When it comes to protecting lives and critical assets, the choice of material can make all the difference. Armox 500T ballistic steel stands out in the field of high-strength protective materials, offering unparalleled hardness and impact resistance. This comprehensive guide delves deep into the properties that make Armox 500T a top choice for ballistic and blast protection. From its impressive Brinell hardness and tensile strength to its superior toughness and impact resistance, you’ll gain an in-depth understanding of why this steel is favored in defense, metalworking, and engineering applications. Curious about how Armox 500T compares to other ballistic steels or how its unique chemical composition enhances its performance? Read on to discover the intricate details and advanced applications of this remarkable material.

Armox 500T is a high-hardness armor steel plate developed by SSAB, known for its outstanding durability and protection capabilities. It is designed to offer superior protection against ballistic and blast threats, making it a preferred choice in defense, security, and protective industries.

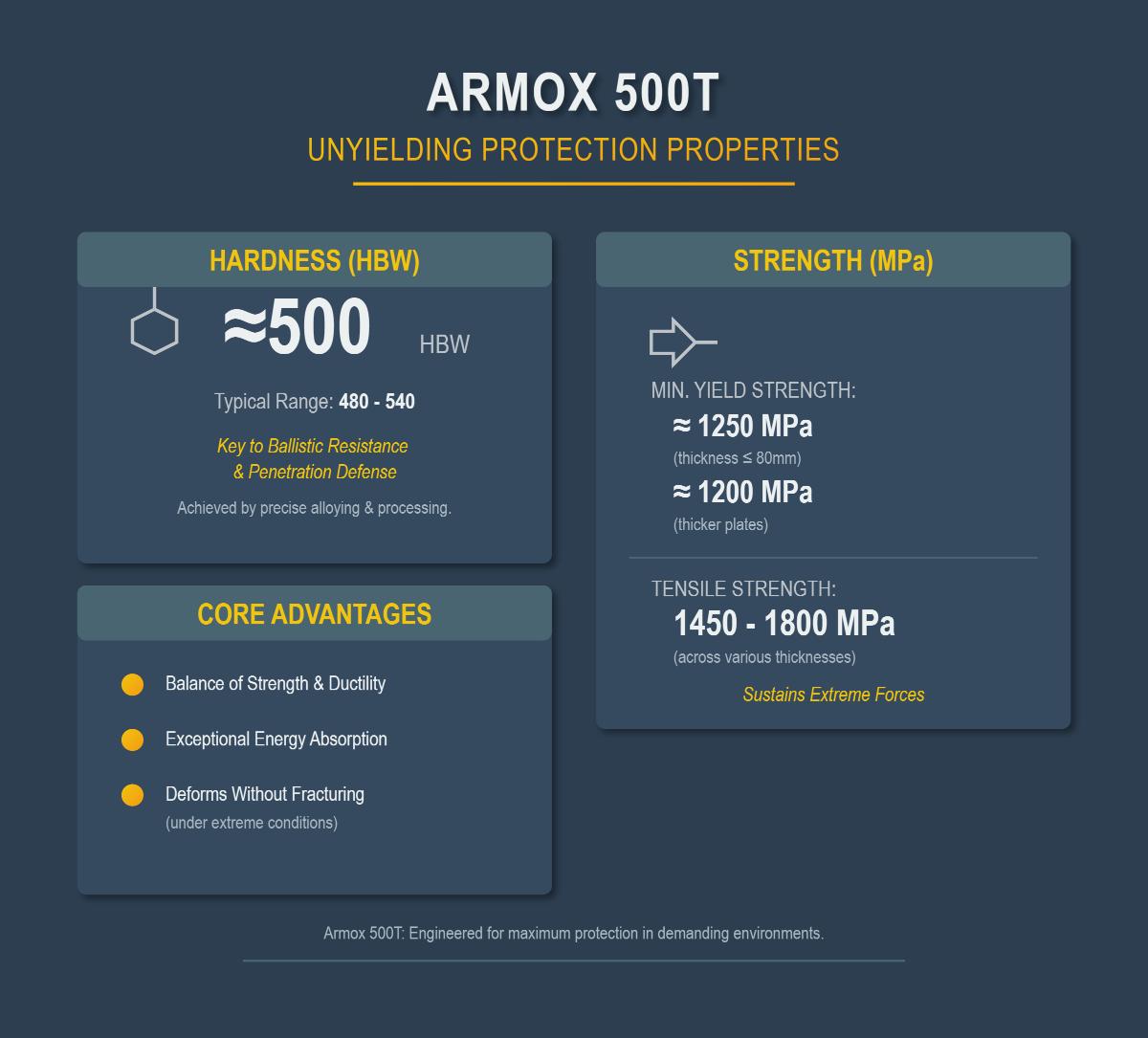

Armox 500T has a nominal Brinell hardness (HBW) of about 500, with values ranging from 480 to 540 HBW, which is essential for resisting penetration from ballistic threats. This high hardness makes it an ideal material for applications requiring robust protective measures.

