Whether you’re a seasoned machinist or someone looking to enhance their tool collection, choosing the right calipers can make all the difference in your precision work. With a myriad of options available, understanding the nuances between digital, dial, and Vernier calipers is crucial. This comprehensive buyer’s guide delves into the top caliper types, highlighting their unique features, pros, and cons. From the unparalleled accuracy of Mitutoyo to the reliability of Starrett, we’ll explore the brands that stand out. Additionally, you’ll learn about the key features to look for, such as accuracy, coolant-proof ratings, and battery life. Ready to find the perfect caliper for your needs? Let’s dive into the details and ensure you make an informed decision.

Digital calipers have gained widespread popularity among machinists for several reasons. Their ease of use is a significant advantage, as they provide instant and clear measurements on a digital display. This feature removes the need for manual interpretation and reduces human error. Additionally, digital calipers can switch between different measurement units, such as inches and millimeters, with just a simple button press, offering flexibility in international machining projects or when working with diverse measurement standards.

In a machine shop environment, where coolants are commonly used, digital calipers often come with a coolant-proof design and are typically crafted from stainless steel. This ensures their durability and reliability even in harsh working conditions while also enhancing their resistance to corrosion and wear. The coolant-proof design prevents liquid ingress, which can otherwise damage the internal electronics and compromise measurement accuracy.

Dial calipers offer a mechanical alternative to digital calipers. One of their main benefits is that they do not require batteries to operate, making them suitable for environments where electronic devices might be damaged, such as in areas with high levels of electromagnetic interference or in situations where a power source is not readily available. They are also known for their reliability, as they do not rely on complex electronic components that could malfunction.

Dial calipers are generally more affordable than their digital counterparts, making them an attractive option for those on a budget or as a backup tool. However, they do have some limitations. They are more prone to mechanical wear and tear over time, which can affect their accuracy. For example, the gear teeth in the dial mechanism may wear down, leading to less precise readings. Reading the measurement on a dial caliper also requires more attention and skill, as misinterpretations can occur, especially during long working shifts.

Vernier calipers are a traditional type of measuring tool. Their primary advantage is that they do not need any power source, such as batteries, which means they can be used in any environment without worrying about power availability. They are particularly useful for specific machining tasks, like scribing lengths on a lathe.

Accurately reading vernier calipers requires a high level of skill and practice. They’re hard to use in low-light due to the difficulty of reading fine scale markings. Compared to digital and dial calipers, vernier calipers are generally slower to use, as the process of taking and interpreting measurements is more complex. Due to these factors, they are less commonly used in modern machining operations but still have their place in certain specialized applications.

Accuracy and resolution are critical when selecting calipers for machining tasks. Machinist-grade calipers are highly precise, often measuring to within ±0.001 inches or better. This level of accuracy ensures minimal deviation in critical dimensions, which is essential for maintaining tight tolerances in precision work. Digital calipers usually provide higher resolution and easier readability compared to dial or vernier types, reducing human error in measurement interpretation.

The IP67 coolant proof rating is a significant feature for calipers used in machining environments. This rating indicates that the caliper is dust-tight and can withstand immersion in water up to 1 meter for 30 minutes. This protection is essential in workshops with frequent coolant splashes, ensuring durability and longevity.

For digital calipers, battery life is an important consideration. High-quality digital calipers often feature energy-efficient designs and automatic shut-off functions, extending battery life and reducing downtime and maintenance interruptions.

Convenient features like unit conversion and zeroing enhance the usability of calipers. The ability to switch between inches and millimeters with a single button press allows for flexibility in different measurement contexts. The zeroing function is particularly useful, enabling users to set the starting point of a measurement accurately and quickly, which is beneficial for comparative measurements and repetitive tasks.

The measurement range of a caliper determines its versatility. A commonly recommended size for machinists is an 8-inch caliper, which strikes a balance between being large enough for a wide range of tasks and small enough to handle easily. Calipers should be capable of measuring external dimensions, internal diameters, and depths, with features like external jaws, internal jaws, and a depth gauge to accommodate various measurements.

