GPa |

This comparison highlights the distinct mechanical properties of ASTM A29 and ASTM A36 steels, emphasizing their suitability for different applications based on strength, ductility, hardness, and elasticity.

Structural steel is a category of steel used for making construction materials in various shapes. It has high strength, flexibility, and durability, making it ideal for building frameworks, bridges, and other load-bearing structures. Structural steel standards, such as ASTM A29 and ASTM A36, provide guidelines for the composition, mechanical properties, and applications of different steel grades.

Applications: ASTM A29 covers a wide range of hot-wrought and cold-finished steel bars, including carbon, alloy, and stainless steel varieties. This standard is versatile, catering to industries such as machinery, automotive, aerospace, and construction. The steel bars produced under ASTM A29 are known for their strength, machinability, and resistance to wear, making them suitable for high-stress applications.

Properties: ASTM A29 steel grades have varied mechanical properties depending on their composition. Common grades, such as 4140 and 4340, can be heat-treated to improve their performance in demanding applications. These steels typically exhibit higher tensile and yield strengths compared to ASTM A36, providing better durability and stress resistance.

Applications: ASTM A36 is primarily used for structural steel in construction projects, including bridges, buildings, and load-bearing structures. Its strength, versatility, and reliability make it a preferred choice for general-purpose industrial applications. Its ease of welding, cutting, and forming further enhances ASTM A36 steel’s suitability for construction.

Properties: ASTM A36 steel is characterized by its low carbon content, which results in excellent ductility and weldability. With a minimum yield strength of 36 ksi, ASTM A36 is suitable for applications where moderate strength is sufficient. The consistent chemical composition and mechanical properties ensure that ASTM A36 steel can be reliably used in various structural applications.

Strength and Durability: ASTM A29 steel grades generally offer higher strength and durability due to their varied compositions and heat-treatable properties. In contrast, ASTM A36 offers moderate strength, adequate for most construction applications, but may not be ideal for high-stress environments.

Machinability and Weldability: ASTM A36 steel excels in weldability and machinability, making it easier to work with in construction settings. While ASTM A29 also offers good machinability, its weldability can vary depending on the specific grade, requiring more careful consideration during fabrication.

Cost and Availability: ASTM A36 is typically more cost-effective and widely available, making it a practical choice for budget-conscious projects. ASTM A29 grades are generally more expensive; varies by grade due to the additional alloying and processing required to achieve their enhanced properties.

| Features | ASTM A29 | ASTM A36 |

|---|---|---|

| Application | Machinery, automotive, aerospace | Construction (bridges, buildings) |

| Type of Steel | Carbon, alloy, stainless steel | Carbon structural steel |

| Strength and Durability | Higher strength and durability | Moderate strength, good ductility |

| Machinability and Weldability | High machinability; varied weldability | Easy welding and machining |

| Cost and Availability | Generally more expensive; varies by grade | Cost-effective; widely available |

| Specific Grades | Includes grades like 4140, 4340 | Single grade with specified properties |

Understanding the differences in structural steel standards like ASTM A29 and ASTM A36 is crucial for selecting the appropriate material for specific projects. The choice between these standards depends on factors such as strength requirements, ease of fabrication, cost, and availability.

ASTM A29 steel bars are widely used in various industries because of their diverse grades and mechanical properties.

In the manufacturing sector, ASTM A29 steel is essential for producing components like crankshafts and gears, where mechanical stress and wear resistance are critical. These include:

ASTM A29 is also prominent in the automotive and aerospace industries. Specific grades like 4140 and 4340 are used for:

These grades are strong and tough, making them suitable for demanding conditions.

In construction, ASTM A29 is used for structural elements such as:

This steel’s mechanical properties ensure the structural integrity and longevity of these components.

ASTM A36 steel is widely utilized in construction and structural projects due to its strength, versatility, and reliability.

ASTM A36 is widely used for building frameworks, including beams, columns, and girders. The moderate strength and good ductility of ASTM A36 make it suitable for these structural components, which require a balance of strength and flexibility.

