Have you ever wondered if that trusty can of Brasso in your cleaning cabinet is safe for your stainless steel appliances? If so, you’re not alone. Many people reach for Brasso, a well-known metal polish, to restore the shine on their stainless steel items, only to question if it’s the best choice. In this article, we’ll dive into whether Brasso is safe for stainless steel and explore the best alternatives for polishing this versatile metal. We’ll also provide a step-by-step guide on how to use Brasso safely, should you choose to proceed. Ready to uncover the secrets to maintaining your stainless steel’s luster? Let’s get started.

Brasso is a popular metal polish renowned for its ability to clean and bring a brilliant shine to various metals. Introduced in the early 20th century, it is particularly effective on softer metals like brass and copper but can also be used on chrome and stainless steel. Brasso removes tarnish and oxidation, leaving the metal shiny and polished.

Brasso contains a combination of chemicals and abrasives. Key ingredients include hydrocarbons, ammonia, silica powder, and oxalic acid. These components work together to polish the metal and remove tarnish. The polishing action of Brasso is often indicated by a chalk-like residue that forms during use, signaling the removal of oxidation.

Stainless steel is a corrosion-resistant alloy made primarily of iron, chromium, and other elements such as nickel and molybdenum. The chromium content (at least 10.5%) forms a thin, protective oxide layer on the surface, which prevents rusting and gives stainless steel its characteristic shine.

Brasso is used for polishing a variety of metal items, including:

Using Brasso on stainless steel is debatable.

To use Brasso safely on stainless steel:

Stainless steel is a highly versatile and popular material known for its impressive range of properties. These characteristics make it suitable for various applications, from kitchen appliances to industrial equipment.

One of the most significant properties of stainless steel is its excellent corrosion resistance. This is mainly because of its chromium content, which creates a thin, self – repairing layer of chromium oxide on the surface. Different grades, such as 304 and 316 stainless steel, offer varying levels of resistance, with 316 being particularly effective in more corrosive environments like marine applications. Additionally, stainless steel is renowned for its strength and durability.

It has high tensile strength, which can be increased through cold working or heat treatment. This makes it an ideal material for applications requiring robust and long – lasting components, such as construction materials and medical instruments.

In addition to its functional properties, stainless steel is also valued for its aesthetic appeal. It has a clean, modern look that is both practical and decorative. Its smooth surface can be polished to a high gloss or given a brushed finish, making it suitable for various design preferences.

Proper care and maintenance of stainless steel are essential to preserve its appearance and functionality. Here are some general tips to help maintain your stainless steel items:

Regular cleaning with mild soap or detergent and warm water, followed by a rinse with clean water, is essential to keep stainless steel looking its best. This method is usually sufficient for most applications and helps prevent staining and build – up of residues.

For more stubborn stains or signs of corrosion, specialized cleaning products may be necessary. Phosphoric acid – based cleaners, such as E – NOX CLEAN, can be effective. However, it is crucial to follow up with an alkaline neutralizer and a thorough rinse to prevent any potential damage to the protective layer.

Even though stainless steel is highly durable, it can still encounter some common issues. Here are a few problems you might face and how to address them:

Scratches can compromise the protective chromium oxide layer. To avoid this, never use abrasive materials or strong acids when cleaning. For existing scratches, you can use a non – abrasive stainless steel polish to minimize their appearance.

Discoloration can occur due to exposure to certain chemicals or high temperatures. To prevent this, avoid using harsh cleaners and ensure regular maintenance. If discoloration occurs, specialized stainless steel cleaners can help restore the original finish.

Maintaining stainless steel involves more than just cleaning; it also includes regular inspections and preventive measures:

Stainless steel can be contaminated by contact with carbon steel or galvanized materials, leading to rust or staining. To prevent this, use stainless steel fasteners and tools when handling stainless steel products.

Performing routine inspections every six months can help identify any potential issues early. Regular maintenance ensures that your stainless steel items remain in optimal condition and continue to perform well.

In aggressive environments, such as areas with high humidity or marine settings, stainless steel may require more frequent maintenance. This helps to prevent corrosion and maintain its appearance over time.

When using Brasso on stainless steel, it’s essential to follow safety guidelines to ensure your safety and protect the environment. Brasso is flammable, can irritate the eyes, and is harmful if swallowed.

Always follow local and national regulations for storing, using, and disposing of Brasso. Make sure the product is labeled correctly and kept out of children’s reach to prevent accidents and environmental harm.

