When it comes to choosing the right material for your next project, understanding the differences between bronze and copper can make all the difference. Is bronze stronger than copper? When should you opt for copper over bronze? How do their corrosion resistance properties stack up against each other? These are just a few of the critical questions we’ll explore in this comprehensive comparison. We’ll delve into the mechanical properties, corrosion resistance, melting points, and electrical conductivity of both metals, providing you with a detailed analysis to help you make an informed decision. Additionally, we’ll break down the costs and maintenance requirements, ensuring you have all the information needed for a balanced evaluation. Ready to discover which metal suits your needs best? Let’s dive in.

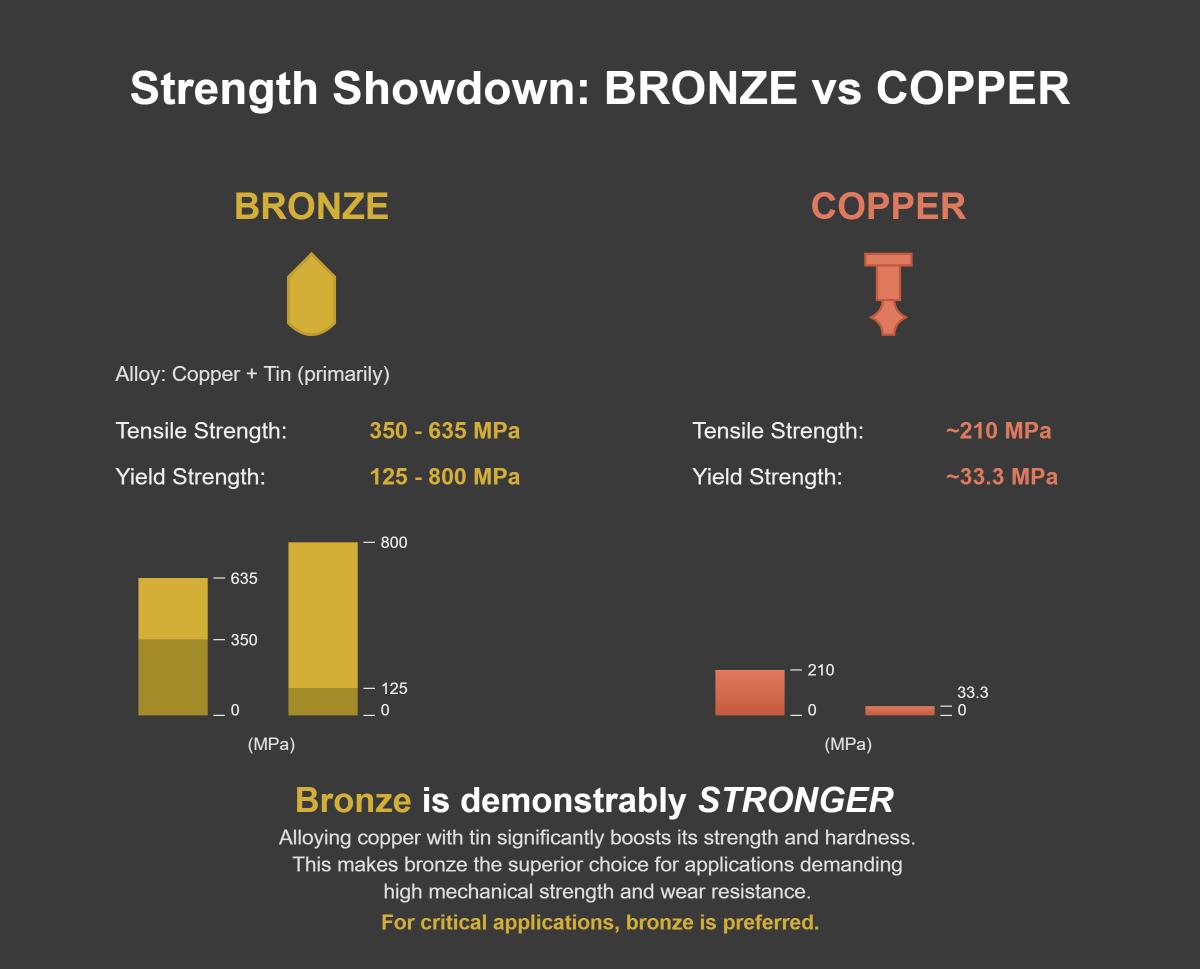

Understanding the mechanical strength of metals is crucial for selecting the right material for specific applications. Strength in metals is often characterized by yield strength and tensile strength.