Armox 500T remains exceptionally tough despite its high hardness, absorbing energy from impacts and blasts without breaking. The steel meets stringent Charpy impact test requirements, demonstrating minimum impact energy absorption of 32 Joules at -40°C for thicknesses up to 80 mm.

Armox 500T boasts a high minimum yield strength of approximately 1250 MPa and a tensile strength ranging from 1450 to 1800 MPa. These strength properties enable the steel to withstand significant mechanical stresses while retaining structural integrity.

In the defense sector, Armox 500T is widely used for making armored military and security vehicles, providing reliable protection against ballistic threats, ensuring the safety of personnel and equipment.

Armox 500T is also utilized in metalworking and manufacturing processes to create protective building structures that require blast resistance. Its unique combination of hardness and toughness makes it suitable for environments where durability and impact resistance are paramount.

In engineering applications, Armox 500T is employed to develop personal protection equipment and secure enclosures. Its ability to withstand high-stress conditions while maintaining lightweight design is crucial for enhancing mobility and efficiency in protective gear.

Armox 500T excels compared to other ballistic steels due to its perfect balance of hardness and toughness, making it ideal for applications that require both penetration resistance and energy absorption from blasts. The combination of high hardness, toughness, and strength makes Armox 500T an ideal choice for demanding protective applications.

| Property | Value/Range |

|---|---|

| Hardness (Brinell HBW) | 480 – 540 |

| Yield Strength (MPa) | Minimum 1250 |

| Tensile Strength (MPa) | 1450 – 1800 |

| Thickness Range (mm) | 3 – 80 (custom thickness available) |

| Impact Energy (Charpy) | ≥ 32 J at -40°C (up to 80 mm thick) |

| Composition | Carbon, Mn, Si, P, S, Cr, Ni, Mo, B (up to 0.005%) |

Armox 500T’s unique properties make it the material of choice for applications where high-level protection and lightweight design are crucial. Its high hardness prevents projectile penetration, while its toughness ensures durability against shocks and blasts, providing comprehensive protection in various demanding environments.

Armox 500T is known for its high Brinell hardness, which ranges from 480 to 540 HBW for plates up to 80 mm thick. For plates between 80.1 mm and 130 mm, the hardness slightly adjusts to a range of 470 to 540 HBW. This exceptional hardness is crucial in providing resistance to penetration by high-velocity projectiles and various ballistic threats.

Yield strength is crucial for materials under high stress, and Armox 500T exhibits a minimum yield strength of 1,250 MPa for plates up to 80 mm thick. For thicker plates (80.1 mm to 130 mm), the minimum yield strength is slightly lower at 1,200 MPa. This high yield strength ensures that Armox 500T can withstand significant mechanical stress without permanent deformation, making it ideal for protective applications.

The tensile strength of Armox 500T ranges from 1,450 to 1,800 MPa, ensuring robust performance across various thicknesses. This high tensile strength allows the steel to endure intense forces without breaking, enhancing its protective capabilities.

The Charpy impact test measures how much energy the material can absorb during fracture at different temperatures. For Armox 500T, the Charpy-V impact energy is impressive, with values ≥32 J at -40°C for plates up to 80 mm thick and ≥20 J at -40°C for plates between 80.1 mm and 130 mm. These results indicate exceptional toughness, allowing the steel to perform reliably under extreme conditions and preventing brittle fractures under dynamic loads.

Despite its high hardness, Armox 500T maintains excellent toughness, which is essential for absorbing and dissipating energy from impacts and blasts. The combination of hardness and toughness allows Armox 500T to withstand harsh conditions without losing its structural integrity. The material’s ability to resist shattering or cracking under high-stress scenarios is vital for its application in protective armor and ballistic-resistant structures.

Armox 500T’s impact resistance is a result of its balanced mechanical properties, including hardness, yield strength, tensile strength, and toughness. This balance ensures that the steel can effectively absorb and disperse the energy from ballistic impacts and explosive blasts, providing reliable protection in critical applications. The high impact resistance of Armox 500T makes it a preferred choice for military vehicles, personal protection equipment, and structural armor designed to withstand severe threats.