The build quality and material of calipers affect their durability and performance. High-quality calipers are typically made from polished stainless steel, offering resistance to corrosion and wear. Some advanced models use carbon fiber, which is both lightweight and strong. Avoid plastic or composite materials for professional use, as they may not withstand the rigors of a machine shop.

Ease of use and readability are essential for efficient workflow. Digital calipers are user-friendly, with clear digital readouts that simplify the measurement process. Dial calipers offer reliable analog readings but require more careful handling to avoid damage. Vernier calipers, while durable and battery-free, demand more skill to read accurately and may slow down measurement processes.

Additional functional features can enhance the efficiency and utility of calipers. Features like an absolute scale and zero/ABS functionality allow users to reset measurements at any point without losing calibration. Some digital models offer data output capabilities for electronic measurement recording, which is advantageous for quality control and traceability. A large, textured thumb wheel or driving wheel can improve precision when setting the jaws for measurement.

The reputation of the brand and the price of the caliper are also important factors. Reputable brands such as Mitutoyo, Brown & Sharpe, and Starrett are known for their precision, durability, and advanced features. Investing in these brands often ensures reliability and long-term performance. For budget-conscious buyers, brands like Shars offer cost-effective options that maintain acceptable quality, suitable for less critical tasks or as secondary tools.

Some calipers come with specialized attachments designed for measuring complex shapes, sheet metal thickness, or gear teeth diameters. These tools are invaluable for achieving exact specifications in high-precision industries. Calipers used for comparative measurements are essential for quality control, ensuring consistency across multiple parts.

Mitutoyo is a renowned leader in precision measurement tools, particularly digital calipers, known for their exceptional accuracy, durability, and smooth operation, making them a top choice for machinists.

Brown & Sharpe calipers are celebrated for their American manufacturing quality and robust stainless steel frames, making them ideal for tough machining environments.

Starrett has a long-standing reputation for producing high-quality measurement tools, including both dial and digital calipers, built to withstand tough machining environments.

Shars is known for offering affordable yet reliable digital calipers, making them a good choice for less critical measurements or as secondary tools in the workshop.

Recognized for larger size digital calipers with enhanced readability.

Offers affordable calipers with high-quality features, recommended as a cost-effective alternative.

Premium Swiss-made calipers known for their precision and advanced features.

Budget-friendly digital calipers with good reliability, suitable for less demanding tasks.

| Caliper Type | Precision | Ease of Use | Durability | Notes |

|---|---|---|---|---|

| Digital | Up to 0.0005″ (0.01 mm) | Very easy (digital readout) | High (especially IP67 rated) | Ideal for quick, accurate readings, easy unit conversion, and data hold features |

| Dial | Approx. 0.001″ (0.025 mm) | Moderate (dial reading) | Very high | Battery-free, reliable, but requires careful handling |

| Vernier | Approx. 0.001″ | Hardest (manual reading) | High | Traditional, no batteries needed, best for skilled users |

Mitutoyo calipers are well-known in the machining community for their precision and reliability. Users frequently praise the Mitutoyo 500-752-20 digital caliper for its outstanding accuracy, robust construction, and long battery life, often remaining operational for several years without a battery replacement. The smooth operation and clear digital display make it a favorite among professionals who require consistent and precise measurements.

Starrett is another top choice, known for its durable and robust calipers. Their stainless steel models, particularly those with IP67 ratings, are favored for their longevity and resistance to harsh working conditions. Users appreciate the solid feel and reliability of Starrett calipers, despite some design changes over the years. The company has managed to maintain a reputation for precision and quality.

Brown & Sharpe calipers are celebrated for their smooth operation and high-quality stainless steel construction. They are often recommended for machinists who prioritize durability and USA-made products. Users highlight the calipers’ reliability and the smooth sliding mechanism, which contributes to precise measurements.

Shars offers the Aventor model, which is praised for its affordability and IP67 waterproof rating. It is suitable for casual measurements and is frequently mentioned for its smooth sliding mechanism. Users find it to be a cost-effective option that does not compromise on reliability, making it a popular choice for hobbyists and budget-conscious professionals.

