In the world of construction, choosing the right rebar can make or break a project. But with so many options, how do you decide between ASTM A706 and ASTM A615? The differences in their mechanical and chemical properties can significantly impact performance, especially in seismic applications. Understanding these standards is crucial for intermediate-level construction professionals.

As we delve deeper, you’ll discover which type might be the better fit for your next project. So, are you ready to find out which rebar reigns supreme?

ASTM A706 is renowned for its low-alloy steel deformed and plain bars, perfect for concrete reinforcement. This standard is particularly valued for its enhanced weldability and ductility, making it an excellent choice for applications requiring significant structural integrity, such as seismic and critical structural elements.

ASTM A615 is a standard specification for deformed and plain carbon-steel bars used for concrete reinforcement. It is widely adopted in the construction industry due to its availability and cost-effectiveness. However, it is generally not recommended for applications where welding is a primary concern.

When comparing ASTM A706 and ASTM A615, there are key differences:

The American Society for Testing and Materials (ASTM) is an international standards organization that creates and publishes standards based on industry – wide agreement. These standards apply to a broad range of materials, products, systems, and services, ensuring quality and safety across multiple industries, including construction and manufacturing.

The consistency brought about by ASTM standards is crucial for several compelling reasons.

ASTM standards are key to assuring that materials and products used in construction meet specific quality benchmarks. This is essential for maintaining the structural integrity of buildings and infrastructure. For instance, in a high – rise building project, ASTM – compliant rebar has predictable mechanical properties. This means that engineers can accurately calculate how much weight the rebar can bear. As a result, they can design the concrete structure with confidence, knowing that the rebar will perform as expected under the building’s load and environmental conditions.

Safety is of utmost importance in construction. ASTM standards help reduce risks by specifying what materials must be like. They cover things such as the chemical makeup, mechanical features, and testing methods for materials like steel rebar. By following these standards, manufacturers and builders can lower the chance of material failures that could lead to accidents or structural collapses.

Standardization makes it possible for materials and components from different suppliers to be used interchangeably and work well together. This is especially important in large – scale construction projects where materials from multiple sources need to fit and function seamlessly. ASTM standards ensure that rebar has consistent dimensions and properties, allowing it to be easily combined with other standardized components.

Rebar, or reinforcing steel bars, are essential for strengthening concrete structures. ASTM A706 and ASTM A615 are two important standards for rebar production. ASTM A706 specifies requirements for low – alloy steel deformed and plain bars for concrete reinforcement, emphasizing enhanced weldability and ductility. It is suitable for critical applications, such as in seismic zones, where reliable welding and good stress performance are necessary. On the other hand, ASTM A615 covers deformed and plain carbon – steel bars for concrete reinforcement. It is widely used in general construction because it is cost – effective and available in various grades. While not specifically designed for welding, it offers sufficient strength for many construction projects where welding is not a major concern.

Rebar, short for reinforcing bar, is a steel bar or mesh of steel wires used as a tension device in reinforced concrete and reinforced masonry structures. It provides the necessary strength and support to concrete, which is naturally weak in tension but strong in compression.

Rebar is embedded in concrete to enhance its tensile strength, enabling the reinforced concrete to withstand stresses without cracking. The primary functions of rebar in construction include:

Rebar comes in various sizes, grades, and types, each with specific properties suitable for different applications, including:

There are several types of rebar, each designed for specific uses in construction:

Knowing the differences between ASTM A706 and ASTM A615 rebar is essential for selecting the right material for specific construction projects:

ASTM A706 rebar is engineered with specific mechanical properties to perform well in demanding applications, especially those requiring enhanced ductility and weldability.

ASTM A706 rebar has a controlled chemical composition to enhance its weldability and mechanical properties.

ASTM A615 rebar is primarily used for general concrete reinforcement and is available in multiple grades, each with distinct mechanical properties.

Unlike ASTM A706, ASTM A615 rebar does not have strict limits on its chemical composition, which can affect its weldability:

ASTM A706 and ASTM A615 rebar cater to different needs. ASTM A706 is ideal for high – performance applications requiring weldability and ductility, while ASTM A615 is cost – effective for general construction where welding isn’t a primary concern.

Yield strength is an important property that indicates the stress level at which a material starts to permanently deform.

Tensile strength measures the maximum stress a material can handle before breaking when stretched or pulled.

Ductility refers to how much a rebar can stretch or deform before breaking, which is crucial for energy absorption in seismic applications.

Carbon content affects both the weldability and strength of rebar.

These elements impact the strength, ductility, and weldability of rebar.

The carbon equivalent is a measure used to predict the weldability of steel.

Industry experts highlight that the controlled chemical composition and consistent mechanical properties of ASTM A706 rebar make it the preferred choice for critical structural applications, especially in seismic zones. In contrast, ASTM A615 rebar is favored for general construction due to its cost-effectiveness and availability, though it requires careful consideration when welding is involved.