For bridges, ASTM A36 is used in:

Its weldability and ease of fabrication facilitate the construction of large-scale bridge components, ensuring safety and durability.

ASTM A36 is also employed in various other engineering projects such as:

Its consistent mechanical properties and availability make it a preferred choice for these applications.

ASTM A29 encompasses a diverse range of steel grades with varying weldability characteristics. Low-carbon grades can be welded using standard methods without the need for preheating or post-weld heat treatments. However, alloy grades present more complexities. Higher carbon content or additional alloying elements may necessitate preheating to prevent cracking and ensure weld integrity. Post-weld heat treatments might also be required to relieve stresses and achieve optimal mechanical properties.

ASTM A36 is known for its exceptional weldability, primarily due to its low carbon content. Standard welding techniques like SMAW, GMAW, and GTAW work well with ASTM A36, making it a preferred choice for structural applications due to its predictable and reliable welds. This ease of welding simplifies the process and reduces costs, enhancing its suitability for various construction projects.

The machinability of ASTM A29 steel varies significantly across its grades. Cold-finished A29 steel bars have smooth surfaces and precise dimensions, making them ideal for high-precision machining. These attributes are perfect for applications requiring tight tolerances and fine finishes. Conversely, hot-rolled bars are more economical but have rougher surfaces, typically used in applications where such precision is not critical. Alloying elements in some grades may affect machinability, sometimes requiring special tools and techniques to achieve desired results.

ASTM A36 steel, with its low carbon content, is easier to machine compared to many ASTM A29 grades. ASTM A36 can be cut, formed, and machined using standard techniques, making it ideal for mass production due to its efficiency and cost-effectiveness. Its machinability allows easy fabrication into various shapes and components without significant tool wear or special equipment. This property is particularly beneficial in construction and manufacturing settings, where straightforward and reliable machining processes are paramount.

| Property | ASTM A29 | ASTM A36 |

|---|---|---|

| Weldability | Varies by grade; low-carbon grades are easy to weld, while alloy grades may require special treatments. | Excellent weldability without preheating due to low carbon content. |

| Machinability | Cold-finished bars offer smooth surfaces ideal for precision tasks; hot-rolled bars are more economical but rougher. | Easy to machine due to low carbon content, making it suitable for mass production. |

| Applications | Used in machinery, automotive components, and high-strength applications. | Commonly used in construction, building frames, bridges, and other load-bearing structures. |

Understanding the differences in weldability and machinability between ASTM A29 and ASTM A36 steels is crucial for selecting the appropriate material for specific applications. While ASTM A29 offers a range of grades suitable for various mechanical properties and precision tasks, ASTM A36 stands out for its consistent and user-friendly characteristics, particularly in structural and construction applications.

When comparing ASTM A29 and ASTM A36, cost is a crucial factor that can significantly impact project budgets and feasibility.

The cost of ASTM A29 steel bars, particularly alloy grades such as 4140 and 4340, tends to be higher due to their enhanced mechanical properties. The increased cost is attributed to advanced alloying elements like chromium, molybdenum, and nickel, additional processing requirements for cold-finished bars, and the specialized applications necessitating higher-quality materials.

ASTM A36 steel is generally more cost-effective due to its simpler chemical composition and lower carbon content. This straightforward composition reduces raw material and processing costs, and its widespread use in construction ensures high production volumes, lowering costs through economies of scale.

Availability is another crucial factor influencing the choice between ASTM A29 and ASTM A36. The ease of sourcing materials can affect project timelines and logistics.

ASTM A29 steel grades can be more limited in availability due to their specialized nature and fluctuating market demand.

In contrast, ASTM A36 is widely available because of its broad application in construction and industrial projects, consistent production volumes, and global reach.

Choosing between ASTM A29 and ASTM A36 depends on specific project needs. ASTM A29 is suitable for projects requiring high strength and specialized properties, while ASTM A36 is ideal for general structural applications prioritizing cost-effectiveness and ease of fabrication.