Yield strength is the point at which a material starts to deform permanently under stress. With yield strengths ranging from 125 to 800 MPa, bronze is significantly stronger than copper, which has a yield strength of around 33.3 MPa, making bronze ideal for high-stress applications.

Tensile strength is the maximum stress a material can withstand while being stretched or pulled before breaking. Bronze can withstand tensile strengths between 350 and 635 MPa, while copper can handle about 210 MPa. The higher tensile strength of bronze means it can endure greater forces without failing, making it ideal for high-stress components.

Hardness is a measure of a material’s resistance to deformation and wear. It is typically evaluated using the Brinell hardness scale.

Bronze has hardness values between 40 and 420, much harder than copper’s hardness of around 35. This increased hardness makes bronze more wear-resistant and durable, suitable for applications involving friction or abrasive conditions. However, the higher hardness can also result in brittleness, making bronze more prone to fracturing under certain conditions.

Machinability and formability are important factors in manufacturing processes. They determine how easily a material can be shaped and processed.

Bronze’s hardness results in moderate to low machinability, needing specialized techniques to prevent tool wear and cracking, while copper is highly machinable and easily shaped into various forms.

Copper excels in formability, being highly ductile and malleable. This makes it easier to fabricate complex shapes and fine wires. Bronze’s formability is moderate but less forgiving due to its rigidity, necessitating careful processing to prevent brittleness-related failures.

Industry standards ensure materials meet specific mechanical properties for various applications. Compliance with these standards is critical for quality assurance and performance.

Bronze and copper must adhere to stringent technical specifications, such as ASTM B505 for bronze and ASTM B152 for copper. These standards define the mechanical properties, chemical composition, and performance criteria for each material, ensuring they meet the required benchmarks for their respective applications.

Manufacturers must ensure their bronze and copper products comply with relevant industry standards to guarantee reliability and safety in their applications. Adherence to these standards is crucial for achieving the desired mechanical properties and performance in engineering and industrial contexts.

Corrosion resistance is a material’s ability to withstand deterioration caused by environmental interactions, such as exposure to moisture, chemicals, or salts. This property is crucial in determining the longevity and suitability of materials for various applications, especially in harsh environments.

Bronze, an alloy primarily composed of copper and tin, exhibits excellent corrosion resistance. When exposed to air, bronze forms a protective oxide layer called patina that prevents further corrosion. The presence of tin enhances bronze’s resistance to corrosion, making it highly effective in environments that are prone to chemical exposure and moisture. Additionally, aluminum bronze, a variant of bronze, offers even better resistance to corrosion, particularly in marine environments where saltwater is a significant factor. However, bronze’s copper content can degrade in the presence of chlorine compounds, limiting its use in certain chemical environments.

Copper is also known for its good corrosion resistance. It forms a protective layer of copper oxide when exposed to air, which helps shield the underlying metal from further corrosion. This makes copper suitable for applications where it is exposed to moisture, such as in plumbing and electrical components. However, copper is less effective than bronze in environments with high levels of salt or chlorine. Despite this, copper’s resistance to moisture and its excellent electrical conductivity make it a popular choice for various applications.

Bronze exhibits superior corrosion resistance due to the formation of a protective patina, making it especially resistant to saltwater and ideal for marine applications. Variants like aluminum bronze offer enhanced resistance in harsh environments.

Copper forms a protective oxide layer that provides good corrosion resistance. Effective in moist environments but less resistant than bronze in highly saline or chlorinated conditions.

