When it comes to selecting the right steel for your project, understanding the differences between ASTM A36 and ASTM A572 can make all the difference in performance, cost, and durability. Are you unsure when to choose A36 over A572, or curious about how their weldability compares? This article dives deep into the mechanical and material properties of these two widely-used steel grades, shedding light on their specific strengths and applications. Whether you’re working on a high-stress construction project or seeking a cost-effective solution, we’ll provide the insights you need to make an informed decision. Ready to discover which steel is the best fit for your needs? Let’s explore the key distinctions that set ASTM A36 and ASTM A572 apart.

The American Society for Testing and Materials (ASTM) is a globally recognized leader in developing and delivering voluntary consensus standards. These standards are essential in various industries, including construction, manufacturing, and materials engineering.

These standards, developed through a rigorous process involving industry experts, scientists, and professionals from around the world, ensure that materials, products, systems, and services are reliable, safe, and of high quality.

Two of the most widely used ASTM standards in the field of structural steel are ASTM A36 and ASTM A572. These standards are pivotal for ensuring the quality and performance of steel used in construction and manufacturing.

Adhering to ASTM standards is like following a trusted recipe in cooking; it ensures that materials meet specific criteria, providing confidence in their use and resulting in safe, reliable, and high – quality outcomes. By following these standards, manufacturers and engineers can ensure safety, reliability, and quality in their projects. This consistency is crucial for maintaining structural integrity and achieving desired outcomes in construction and manufacturing.

Yield strength measures the maximum load a material can bear without permanent deformation.

Tensile strength measures the maximum load a material can support without breaking.

The chemical composition of a steel grade greatly influences its properties and suitability for various applications.

For materials exposed to harsh environments, corrosion resistance is essential.

Machinability and weldability influence how easily a material can be worked with, impacting manufacturing processes and project costs.

Knowing the best applications for each steel grade helps in selecting the right material for your project.

The cost-effectiveness and durability of materials influence project budgets and longevity.

The chemical composition of ASTM A36 and ASTM A572 steels significantly impacts their properties and uses.

ASTM A36 is a low-carbon steel with a carbon content ranging from 0.05% to 0.25%, typically including the following elements:

This composition ensures good machinability and weldability, making ASTM A36 suitable for a variety of general construction applications.

ASTM A572 Grade 50 is a high-strength, low-alloy (HSLA) steel, characterized by the following elements:

These alloying elements improve ASTM A572’s strength and corrosion resistance compared to ASTM A36.

The mechanical properties of these steels are critical for determining their suitability for various applications.

ASTM A572’s higher yield strength makes it more suitable for high-stress applications.

The higher tensile strength of ASTM A572 contributes to its ability to withstand greater loads without breaking.

ASTM A36 steel’s lower carbon content and lack of extra alloying elements make it highly ductile and easy to work with. It is easily machined, welded, and formed, making it ideal for fabrication and manufacturing processes.

ASTM A572 steel, on the other hand, requires specific welding techniques to handle its higher strength and alloying elements. Although it is still weldable, the presence of elements like columbium and vanadium necessitates the use of low-hydrogen electrodes and controlled welding conditions to prevent weld zone weakening.

ASTM A36 generally requires protective measures like painting or galvanizing for outdoor use due to its lower corrosion resistance.

The alloying elements in ASTM A572 improve its atmospheric corrosion resistance, making it better suited for outdoor and harsh environments. While still benefiting from protective treatments, it is inherently more resistant to corrosion than ASTM A36.

Both ASTM A36 and ASTM A572 steels can withstand temperatures up to approximately 750°F. However, ASTM A572 maintains better shape retention under heat due to its higher strength and alloy composition.

Understanding these material properties and compositions helps in selecting the appropriate steel grade for specific applications, balancing factors like strength, workability, and environmental resistance.