Digital calipers are favored for their ease of use and instant readings, which help reduce human error. The ability to switch between units with a simple button press is a significant advantage. However, some users prefer dial calipers for their mechanical reliability and the absence of battery dependency. Dial calipers offer a tactile feedback that some professionals find reassuring, despite the need for careful handling to avoid misalignment.

Polished stainless steel is preferred for its wear resistance and durability. Some advanced models incorporate carbon fiber for added strength without increasing weight. The choice of material impacts the longevity and reliability of the caliper, with stainless steel being a common choice for professional-grade tools.

An 8-inch caliper is often recommended for its balance between usability and precision. Calipers should be versatile enough to measure external, internal, and depth dimensions. This versatility makes them suitable for a wide range of tasks in a machining environment, from simple measurements to more complex evaluations.

An IP67 rating is highly valued for its protection against dust, water, and coolant. This rating ensures that the caliper can withstand the demanding conditions of a workshop, contributing to its durability and reliability.

Users frequently emphasize the importance of brand reputation when choosing calipers. Brands like Mitutoyo and Starrett are often mentioned as top choices due to their precision and durability. The ability to easily switch between measurement units is another significant advantage of digital calipers, enhancing productivity and reducing the likelihood of conversion errors.

While some users express concerns about battery life in digital calipers, many report satisfactory performance, with batteries lasting at least a couple of years. This long battery life is particularly appreciated in high-demand environments where downtime can be costly.

Experts advise professional machinists to invest in high-quality digital calipers from reputable brands. These tools offer superior accuracy and durability, often lasting decades with proper care. High-end models from brands like Mitutoyo and Starrett are ideal for precise measurements, while more affordable options like the Shars Aventor can suffice for less critical tasks.

Selecting the right caliper depends on specific requirements, including budget, precision needs, and personal preference regarding digital or mechanical models. Top brands like Mitutoyo, Starrett, and Brown & Sharpe provide reliable and durable options that cater to various machining environments.

Choosing the correct caliper size is crucial for precise measurements in various machining tasks. The size of the caliper affects its usability, accuracy, and the types of measurements it can perform.

Digital calipers are favored for quick and accurate readings. Features such as zero setting and unit conversion make them ideal for modern machining environments. They are suitable for a range of tasks, from general machining to precision measurements.

Vernier calipers are excellent for precise measurements of internal, external, and depth dimensions. They are often used in applications requiring high accuracy, such as aerospace and automotive industries. While they do not require batteries, reading the scale accurately demands practice.

Dial calipers provide easy-to-read measurements and are commonly used in woodworking and crafts. They require careful handling to avoid damage to the dial mechanism. Dial calipers are reliable for tasks where electronic interference might be an issue.

Ensure the caliper jaws are square to the measurement surface to avoid errors. Apply gentle pressure to prevent deflection and ensure accurate readings.

Always zero the caliper before use. Verify the zero setting by repeating the process. Taking multiple measurements helps confirm accuracy and consistency.

Regularly clean the jaws to ensure proper contact and avoid parallax errors. Lubricate moving parts to maintain smooth operation and extend the caliper’s lifespan.

Choosing the right caliper size involves assessing the precision required, the size of the workpieces, and the tool’s durability. By selecting appropriate caliper models and following best practices for usage and maintenance, machinists can enhance the accuracy and efficiency of their measurements.

To ensure the long – term performance of your calipers, regular cleaning and lubrication are essential. Use a soft – bristled brush and a non – corrosive cleaner to remove dirt and debris from the measuring surfaces. This stops particles from building up and affecting measurement accuracy. After cleaning, apply a high – quality lubricant to the moving parts. This not only prevents corrosion but also ensures smooth operation. Always follow the manufacturer’s guidelines when selecting the appropriate lubricant and application method.

Proper storage is key to extending the lifespan of calipers. Store them in a dry, vibration – free environment to avoid moisture and extreme temperatures, which can cause rust and damage. Keep calipers in a protective case. This protects them from scratches and other physical damage. Ensure the storage area is free from heavy tools and objects that could accidentally harm the calipers.

