Imagine a skyscraper swaying gracefully in the wind, its stability and strength relying on every bolt and joint. The seemingly minute details, such as the diameter of bolt holes, play a critical role in the structural integrity of such massive constructions. Determining the correct oversized hole diameters is not just a matter of precision; it’s a fundamental aspect of ensuring safety and durability in structural engineering. In this article, we delve deep into the best practices for identifying oversized hole diameters, exploring the impact of hole size on structural performance, and offering a comprehensive guide aligned with AISC standards. Whether you’re a seasoned engineer or an intermediate practitioner looking to refine your skills, this technical deep dive will equip you with the knowledge to make informed decisions. Curious about how the choice of hole diameter can affect your next project? Let’s uncover the nuances together.

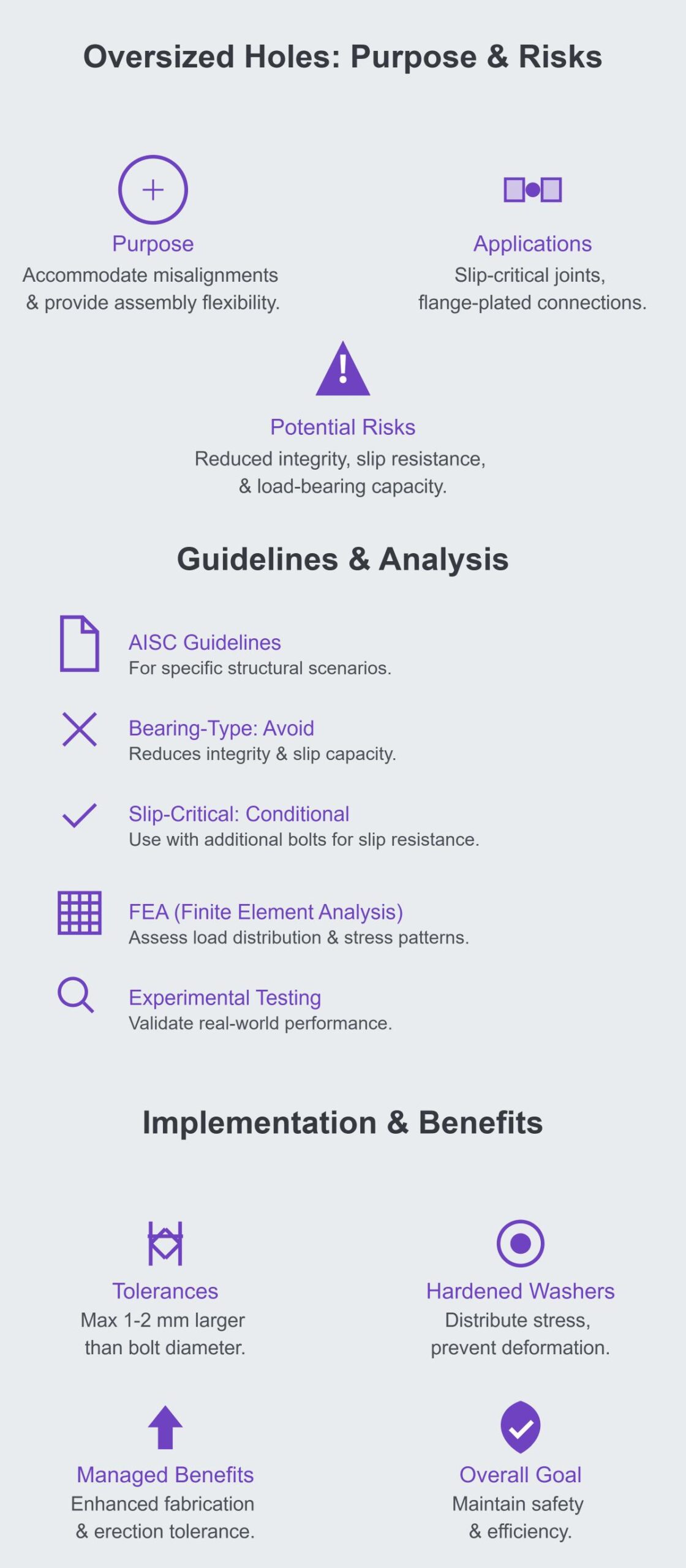

Oversized hole diameters refer to bolt holes that are intentionally made larger than the bolts meant to fit through them. This practice is common in structural engineering to accommodate various fabrication and assembly requirements.