High Strength Low Alloy (HSLA) steel is a type of carbon steel that uses small amounts of alloying elements to boost its strength and resistance to corrosion. These enhancements make HSLA steel highly desirable in various engineering applications, particularly where strength and durability are crucial.

HSLA steels usually have low carbon content (0.05% to 0.25%) and include alloying elements like Manganese (up to 2%), Vanadium, Niobium, Titanium, Copper, Silicon, Nickel, and Chromium. These elements collectively contribute to the improved performance characteristics of HSLA steels compared to traditional carbon steels.

HSLA steels are renowned for their high yield strengths, which range from 250 MPa to 590 MPa. This high strength-to-weight ratio makes them suitable for applications requiring robust yet lightweight materials. Key mechanical properties include:

HSLA steel stands out for its superior corrosion resistance compared to traditional carbon steels like ASTM A36 and A572. Elements like copper, silicon, nickel, and chromium make HSLA steel more suitable for outdoor and harsh environments.

HSLA steel is ideal for demanding applications due to its high strength, formability, and corrosion resistance. In the automotive industry, it’s used to make lightweight yet strong components. In construction, it supports long-span bridges and high-rise buildings. It is also perfect for weathering applications, such as in marine and industrial environments, where corrosion resistance is crucial.

ASTM A36 is widely used in general construction due to its versatility and cost – effectiveness. It is commonly employed in building frames, bridges, and other structural components where moderate strength is sufficient. The low – carbon content of A36 steel allows for easy machining, welding, and fabrication, which is ideal for projects needing extensive shaping and joining. Additionally, its affordability makes it a popular choice for budget – conscious projects that do not demand high stress or corrosion resistance.

In contrast, ASTM A572 is preferred for more demanding construction applications. Its higher yield and tensile strengths make it suitable for high – stress environments such as long – span bridges, high – rise buildings, and heavy machinery. The enhanced toughness and durability of A572 steel allow for the construction of robust structures that can withstand greater loads and harsh conditions. Its improved corrosion resistance, due to alloying elements like manganese and vanadium, makes it a better choice for outdoor and corrosive environments compared to A36.

While A36 steel can be used in some heavy – duty structures, it is typically limited to less critical components or areas where high strength is not paramount. For instance, A36 may be used in non – load – bearing parts of bridges or buildings, providing adequate support without the need for the superior strength of more advanced steel grades.

ASTM A572 excels in heavy – duty structural applications, particularly in sectors that require high performance and reliability. It is extensively used in the construction of bridges, offshore platforms, and industrial structures where weight reduction and high strength are crucial. The higher yield strength of A572 allows for lighter yet stronger structural components. This is particularly advantageous in projects where minimizing weight without compromising strength is essential.

In the energy sector, A36 steel is typically used in less demanding applications where its moderate strength and machinability are sufficient. It’s used in structural supports, secondary framing, and other components that don’t need high – grade steel properties.

ASTM A572 is more commonly used in the energy sector for critical infrastructure such as pipelines, drilling rigs, and industrial plants. Its high strength, toughness, and corrosion resistance make it ideal for withstanding the rigorous demands of energy production and transportation. The alloying elements in A572 steel enhance its performance in extreme conditions, ensuring long – term reliability and safety in energy – related applications.

Using steel in cold environments requires careful consideration of its properties to prevent brittleness and failure. ASTM A36 may be used, but its performance is limited by its lower yield strength and toughness compared to A572. Protective measures are often required. On the other hand, ASTM A572 is better suited for cold environments due to its superior toughness and resistance to low – temperature embrittlement. The alloying elements in A572 steel improve its performance under freezing conditions, making it a reliable choice for structures exposed to cold climates, such as cold storage facilities and arctic exploration equipment.

The material composition of ASTM A36 and ASTM A572 significantly impacts their costs.

