Have you ever wondered why some structures use chemical bolts while others rely on anchor bolts? At first glance, they might seem interchangeable, but these two fasteners serve distinct purposes in construction and engineering. Understanding their differences can be crucial for ensuring the stability and longevity of your projects.

In this article, we’ll delve into the world of chemical and anchor bolts, exploring their definitions, uses, and advantages. We’ll compare the processes of chemical and mechanical anchoring to help you decide when to use each type. Along the way, you’ll discover their load-bearing capacities, installation procedures, and long-term performance.

So, which bolt is right for your next project? Let’s dive in and find out!

A chemical bolt, also known as a chemical anchor or glued-in anchor, is a fastening system that uses a specially formulated adhesive to secure an anchor within a substrate like concrete. This adhesive is typically a two-part epoxy, polyester, or vinylester resin. The system includes a high-strength threaded rod or rebar, a chemical cartridge containing the resin and hardener, and an injection gun for dispensing and mixing the resin components into a pre-drilled hole. Once installed, the chemical adhesive bonds the rod to the substrate, creating a strong, durable connection that resists vibrations and environmental conditions.

Chemical bolts are widely used in various construction scenarios due to their adaptability and strength. Some common applications include:

Chemical bolts offer a robust and versatile solution for demanding construction applications. They provide superior performance in challenging environments and ensure long-term structural integrity.

Anchor bolts are specialized fasteners that connect structural or non-structural elements to concrete. They play a crucial role in construction and engineering projects by securing steel columns, machinery, light poles, and other heavy equipment to concrete foundations or surfaces. Anchor bolts are designed to transfer loads such as tension (pulling forces) and shear (sliding forces), ensuring the stability of attached structures under various stresses.

Typically made of high-strength steel and featuring a threaded end for nuts or washers, anchor bolts are designed to withstand substantial loads and resist compromising forces. These bolts are embedded securely in concrete, providing a permanent and durable solution essential for industrial and civil engineering applications.

There are several types of anchor bolts, each designed for specific installation methods and applications:

Cast-in-place anchor bolts are set in concrete before it hardens, providing a permanent anchor. These bolts are ideal for new construction projects where the concrete can be molded around the bolt, ensuring a strong and stable connection.

Mechanical expansion anchors are inserted into drilled holes and expanded to securely grip the concrete. This type includes wedge anchors and sleeve anchors, which use wedges or sleeves to secure the bolt in the hole. They are suitable for applications where the bolt needs to be inserted after the concrete has cured.

Undercut anchors are designed with a special undercut shape that enhances grip within the concrete. These anchors provide superior holding strength by creating a mechanical interlock with the concrete, making them ideal for heavy-duty applications.

Anchor bolts are preferred in scenarios requiring robust, permanent fastening embedded within concrete. They are ideal for:

Anchor bolts differ from chemical bolts primarily in their installation and bonding mechanisms. While anchor bolts rely on mechanical embedment or cast-in-place methods, chemical bolts use adhesive resin injected into drilled holes to bond the bolt to the concrete chemically.

| Feature | Anchor Bolt | Chemical Bolt |

|---|---|---|

| Installation Method | Mechanical embedment or cast-in-place | Bonded with adhesive resin injected into drilled hole |

| Load Transfer | Direct mechanical interlock with concrete | Load transferred through chemical adhesive bond |

| Holding Strength | Depends on bolt design and concrete strength | Generally offers higher tensile and shear strengths due to chemical adhesion |

| Flexibility | Less flexible once installed, requires precise placement | More flexible placement as adhesive fills gap, allowing for irregular holes |

| Corrosion Resistance | Depends on bolt coating and material | Adhesive can provide some protection, but bolt material still critical |

| Applications | Heavy structural anchoring, machinery bases, steel columns | Retrofitting, cracked concrete, thin slabs, or where vibration resistance is needed |

These distinctions help engineers and builders choose the best fastening method for safety, durability, and performance in different construction scenarios.

Chemical anchoring involves using resin-based adhesives to secure anchors within substrates like concrete, brick, or block. The process begins by drilling a hole in the substrate, cleaning it thoroughly, and then injecting the adhesive. The anchor is then inserted into the adhesive-filled hole, and the adhesive hardens to form a strong chemical bond.