Bronze is ideal for marine hardware, boat fittings, and industrial uses where saltwater and harsh conditions are common. Its durability and resistance to wear make it suitable for parts subjected to heavy use.

Copper is suitable for general plumbing, electrical wiring, and electronic components. While it handles moisture well, it is not as effective as bronze in highly corrosive environments.

Materials used in engineering and industrial applications must meet specific corrosion resistance standards, which provide guidelines on acceptable corrosion levels for various materials.

Manufacturers must ensure that their bronze and copper products comply with relevant industry standards to guarantee their performance in corrosive environments. Adherence to these standards is essential for achieving the desired longevity and reliability in applications ranging from marine hardware to electrical components.

A material’s melting point is the temperature at which it changes from solid to liquid. This property is critical in manufacturing and engineering as it influences how materials are processed, their suitability for various applications, and their performance under different conditions.

Bronze, an alloy of copper and tin, generally melts between 913°C and 1050°C (1675°F to 1922°F), depending on its composition. Common bronze melts at around 913°C (1675°F), while bearing bronzes with lead and zinc melt at about 977°C (1790°F). Silicon bronze, another variant, has a higher melting point near 1025°C (1880°F).

Pure copper has a higher melting point compared to bronze, typically around 1083°C (1981°F). This higher melting point is a defining characteristic of copper, making it suitable for applications that require durability and stability at elevated temperatures.

| Material | Melting Point Range (°C) | Melting Point Range (°F) |

|---|---|---|

| Copper (pure) | 1083 | 1981 |

| Bronze (general) | 913 – 1050 | 1675 – 1922 |

Copper stays solid at temperatures where bronze alloys start to melt, thanks to its higher melting point. This difference is crucial for applications involving heat exposure, ensuring it retains structural integrity at high temperatures. For instance, in electrical wiring and heat exchangers, copper’s high melting point ensures reliability and safety under thermal stress.

Bronze, with its lower melting point, is easier to cast into complex shapes, making it ideal for applications that require detailed or intricate components. The lower melting range of bronze alloys allows for more energy-efficient casting processes, which can be beneficial in manufacturing. Bronze’s moderate melting point also makes it suitable for applications requiring good corrosion resistance and moderate strength, such as bearings, sculptures, and marine hardware.

Various industry standards specify the melting point requirements for materials to ensure their suitability for specific applications. These standards help in maintaining consistency and reliability in material performance.

Manufacturers must ensure that their bronze and copper products comply with the relevant industry standards to guarantee their performance in various applications. Adherence to these standards is essential for achieving the desired properties and ensuring material reliability in engineering and industrial contexts.

Electrical conductivity measures how well a material can carry an electric current. This property is usually measured in Siemens per meter (S/m).

Bronze, an alloy primarily composed of copper and tin, has a significantly lower electrical conductivity compared to pure copper. Alloying elements like tin and silicon in bronze lower its electrical conductivity. Generally, bronze’s electrical conductivity is about 15% of copper’s conductivity. Despite this, bronze’s mechanical properties make it suitable for applications where high strength and corrosion resistance are required, but electrical performance is less critical.

Copper is renowned for its excellent electrical conductivity, which is the highest among pure metals. Copper’s high conductivity comes from its ability to let electrons move freely. This makes copper the preferred choice for applications requiring efficient electrical transmission. Minor alloying elements do not significantly affect copper’s conductivity, maintaining its superior performance in electrical systems.

| Material | Electrical Conductivity | Thermal Conductivity |

|---|---|---|

| Copper | 100% (benchmark) | 223 BTU/hr-ft²-°F |

| Bronze | ~15% of copper’s | 229 – 1440 BTU/hr-ft²-°F |

Copper is perfect for wiring and circuit boards due to its unmatched conductivity, while bronze is better for high-stress, corrosion-prone environments where strength is more important than electrical performance.

Standards for electrical conductivity ensure that materials meet specific performance criteria necessary for their intended applications. Compliance with these standards guarantees reliability and safety in electrical systems.

