Imagine you’re tasked with choosing the perfect material for an ambitious aerospace project or a high-stakes medical device. The decision isn’t trivial—every property counts. Enter the debate between carbon steel and titanium, two titans in the world of materials science. What are the key differences between them? Which one excels in specific industries like aerospace or construction? And how do they stack up in terms of cost and manufacturing complexity? This article dives deep into these questions, offering a comprehensive comparison of carbon steel and titanium, from their material properties to their applications, manufacturing considerations, and environmental impact. Are you ready to uncover which material reigns supreme for your next big project? Let’s explore the fascinating nuances of carbon steel versus titanium.

Carbon steel is an alloy made mostly of iron and carbon, with the carbon content varying up to 2.1% by weight. It can also include other elements such as manganese, silicon, and trace amounts of impurities. Titanium, on the other hand, is a pure metal often alloyed with elements like aluminum and vanadium to enhance its properties.

One of the most notable differences between carbon steel and titanium is their density; carbon steel has a density of approximately 7.8 to 8 g/cm³, whereas titanium is much lighter, with a density of about 4.5 g/cm³. This makes titanium a preferred choice for applications where weight reduction is crucial.

Tensile strength is a measure of the force required to pull something to the point where it breaks. Carbon steel generally exhibits higher tensile yield strength, ranging from 250 to 750 MPa depending on the specific grade. Titanium’s tensile yield strength varies from 140 to 350 MPa, but titanium alloys can achieve higher values, making them suitable for high-stress applications.

Titanium is known for its high strength compared to its weight. Despite being lighter, it can handle significant forces, making it ideal for aerospace and other weight-sensitive applications. Carbon steel, while strong, is heavier, which can be a disadvantage in applications requiring lightweight materials.

Titanium naturally forms a protective oxide layer, giving it excellent resistance to corrosion, especially in tough environments like marine and medical applications. In contrast, carbon steel tends to corrode more easily and often needs protective coatings or treatments to last longer.

Fatigue strength measures how well a material can endure repeated loading and unloading without breaking. Titanium excels in this area, with values ranging from 530 to 630 MPa, compared to carbon steel’s approximate 200 MPa. This makes titanium especially suitable for applications involving cyclic stress, like medical implants and aerospace components.