Mechanical anchoring relies on friction or expansion to secure anchors within substrates. These anchors are typically installed by screwing or wedging them into pre-drilled holes, providing immediate holding power.

| Feature | Chemical Anchors | Mechanical Anchors |

|---|---|---|

| Bonding Method | Chemical adhesive bond | Mechanical friction or expansion |

| Installation Time | Requires curing time | Immediate use after installation |

| Flexibility | Offers flexibility against vibrations and movements | Less flexible, may not handle vibrations well |

| Load Capacity | High load capacity | Generally lower load capacity than chemical anchors |

| Cost and Sensitivity | More expensive to install; sensitive to installation conditions and environmental factors | Less expensive to install; more tolerant of minor installation errors |

| Applications | Heavy-duty applications requiring high load capacity and flexibility; sensitive to environmental conditions | Quick installations with moderate load requirements; less suitable for applications with significant movements |

Chemical anchors are ideal for:

Mechanical anchors are best for:

Chemical bolts utilize a resin-based adhesive to secure bolts into substrates such as concrete or masonry. This method ensures high load capacity and resistance to environmental factors. The installation process is detailed and requires precision.

Mechanical anchor bolts rely on physical expansion or deformation to secure the bolt in the substrate. This method is faster and simpler compared to chemical bolts.

| Aspect | Chemical Bolt (Chemical Anchor) | Mechanical Anchor Bolt |

|---|---|---|

| Installation Complexity | More involved; requires precise cleaning and curing time | Simpler; involves inserting and setting the anchor |

| Hole Cleaning Importance | Critical; thorough cleaning required | Important but less critical |

| Setting Method | Bolt rotation to mix adhesive inside hole | Physical expansion or deformation |

| Curing Time | Requires time for gelling and hardening | Immediate load-bearing after setting |

| Load Capacity | Generally higher due to chemical bonding | Depends on mechanical expansion; less effective in cracked substrates |

| Resistance to Corrosion/Vibration | High due to adhesive bond | Moderate; may loosen under vibration over time |

| Use in Wet or Contaminated Holes | Possible with extended curing time | Generally less suitable for wet holes |

Chemical bolts provide superior load capacity and durability but involve a more complex installation process. In contrast, mechanical anchor bolts provide a quicker, simpler installation with immediate load application, though they generally have lower performance in adverse conditions.

Chemical bolts, also known as resin or epoxy anchors, are ideal for applications needing high load-bearing capacities. These bolts are particularly effective in scenarios where traditional mechanical fasteners might fail, such as in cracked or weakened concrete. The load-bearing capacity of chemical bolts is influenced by several factors, which must be carefully considered to ensure optimal performance.

Typical load capacities for chemical bolts depend on the specific application and installation parameters. For example, a 1/2″ epoxy anchor can generally support loads ranging from 3,000 to 3,500 lbs, making them suitable for heavy-duty applications such as machinery anchoring and seismic reinforcements.

Anchor bolts are versatile fasteners used to secure structural elements to concrete foundations. They come in various types, including wedge, sleeve, and undercut anchors, each offering different load-bearing capabilities based on their design and installation.

Typical load capacities for anchor bolts also vary based on their type and installation. For instance, a 3/4″ wedge anchor can support loads between 4,800 to 5,600 lbs, while a 1/2″ sleeve anchor typically supports loads ranging from 1,800 to 2,200 lbs.

A comparative analysis of chemical bolts and anchor bolts reveals distinct advantages and limitations for each fastening system in terms of load-bearing capacities:

| Characteristics | Chemical Bolts (Epoxy) | Anchor Bolts |

|---|---|---|

| Load Capacity | Higher in weaker concrete conditions | Varies by type; generally higher in strong concrete |

| Application | Ideal for high tensile/shear applications | Suitable for a wide range of structural applications |

| Factors Influencing Load | Concrete strength, epoxy quality, embedment depth | Bolt material, diameter, length, concrete condition |

| Environmental Impact | Susceptible to chemical and moisture degradation | Less susceptible, but can be affected by improper installation |

Understanding these factors and their impact on load-bearing capacities helps in selecting the appropriate fastening system for specific construction needs, ensuring safety and structural integrity.