Manufacturers must ensure their copper and bronze products meet these standards to provide consistent and dependable performance in various applications, from electrical wiring to industrial components. Adherence to these standards is essential for achieving the desired electrical and mechanical properties in engineering and industrial contexts.

When comparing the costs of bronze and copper, several factors such as raw material prices, production processes, and market demand must be considered. Both metals have unique characteristics that influence their overall cost.

Copper: Copper is a pure metal, and its price is influenced by the costs associated with mining, extraction, and refining. Achieving high-purity copper requires significant resource input, which elevates its market value. The labor-intensive mining process and the need for heavy equipment also contribute to the higher cost of copper.

Bronze: Bronze is an alloy primarily composed of copper and tin, along with other elements like aluminum or manganese. Adding tin and other materials generally makes bronze cheaper than pure copper. Tin is usually less expensive and more price-stable, although its scarcity can occasionally affect bronze prices. The alloying process, which involves precise melting and mixing, adds complexity and cost but overall, bronze tends to be cheaper than copper.

Copper: Producing pure copper involves moderately complex processes focused on achieving and maintaining high purity levels. This requires sophisticated equipment and stringent quality control measures, adding to the production costs.

Bronze: Making bronze is more complex because it involves alloying. It requires melting copper with tin and other elements, necessitating precise control to ensure the desired properties. This complexity can increase manufacturing costs, but the use of less expensive alloying elements often offsets these expenses.

Copper: The demand for copper is substantial, especially in electrical and telecommunications sectors, where its superior conductivity is crucial. High demand keeps copper prices elevated and sensitive to market changes driven by industrial needs and global economic conditions.

Bronze: While bronze also has significant industrial applications, its market demand is generally lower than that of copper. The price stability of bronze is influenced by the availability and cost of tin and other alloying elements. Fluctuations in tin supply can impact bronze prices, but these are often less volatile compared to copper.

| Aspect | Copper | Bronze |

|---|---|---|

| Raw material cost | Higher because of purity and mining costs | Generally lower due to alloying |

| Production complexity | Moderate, focused on purity | Higher, involves alloying steps |

| Price stability | Influenced by copper market demand | Affected by tin availability |

| Typical Brinell hardness | ~35 | 40–42 (harder and stronger) |

| Market price tendency | Generally more expensive | Mid-range, less costly |

When selecting between bronze and copper, it is crucial to consider the cost-benefit tradeoffs in relation to their specific applications.

Electrical and Telecommunications: Copper’s higher cost is justified by its unparalleled electrical conductivity, making it indispensable for wiring and power transmission where performance cannot be compromised.

Marine and Petrochemical Applications: Bronze’s excellent corrosion resistance and durability make it a cost-effective choice for marine and harsh industrial environments. Despite higher production complexity, its long-term performance offers significant savings.

Mechanical Components: Bronze’s higher hardness and strength make it ideal for bearings, bushings, and springs, where mechanical robustness is essential. The increased production cost is offset by its superior mechanical properties.

Manufacturing and Machining: Copper is easier and less costly to machine due to its softness, making it suitable for applications where ease of fabrication is a priority. Bronze requires specialized tools due to its hardness, which can increase machining costs.

In addition to upfront costs, the long-term value of bronze and copper depends on their durability, maintenance needs, and application-specific performance.

When comparing the maintenance and sustainability of bronze and copper, it is essential to consider their distinct material properties, which influence their longevity, upkeep, and environmental impact.

| Property | Bronze | Copper |

|---|---|---|

| Composition | Alloy of copper with tin, nickel, zinc | Pure copper metal |

| Strength & Hardness | Higher due to tin and other additives | Softer, more ductile |

| Corrosion Resistance | Excellent, forms protective patina | Moderate, forms protective oxide layer |

| Machinability | Lower, harder to machine | Higher, more flexible and easier to bend and shape |

| Electrical Conductivity | Lower | Very high |

| Melting Point | Around 913°C | Higher, around 1085°C |

Bronze develops a protective patina when exposed to air and moisture, which helps prevent further corrosion. This makes bronze particularly suitable for harsh environments, including marine settings, where saltwater corrosion resistance is critical. Copper also oxidizes, forming a greenish layer known as verdigris. However, copper’s corrosion resistance is generally lower than that of bronze, especially in chloride-rich environments, requiring more frequent maintenance to prevent degradation.