The mechanical properties of these steels affect their cost efficiency:

Different applications influence the cost-effectiveness of using ASTM A36 or ASTM A572:

| Aspect | ASTM A36 | ASTM A572 |

|---|---|---|

| Material Cost | Lower (2.5% to 5% less expensive) | Higher due to alloying elements |

| Yield Strength | ~36,000 psi (250 MPa) | ~50,000 psi (345 MPa) and up |

| Corrosion Resistance | Lower; requires coating | Higher due to alloy content |

| Workability & Welding | Easier, lower labor costs | Harder, may require more prep |

| Material Usage | More material needed for strength | Less material needed (weight savings) |

| Lifecycle Cost | Potentially higher due to maintenance | Lower due to durability |

| Best Use Cases | Light construction, easy fabrication | Heavy load, long-term, harsh environments |

ASTM A36 is a low-carbon steel with a simple chemical makeup, typically containing 0.05% to 0.25% carbon, plus small amounts of manganese, phosphorus, sulfur, and silicon. This straightforward composition contributes to its excellent weldability. The low carbon content reduces the risk of forming hard and brittle microstructures in the weld zone, making it easier to achieve strong, defect-free welds.

ASTM A572, particularly Grade 50, is a high-strength, low-alloy (HSLA) steel that contains additional alloying elements like manganese, silicon, copper, vanadium, and niobium. These elements enhance the steel’s strength and corrosion resistance but can complicate the welding process. The higher carbon content (up to 0.26%) and alloying elements can increase the hardness of the heat-affected zone (HAZ), requiring more precise control of welding parameters to prevent issues such as cracking.

Studies comparing the weldability of ASTM A36 with A36/A572 Grade 50 dual-certified steel indicate that:

| Feature | ASTM A36 | ASTM A572 Grade 50 |

|---|---|---|

| Chemical Complexity | Lower (carbon steel) | Higher (HSLA with alloying elements) |

| Welding Ease | Excellent, forgiving | Good, but requires more precise control |

| Welding Techniques Used | SMAW, GMAW, FCAW, SAW easily | Same techniques but with tighter controls |

| Electrode Requirements | Standard electrodes | May require low-hydrogen electrodes |

| Weld Cracking Risk | Low | Slightly higher, controlled by parameters |

| Heat-Affected Zone Hardness | Lower, more ductile | Higher, risk of weld zone hardening |

| Weld Impact Toughness | Generally good | Slightly lower in thick sections |

| Welding Procedure Flexibility | High | Moderate, requires procedure qualification |

Understanding the differences in weldability between ASTM A36 and ASTM A572 is essential for optimizing fabrication efficiency and ensuring structural integrity in various construction projects.

To ensure substituting ASTM A572 for ASTM A36 meets project requirements, several factors need to be evaluated. These include mechanical properties, environmental conditions, fabrication processes, and economic considerations.

ASTM A36, with a yield strength of 36,000 PSI and tensile strength ranging from 58,000 to 80,000 PSI, is suitable for general construction needs. In comparison, ASTM A572, particularly Grade 50, offers a higher yield strength starting at 50,000 PSI and a tensile strength of 65,000 to 90,000 PSI, making it more appropriate for high-stress applications requiring greater durability.

ASTM A36 requires protective measures such as painting or galvanizing when used in outdoor or corrosive environments due to its lower corrosion resistance. On the other hand, ASTM A572 offers improved corrosion resistance owing to its alloying elements like manganese and vanadium, making it more suitable for harsh or outdoor conditions.

ASTM A36 is known for its excellent weldability due to its low carbon content and simple composition, allowing it to be welded using standard techniques without special precautions. Although ASTM A572 is weldable, it requires stricter controls because of its higher carbon content and additional alloys. Techniques such as using low-hydrogen electrodes and controlled heat input are necessary to prevent weld zone weakening.

ASTM A36 is easier to machine and fabricate due to its lower hardness and simpler composition. In contrast, ASTM A572 is harder and may require more advanced machining techniques, increasing fabrication complexity and costs.