Weldability refers to the ability of a material to be welded under specified conditions and to perform satisfactorily in the intended service. It is a critical property for reinforcing bars (rebar) used in construction, especially in applications requiring high structural integrity. The weldability of rebar is influenced by its chemical composition, mechanical properties, and the specific standards it adheres to.

ASTM A706 rebar is specifically designed to offer enhanced weldability. This is achieved through stringent control over its chemical composition, particularly the carbon equivalent (C.E.), which is kept at or below 0.55%. By keeping the carbon equivalent low, ASTM A706 rebar minimizes the risk of weld cracking and hardening, making it highly suitable for welding.

ASTM A706 rebar offers higher yield strengths (60 ksi for Grade 60 and 80 ksi for Grade 80) and tensile strengths (80 ksi for Grade 60 and 100 ksi for Grade 80). These properties, combined with its controlled chemical composition, make ASTM A706 rebar ideal for critical applications, including seismic zones where reliable welding is essential.

ASTM A615 rebar is primarily designed for general construction use and does not prioritize weldability. The chemical composition of ASTM A615 rebar is less controlled, particularly regarding the carbon equivalent, which can vary significantly.

ASTM A615 rebar is available in multiple grades:

While ASTM A615 rebar offers sufficient mechanical strength for many construction projects, its variable chemical composition can pose challenges for welding.

In seismic applications, where structural integrity and flexibility are paramount, ASTM A706 rebar is preferred due to its enhanced weldability and consistent mechanical properties. For example, using ASTM A706 rebar in a high-rise building in a seismic zone ensures the welded joints can handle dynamic loads without failing.

For general construction projects where cost and availability are significant considerations, ASTM A615 rebar is commonly used. However, when welding is required, additional precautions such as preheating and careful selection of filler metals are necessary to mitigate the risk of weld defects.

Understanding the weldability differences between ASTM A706 and ASTM A615 rebar is crucial for selecting the appropriate material for specific construction needs, ensuring both structural integrity and safety.

ASTM A706 rebar is particularly advantageous in seismic construction due to its superior weldability and high ductility. These properties ensure that structures can better absorb and dissipate the energy from an earthquake, maintaining their integrity. For example, in high – rise buildings located in earthquake – prone regions, the connections made with ASTM A706 rebar remain strong and flexible under stress. This rebar’s ability to deform plastically without breaking is crucial for preventing catastrophic failures.

In general construction, ASTM A706 rebar is also beneficial when welding is required. Its controlled chemical composition ensures reliable welds, making it suitable for projects involving pre – fabricated steel components. Even if seismic resistance isn’t the primary concern, the higher yield and tensile strengths of ASTM A706 provide additional safety margins, which are valuable in structures like large commercial buildings.

ASTM A615 rebar is not ideal for seismic construction. Its variable weldability and lower ductility increase the risk of structural failure during an earthquake. The inconsistent chemical composition can lead to unreliable welded joints, making it less suitable for areas prone to seismic activity.

However, ASTM A615 rebar is widely used in general construction where seismic resistance is not a major factor and welding is unnecessary. It is cost – effective and available in multiple grades, offering flexibility for different construction needs. For example, it works well in residential buildings, sidewalks, and small – scale structures, providing sufficient strength at a lower cost.

When selecting between ASTM A706 and ASTM A615 rebar, several factors must be considered. If the project is in a seismic zone or requires high – quality welding, ASTM A706 is the better option. Conversely, for general construction projects where cost is a significant concern and welding is not essential, ASTM A615 can be a more practical choice. Industry experts also recommend evaluating the specific design requirements and load – bearing capacities of the structure to make an informed decision.

ASTM A615 rebar is typically more affordable. Its widespread use in the construction industry means that economies of scale come into play. High demand and large – scale production help reduce per – unit costs. Since it is a carbon – steel rebar and doesn’t require the strict chemical composition control of ASTM A706, the manufacturing process is relatively less complex and costly. It is a go – to choice for general construction projects where welding is not a critical factor, as the lower cost allows for significant savings on large – scale projects.

ASTM A706 rebar is more expensive due to its enhanced properties, such as high ductility and reliable weldability, which are achieved through controlled chemical composition. Furthermore, its use in seismic construction requires higher quality assurance, which adds to the cost.

ASTM A615 rebar is widely available across the globe. It is used in a vast array of construction projects, from small residential buildings to large – scale infrastructure developments. There are numerous suppliers in the market, which not only makes it easily accessible but also contributes to its cost – effectiveness. The large number of suppliers creates a competitive market environment, keeping the prices in check and ensuring a steady supply.