The V50 ballistic limit is a crucial measure for assessing the effectiveness of armor materials like Armox 500T. It refers to the velocity at which 50% of projectiles penetrate the armor while the other 50% are stopped. Armox 500T boasts a high V50 value due to its exceptional hardness and toughness, ensuring effective resistance against high-velocity projectiles, making it ideal for protective applications.

Armox 500T’s blast protection capabilities are impressive, thanks to its high yield strength and tensile strength, which allow it to withstand the immense pressures generated by explosive blasts. The steel’s ability to absorb and distribute energy from blasts helps prevent catastrophic failure. Additionally, its toughness allows the material to deform plastically rather than fracturing, maintaining structural integrity under extreme conditions.

Compared to other ballistic steels, Armox 500T excels due to its balanced combination of hardness, strength, and toughness. While some steels may offer higher hardness or strength, they often sacrifice toughness, making them more prone to brittle fracture under impact. Armox 500T maintains a balance that provides robust protection against both ballistic and blast threats, making it superior in applications where both types of threats are present.

| Property | Specification/Range | Impact on Protection Performance |

|---|---|---|

| Hardness (HBW) | 480 – 540 | Provides high resistance to penetration and ballistic impact |

| Yield Strength (MPa) | Min. 1250 | Prevents permanent deformation under stress |

| Tensile Strength (MPa) | 1450 – 1800 | Maintains structural integrity during high stress |

| Elongation (%) | A5: ~8%, A50: ~10% | Absorbs impact energy and resists brittle fracture |

| Thickness Range (mm) | 3.0 – 130.0 | Allows adjustable protection level and weight optimization |

| Ballistic Standard | MIL-DTL-46100E | Certified for ballistic protection |

| Weldability | EN 10163 Class B Subclass 3 | Facilitates complex armor fabrication |

These properties collectively ensure that Armox 500T delivers exceptional performance in both ballistic and blast protection scenarios, making it a reliable choice in the most demanding environments.

The chemical composition of Armox 500T is meticulously designed to achieve the optimal balance of hardness, strength, and toughness required for ballistic protection. The primary elements in its composition are carbon, silicon, manganese, phosphorus, sulfur, chromium, nickel, and molybdenum.

Each alloying element in Armox 500T is selected for its specific contribution to the overall properties of the steel:

The careful selection and balance of these elements ensure that Armox 500T possesses the desired mechanical properties needed for effective ballistic and blast protection.

The chemical composition of Armox 500T is meticulously engineered to provide an optimal balance of hardness, strength, and toughness, which are critical for ballistic protection. The key alloying elements and their respective roles are as follows:

Armox 500T undergoes a series of precise heat treatment processes to achieve its high hardness and excellent toughness. These processes include hot rolling, solution annealing, quenching, and tempering.

The combination of these alloying elements and heat treatment processes results in a steel plate with a nominal hardness of approximately 500 HBW. This balance of hardness and toughness ensures that Armox 500T provides superior ballistic protection while maintaining structural integrity under impact conditions. The pre-quenched and tempered condition of the steel allows it to be used directly in protective applications without the need for further heat treatment.

Armox 500T plates come in thicknesses ranging from 3.0 mm to 80.0 mm, with options up to 130.0 mm available on special request. This range provides flexibility for various protective needs. Thinner plates are suitable for lighter applications, while thicker plates are ideal for more robust, heavy-duty uses.

The plates meet strict size accuracy standards to ensure they fit precisely in all applications. This precision is critical for performance and integration into complex assemblies.

Armox 500T plates can be customized in width and length to meet specific project requirements. While standard sizes are available, SSAB can produce plates in non-standard dimensions, allowing for adaptability in various structural and protective applications.

With a density of approximately 7.8 g/cm³, Armox 500T offers strong protection without being too heavy. This density is particularly important in applications where weight savings are crucial, such as in armored vehicles.

The nominal hardness of Armox 500T is around 500 HBW (Brinell Hardness), with an operational range of 480 to 540 HBW depending on the thickness. This high hardness is essential for resisting penetration and abrasion, making the steel ideal for ballistic protection.

| Thickness (mm) | Hardness (HBW) | Yield Strength (min MPa) | Tensile Strength (MPa) | Elongation (min %) |

|---|---|---|---|---|

| 3.0 – 80.0 | 480 – 540 | 1250 | 1450 – 1800 | 8 – 10 |

| 80.1 – 130.0 | 470 – 540 | 1200 | 1450 – 1800 | — |

The steel’s mechanical properties ensure it can withstand high-stress conditions without permanent deformation or failure.