ASTM A36’s lower carbon content simplifies welding and fabrication, reducing the likelihood of cracking during the welding process. This makes it an ideal choice for construction purposes where ease of welding and high strength are essential.

The demand for ASTM A36 is generally higher due to its widespread use in construction and structural applications. This high demand ensures consistent supply and pricing stability. ASTM A29 grades may experience fluctuations based on specific application demand, impacting availability and cost.

Understanding the distinctions between ASTM A29 and ASTM A36 steel standards is crucial for selecting the appropriate material for various industrial and construction applications. Each standard has its own strengths and is suited to specific purposes based on their unique chemical compositions, mechanical properties, and cost considerations.

When it comes to mechanical properties, ASTM A29 offers a broader range of tensile and yield strengths due to the various grades available, such as carbon and alloy steels, making it ideal for applications requiring specific mechanical characteristics, such as high strength and toughness. In contrast, ASTM A36 provides consistent and moderate tensile and yield strengths, making it suitable for general structural applications where ease of fabrication and good ductility are more critical.

The choice between ASTM A29 and ASTM A36 also depends on the intended application. ASTM A29’s wide range of grades makes it versatile for use in manufacturing, automotive, and aerospace industries, where specific mechanical properties are necessary. ASTM A36, with its excellent weldability and machinability, is preferred for construction projects, including buildings and bridges, due to its reliable performance and cost-effectiveness.

Cost and availability are also important factors. ASTM A36 is typically more affordable and widely available, making it an excellent option for large-scale construction projects. Although ASTM A29 is generally more expensive due to its specialized grades, it offers enhanced properties that justify the higher cost for critical applications.

In practical terms, ease of welding and machining is crucial. ASTM A36 excels in these areas, making it easier to work with during fabrication and reducing Selecting between ASTM A29 and ASTM A36 should be guided by the specific requirements of the project, including the mechanical properties needed, cost constraints, and the intended application. By carefully evaluating these factors, professionals can ensure they choose the most suitable steel standard to efficiently and effectively meet their project objectives.

Below are answers to some frequently asked questions:

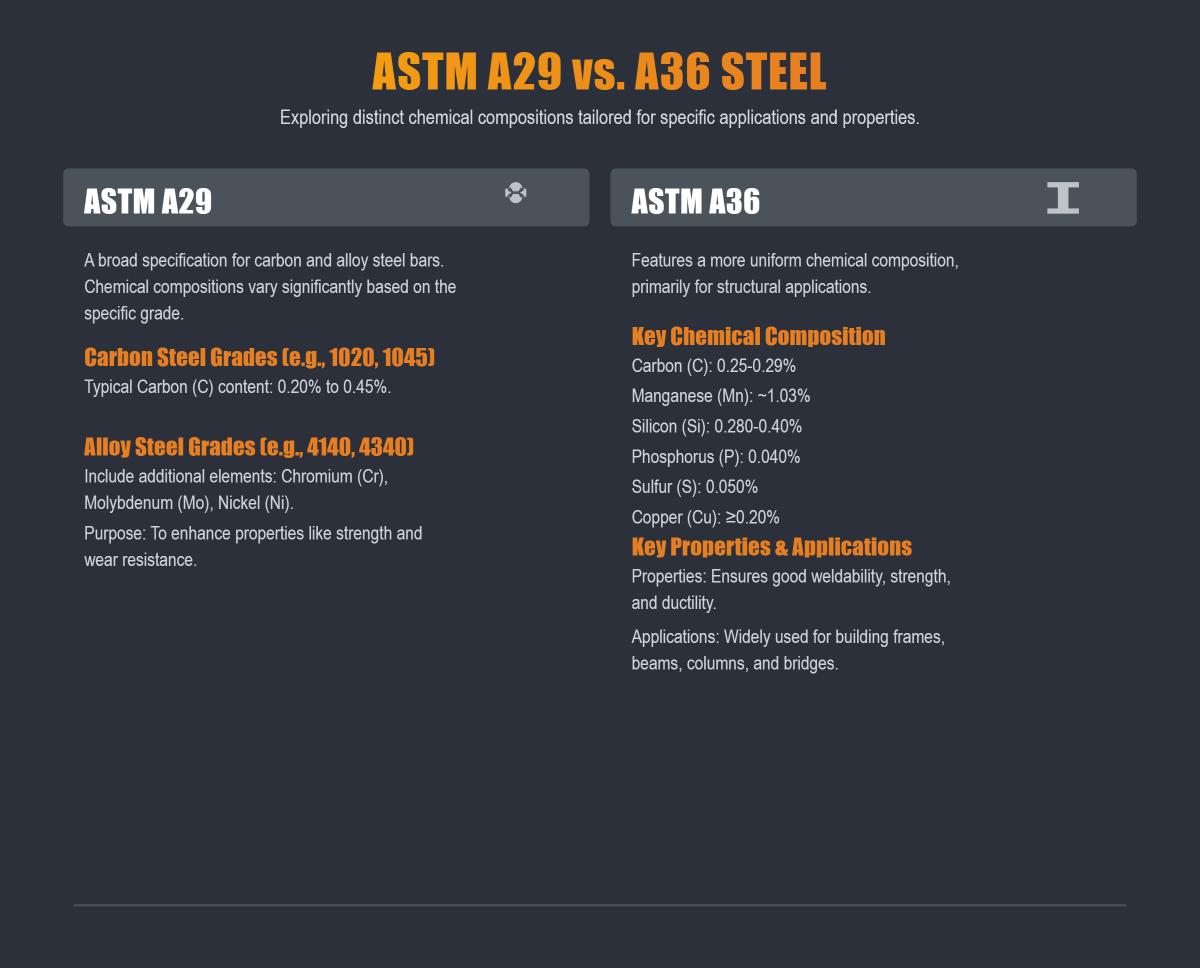

ASTM A29 and ASTM A36 have distinct differences in their chemical compositions, tailored to their specific applications and properties.

ASTM A29 encompasses a broad range of carbon and alloy steel bars, with compositions varying significantly depending on the specific grade. For instance, carbon steel grades like 1020 and 1045 have carbon content typically ranging from 0.20% to 0.45%. Alloy steel grades under ASTM A29, such as 4140 and 4340, include additional elements like chromium, molybdenum, and nickel to enhance their strength and wear resistance.

In contrast, ASTM A36 has a more uniform chemical composition, focusing on structural applications. Key elements in A36 steel include carbon (0.25-0.29%), manganese (~1.03%), silicon (0.280-0.40%), phosphorus (0.040%), sulfur (0.050%), and copper (≥0.20%). This consistent composition ensures good weldability, strength, and ductility, making it suitable for building frames, beams, columns, and bridges.

For high-strength applications, ASTM A29 is generally better suited compared to ASTM A36. ASTM A29 encompasses a variety of grades, including high-carbon and alloy steels such as AISI 4140 and 4340, which offer superior mechanical properties. These grades typically exhibit higher yield and tensile strengths, often exceeding 90,000 psi (620 MPa), making them ideal for demanding environments where enhanced durability and performance are required.

In contrast, ASTM A36 is a general-purpose structural steel with a yield strength of around 36 ksi (250 MPa) and ultimate tensile strength between 58,000 and 79,800 psi (400 to 550 MPa). While A36 is versatile and cost-effective for general construction and structural applications, it lacks the high-strength characteristics necessary for more demanding applications.

Therefore, for scenarios that necessitate higher strength and specific mechanical properties, ASTM A29 is the preferred choice due to its higher strength and adaptability.

ASTM A29 and ASTM A36 differ significantly in terms of weldability and machinability.