Wear gloves and eye protection to avoid skin and eye irritation, and ensure good ventilation by opening windows or using fans to avoid inhaling vapors.

Keep Brasso away from heat, sparks, and open flames. Use non-sparking tools and explosion-proof equipment, and store it in a cool, dry place with the container tightly sealed.

Clean the stainless steel surface thoroughly before applying Brasso to remove any dirt, grease, or residue.

By following these steps and precautions, you can use Brasso on stainless steel safely, ensuring a polished and shiny finish without risking damage to the surface.

When it comes to polishing stainless steel, several alternatives to Brasso can provide effective and safe results without its potential drawbacks.

Features and Benefits:

Magic Stainless Steel Cleaner & Polish is specifically designed for stainless steel surfaces, making it a reliable choice for maintaining a clean and shiny appearance.

Features and Benefits:

Hope’s Perfect Sink Cleaner and Polish is particularly useful for kitchen sinks and other high-use areas, ensuring they remain spotless and shiny with minimal effort.

Features and Benefits:

Bar Keepers Friend is a strong cleaner that can tackle difficult stains but should be used carefully to avoid damage.

Features and Benefits:

Simichrome Polish is known for its ability to produce a high-gloss finish, making it a good choice for those seeking a polished, reflective surface.

Features and Benefits:

Autosol is versatile and provides a durable finish, making it a valuable option for stainless steel items that require regular maintenance.

Features and Benefits:

Flitz and Maas Polishes are gentle yet effective, making them suitable for a variety of applications without the risk of scratching or damaging the surface.

When selecting a polish for stainless steel, it is essential to consider the specific needs and characteristics of the item being polished. Here’s a comparative analysis to help you choose the best product:

When polishing stainless steel, it’s important to choose products that are non-abrasive to avoid damaging the surface. Regular maintenance and using the right polish can help preserve the appearance and durability of your stainless steel items. Always follow the manufacturer’s instructions for the best results and ensure that the chosen product is appropriate for the specific type of stainless steel you are working with.

Below are answers to some frequently asked questions:

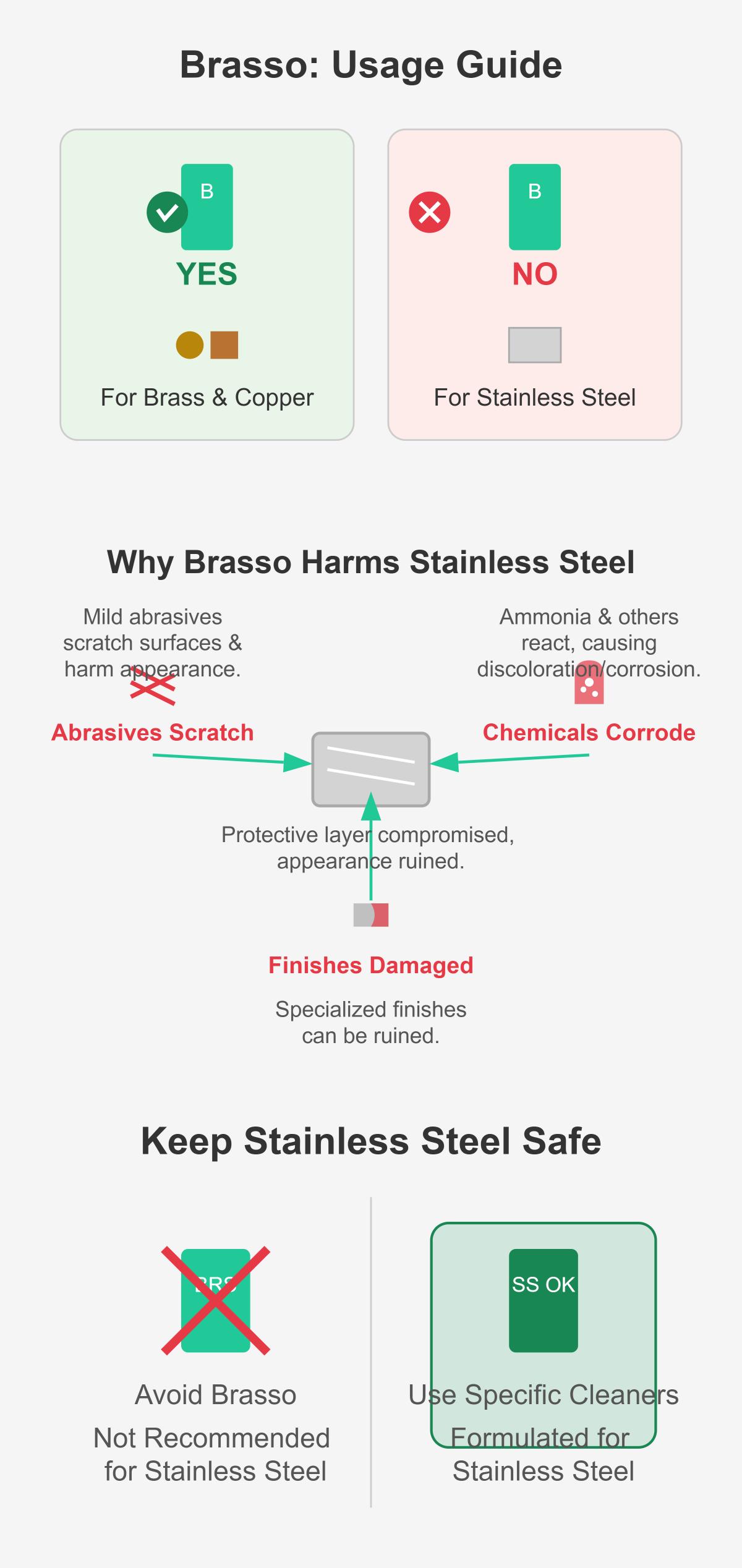

Brasso is a well – known metal polish for brass and copper, but its use on stainless steel is debated. It contains mild abrasives that can scratch stainless steel surfaces, harming the appearance and protective chromium oxide layer, making it prone to corrosion. The ammonia and other chemicals in Brasso may react negatively with stainless steel, causing discoloration or corrosion over time. It can also damage specialized finishes on stainless steel. In general, Brasso is not recommended for stainless steel. Instead, use cleaners specifically formulated for this material.

For polishing stainless steel, there are several effective alternatives to Brasso that are specifically formulated to avoid potential damage and leave a streak-free finish:

When choosing an alternative, consider products that are non-abrasive, provide a streak-free finish, offer protective coatings, and are specifically formulated for stainless steel to maintain its protective layer and aesthetic appeal.

The frequency of polishing stainless steel items depends on their usage and environment. For items in demanding settings like food handling or medical applications, daily or weekly polishing might be necessary to maintain hygiene and prevent corrosion. Household items such as appliances and cutlery generally require polishing every couple of months to maintain their shine and protect the surface. External applications, particularly in coastal or marine environments, might need polishing every 3-12 months due to exposure to salt and humidity. Avoid using abrasive products like Brasso, which can scratch and discolor stainless steel. Instead, use non-abrasive cleaners specifically formulated for stainless steel.

Brasso, a metal polish traditionally used for brass and copper, can technically be used on stainless steel but is not recommended for removing scratches. This is because Brasso contains abrasive particles that can further scratch and damage the surface of stainless steel, especially on polished or brushed finishes. The abrasive nature of Brasso can also compromise the protective chromium oxide layer on stainless steel, leading to increased vulnerability to rust and discoloration.

For safer alternatives to remove scratches from stainless steel, consider using products like Bar Keepers Friend, which is gentle yet effective, or Scotch Brite pads, available in various grades for buffing out scratches. For deeper scratches, fine-grit sandpaper can be used carefully. Always follow the grain of the stainless steel to avoid additional damage.

Yes, there are eco-friendly stainless steel polishes available. These products are designed to clean and polish stainless steel surfaces effectively while using environmentally safe ingredients. For example, ECOS Stainless Steel Cleaner + Polish is free from chlorine, bleach, and ammonia, and is certified by the U.S. Environmental Protection Agency’s Safer Choice program. Another option is ECOS PRO Stainless Steel Cleaner & Polish, which is water-based and recognized by both the U.S. EPA’s Safer Choice and USDA’s BioPreferred Program. Additionally, Eco-Me Stainless Steel Polish uses a plant-based cleaning system and essential oils, avoiding harsh preservatives and sulfates. These eco-friendly alternatives provide a safer choice for both users and the environment.

Using Brasso on stainless steel can pose several risks. Brasso contains mild abrasives that may scratch the smooth surface of stainless steel and compromise its protective chromium oxide layer, making it more prone to corrosion. The ammonia in Brasso can cause discoloration or streaks, especially on high – gloss or fingerprint – resistant finishes, and may even strip away specialty coatings. Additionally, if not cleaned thoroughly, Brasso residue can build up, dulling the surface and potentially promoting corrosion. It’s advisable to use products designed for stainless steel to avoid these issues.