Armox 500T is extensively used in the manufacture of armored military vehicles, including tanks, personnel carriers, and tactical vehicles. Its high hardness and strength provide effective protection against ballistic threats and explosive blasts, ensuring the safety of personnel and equipment. Customizable plate thickness and dimensions allow for designs that balance protection with mobility and fuel efficiency.

Armox 500T is used in personal and structural armor, including secure buildings, safe rooms, and protective barriers. Its superior toughness and hardness make it ideal for creating barriers that can withstand significant impact forces, ensuring resistance to bullets and blast fragments.

In security and law enforcement, Armox 500T is used to build armored vehicles, security doors, and vaults. These structures require certified ballistic resistance to ensure the safety of occupants and secure valuable assets. The steel’s excellent weldability and surface quality facilitate the fabrication of complex shapes and assemblies.

Armox 500T is suitable for specialized industrial applications where high impact resistance and durability are required. This includes blast-resistant containers, protective housings, and critical infrastructure protection. The steel’s ability to absorb and distribute energy from impacts and blasts prevents catastrophic failure, making it a reliable choice for protecting sensitive equipment and structures.

The superior workshop properties of Armox 500T, such as formability and weldability, allow manufacturers to create complex shapes and assemblies without compromising the steel’s ballistic integrity. This enhances its versatility and application scope.

To compare Armox 500T with other high-hardness ballistic steels, we focus on several key properties. These properties determine the material’s effectiveness in providing ballistic and blast protection.

Armox 500T has a nominal Brinell hardness (HBW) of approximately 500, ranging from 480 to 540 HBW, which is essential for resisting penetration from projectiles. In comparison, other high-hardness steels like Armox 600T exhibit higher hardness values, reaching up to 600 HBW. While higher hardness can improve penetration resistance, it often comes at the cost of reduced toughness.

Armox 500T has a yield strength starting from 1250 MPa, with some reports showing values up to 1810 MPa. This property enables the steel to withstand high stress without undergoing permanent deformation. Other ballistic steels might offer comparable or higher yield strengths, but the balance between yield strength and other properties like toughness is crucial for overall performance.

Armox 500T’s tensile strength ranges from 1450 to 1750 MPa. This high tensile strength ensures that the steel can endure significant forces without breaking. Comparing this to other steels, some may have higher tensile strength but may not maintain the same level of toughness, which is vital for absorbing and dispersing impact energy.

One of the standout features of Armox 500T is its impact toughness. It shows a minimum Charpy impact energy of 32 J at -40°C for plates up to 80 mm thick. This toughness is critical for preventing brittle failure in extreme conditions. Other high-hardness steels may have lower impact toughness, making them more susceptible to cracking under dynamic loads.

The V50 ballistic limit is a crucial metric for assessing the protective capabilities of armor materials. Armox 500T demonstrates a high V50 value, indicating its superior ability to stop projectiles at high velocities. While Armox 600T and other advanced steels might offer higher V50 limits due to their increased hardness, Armox 500T provides a balanced performance that includes both penetration resistance and energy absorption.

Armox 500T’s blast resistance is enhanced by its high yield strength and tensile strength. These properties enable the steel to absorb and distribute the energy from blasts, preventing catastrophic failure. In contrast, steels with higher hardness but lower toughness might not perform as well under blast conditions, as they can be more prone to brittle fracture.

Armox 500T enables lighter armor designs without compromising protection, which is particularly advantageous in applications like armored vehicles, improving mobility and fuel efficiency. Other high-hardness steels often require thicker plates to achieve similar levels of protection, resulting in increased weight.

Armox 500T is supplied in a pre-hardened and tempered condition, meaning it does not require further heat treatment. This is a significant advantage in terms of manufacturing efficiency and consistency in properties. Some other steels might require additional heat treatments to optimize their properties, adding complexity to the fabrication process.

Armox 500T is versatile, suitable for a wide range of applications, including vehicles, buildings, and security barriers. Its combination of hardness, toughness, and strength makes it an excellent choice for both military and civilian protective solutions. Other high-hardness steels may be more specialized, limiting their applicability to certain high-end military uses.

Below are answers to some frequently asked questions:

Armox 500T ballistic steel is renowned for its exceptional hardness and strength properties, making it a top choice for high-performance armor applications. The nominal Brinell hardness (HBW) of Armox 500T is around 500, typically ranging between 480 and 540 HBW depending on thickness and batch conditions. This high hardness is crucial for resisting penetration from ballistic threats and is achieved through precise alloying and controlled processing.