Weldability: ASTM A29 encompasses a wide range of carbon and alloy steel bars, with weldability varying by grade. Low-carbon grades under ASTM A29 generally offer good weldability, whereas alloy grades may necessitate preheating or post-weld heat treatments to prevent cracking. In contrast, ASTM A36 is renowned for its excellent weldability, which can be attributed to its low carbon content. This property reduces the risk of weld cracking, allowing A36 to be welded using standard techniques without special precautions, making it ideal for construction and structural applications.

Machinability: The machinability of ASTM A29 also varies depending on whether the bars are cold-finished or hot-rolled. Cold-finished ASTM A29 bars offer smoother surfaces and more precise dimensions, making them suitable for high-precision machining tasks. Hot-rolled bars, while more economical, have rougher surfaces and are typically used in less demanding applications. On the other hand, ASTM A36 has a reasonable machinability rate of approximately 72%, though it is not as easily machined as some low-carbon steels like AISI 1018. For optimal machining performance with A36, it is recommended to use slower cutting speeds and ensure that tools are sharp and well-maintained to manage potential issues with hard spots.

ASTM A29 and ASTM A36 each have specific applications where they are preferred due to their distinct properties. ASTM A29, which includes various grades such as 4140 and 4340, is favored in applications demanding high strength and durability, such as machinery, automotive, and aerospace industries. These grades can withstand high stresses and loads, making them suitable for components like gears, shafts, and heavy-duty machinery parts.

On the other hand, ASTM A36 is commonly used in general construction and structural applications due to its moderate tensile strength, excellent weldability, and cost-effectiveness. It is ideal for building frames, bridges, and storage tanks where ease of fabrication and assembly are critical. Therefore, ASTM A36 is the preferred choice for projects where rapid construction and cost efficiency are more important than high strength.

The cost comparison between ASTM A29 and ASTM A36 steel reveals distinct differences influenced by their composition and intended applications. ASTM A36 is generally more cost-effective due to its simpler chemical makeup, lower carbon content, and extensive availability, making it a popular choice for general construction and structural applications. Its affordability stems from ease of fabrication and widespread use, reducing production costs.

In contrast, ASTM A29 encompasses a broader range of carbon and alloy steel bars, often including additional alloying elements that enhance mechanical properties for specialized applications. These enhancements typically lead to higher costs, especially for cold-finished bars requiring precise dimensions and improved surface quality. Therefore, ASTM A29 is more suitable for projects demanding higher strength and precision, justifying its higher price.

When choosing between ASTM A29 and ASTM A36, several key factors should be considered to ensure the material selected meets the specific needs of your project.

Chemical Composition and Mechanical Properties: ASTM A29 covers a wide range of steel grades, including carbon, alloy, and stainless steels, each with specific mechanical properties tailored for high strength and stress resistance. In contrast, ASTM A36 is a mild carbon steel with lower carbon content, making it highly weldable but less strong than ASTM A29 grades.

Applications and Industry Uses: ASTM A29 is versatile and suited for industries such as automotive, machinery, and aerospace, where high strength and durability are critical. ASTM A36 is commonly used in construction for beams, columns, and structural components due to its cost-effectiveness and ease of fabrication.

Cost and Availability: ASTM A36 is typically more affordable and widely available, making it ideal for large-scale construction projects. ASTM A29 steel bars vary in cost depending on the grade and processing, with alloy grades being more expensive.

Processing and Machinability: ASTM A29 offers better machinability and strength, suitable for precision engineering components. ASTM A36 is easier to fabricate and weld but has lower machinability compared to ASTM A29 grades.

Environmental and Corrosion Resistance: Some ASTM A29 grades offer better corrosion resistance depending on the alloying elements. ASTM A36 has limited corrosion resistance and often requires protective coatings in corrosive environments.

In summary, the choice between ASTM A29 and ASTM A36 depends on the project’s specific requirements for strength, machinability, cost, and application. ASTM A29 is preferable for high-strength, durable components, while ASTM A36 is better suited for structural applications where ease of fabrication and cost are priorities.