Chemical bolts use a chemical adhesive, such as epoxy or polyester resin, to create a strong bond with the substrate. This bonding mechanism provides exceptional durability and load-bearing capacity, making chemical bolts ideal for heavy-duty applications, especially in environments requiring high strength and resilience, such as cracked concrete or seismic zones. The chemical bond distributes loads evenly, reducing stress concentrations and preventing substrate damage, which enhances long-term performance and reliability.

Anchor bolts, also known as mechanical anchors, use physical mechanisms like expansion or friction to secure themselves within the substrate, making them simpler to install and generally more cost-effective than chemical bolts. However, their holding capacity may be lower, particularly in weaker materials. The mechanical grip of anchor bolts can be compromised over time due to substrate degradation, which can affect their durability in the long run.

The installation process for chemical bolts involves precise cleaning and curing stages to ensure a strong chemical bond. This method can be time-consuming and requires specialized equipment, such as injection guns for resin application. The curing time for chemical bolts can vary from a few hours to several days, depending on the environmental conditions, such as temperature and humidity. Despite the complexity, this meticulous process results in a durable and sustainable anchoring solution capable of withstanding harsh environmental conditions.

The installation process involves drilling a hole, inserting the bolt, and securing it by tightening a nut or hammering. Anchor bolts are quicker to install and can be used immediately after installation, without the need for curing time. This makes them suitable for projects with tight deadlines. While anchor bolts offer immediate mechanical strength and are more tolerant of installation errors, they may not provide the same level of environmental resistance and long-term sustainability as chemical bolts.

Chemical bolts provide excellent environmental resistance, making them suitable for applications that require waterproofing or exposure to harsh conditions. The chemical adhesive forms a protective barrier that enhances resistance to corrosion and moisture, ensuring durability even in challenging environments. This environmental resilience contributes to the sustainability of chemical bolts, as they maintain their performance over extended periods.

While anchor bolts are less expensive and easier to install, their environmental resistance may not match that of chemical bolts. The mechanical grip of anchor bolts can be compromised by material degradation over time, especially in extreme environmental conditions. This limitation can affect their sustainability, as frequent replacements or maintenance may be required to ensure long-term performance.

Chemical bolts offer superior durability and sustainability due to their strong chemical bond and ability to handle high loads in demanding conditions. However, their installation process is more complex and time-consuming. In contrast, anchor bolts are cost-effective and easy to install, providing immediate mechanical strength, but may not match the durability and environmental resistance of chemical bolts in heavy-duty applications. The choice between chemical and anchor bolts ultimately depends on specific project requirements, including load type, substrate condition, and environmental factors.

Choosing the right anchor for your project involves evaluating several critical factors to ensure the best performance and longevity. These factors include the type of construction, load requirements, environmental conditions, and project timelines.

The type of construction project plays a crucial role in determining the best anchor to use:

Knowing the load requirements is essential for choosing the right anchor:

Environmental factors can affect the performance and longevity of anchors:

Project deadlines and timelines also play a role in anchor selection:

Examining case studies and real-world examples can provide valuable insights into the effectiveness of different anchors:

Chemical bolts have been successfully used in seismic zones to reinforce building structures, providing enhanced safety during earthquakes. Their ability to bond with cracked concrete and evenly distribute loads makes them reliable for critical applications.

Anchor bolts are widely used in industrial settings to secure heavy machinery bases. Their immediate load-bearing capability and ease of installation have proven effective in maintaining stability and operational efficiency in factories and plants.

To assist in choosing the right anchor for your project, various interactive tools and resources are available:

When choosing between chemical bolts and anchor bolts, consider the following:

By evaluating these factors and utilizing available resources, you can make an informed decision to ensure the success and safety of your construction project.

Below are answers to some frequently asked questions:

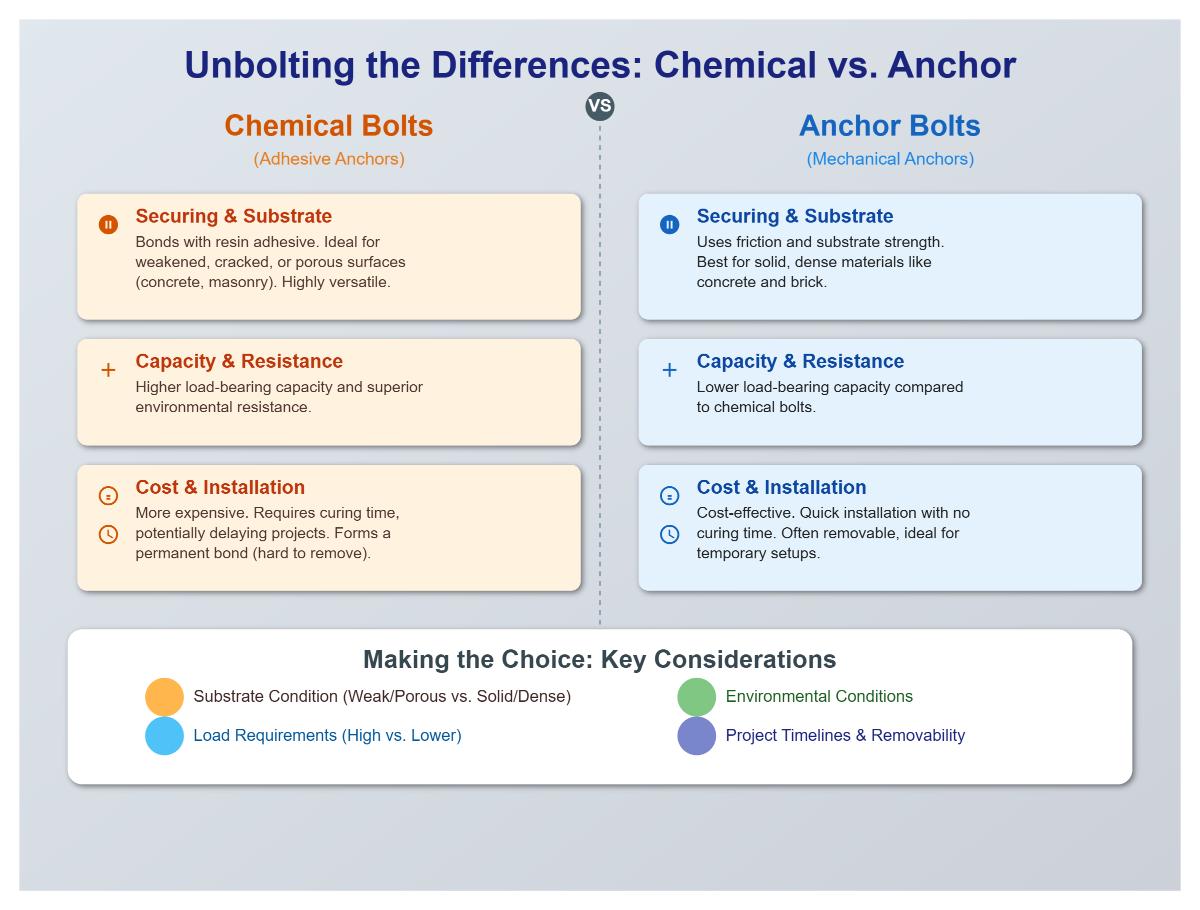

Chemical bolts and anchor bolts differ primarily in their method of securing to substrates and their applications.

Chemical bolts, also known as adhesive anchors, use a resin-based adhesive to bond the bolt to the substrate. This method is ideal for weakened or cracked substrates, offering higher load-bearing capacity and environmental resistance. Chemical bolts are versatile, suitable for a range of materials, including concrete, masonry, and porous surfaces. However, they are more expensive, require curing time, and form a permanent bond that is difficult to remove.

Anchor bolts, or mechanical anchors, rely on friction and the substrate’s strength for securing. They are best suited for solid, dense materials like concrete and brick. While they have a lower load-bearing capacity compared to chemical bolts, they are cost-effective, can be installed quickly without curing time, and are removable, making them ideal for temporary installations.

Choosing between chemical bolts and anchor bolts depends on factors such as substrate condition, load requirements, environmental conditions, and project timelines.

Choosing between chemical anchoring and mechanical anchoring depends on several factors related to the project’s requirements.

Chemical anchoring, which involves using resin or epoxy-based adhesives to secure bolts in drilled holes, is ideal for applications requiring high load capacity and superior pull-out strength. It is particularly effective in weak, porous, or hollow substrates where mechanical anchors may not grip sufficiently. Chemical anchors also provide some flexibility to absorb vibrations and slight movements, making them suitable for dynamic or seismic conditions. However, they require thorough hole cleaning, proper adhesive mixing, and curing time, which can slow down the installation process and increase costs.