In terms of strength, Armox 500T boasts a minimum yield strength of approximately 1250 MPa for thicknesses up to 80 mm, slightly reducing to around 1200 MPa for thicker plates. Its tensile strength ranges from 1450 MPa to 1800 MPa across various thicknesses, indicating the steel’s ability to withstand very high stresses before failure. These properties ensure that Armox 500T maintains a balance of strength and ductility, essential for absorbing energy and deforming under extreme conditions without fracturing.

Armox 500T steel provides ballistic and blast protection through its unique combination of high hardness and superior toughness. The steel’s nominal hardness of 500 HBW enables it to resist penetration from projectiles effectively, making it ideal for armor applications. This high hardness is achieved through precise alloying, including elements like boron, which enhances the steel’s strength and hardness.

In ballistic protection, the V50 ballistic limit is a critical performance metric, indicating the velocity at which there is an equal chance of projectile penetration. Armox 500T undergoes rigorous testing to ensure it meets stringent standards, such as those outlined in MIL-STD-662F, confirming its capability to withstand high-velocity impacts.

For blast protection, Armox 500T’s high yield strength (minimum 1250 MPa) allows it to absorb and dissipate energy from explosions, preventing structural failure. This combination of properties ensures that Armox 500T can effectively protect against both ballistic threats and explosive forces, making it a preferred material for defense applications, including vehicle and building armor.

Armox 500T is a high-performance ballistic steel with a carefully controlled chemical composition to optimize its hardness, toughness, and ballistic resistance. The typical composition includes approximately 0.32% Carbon (C) for hardness and strength, 0.40% Silicon (Si) for strength and hardness enhancement, and 1.20% Manganese (Mn) for tensile strength and reduced brittleness. It also contains low levels of Phosphorus (P) and Sulfur (S) (≤0.010% each) to maintain toughness.

Key alloying elements include up to 1.5% Chromium (Cr) for wear and corrosion resistance, up to 3.5% Nickel (Ni) for improved toughness and impact resistance, and up to 0.7% Molybdenum (Mo) for strength and high-temperature performance. Boron (B) is present in small amounts to enhance hardenability.

This composition results in a steel with a Brinell Hardness of approximately 500 HBW, combining high hardness with superior toughness. The balanced alloying elements ensure excellent ballistic and blast protection, wear resistance, and maintain good weldability, making Armox 500T ideal for armored vehicles and secure constructions.

Armox 500T ballistic steel is available in a variety of thicknesses and forms to suit different protective applications. The thickness range for Armox 500T sheets and plates extends from 3.0 mm to 130.0 mm. Standard product dimensions typically go up to 80.0 mm in thickness, while thicknesses beyond 80.0 mm require specific agreements with the manufacturer, SSAB.

This steel is primarily supplied in sheet and plate forms, ensuring adherence to strict shape and flatness tolerances. These forms are designed to provide minimal deviations, which is critical for maintaining a flat and consistent surface necessary for optimal ballistic and blast protection performance. The availability of these various thicknesses and forms allows Armox 500T to be effectively used in numerous defense and security applications, including military vehicles and protective installations.

Armox 500T steel is known for its exceptional toughness and impact resistance, which are crucial for applications requiring robust ballistic and blast protection. The steel combines high hardness (nominally 500 HBW) with remarkable toughness, allowing it to absorb significant energy during impacts without cracking. This balance is achieved through precise alloying and heat treatment processes.

The key mechanical properties contributing to its toughness include a minimum yield strength of 1250 MPa and tensile strength ranging from 1450 to 1800 MPa. These properties ensure that Armox 500T can withstand high stresses and forces without permanent deformation or breaking. Additionally, it has good ductility, with elongation values of 8% for A5 and 10% for A50, which enhances its ability to absorb energy during impacts.

Heat treatment plays a crucial role in defining the properties of Armox 500T ballistic steel. During the manufacturing process, Armox 500T undergoes a quenching and tempering (QT) treatment. Quenching involves heating the steel to a high temperature followed by rapid cooling, which hardens the steel. Tempering then adjusts the hardness and toughness to ensure a balanced performance suitable for ballistic applications, resulting in a nominal hardness of approximately 500 HBW.

After delivery, it is essential that Armox 500T is not subjected to any further heat treatment, particularly avoiding temperatures above 190°C. Heating the steel beyond this limit can cause microstructural changes, such as the precipitation of carbon and the diffusion of alloying elements, which reduce the hardness and mechanical strength. These changes compromise the steel’s ballistic resistance and impact toughness, undermining its protective capabilities.