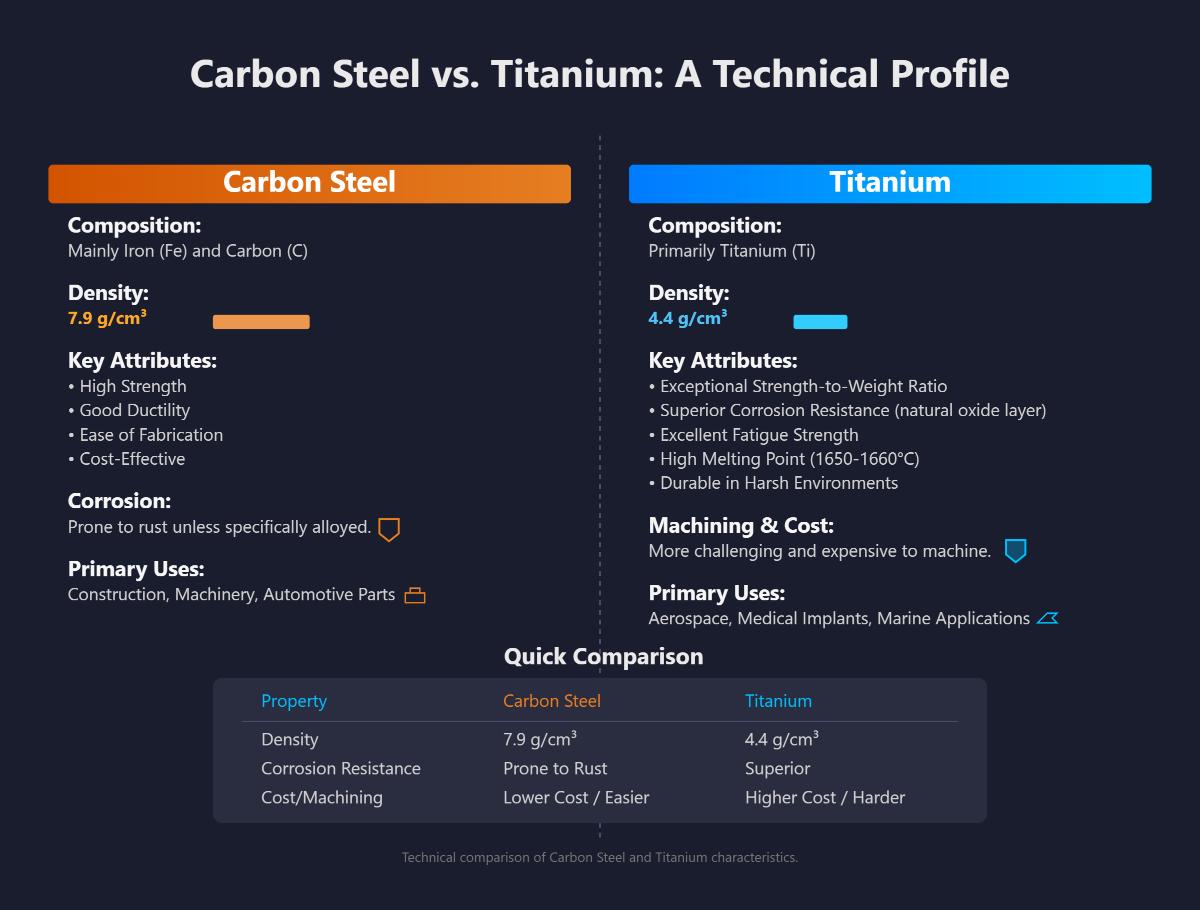

To provide a clear and concise comparison, the following table summarizes the key material properties of carbon steel and titanium:

| Property | Carbon Steel | Titanium |

|---|---|---|

| Density (g/cm³) | 7.8 – 8 | 4.5 |

| Tensile Yield Strength (MPa) | 250 – 750 | 140 – 350 |

| Strength-to-Weight Ratio | Lower | Higher |

| Corrosion Resistance | Moderate | High |

| Fatigue Strength (MPa) | ~200 | 530 – 630 |

Aerospace applications prioritize materials with a high strength-to-weight ratio. Titanium’s high strength and low density make it ideal for aerospace use, where minimizing weight is essential without compromising structural integrity. Its exceptional corrosion resistance ensures longevity and reliability in harsh environments, such as high-altitude conditions and exposure to aviation fuels. Titanium is commonly used in airframe structures, engine components, and fasteners. Carbon steel, while robust, is significantly heavier, making it less suitable for weight-sensitive aerospace applications. However, it may still be used in areas where cost constraints are more critical, and weight is less of a concern.

Titanium’s biocompatibility makes it the material of choice for medical implants and devices. Its resistance to corrosion in bodily fluids and non-toxic nature ensure that it can remain in the body without causing adverse reactions. Additionally, titanium’s high fatigue strength is crucial for implants subjected to repetitive loading, such as hip and knee replacements. Carbon steel, though strong and durable, lacks the corrosion resistance and biocompatibility required for long-term implantation in the human body. It is more commonly used in external medical devices and instruments where it is not in direct contact with bodily fluids.

In marine environments, materials must withstand constant exposure to saltwater, which can be highly corrosive. Titanium’s natural coating that resists corrosion makes it suitable for long-term use in seawater without significant degradation. It is used in applications such as ship hulls, offshore platforms, and marine hardware. The high initial cost of titanium is offset by its low maintenance requirements and extended service life. Carbon steel, while initially less expensive, requires protective coatings and regular maintenance to prevent rust and corrosion. It is often used in shipbuilding and marine infrastructure where cost considerations are paramount, and regular maintenance is feasible.

The automotive industry benefits from both carbon steel and titanium, depending on the application. Carbon steel is prevalent in mass-produced vehicles due to its affordability and ease of fabrication. It also provides sufficient strength for most structural components like chassis and body panels. However, in high-performance and racing vehicles, where weight reduction directly translates to improved speed and fuel efficiency, titanium is preferred. Titanium’s strength-to-weight ratio and resistance to high temperatures make it ideal for components such as exhaust systems, suspension parts, and engine valves. While more costly, the performance benefits in these niche applications justify the use of titanium.

Titanium’s unique properties have made it a popular choice in the sporting goods industry. Its high strength, light weight, and fatigue resistance are advantageous in products like high-end golf clubs, bicycle frames, and tennis rackets. Athletes and enthusiasts seek equipment that offers superior performance and durability, and titanium’s characteristics meet these demands. Carbon steel, being heavier and less flexible, is less commonly used in high-end sporting goods. However, it remains a cost-effective option for entry-level and recreational equipment where the performance demands are lower, and affordability is a key factor.