Using and handling calipers correctly is crucial for maintaining their accuracy and functionality. Never use calipers as a substitute for other tools such as spanners or pliers. Misusing them can damage their precision surfaces and internal mechanisms. Also, avoid exceeding the caliper’s maximum measurement range, as this can lead to mechanical failure or misalignment. Always make sure the jaws of the calipers are flat and aligned when taking measurements to maintain precision.

Handle calipers with care to prevent accidental damage. Avoid dropping or subjecting them to impacts, as these can cause miscalibration or physical damage. Before using calipers, especially after long – term storage, inspect them for any signs of damage.

Regular inspections help identify and address potential issues before they affect the calipers’ accuracy. Look for scratches, burrs, or rust on the measuring surfaces. Check for any loose components or damage that could impact performance. Regular maintenance checks ensure that the calipers stay in optimal working condition.

Calibrating calipers is crucial for keeping them accurate. Calibrate your calipers regularly according to the manufacturer’s guidelines. For critical measurements, consider more frequent calibration, ideally every 6 to 12 months. Proper calibration ensures consistent and precise measurements, which are vital for high – precision machining tasks.

Digital calipers have undergone significant advancements, making them more precise and user-friendly. Here are some of the latest key features:

Many modern digital calipers, including the Dasqua Bluetooth Absolute Digital Calipers, now feature Bluetooth capabilities. This feature allows users to wirelessly transmit measurements to computers, tablets, or smartphones. This connectivity simplifies data management and analysis, making it easier to integrate measurement data into digital records or quality control systems.

Innovations like Mitutoyo’s ABSOLUTE digital calipers have introduced an absolute positioning system. This technology uses multiple sensors to continuously track the slider’s position, removing the need to reset to zero. This feature enhances accuracy and convenience, allowing for consistent and reliable measurements without frequent recalibration.

Many digital calipers today are made from hardened stainless steel and feature IP54 protection, making them resistant to water, oil, dust, and other elements that could compromise accuracy. The robust construction ensures that these tools can withstand harsh conditions typically found in machining environments, thereby extending their lifespan and maintaining their accuracy.

Digital calipers offer various measurement modes, such as internal, external, depth, and step measurements. They also allow users to easily switch between different units, such as inches, millimeters, and fractions. This versatility makes digital calipers suitable for a wide range of applications and simplifies the measurement process, especially in diverse machining tasks.

The latest digital calipers provide high accuracy and resolution, often with an accuracy of ±0.001 inches (±0.02 mm) and a resolution of 0.00005 inches (0.01 mm). This level of precision is crucial for tasks that require exact measurements, helping machinists meet the strict tolerances required in precision work.

When selecting a digital caliper, consider the following factors to ensure it meets your needs:

Here are some top digital caliper models recommended for machinists:

These advanced features and best practices help machinists select the right digital caliper, ensuring they have the precision and functionality needed for their specific applications.

Before using calipers, it’s crucial to ensure they are clean and properly zeroed. Clean the jaws and other measuring surfaces with a soft-bristled brush and a non-corrosive cleaner. This helps avoid debris interference and ensures precise readings. For digital calipers, press the zero button to set the initial value. For Vernier or dial calipers, manually align the zero marks. This step is essential as it eliminates any pre-existing errors and provides a reliable starting point for measurements.

To measure external dimensions, use the outer jaws of the caliper. Place the object between the jaws, ensuring the measurement surface is close to the caliper’s reference edge and the jaws are square to the object. Proper alignment is crucial to avoid inaccurate readings. By taking proper outside measurements, you can precisely determine the width, diameter, or thickness of an object, which is essential for tasks like fitting parts together.

When measuring internal dimensions, use the inner jaws. Insert the inner jaws as deeply as possible into the opening of the object. This minimizes measurement error. Accurate inside measurements are crucial for tasks such as checking the diameter of a hole, which is often a critical dimension in machining and engineering applications.