ASTM A36 is generally less expensive due to its simpler composition. ASTM A572, however, has a higher cost attributed to additional alloying elements and enhanced properties.

For general construction, ASTM A36 is often sufficient where moderate strength is acceptable. However, substituting ASTM A572 can provide additional safety margins and extend the lifespan of the structure due to its higher strength and better resistance to environmental stressors. In high-stress environments, such as long-span bridges, high-rise buildings, or offshore platforms, ASTM A572 is preferable due to its superior mechanical properties. Substituting ASTM A36 in such scenarios might compromise structural integrity and safety.

Using ASTM A572 instead of ASTM A36 is advantageous in high-stress and harsh environments because of its superior strength and durability. While the initial material cost is higher, the long-term benefits of reduced maintenance, longer service life, and enhanced safety can justify the investment. Conversely, for less demanding applications, the cost savings from using ASTM A36 may outweigh the benefits of higher performance from ASTM A572.

The project’s engineering team should approve any substitution. This ensures that all mechanical, environmental, and economic factors are considered and that the substitution will not negatively impact the project’s performance or safety. Compliance with relevant standards and specifications is crucial to maintain the integrity and reliability of the structure.

ASTM A36 and ASTM A572 have different characteristics regarding material efficiency and carbon footprint. ASTM A36 has a lower initial carbon footprint due to its simpler production processes and lack of alloying additives, but it requires more material for equivalent strength, increasing transportation emissions and resource use.

On the other hand, ASTM A572 offers a higher strength-to-weight ratio, reducing material requirements for equivalent structural performance and lowering the embodied carbon per project. Its longer lifespan, due to superior fatigue strength and resilience, minimizes replacement frequency and long-term emissions. However, its carbon footprint per unit is slightly higher than A36 due to the presence of alloying elements and more complex manufacturing.

The chemical composition of ASTM A36 plays a significant role in its environmental impact. With its simpler chemical composition of low carbon and no alloys, it results in lower energy use during manufacturing. Its easier machinability also reduces energy waste during fabrication.

ASTM A572, with alloying elements such as manganese and vanadium, requires more energy during production. However, its superior weldability enhances fabrication efficiency, which partially offsets the higher production emissions.

Both ASTM A36 and ASTM A572 are 100% recyclable, and there are no significant differences in their end-of-life sustainability. However, the durability of ASTM A572 decreases the need for new steel over time. This aligns better with circular economy principles, as it helps conserve natural resources and reduces the environmental impact associated with steel production from raw materials.

The corrosion resistance of ASTM A36 and ASTM A572 significantly affects their environmental impact. ASTM A36 requires regular coatings in outdoor applications, increasing lifecycle chemical use and waste. In contrast, ASTM A572 has slightly better atmospheric corrosion resistance due to alloying elements like copper and manganese. This reduces the maintenance frequency and provides long-term environmental benefits by decreasing the need for protective coatings and repainting.

ASTM A36 is cost-effective for low-stress projects but is less optimal for sustainability-focused designs that require material efficiency. ASTM A572, however, is preferred in green building projects because of its lightweight, high-strength properties, which support energy-efficient designs. It is also well-suited for highway infrastructure, where its durability lowers lifetime emissions.

Below are answers to some frequently asked questions:

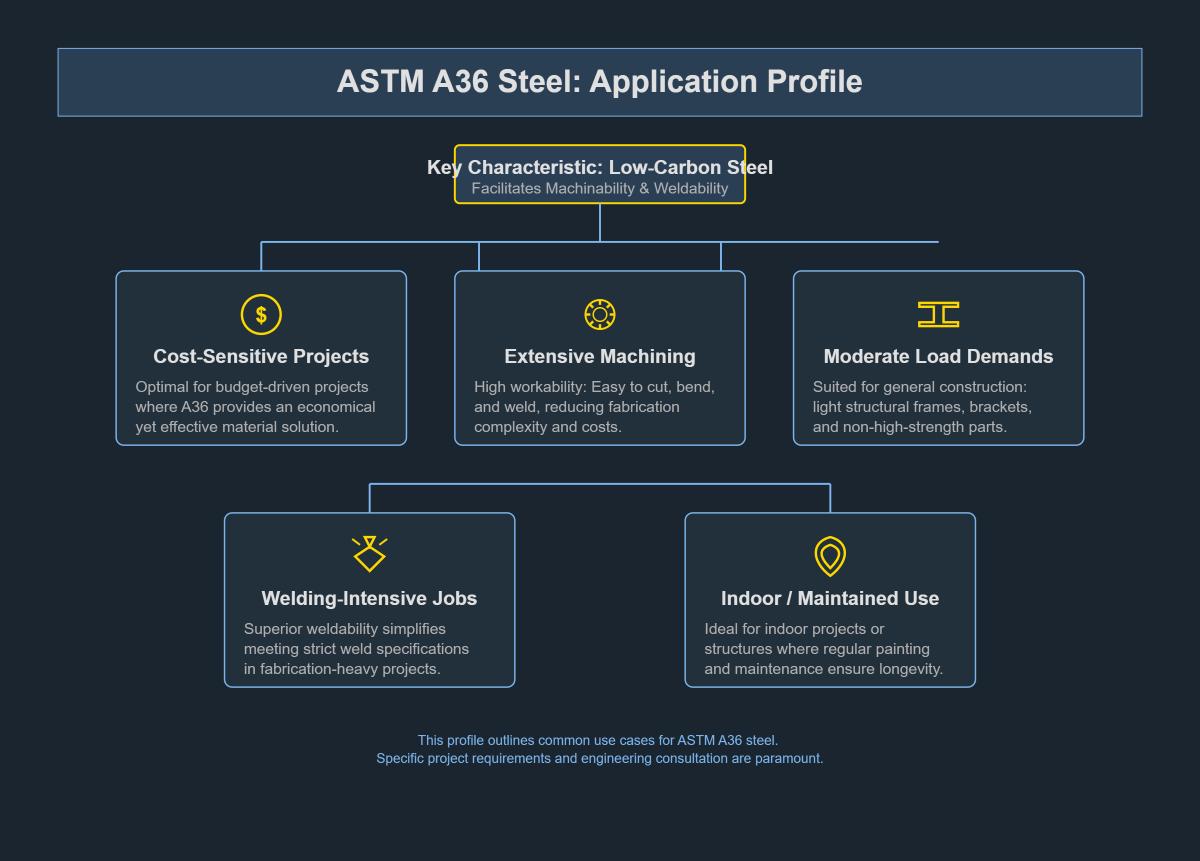

You should use ASTM A36 instead of ASTM A572 when the project is cost-sensitive, requires extensive machining, or involves general construction with moderate load-bearing demands. A36 is a low-carbon steel that is easier to cut, bend, and weld, making it suitable for applications such as light structural frames, brackets, and components that do not require high strength. Additionally, A36 is ideal for welding-intensive jobs due to its excellent weldability, simplifying compliance with strict weld specifications. It’s also appropriate for indoor projects or structures that will be regularly maintained and painted for corrosion resistance.

Weldability between ASTM A36 and ASTM A572 differs primarily due to their material compositions. A36 steel has a lower carbon content and lacks high-strength alloys, making it easier to weld and more forgiving for intricate or high-precision welds. In contrast, A572 is a high-strength, low-alloy (HSLA) steel that includes elements like manganese, phosphorus, and microalloys, which enhance its strength but may necessitate adjustments in welding parameters, especially for thicker sections.

Both steels can be welded using standard methods such as SMAW, GMAW, FCAW, and SAW, and AWS D1.1 prequalified procedures apply to both without the need for special low-hydrogen electrodes. However, A572 may exhibit slightly reduced heat-affected zone (HAZ) toughness in thick sections, necessitating careful parameter control. Despite these differences, dual-certified A36/A572 Gr 50 steel maintains similar weldability to A36 when using identical welding consumables and techniques.