The choice between carbon steel and titanium depends largely on specific application requirements, balancing factors such as weight, strength, corrosion resistance, and cost. Each material offers distinct advantages that make it suitable for different industrial and consumer needs.

Carbon steel is known for its superior machinability and ease of fabrication, thanks to its higher elasticity and lower hardness. These properties allow for faster cutting speeds and reduced tool wear, making the machining process more efficient and cost-effective. Standard machining techniques and conventional tools are compatible with carbon steel, minimizing setup complexity and reducing the need for specialized equipment. This compatibility with existing machinery and processes simplifies production and lowers overall manufacturing costs.

Titanium, in contrast, presents more challenges in machining and fabrication. Its low thermal conductivity causes heat buildup during cutting, leading to tool sticking, work hardening, and deformation, which necessitates lower cutting speeds, advanced cooling systems, and coated tools like carbide. These specialized tools and processes increase the complexity and cost of machining titanium. Additionally, titanium’s high reactivity at elevated temperatures necessitates careful control of the fabrication environment to prevent contamination and ensure quality.

Carbon steel’s melting point varies with carbon content, making it easier to work with during thermal treatments like casting and welding. Titanium, with a high melting point of around 1,668°C, requires energy-intensive processes for forming and joining. This high melting point increases the complexity and cost of processing titanium, requiring specialized equipment and techniques.

Carbon steel responds predictably to common heat treatments such as annealing, quenching, and tempering. These treatments allow manufacturers to tailor the material’s strength and toughness to meet specific requirements. Titanium, however, requires precise temperature control during heat treatment to avoid embrittlement. The need for such precision increases processing costs and demands a higher level of expertise, further contributing to the complexity of working with titanium.

The manufacturing overheads for titanium are higher due to the need for specialized labor, tooling, and slower production rates. The additional expenses associated with managing heat buildup and preventing tool wear during machining also contribute to the increased costs. Carbon steel’s simpler processes reduce these overheads, making it more cost-efficient for large-scale production where budget constraints are a primary concern.

Carbon steel, although strong and versatile, is prone to rust and corrosion unless coated or alloyed. Protective measures like painting or galvanizing add to maintenance costs but are necessary for durability. These measures, however, add to the long-term maintenance costs and require regular upkeep to ensure the material’s longevity.

Titanium naturally forms a protective oxide layer that gives it excellent corrosion resistance, especially in harsh environments like marine, chemical, and biomedical applications. This inherent resistance eliminates the need for additional coatings and reduces maintenance costs over the material’s lifespan. Although the upfront investment for titanium is higher, its durability and low maintenance requirements can justify the initial expense in applications where corrosion resistance is critical.

Titanium’s superior strength-to-weight ratio makes it particularly advantageous in industries such as aerospace and automotive, where reducing weight without compromising strength is essential. Titanium is up to three times lighter than carbon steel at comparable strength levels, which translates to significant performance benefits in weight-sensitive applications. Its high fatigue resistance further enhances its suitability for dynamic load applications, where materials must withstand repeated stress cycles.

While carbon steel offers higher absolute tensile strength in some high-carbon alloys, its greater weight can be a disadvantage in applications where weight savings are crucial. This higher weight limits its use in designs that prioritize weight reduction, such as aerospace components and high-performance automotive parts. However, carbon steel remains ideal for heavy-load structures like bridges and buildings, where its strength and stiffness are more critical than weight savings.

Carbon steel is commonly used in construction and manufacturing because it is affordable and readily available. Its production is energy-intensive and leads to a significant carbon footprint. Additionally, it is prone to rust, necessitating frequent maintenance and protective coatings.

Titanium is known for its strength, corrosion resistance, and high strength-to-weight ratio, making it ideal for aerospace and marine applications. While its production is more energy-intensive compared to carbon steel, titanium’s long lifespan and recyclability mitigate its initial environmental impact.

While carbon steel production generates substantial CO2 emissions, titanium’s more energy-intensive production process results in a higher initial carbon footprint. However, titanium’s durability can offset its initial energy costs over time.

Steel is recyclable, but its recycling rate is generally lower compared to titanium. Often, reprocessing is required to maintain quality, which can be energy-consuming. The environmental impact of steel production remains significant due to high energy consumption and emissions. Titanium boasts an impressive recycling rate of approximately 95%, allowing it to be reused multiple times without significant degradation in quality. This high recyclability significantly reduces the environmental impact associated with mining and processing new titanium resources.