Use the caliper’s depth gauge for depth measurements. Place the base of the caliper on the surface of the object and extend the depth gauge into the hole or recess. Ensure the depth gauge is perpendicular to the surface. This perpendicularity is necessary to obtain an accurate depth measurement, which is useful for tasks like determining the depth of a drilled hole or a machined pocket.

Applying excessive pressure when using calipers can result in smaller readings than the actual dimensions. Gentle pressure is sufficient to ensure proper contact between the caliper and the object. This way, you can avoid deformation of the object or the caliper itself, leading to more accurate and reliable measurements.

Whether you’re using the jaws for outside or inside measurements or the beam for depth measurements, always ensure they are square to the object. Squareness eliminates tilting errors, which can significantly affect the measurement accuracy. This simple yet important tip can greatly improve the quality of your measurements.

To confirm the accuracy and consistency of your measurements, take multiple readings. If the measurements vary, check for any issues such as debris on the caliper or incorrect alignment. Taking multiple measurements helps to identify and correct potential errors, ensuring that you get the most accurate result possible.

Below are answers to some frequently asked questions:

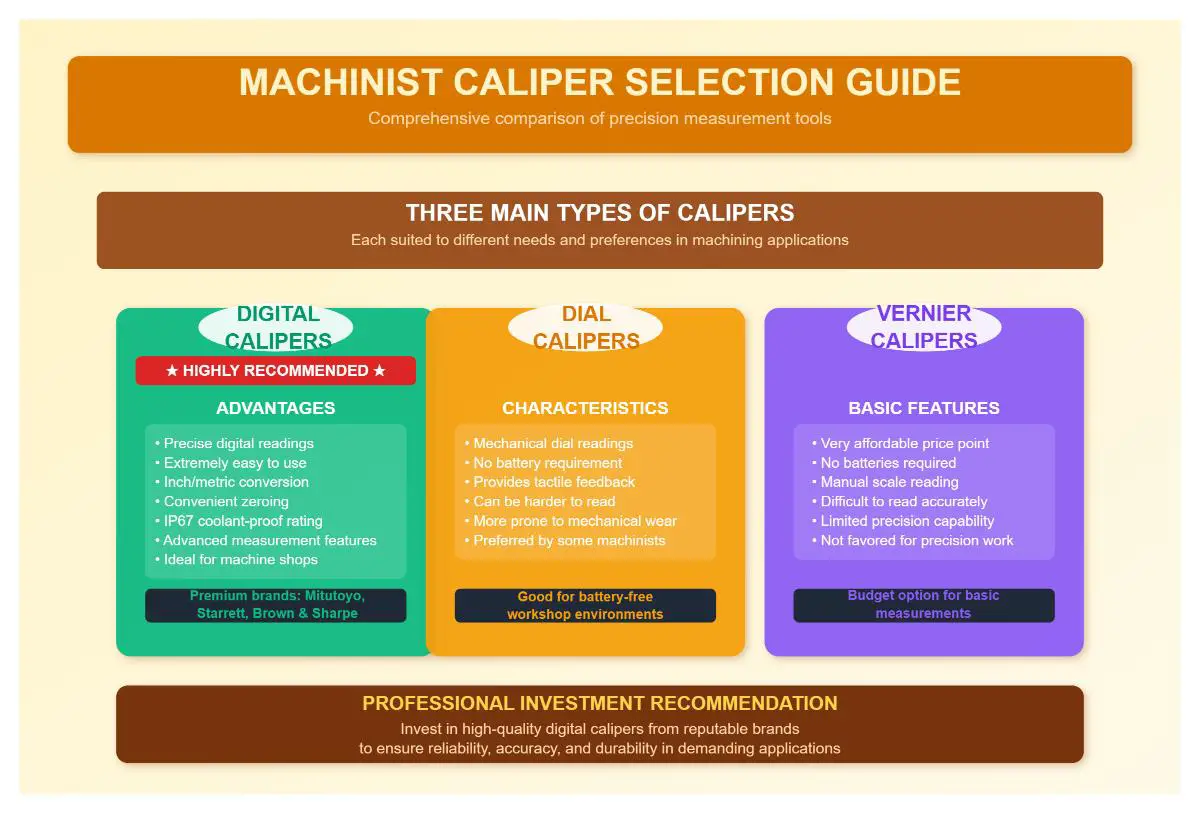

The best types of calipers for machinists are digital calipers, dial calipers, and vernier calipers, each suited to different needs and preferences. Digital calipers are highly recommended for their ease of use, precise digital readings, and advanced features like inch/metric conversion and zeroing. They often come with IP67 coolant-proof ratings, making them ideal for harsh machine shop environments. Dial calipers offer mechanical readings without the need for batteries, providing a tactile feedback that some machinists prefer, although they can be harder to read and more prone to mechanical wear. Vernier calipers, while the most basic, are very affordable and require no batteries, but can be difficult to read accurately and are generally not favored for precision measurements. For machinists, investing in high-quality digital calipers from reputable brands like Mitutoyo, Starrett, and Brown & Sharpe ensures reliability, accuracy, and durability.

When selecting calipers for machinists, the most reliable and accurate brands consistently recommended by professionals are Mitutoyo, Brown & Sharpe, and Starrett. Mitutoyo is renowned for its exceptional precision and durability, particularly their digital calipers which feature advanced technology like absolute scale that eliminates the need for zero resetting. Brown & Sharpe is known for its American-made quality and rugged construction, ideal for harsh work environments. Starrett, another historic American brand, offers both dial and digital calipers that are well-regarded for their meticulous accuracy and durability, often featuring IP67 coolant-proof ratings for tough conditions. These brands provide consistent, repeatable accuracy and are highly valued in demanding machining environments.