In structural engineering, oversized hole diameters serve several critical purposes:

Oversized holes are particularly useful in managing minor misalignments during the assembly of structural components. By allowing a bit more room for bolt insertion, these holes can compensate for slight inaccuracies in the fabrication or placement of structural elements, ensuring that connections can be made more easily and accurately. Making bolt holes slightly larger than the bolt diameter simplifies the process of inserting bolts, especially in situations where precise alignment is challenging. This is particularly beneficial in field conditions where perfect alignment may be difficult to achieve.

Most fabrication standards, including those set by AS4100 and AS3990, suggest that oversized holes should not exceed 2mm larger than the nominal bolt size for bolts up to M24 and 3mm for larger bolts. The American Institute of Steel Construction (AISC) provides detailed guidelines on using oversized holes, emphasizing the importance of considering specific application needs.

Oversized holes are essential in various applications, including road bridge construction and slip-critical joints, where they help maintain structural integrity while accommodating minor misalignments. They ensure that connections remain strong and stable without compromising the overall performance and safety of the structure.

Incorrect hole sizes can create areas of high stress around the bolt holes, leading to cracks and structural issues over time. It’s crucial to determine the right oversized hole diameters to maintain structural integrity.

Using oversized holes without proper support, such as hardened washers, can result in uneven stress distribution and washer deformation. It is essential to use appropriate washers to maintain joint stiffness and prevent these issues.

The AISC Manual of Steel Construction recommends specific oversized hole diameters for different bolt sizes and requires engineer approval for certain types of holes. While oversized holes are usually not advised for bearing-type connections, they can be used in slip-critical connections if proper washers are included.

In column base plates, oversized holes help manage field variations in anchor bolt placement. However, if the misplacements exceed 1/2 inch, corrective measures may be needed. AISC suggests adding up to 1/4 inch to the recommended hole size to accommodate potential misalignments.

The American Institute of Steel Construction (AISC) sets forth comprehensive standards for the design and construction of steel structures. These standards are essential to guarantee the safety, reliability, and efficiency of steel construction projects. The AISC Specification for Structural Steel Buildings, commonly referred to as the AISC Manual, provides detailed guidelines on various aspects of structural steel design, including specifications for bolt holes.

The AISC Specification Table J3.3 specifies the maximum allowable sizes for bolt holes, including standard, oversized, short-slotted, and long-slotted holes. These specifications help maintain the structural integrity of connections. If the actual hole dimension exceeds the maximum size listed in the table, it must be treated as the next larger hole size to ensure the connection remains robust and compliant with AISC standards.

Oversized holes are generally restricted in bearing-type connections because they can introduce “slop,” affecting load distribution, erection tolerances, precision, and stability. However, oversized holes are permitted in slip-critical connections, provided they do not compromise the structural integrity. Slip-critical connections transfer loads through friction between connected surfaces, so the use of oversized holes must be managed carefully to maintain effectiveness.

Standard holes are typically used for most structural connections. They provide a snug fit for the bolts, ensuring proper load transfer and minimizing movement within the connection. The use of standard holes is preferred unless specific conditions necessitate the use of oversized or slotted holes.

Oversized holes are larger than standard holes and are used to accommodate minor misalignments during assembly. The maximum allowable oversized hole diameter is specified in the AISC Manual, and its use must be approved by the Engineer of Record (EOR). In slip-critical connections, the use of oversized holes requires careful consideration of the connection’s load-carrying capacity and the potential for slippage.

Slotted holes, both short and long, are used in situations where there is a need for movement or adjustment in the connection. Short-slotted holes are usually perpendicular to the load direction, while long-slotted holes can be in any direction. The dimensions and allowable use of slotted holes are also specified in the AISC Manual.

In addition to AISC standards, compliance with ASTM (American Society for Testing and Materials) standards is crucial for ensuring the quality and performance of structural steel connections. ASTM standards provide specifications for materials, testing methods, and procedures used in steel construction. Adherence to both AISC and ASTM standards ensures that the structural components meet the required performance criteria and are suitable for their intended applications.

The EOR plays a critical role in determining the appropriate use of oversized holes. Their judgment is essential in assessing whether the use of such holes will affect the structural integrity of the connection. The EOR’s approval is typically limited to slip-critical connections, where the oversized holes do not compromise the connection’s performance.