Bronze’s hardness allows it to resist wear and scratches better than copper, reducing the need for frequent repairs or replacements in mechanical parts like bearings, bushings, and marine hardware. Copper is durable but may require more frequent replacements in harsh environments. Its superior machinability and flexibility allow for easier fabrication and repairs. Copper can be bent and shaped with relative ease, facilitating simpler maintenance procedures. Bronze, on the other hand, is harder and less flexible, making it more challenging to machine and form. This increased difficulty can raise maintenance complexity or costs if parts require replacement or modification.

Bronze’s enhanced durability and corrosion resistance contribute to a longer service life, reducing the need for frequent replacements and the associated resource consumption. This extended lifespan improves sustainability by lowering material waste and the environmental footprint of manufacturing cycles. Copper, while durable, may not last as long in harsh environments, potentially leading to more frequent replacements.

Both copper and bronze are highly recyclable metals. Copper can be recycled repeatedly without significant loss of quality. Bronze, being an alloy of copper, can also be efficiently recycled. However, recycling bronze may require extra steps due to the alloying elements.

Pure copper requires higher melting temperatures (about 1085°C) compared to bronze (around 913°C), which can translate to higher energy consumption during processing. However, the improved durability of bronze may offset this by reducing the frequency of new production. The mining and extraction of tin and other metals for bronze alloys add to its environmental footprint compared to pure copper.

Bronze is generally more expensive than copper due to the alloying elements and more complex production processes. Its higher hardness and lower machinability may also increase fabrication costs. Copper, being a pure metal, is less costly to produce and easier to work with, which can reduce initial manufacturing expenses.

Although bronze has higher upfront costs, its superior corrosion resistance and durability can lower long-term maintenance and replacement expenses. Copper may incur lower initial costs but could require more frequent upkeep or earlier replacement, especially in corrosive environments.

Bronze is commonly utilized in industrial machinery for its strength, hardness, and superior wear resistance. Lead-free bronze bushings and continuous cast bronze bars are highly valued in industrial settings for their superior performance under high-pressure conditions and use in manufacturing worm gears.

Copper is essential in industries needing high thermal and electrical conductivity. It is commonly used in brazing alloys and heat sink components within power electronics. Copper’s superior machinability also makes it ideal for intricate parts that require precision manufacturing. Additionally, copper’s antimicrobial properties benefit industries such as food processing and medical equipment, where hygiene is paramount.

Bronze’s outstanding corrosion resistance makes it ideal for marine applications. Aluminum bronze propellers and naval brass fittings are renowned for their ability to resist saltwater corrosion, ensuring longevity and reliability in harsh marine environments. Phosphor bronze bearings excel in submerged applications, providing durability and reduced maintenance requirements.

Copper is also used in marine applications, primarily in seawater piping systems. Its resistance to corrosion and biofouling makes it suitable for submerged environments. However, copper requires cathodic protection to prevent rapid degradation when in direct contact with seawater, making it less ideal than bronze for certain marine hardware.

Bronze is used in electrical connectors and conductive springs where both strength and corrosion resistance are critical. Although its conductivity is lower than copper, bronze’s mechanical properties allow it to perform well in applications where durability is more important than maximum conductivity.

Copper wiring is found everywhere in residential, commercial, and industrial electrical systems due to its high conductivity and reliability, making it indispensable in electric vehicles and renewable energy infrastructure.

Bronze finds use in medical devices where durability and corrosion resistance are crucial. Components such as surgical instruments and orthopedic implants benefit from bronze’s biocompatibility and resistance to wear. The material’s ability to maintain structural integrity over time is essential in medical applications.