ASTM A706 rebar is also widely available, but it may be more specialized. Due to its enhanced properties, it is often used in critical applications where its specific characteristics are required, such as in seismic zones or projects with high – quality welding requirements. While there are still many suppliers, the market may be more focused on serving projects with these specific needs. This specialization can sometimes lead to longer lead times or more limited availability in certain regions compared to ASTM A615.

The cost of both types of rebar can be affected by raw material prices. Fluctuations in the price of steel, which is the primary component of rebar, can directly impact the cost. For ASTM A706, the cost of alloying elements used to achieve the desired chemical composition also plays a role. Additionally, manufacturing costs, including energy costs and labor, can influence the final price.

Production capacity affects market availability. If a supplier experiences production issues or capacity constraints, it can lead to shortages. Geographical location also matters; regions with a high demand for seismic – resistant construction will likely have better availability of ASTM A706, while areas with more general construction needs will have a more abundant supply of ASTM A615. Transportation costs and logistics can also affect availability, as getting rebar to remote locations may be more challenging and costly.

Below are answers to some frequently asked questions:

The primary differences between ASTM A706 and ASTM A615 rebar revolve around their mechanical properties, chemical composition, and weldability.

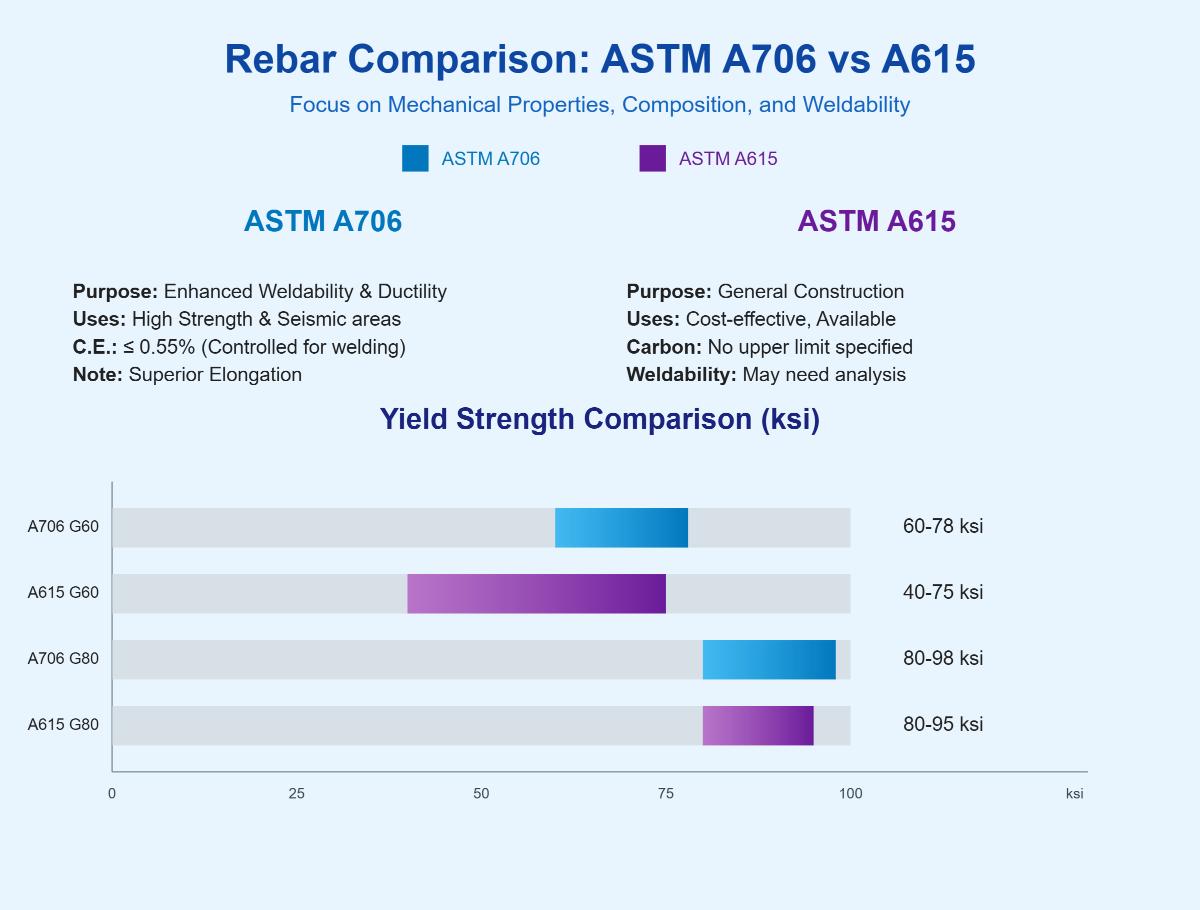

ASTM A706 rebar is designed for enhanced weldability and ductility, making it ideal for applications requiring high strength and seismic performance. It has a controlled carbon equivalent (C.E.) of no more than 0.55%, which reduces the risk of weld cracking. A706 rebar typically exhibits yield strengths of 60 to 78 ksi for Grade 60 and 80 to 98 ksi for Grade 80, with superior elongation properties.