By adhering to these guidelines and utilizing the judgment of the EOR, engineers can ensure that the use of oversized holes in structural connections is both safe and effective.

In construction, bolts come in various sizes to meet the requirements of different structural applications. The size of a bolt is typically defined by its diameter, length, and thread pitch.

The diameter, measured across the threaded part of the bolt, is the most crucial dimension. Common diameters used in construction include:

Bolt length, measured from the flat part of the head to the end of the threaded part, can vary significantly depending on the application, ranging from a few millimeters to several inches.

Thread pitch is the distance between bolt threads, specified in threads per inch (TPI) for imperial sizes or millimeters for metric sizes. Common thread pitches include:

Bolts are designed for specific purposes, and their types can vary based on their head shape, strength, and material. Here are some common types used in construction:

Hex bolts, with their hexagonal heads, are popular in construction for their versatility and strength. They are used in various applications, including steel structures and machinery assembly.

Carriage bolts have a smooth, rounded head with a square section underneath that prevents rotation when the nut is tightened. They are often used in wood-to-wood connections or wood-to-metal applications where a smooth finish is desired.

Anchor bolts are designed to attach structural elements to concrete. They come in various designs, such as L-shaped, J-shaped, and wedge anchors, each suited for specific applications like securing columns, beams, and heavy machinery.

Flange bolts have a flange beneath the head, which acts as a washer, distributing the load over a larger area. This type is commonly used in automotive and structural applications where vibration resistance is needed.

Eye bolts feature a loop (or eye) at one end and are used for lifting and securing cables, ropes, and chains. They are crucial in applications requiring strong anchorage points.

Bolts are manufactured from various materials, each offering different strengths and properties suitable for specific environments and loads.

Carbon steel bolts are the most common and are used for general construction purposes. They offer a good balance of strength and cost-effectiveness.

Stainless steel bolts are known for their corrosion resistance and are used in environments where exposure to moisture and chemicals is a concern. They are ideal for exterior applications and marine environments.

High-strength bolts, such as ASTM A325 and A490 bolts, are used in structural steel connections where high load-carrying capacity is required. They are heat-treated to achieve higher tensile strengths.

Alloy steel bolts are used in high-stress applications where enhanced strength and toughness are necessary. They are often utilized in heavy machinery and structural applications subjected to dynamic loads.

Selecting the appropriate bolt size and type is essential for maintaining the structure’s integrity and safety. Considerations include:

Proper selection and application of bolts are essential for the structural integrity and longevity of construction projects. By understanding the various sizes, types, and material properties, engineers can ensure robust and reliable connections in their designs.

Calculating oversized hole diameters is a precise process that ensures easy assembly and strong structural integrity. The process typically follows these steps:

Several critical factors must be considered to ensure the oversized hole diameters are both effective and safe:

For a structural steel beam connection using 1/2 inch bolts, the oversized hole diameter is 9/16 inch. For a bridge project with 1 inch high-strength bolts, the oversized hole diameter is 1 1/8 inch.

The table below provides recommended oversized hole diameters for common bolt sizes, ensuring proper fit and performance:

| Bolt Size | Standard Hole Diameter | Oversized Hole Diameter |

|---|---|---|

| 1/2 inch | 9/16 inch | 5/8 inch |

| 3/4 inch | 13/16 inch | 1 inch |

| 1 inch | 1 1/16 inch | 1 1/8 inch |

By carefully calculating oversized hole diameters using these methods and considerations, engineers can ensure that connections are both efficient and structurally sound.

The diameter of bolt holes significantly impacts the structural performance of connections in engineering applications. Oversized holes, while useful for accommodating misalignments, can introduce several challenges that must be carefully managed to maintain the integrity of the structure.

Oversized bolt holes can significantly reduce the load-bearing capacity of a connection. Larger holes reduce the contact area between the bolt and the material, leading to lower slip and ultimate strengths. This diminished contact area means the connection may not be able to support the intended loads, potentially leading to structural failures.

Stress concentrations around the edges of oversized holes can become focal points for fatigue and eventual failure. In bearing-type connections, the American Institute of Steel Construction (AISC) strongly advises against the use of oversized holes due to the increased risk of stress-related issues. Properly managing these stress concentrations is essential to prevent long-term damage to the structure.

Using oversized holes can make assembly easier by allowing for quicker bolt insertion and accommodating minor misalignments. This is particularly beneficial in field conditions where precision alignment can be challenging. By providing additional space, oversized holes enable quicker and more accurate assembly of structural components, reducing construction time and labor costs.