Choosing ASTM A572 for high-stress environments is advantageous due to its superior mechanical properties compared to ASTM A36. A572 offers significantly higher yield and tensile strengths, with minimum yield strengths ranging from 42 ksi to 65 ksi, and tensile strengths from 60 ksi to 80 ksi. This allows A572 to withstand larger loads and greater forces without permanent deformation or failure, making it ideal for demanding structural applications such as bridges, heavy machinery, and large buildings.

Additionally, A572’s composition includes alloying elements like manganese, silicon, and copper, which enhance its toughness and resistance to environmental wear and impact. These properties ensure that A572 performs reliably under dynamic stresses and harsh conditions. Although A572 requires specific welding techniques to maintain its mechanical integrity, its versatility and high strength-to-weight ratio make it ideal for applications in construction, heavy equipment, and infrastructure projects.

Yes, ASTM A572 can be used as a substitute for ASTM A36 in construction projects, but the decision should be based on specific project requirements. ASTM A572, being a high-strength low-alloy (HSLA) steel, offers a higher yield strength (50 ksi) compared to ASTM A36 (36 ksi). This enhanced strength allows for the use of thinner and lighter sections, which can be advantageous in high-stress environments, such as bridges, high-rise buildings, and heavy machinery.

However, A572’s higher strength and alloy content can complicate fabrication processes, particularly welding and machining, which may require more controlled techniques to avoid weakening in the heat-affected zones. On the other hand, A36 is easier to weld and machine due to its lower hardness and carbon content, making it more suitable for projects where extensive welding and shaping are needed.

While A572 offers better corrosion resistance due to its alloying elements, making it preferable for outdoor or harsh environments, A36 is generally more cost-effective and readily available, making it a practical choice for general structural purposes and light fabrication. Therefore, the suitability of A572 as a substitute for A36 depends on the balance between the project’s mechanical performance requirements, fabrication complexity, environmental exposure, and cost considerations.

The environmental impacts of ASTM A36 and ASTM A572 steel differ due to their composition and manufacturing processes. ASTM A36 is a low-carbon steel with a simpler composition, resulting in a lower initial environmental footprint. This means less energy consumption, lower CO2 emissions, and reduced water usage during production. On the other hand, ASTM A572, a high-strength, low-alloy (HSLA) steel, includes additional alloying elements like manganese, silicon, and vanadium, which enhance its strength and corrosion resistance but require more intensive processing, leading to higher embodied energy and carbon emissions.

However, A572’s higher yield strength allows for the use of less material to achieve the same structural performance, reducing the overall weight and cost of construction.

When choosing between ASTM A36 and ASTM A572 steel, several key factors should be considered to ensure optimal performance and cost-effectiveness for your project. The primary considerations include mechanical properties, chemical composition, workability, durability, cost, environmental conditions, and specific application requirements.

ASTM A36 steel offers lower yield and tensile strengths, making it suitable for general structural purposes where high strength is not critical. It is easier to machine and weld due to its lower hardness and carbon content, which can reduce labor costs. However, it has limited corrosion resistance and may require protective coatings for outdoor use.

ASTM A572 steel, on the other hand, provides higher yield and tensile strengths, ideal for high-stress applications such as bridges and high-rise buildings. Its high-strength, low-alloy composition includes elements that enhance durability. Although it is more challenging to machine and weld, it offers better performance in harsh environments and can reduce material usage in critical structures.

Cost is another significant factor; A36 steel is generally less expensive, making it cost-effective for less demanding applications. A572 steel, while more costly, delivers better value in applications requiring superior strength and durability.

By weighing these factors, project managers can select the appropriate steel grade that meets structural needs, budget constraints, and environmental conditions effectively.