Copper’s antimicrobial properties make it highly valuable in healthcare settings. It is used in surfaces, fixtures, and medical devices to reduce the risk of infection. Copper’s ability to kill bacteria and other pathogens on contact helps maintain sterile environments, crucial in hospitals and clinics.

These applications highlight the distinct advantages of bronze and copper in various industries, emphasizing the importance of selecting the right material based on specific performance requirements and environmental conditions.

Copper is a highly valued pure element known for its excellent electrical and thermal conductivity, malleability, and natural resistance to corrosion. It forms a protective patina when exposed to air, which helps prevent further corrosion. Unfortunately, mining operations frequently cause habitat destruction, soil erosion, and water contamination. Despite these drawbacks, copper’s recyclability is a major advantage. It can be recycled indefinitely without loss of quality, reducing the need for continuous mining and mitigating some of its environmental impacts.

Bronze, an alloy primarily composed of copper and tin, sometimes with additions of aluminum or manganese, is known for its superior strength and durability compared to pure copper. Tin’s presence improves bronze’s corrosion resistance, making it especially suitable for harsh environments like marine settings. Like copper, bronze is highly recyclable, and its recycling process requires less energy than primary production, which helps reduce its carbon footprint. The durability of bronze also means that it needs to be replaced less frequently, which further lowers its overall environmental impact.

Copper’s exceptional electrical conductivity makes it essential for electrical wiring and electronic components. Its malleability allows for easy fabrication, potentially reducing manufacturing energy costs. However, copper is less resistant to corrosion in marine environments, which can lead to more frequent replacements and associated environmental costs.

Bronze’s strength, hardness, and corrosion resistance make it ideal for applications that involve wear and mechanical stress, such as marine hardware and bearings. Its durability translates into fewer maintenance requirements and less frequent replacements, which benefits long-term environmental sustainability. The initial production cost of bronze may be higher, but its long-term benefits often outweigh these costs.

Copper has a higher initial cost due to the extensive extraction and refining processes required and strong demand from various industries. The environmental impact of mining and refining copper is considerable, involving energy-intensive operations and ecological disturbance. However, the ability to recycle copper reduces the long-term environmental burden by decreasing reliance on virgin ore.

Bronze generally has a lower or comparable cost to copper despite being an alloy. The addition of tin and other elements can increase production costs but often reduces overall expenses by enhancing durability and reducing maintenance needs. The energy savings from recycling bronze and its longevity contribute to a reduced carbon footprint over its lifecycle.

| Aspect | Copper | Bronze |

|---|---|---|

| Composition | Pure element (Copper) | Alloy (Copper + Tin + others) |

| Strength & Hardness | Softer, more malleable | Harder, stronger, more wear-resistant |

| Corrosion Resistance | Good (patina protects), less in marine | Superior in marine and harsh environments |

| Electrical Conductivity | Excellent, top choice for wiring | Lower than copper, less used in electrical |

| Recyclability | Highly recyclable, which lowers environmental impact | Highly recyclable, with energy-efficient recycling |

| Environmental Impact of Extraction | Significant habitat disruption and contamination | Similar copper base impact, mitigated by alloying and recyclability |

| Durability & Maintenance | Medium, prone to corrosion in saltwater | High durability, less maintenance needed |

| Cost | Higher initial cost due to refining and demand | Slightly lower or comparable, cost-effective long-term |

Below are answers to some frequently asked questions:

Bronze is stronger than copper. Bronze, an alloy primarily composed of copper and tin, exhibits a tensile strength ranging from 350 to 635 MPa, whereas copper’s tensile strength is around 210 MPa. The yield strength of bronze varies between 125 to 800 MPa, significantly higher than copper’s yield strength of approximately 33.3 MPa. The addition of tin or other elements in bronze enhances its strength and hardness, making it ideal for applications requiring durability and resistance to wear. Therefore, for applications where mechanical strength and resistance to deformation are critical, bronze is the preferred material over copper.