Despite the advantages in assembly, it is crucial to ensure that oversized holes do not compromise structural integrity. Engineers must follow best practices and guidelines, such as those provided by AISC, to maintain performance standards. Accurate measurement and adherence to tolerances are vital to ensure that oversized holes function correctly without weakening the connection. In some cases, compensating for reduced strength by using additional bolts can help distribute loads more evenly and maintain stability.

The AISC provides detailed recommendations for the use of oversized holes in structural steel connections. These guidelines emphasize the importance of considering construction tolerances and ensuring reliable performance. Engineers should adhere to these standards to mitigate risks associated with oversized holes.

Utilizing Finite Element Analysis (FEA) and experimental testing can help engineers understand the effects of oversized holes on load distribution and stress patterns. These methods provide valuable insights into how oversized holes impact the structural integrity of connections, allowing for informed decision-making and design adjustments.

Maintaining precise tolerances is crucial. Use clearance hole charts to determine appropriate diameters based on bolt size and desired fit to ensure efficient and secure connections.

In road bridge construction, oversized holes are crucial in slip-critical joints. They help accommodate minor misalignments and ensure stability under dynamic loads, contributing to the overall structural integrity and longevity of the bridge.

For column base plates, oversized holes manage variations in anchor bolt placement, ensuring proper alignment without compromising stability. This application underscores the importance of accurately calculating oversized hole diameters to maintain structural integrity in critical connections.

The AISC Manual of Steel Construction is a crucial guide for engineers dealing with oversized holes in structural connections. It provides comprehensive guidelines, emphasizing the importance of considering factors such as misalignment, structural integrity, and load types. This manual helps ensure that connections using oversized holes are designed correctly, maintaining the ASTM standards offer detailed recommendations on bolt hole sizes and tolerances. These standards are crucial for ensuring that structural assemblies maintain their integrity while accommodating thermal expansion and other environmental factors, ensuring that oversized holes do not compromise the connection’s performance.

Australian standards AS4100 and AS3990 specify that hole sizes should not exceed 2mm larger than the nominal bolt size for bolts up to M24, and 3mm for larger bolts. They also recommend using hardened washers over oversized holes to keep joints stiff and avoid deformation. Adhering to these standards helps ensure the reliability and durability of structural connections.

Oversized holes help accommodate minor misalignments in structural connections. By allowing for slight deviations during fabrication and assembly, they ensure precise placement without compromising the strength of the connection. This practice is particularly beneficial in complex structures where alignment challenges are common.

Oversized holes facilitate faster assembly by providing extra room for bolt insertion. This efficiency is crucial in large-scale construction projects, reducing assembly time and labor costs. Engineers can expedite the construction process while maintaining the quality and integrity of the connections.

Maintaining structural integrity is paramount when using oversized holes. To prevent washer deformation and ensure even stress distribution, oversized holes should be used with hardened or plate washers. This practice helps maintain joint stiffness and prevents issues that could compromise the connection’s performance.

Oversized holes are permissible in slip-critical connections, where loads are transferred through friction between connected surfaces. However, they are generally not advised for bearing-type connections unless approved by the engineer of record (EOR). Understanding the load types and their impact on connection performance is critical for the safe use of oversized holes.

Finite Element Analysis (FEA) is a powerful tool that helps engineers identify stress concentration zones around bolt holes. By simulating various load conditions and material properties, FEA aids in the optimization of hole diameters, ensuring that connections are both efficient and robust.

Clearance hole charts are invaluable resources for determining appropriate hole diameters based on bolt size and desired fit. These charts provide standardized values that help engineers achieve accurate assembly and optimal structural performance.

Platforms like Eng-Tips offer valuable insights from experienced engineers on interpreting standards and best practices for oversized holes. Engaging with these forums can provide practical advice and solutions to common challenges faced in structural engineering.

Recent discussions in the engineering community highlight the importance of accommodating field variations in anchor bolt placement. Oversized holes often require additional clearance to manage these variations, ensuring proper alignment and connection stability.

Advances in machining and manufacturing processes continue to refine the precision and efficiency of creating oversized holes. These technological improvements enhance the structural assembly process, contributing to faster and more accurate construction practices.