Carbon steel requires regular maintenance to prevent rust and corrosion, leading to higher long-term costs. Protective coatings and inspections add to its environmental footprint. Titanium offers superior corrosion resistance, reducing the need for protective coatings and frequent inspections. Its long lifespan means fewer replacements are needed, minimizing waste and reducing the cumulative environmental impact.

Carbon steel is suitable for less demanding applications where cost-effectiveness is a priority. Its stiffness and higher elongation at break make it beneficial in applications requiring flexibility and toughness. Titanium is ideal for harsh environments where corrosion resistance and strength are crucial, such as marine and aerospace industries. Its superior strength-to-weight ratio is advantageous in applications where reducing weight is important.

Titanium’s lower density offers a better strength-to-weight ratio, making it ideal for weight-sensitive applications like aerospace and high-performance vehicles.

Carbon steel typically has a higher tensile yield strength (250-750 MPa) compared to titanium (140-350 MPa). However, titanium alloys can achieve higher values, making them suitable for high-stress applications. Titanium also exhibits excellent fatigue strength, ranging from 530 to 630 MPa, compared to carbon steel’s approximate 200 MPa, making it particularly suitable for applications involving cyclic stress, such as medical implants and aerospace components.

Titanium forms a natural oxide layer that resists corrosion, making it ideal for marine and medical uses. Carbon steel, on the other hand, tends to corrode more easily and often requires protective coatings or treatments to enhance its longevity.

Titanium is significantly more expensive than carbon steel, with prices ranging from $35 to $50 per kilogram compared to carbon steel’s generally lower cost. Titanium’s higher cost is justified by its advantages in applications where weight and corrosion resistance are crucial.

Titanium’s high strength-to-weight ratio and exceptional corrosion resistance make it ideal for aerospace applications, including airframe structures, engine components, and fasteners. Carbon steel, though robust, is heavier and less suitable for weight-sensitive aerospace components.

Titanium’s biocompatibility and high fatigue strength make it the preferred material for medical implants and devices. Carbon steel, while strong, lacks the necessary corrosion resistance and biocompatibility for long-term implantation in the human body.

In marine environments, titanium’s resistance to corrosion in saltwater makes it suitable for ship hulls, offshore platforms, and marine hardware. Carbon steel, requiring protective coatings and regular maintenance, is often used in shipbuilding and marine infrastructure where cost considerations are more critical.

Carbon steel is easier to machine and fabricate due to its higher elasticity and lower hardness, making the machining process more efficient and cost-effective. Titanium presents more challenges, requiring specialized tools and slower production rates due to its lower thermal conductivity and higher reactivity at elevated temperatures.

While titanium production is more energy-intensive, its high recyclability and long lifespan mitigate its initial environmental impact. Carbon steel production generates substantial CO2 emissions, but its recyclability, though lower than titanium, still contributes to reducing its overall environmental footprint.

Choosing between carbon steel and titanium depends on the application, balancing weight, strength, corrosion resistance, and cost. Each material has unique advantages for different uses. Carbon steel’s higher stiffness and strength make it suitable for heavy load-bearing structures like bridges and buildings. Titanium is favored in dynamic applications with repeated stress and where weight reduction is critical, such as in aerospace and sports equipment. Titanium’s natural oxide layer provides superior corrosion resistance, reducing maintenance costs over its lifespan. Carbon steel requires protective coatings and regular upkeep to prevent rust and ensure durability.

Below are answers to some frequently asked questions:

Carbon steel and titanium differ significantly in several key aspects, making them suited to distinct applications. Carbon steel, composed mainly of iron and carbon, is known for its high strength and ductility, with a density of 7.9 g/cm³. It is commonly used in construction and machinery due to its ease of fabrication and cost-effectiveness. However, it is prone to rust unless alloyed for improved corrosion resistance.

Titanium, with a density of 4.4 g/cm³, is much lighter and offers an exceptional strength-to-weight ratio, making it ideal for aerospace and medical applications. It boasts superior corrosion resistance thanks to its natural oxide layer, excellent fatigue strength, and a higher melting point (1650 to 1660°C). These properties make titanium more durable in harsh environments but also more challenging and expensive to machine.

In specific industries such as aerospace and construction, the suitability of materials like carbon steel and titanium varies based on their unique properties.

For the aerospace industry, titanium is the preferred material due to its superior strength-to-weight ratio, excellent corrosion resistance, and ability to withstand extreme temperatures. Its lower density (4.5 g/cm³ compared to carbon steel’s 7.9 g/cm³) helps reduce the overall weight of aircraft, improving fuel efficiency and performance. Additionally, titanium’s high fatigue strength and natural corrosion resistance are crucial for components exposed to repeated stress cycles and harsh environments.