Choosing copper over bronze is preferable when your application prioritizes high electrical or thermal conductivity, as copper excels in these areas. Copper is also advantageous when ease of forming or shaping is essential, given its high ductility and malleability. This makes copper ideal for uses such as electrical wiring, roofing, and decorative elements, where detailed work is necessary. Additionally, copper is a good choice when the environment is not highly corrosive, or if corrosion resistance can be managed through other means. Copper tends to be more cost-effective due to its simpler processing and availability, making it suitable for projects with budget constraints. Flexibility and wear resistance are important factors, but if structural strength is less critical, copper is the material of choice.

When comparing corrosion resistance between bronze and copper, bronze generally offers superior performance. Copper, a pure metal, forms a protective oxide layer known as patina when exposed to air, which helps shield it from further corrosion. This makes copper suitable for applications exposed to moisture and atmospheric elements, such as water pipes and electrical components.

Bronze, an alloy primarily composed of copper and tin, sometimes includes other elements like aluminum, nickel, or phosphorus, which significantly enhance its corrosion resistance. Bronze also forms a protective patina, but it is particularly resistant to harsh environments, including marine settings. Tin and aluminum bronzes excel in resisting saltwater corrosion, making them ideal for boat fittings, ship propellers, and other marine hardware. Furthermore, bronze alloys often perform better than pure copper in industrial settings where exposure to corrosive substances is common.

Copper offers significantly better electrical conductivity compared to bronze. Copper is the industry standard for electrical conductivity, rated at 100%, making it the preferred choice for applications requiring efficient energy transfer, such as electrical wiring, connectors, and circuit boards. Bronze, an alloy primarily composed of copper and tin, has a much lower electrical conductivity, roughly 15% of that of copper. This reduction in conductivity is due to the presence of alloying elements that disrupt the uniform lattice structure of copper, impeding the free flow of electrons. Consequently, while copper is ideal for electrical applications, bronze is more suitable for uses where mechanical strength, corrosion resistance, and wear resistance are prioritized over electrical performance.

Bronze and copper have distinct cost differences driven by their composition and production processes. Copper, being a pure metal, generally commands a higher price due to intensive mining, extraction, and refining processes. It is highly demanded in electrical and telecommunications industries for its superior conductivity, which justifies its higher cost.

Bronze, on the other hand, is an alloy primarily composed of copper and tin, with other elements like aluminum, manganese, or silicon. The cost of bronze is influenced by the prices of these constituent metals, particularly tin, which can fluctuate based on availability. While the alloying process for bronze adds complexity and cost, bronze typically remains less expensive than pure copper due to its reduced copper content and the inclusion of cheaper alloying elements.

When comparing the environmental impacts of using bronze versus copper, several factors are relevant, including material sourcing, production processes, recyclability, and durability.

Copper extraction and processing have significant environmental impacts, such as habitat disruption and water contamination. However, copper is highly recyclable, which helps mitigate some of these effects by reducing the need for primary extraction. This recyclability also contributes to copper’s long lifespan, making it a sustainable material over time.

Bronze, an alloy primarily composed of copper and tin, shares some of the environmental concerns associated with copper extraction. Nonetheless, bronze is highly durable and recyclable, which means it requires less frequent replacement compared to copper. This enhanced durability reduces waste generation and the environmental footprint associated with producing new materials.

In terms of applications, copper is extensively used in industries requiring high electrical and thermal conductivity, such as electrical wiring and water pipes. This widespread use increases demand and can lead to greater environmental impacts due to more intensive extraction needs. On the other hand, bronze is preferred for applications like marine hardware and high-strength components due to its superior corrosion resistance and mechanical strength, which reduces the need for frequent replacements and minimizes waste.

Cost-wise, copper is generally more expensive than bronze due to its extensive extraction and refining processes. However, its recyclability and long lifespan contribute to its overall sustainability. Bronze, while possibly having a higher initial cost, offers cost-effective benefits over time due to its durability and lower maintenance needs, thereby reducing long-term environmental impacts.