When buying calipers for machining, several critical features should be considered to ensure precision, durability, and ease of use. Firstly, accuracy and resolution are paramount; digital calipers typically offer high precision down to 0.001 inches or 0.02 mm, essential for detailed measurements. The type of caliper is also important: digital calipers are favored for their instant readability and ease of use, dial calipers offer mechanical reliability without batteries, and Vernier calipers provide traditional accuracy but require more skill to read. Material and build quality are crucial, with polished stainless steel being preferred for durability. Measurement range should be considered, with 8-inch calipers generally recommended for their balance of usability and precision. Versatility is important, ensuring the caliper can measure external, internal, depth, and step dimensions. Usability features such as a large thumb wheel, locking screws, and data output capability enhance workflow efficiency. Environmental resistance, such as IP67 coolant-proof rating, is beneficial for machinists working in harsh environments.

For general machining tasks, a 6-inch caliper is typically the best choice. This size is optimal for a wide range of measurements that machinists commonly encounter. A 6-inch caliper provides a practical balance between ease of handling and sufficient measurement range, making it versatile for various applications.

Larger calipers, like 8-inch or 12-inch, are used for specific tasks that require measuring bigger workpieces, but they can be bulkier and less convenient for everyday use. Therefore, for general purposes, a 6-inch caliper is recommended due to its portability, accuracy, and ability to handle most machining measurements efficiently.

There’s no one-size-fits-all answer to whether digital calipers are better than dial or Vernier calipers. Digital calipers offer easy reading, high accuracy, instant unit conversion, and convenient zeroing. They’re great for high-precision work and productivity. However, they’re sensitive to environmental factors and rely on batteries. Vernier calipers are durable, don’t need power, and are cost – effective, suitable for harsh environments and those on a budget. Dial calipers are easier to read than Vernier but have mechanical sensitivities. The choice depends on skill level, working environment, precision needs, and budget.

The battery life of calipers varies depending on the type and brand. For digital calipers, batteries typically last between 6 months to 2 years, with high-quality brands like Mitutoyo often exceeding this range due to their efficient power consumption. The type of battery used also plays a significant role; SR44 batteries, which are more durable and maintain a consistent voltage, tend to last longer than the more common LR44 batteries. Factors such as usage patterns and whether the calipers are turned off when not in use also influence battery longevity.