In contrast, carbon steel is more suited for the construction industry. Its high strength, stiffness, and cost-effectiveness make it ideal for building frames, beams, and other structural elements. While carbon steel’s higher density limits its use in weight-sensitive applications, its durability and ease of fabrication are advantageous in large-scale construction projects. The material’s high thermal conductivity also aids in heat dissipation, which can be beneficial in certain construction scenarios.

Thus, titanium is better suited for aerospace applications, where weight and corrosion resistance are critical, while carbon steel is the preferred choice in construction due to its strength, cost-effectiveness, and ease of manufacturing.

In terms of cost, carbon steel is generally more affordable than titanium. This is due to its widespread availability and simpler manufacturing processes, which include rolling, forging, and heat treatment. These processes are well-established and can be easily scaled for large production volumes, making carbon steel a cost-effective choice for many applications.

On the other hand, titanium is significantly more expensive. Its high cost stems from the complex extraction and processing methods required, as well as the need for specialized equipment and techniques. Despite these higher costs, titanium offers unique advantages, such as a superior strength-to-weight ratio and excellent corrosion resistance, which can justify its use in industries where these properties are critical.

Manufacturing complexity further distinguishes the two materials. Carbon steel is easier to machine and fabricate, reducing the need for specialized tools. Titanium, however, presents challenges due to its poor thermal conductivity and tendency to work harden, necessitating advanced machining tools and techniques, as well as specialized coolants.

When comparing the environmental impacts of using carbon steel versus titanium, several factors must be considered: raw material extraction, production energy consumption, recyclability, lifespan, and overall carbon footprint.

Titanium production is significantly more energy-intensive than carbon steel, primarily due to the Kroll process, which requires high temperatures and substantial energy, leading to higher CO2 emissions. Titanium mining also has notable environmental impacts such as deforestation and habitat destruction. However, titanium’s high recyclability rate (approximately 95%) and its long service life due to excellent corrosion resistance offset these initial environmental costs. This durability reduces the frequency of replacements and maintenance, thus lowering long-term environmental impact.

In contrast, carbon steel has a lower initial carbon footprint due to less energy-intensive production processes. However, carbon steel is prone to rust and corrosion, necessitating frequent maintenance and protective coatings, which can increase its cumulative environmental impact over time. Additionally, carbon steel’s recyclability is lower than that of titanium, and its shorter lifespan means more frequent replacements, leading to higher overall material consumption.

Several case studies highlight the advantages of carbon steel and titanium in different applications. For instance, in the construction of high-rise buildings, carbon steel is preferred due to its excellent structural integrity, higher ductility, and cost-effectiveness. It exhibits an elongation at break of about 22%, which allows it to absorb more energy before fracture, making it ideal for dynamic loads such as wind and seismic activity.

In contrast, titanium demonstrates significant advantages in highly corrosive environments, such as offshore seawater piping. Its natural oxide layer provides superior corrosion resistance, reducing maintenance costs and extending service life. Although the initial cost of titanium is higher, its long-term durability makes it a cost-effective choice for marine and chemical processing industries.

In aerospace and automotive applications, titanium’s low density and high strength make it suitable for components where weight reduction is crucial without compromising mechanical performance. Titanium also maintains structural integrity at higher temperatures, which is essential for aerospace engines and high-performance vehicles.

These examples underscore the importance of selecting materials based on specific application requirements, balancing factors such as mechanical properties, environmental conditions, cost, and longevity.

When comparing the strength and fatigue properties of carbon steel and titanium in real-world applications, key distinctions become evident.

Carbon steel generally exhibits higher tensile and yield strength compared to titanium, with carbon steel’s yield strength ranging from 350 MPa to over 1,800 MPa, whereas titanium’s yield strength is around 140–350 MPa. This makes carbon steel advantageous for applications requiring high strength. However, titanium’s superior strength-to-weight ratio makes it ideal where weight reduction is crucial, such as in aerospace and automotive industries.

Regarding fatigue properties, titanium outperforms carbon steel. Titanium’s ability to endure repeated stress cycles without significant degradation is essential in applications like aerospace and sports equipment, where components face cyclic stresses. Carbon steel, while stronger in some respects, is more prone to fatigue cracking, limiting its suitability for such applications.

In terms of elongation at break, titanium shows greater ductility, with some alloys stretching nearly 54% before breaking compared to carbon steel’s 15–22%. This higher ductility makes titanium better for applications requiring toughness and resistance to sudden impacts, such as medical implants.