Mechanical anchoring, on the other hand, relies on physical expansion or wedging mechanisms to secure bolts in solid substrates like concrete, brick, or stone. This method offers quick installation and immediate load-bearing capabilities, making it suitable for projects with tight schedules. Mechanical anchors are generally more cost-effective and less sensitive to installation errors but may not perform well in weak or crumbly materials.

Chemical anchoring, also known as resin anchoring, offers several distinct advantages over traditional mechanical anchoring methods. Firstly, it is highly versatile, making it suitable for various masonry types, including hollow brick and block, without causing damage. This versatility extends to its ability to achieve greater embedding depths with fixed-length studs or cut-to-size bars, allowing for secure heavy load applications.

Chemical anchors also excel in close-edge anchoring, minimizing the risk of base material damage and ensuring high load capacities. Their superior holding strength is a result of the resin bonding with the metal over a larger area, which enhances the structural integrity. Additionally, chemical anchors provide excellent chemical and heat resistance, as well as protection against moisture and corrosion, ensuring long-term durability and safety in harsh environments.

Furthermore, chemical anchors exert no setting stresses on the base material, making them ideal for applications requiring minimal material stress. While chemical anchoring offers these substantial benefits, it does require more time and labor due to the resin application and curing processes, and it tends to be more expensive compared to mechanical anchoring.

Mechanical anchoring offers several advantages in construction applications. Firstly, mechanical anchors can be loaded immediately after installation, eliminating the wait time required for chemical anchors to cure. This feature allows for faster project progression and quicker attachment of structural elements. Additionally, mechanical anchors are less sensitive to environmental conditions, performing reliably in various thermal conditions and unaffected by moisture presence, except in damp or chemically aggressive environments where corrosion risk is high.

Mechanical anchors are also known for their superior performance in solid substrates like concrete or masonry, where their expansion or gripping mechanisms can fully engage. This makes them ideal for applications requiring immediate strength. The installation process for mechanical anchors is generally simpler and less demanding compared to chemical anchors, which require precise mixing and hole cleaning. Mechanical anchors are also cost-effective, both in terms of material costs and installation time, and they can be removed if necessary, making them suitable for temporary or reusable applications. Lastly, mechanical anchors allow for easier inspection and maintenance post-installation, as their expansion or torque can be checked to ensure proper performance.

To determine the load-bearing capacity of an anchor, you need to consider several key factors: bolt material and diameter, embedment depth, concrete or base material strength, type of load (tensile vs. shear), and the installation method.

For theoretical calculations, refer to manufacturer specifications that provide load capacities based on these variables. Ensure to apply safety factors according to design codes. For example, typical load capacities for anchor bolts in 4000 psi concrete can range from 2,500 lbs for a 1/2″ bolt in tension to 5,600 lbs for a 3/4″ bolt in shear.

On-site proof testing is the most accurate method to confirm the load-bearing capacity. This involves simulating the expected load on the installed anchor to verify it meets or exceeds design requirements. Additionally, consider the environmental conditions and proper installation techniques, especially for chemical anchors which require clean holes and curing time.

Chemical bolts generally provide higher tensile capacities due to the adhesive bond, making them suitable for cracked or lower-quality concrete. Mechanical anchors offer immediate load capacity but are more sensitive to installation conditions.

Chemical anchors and mechanical anchors have distinct environmental impacts. Chemical anchors, which use synthetic adhesives and resins, often emit volatile organic compounds (VOCs) during manufacturing and curing. These emissions contribute to air pollution and pose health risks. Additionally, the chemicals in these anchors can be toxic and persistent in the environment, potentially contaminating soil and water if not properly disposed of. Innovations such as eco-friendly adhesives and glass-encapsulated formulations are reducing these impacts by minimizing VOC emissions and enhancing recyclability.

Mechanical anchors, typically made of steel or other metals, have an energy-intensive production process with a significant carbon footprint. However, they generally do not emit VOCs. These anchors can be more durable and recyclable, but they are susceptible to corrosion in harsh environments, which can reduce their lifespan and necessitate replacement. The removal process for mechanical anchors can create dust and debris, impacting both human health and the environment.