Below are answers to some frequently asked questions:

Determining oversized hole diameters in structural engineering requires adherence to specific guidelines to ensure structural integrity and functionality. First, understand that oversized holes are used to accommodate misalignments and provide flexibility during assembly, especially in slip-critical joints and flange-plated moment connections. However, these holes can decrease the structural integrity by reducing slip resistance and load-bearing capacity.

The American Institute of Steel Construction (AISC) provides detailed guidelines for the appropriate use of oversized holes, emphasizing their application in specific structural scenarios. It is crucial to avoid oversized holes in bearing-type connections due to potential reductions in structural integrity and slip capacity. For slip-critical connections, oversized holes can be used if additional bolts are employed to maintain slip resistance.

Finite Element Analysis (FEA) is recommended to assess the impact of oversized holes on load distribution and stress patterns. Experimental testing can further validate the performance of such connections under real-world conditions. Ensure that clearance holes adhere to standard tolerances, typically not exceeding 1-2 mm larger than the bolt diameter for standard applications.

Use hardened washers over oversized holes to evenly distribute stresses and prevent deformation. In some cases, multiple washers may be needed to maintain joint stiffness. Oversized holes can enhance fabrication efficiency and erection tolerance but must be carefully managed to avoid compromising structural integrity. Following these best practices helps engineers effectively use oversized holes while maintaining safety and efficiency in structural projects.

The choice of hole diameter critically affects structural performance in several ways. Oversized holes in structural materials such as steel and concrete can lead to higher stress concentrations around the hole edges, which may reduce the For concrete structures, larger hole diameters can reduce the axial load-carrying capacity and bearing strength, particularly in reinforced concrete columns and blocks. In steel structures, punched holes generally lower strength and ductility compared to drilled holes, with dynamic loads further exacerbating these effects. Following established standards like those from the AISC and considering application-specific factors such as vibrations and thermal expansion are crucial for maintaining structural integrity when determining hole diameters.

When calculating oversized hole diameters in structural engineering, common mistakes include:

To avoid these mistakes, engineers should follow best practices such as adhering to standards, considering material properties and load conditions, and using appropriate tools and methods for precise hole sizing.

Different bolt types influence the choice of hole diameter primarily through their size, thread type, and application requirements. The major diameter of the bolt, which is the outermost part of the bolt thread, dictates the basic hole size. For standard bolts, holes are typically made 1/16 inch larger than the bolt to allow for slight misalignments. However, oversized holes, which are generally 3/16 inch larger than the bolt diameter, are used for applications needing more flexibility, like column base plates.

The thread type, whether coarse or fine, can also affect the hole diameter due to variations in thread engagement and clearance. For example, fine-threaded bolts might require slightly different hole sizes compared to coarse-threaded bolts of the same nominal diameter.

Standards, such as those from the American Institute of Steel Construction (AISC), provide specific guidelines for hole sizes based on bolt diameters and structural needs. These guidelines ensure proper fit, strength, and safety of the structure. Additionally, the material properties and application environment (e.g., thermal expansion or vibrations) must be considered to maintain structural integrity under dynamic loads.

Yes, there are several case studies that examine the impact of oversized hole diameters in real-world structural engineering projects. For example, in plant construction, instances where bolt holes exceeded standard sizes were resolved using methods such as plate washers, reaming to the correct size, or switching to welded connections. Another case study focused on cable tray hangers, where oversized bolt holes were found to potentially affect system integrity. Additionally, research on bolted friction type connections indicated that oversized holes could reduce slip and ultimate strengths under dynamic loading, though these connections remained acceptable for such conditions. These studies highlight the importance of addressing oversized holes to maintain structural integrity and suggest various corrective actions and best practices.

Engineers can utilize a variety of tools and resources to determine the correct hole diameters for structural applications. Precision measuring tools like hole gages and bore gages are essential for accurate measurements of existing holes. Engineering drawings and standards, including those from ISO and ASME, provide guidelines for dimensioning and ensure uniformity. Clearance hole charts are useful for selecting the appropriate drill bit sizes based on bolt size and the desired fit.

Additionally, design software such as Doma Sizer™ and online calculators offer precise calculations for optimal hole sizes and compliance with industry standards. Best practices, as outlined by the American Institute of Steel Construction (AISC), include guidelines for oversized holes to manage misalignments and ensure structural integrity. For instance, AISC recommends using a 5/8-inch hole for a 1/2-inch bolt and a 1-inch hole for a 3/4-inch bolt. Understanding tolerances, material properties, and application requirements is crucial in determining the ideal hole diameter.