In contrast, ASTM A615 rebar is commonly used in general construction due to its cost-effectiveness and availability. However, it lacks a specified upper carbon limit, which can affect weldability and may require chemical analysis to ensure proper welding. The yield strength for A615 rebar ranges from 40 to 75 ksi for Grade 60 and 80 to 95 ksi for Grade 80.

ASTM A706 rebar is better suited for seismic applications compared to ASTM A615. The primary reasons are its enhanced ductility, superior weldability, and higher yield strength. ASTM A706 rebar is specifically designed with a low-carbon alloy that improves its ability to deform under stress without breaking, which is crucial during seismic events. It also has a controlled carbon equivalent, ensuring reliable welds without the need for preheating, reducing the risk of weld cracking.

On the other hand, ASTM A615 rebar has a higher carbon content, leading to variable weldability and less ductility. Although ASTM A615 is cost-effective and suitable for general construction, it does not offer the same level of performance in dynamic loading conditions as ASTM A706.

The mechanical properties of ASTM A706 and ASTM A615 rebar exhibit notable differences. ASTM A706 rebar is designed for applications requiring higher ductility and weldability, with yield strengths ranging from 60 to 98 ksi and tensile strengths of 80 ksi for Grade 60 and 100 ksi for Grade 80. It is specifically formulated for enhanced ductility, making it ideal for seismic applications and dynamic loading conditions. The controlled chemical composition, including a carbon content of ≤0.30%, further enhances its weldability.

In contrast, ASTM A615 rebar is available in Grades 40, 60, 75, and 80, with yield strengths ranging from 40 to 95 ksi and tensile strengths of 70 to 90 ksi for Grade 60 and around 105 ksi for Grade 80. While it offers adequate strength and elongation of around 12-14% for general construction, it does not possess the same level of ductility and weldability as A706 due to less stringent chemical controls.

When welding ASTM A706 and ASTM A615 rebar, specific techniques and considerations apply due to their distinct chemical compositions and mechanical properties.

ASTM A706 rebar is designed for enhanced weldability, featuring a controlled carbon equivalent (C.E.) of no more than 0.55%. This makes it suitable for welding using methods like Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), and Flux-Cored Arc Welding (FCAW). Typically, 80 series filler metals are recommended to match its controlled composition. Preheating is generally not required for common bar sizes, simplifying the welding process.

In contrast, ASTM A615 rebar lacks an upper carbon limit, resulting in variable weldability. It often requires a C.E. calculation to determine the need for preheating, especially if the C.E. exceeds recommended limits. Welding techniques such as SMAW, GMAW, and FCAW are also applicable, but 70 series filler metals are preferred due to its higher C.E. Higher preheat and interpass temperatures are often necessary to prevent cracking during welding.

When choosing between ASTM A706 and A615 rebar for a project, several factors need to be considered to ensure optimal performance and compliance with building codes. First, evaluate the chemical composition: A706 has a lower carbon content and higher manganese, enhancing weldability and ductility, which is crucial for seismic applications. In contrast, A615 has a variable carbon content, making it less predictable in weldability.

Next, consider the mechanical properties: A706 offers higher ductility and consistent yield and tensile strengths, making it suitable for applications where the rebar must endure significant deformation. A615, while adequate for general construction, may not meet the stringent requirements of critical applications.

Weldability is another essential factor. A706 rebar is designed for superior weldability without requiring preheat for most sizes, reducing the risk of weld cracking. A615 rebar, with its variable carbon content, may need specific preheat and welding procedures.

Application suitability is also important: A706 is ideal for projects requiring high weldability and ductility, such as seismic reinforcement, bridges, and high-rise buildings. A615 is more suited for less critical areas in general construction where enhanced weldability is not essential.

The cost and market availability of ASTM A706 and ASTM A615 rebar significantly impact construction decisions by influencing budget constraints and project timelines. ASTM A706 rebar, known for its enhanced weldability and high ductility, tends to be more expensive due to its stringent mechanical properties and chemical composition standards. This makes it ideal for seismic applications or structures requiring welding, despite the higher costs involved.

On the other hand, ASTM A615 rebar is generally less expensive and widely available, making it suitable for general construction projects where welding is not a primary concern. Its lower cost and broader availability help maintain consistent supply and keep project expenses manageable.

Construction decisions between these two types of rebar hinge on specific project requirements, budget considerations, and supply chain factors. While ASTM A706 is preferred for specialized applications needing higher performance, ASTM A615 offers a cost-effective solution for typical construction needs. Ensuring a reliable supply chain for either type of rebar is crucial to avoid delays and maintain project schedules.