In the world of steel alloys, the choice between Chrome Molybdenum and Chromium-Vanadium can be the deciding factor in the success of your project. Both revered for their strength and resilience, these alloys have carved out essential roles across various industries. But what exactly sets them apart? Is one superior when it comes to enduring high temperatures or meeting stringent industry standards? This article delves into the intricate details of these two formidable contenders, offering a comparative analysis that highlights their unique chemical compositions, mechanical properties, and suitability for different applications. As we explore these aspects, you’ll gain the insight needed to make an informed decision about which alloy best suits your specific requirements. So, which steel alloy will rise to the occasion? Let’s find out.

Steel alloys are primarily composed of iron, combined with various elements to enhance their mechanical and chemical properties. These enhancements make steel alloys suitable for a wide range of industrial applications. Knowing the different types of steel alloys and their unique properties helps in choosing the right material for specific applications.

Chromium is a vital element in many steel alloys, enhancing corrosion resistance by creating a protective layer on the steel surface that prevents rust and corrosion. It also increases hardness and wear resistance.

Molybdenum is often added to steel to improve high-temperature strength and creep resistance. It enhances hardness and toughness, making molybdenum-containing steels suitable for high-stress applications.

Vanadium significantly improves the strength, toughness, and wear resistance of steel alloys. It refines the grain structure of the steel, leading to enhanced mechanical properties. Vanadium-containing steels are often used in applications requiring high impact and abrasion resistance.

Steel alloys can be broadly categorized based on their primary alloying elements and the specific properties they impart. Two prominent categories are Chrome Molybdenum (Cr-Mo) steels and Chromium Vanadium (Cr-V) steels.

Cr-Mo steels, known for their high strength, toughness, and resistance to wear and corrosion, are characterized by the addition of chromium and molybdenum. These steels are commonly used in high-pressure and high-temperature applications such as power generation, petrochemical processing, and automotive components.

Cr-V steels incorporate chromium and vanadium as their primary alloying elements. They are renowned for their exceptional hardness, wear resistance, and toughness. Cr-V steels are often utilized in the manufacturing of tools, automotive parts, and other components that require high durability and resistance to mechanical stress.

Choosing the right alloy depends on factors like required strength, environmental conditions, and performance needs. Selecting the appropriate steel alloy ensures the performance and longevity of components in various applications.

Analyzing the benefits and limitations of each alloy type helps identify the best use cases for them. A detailed understanding of the specific advantages and constraints of each type allows for informed material selection, ensuring the alloy meets operational demands and provides the desired performance characteristics.

Chrome Molybdenum (Cr-Mo) steel, commonly known as Chromoly, is distinguished by its inclusion of chromium and molybdenum as key alloying elements.

Chromium content in Cr-Mo steel ranges between 0.50% and 9.00%, significantly enhancing the alloy’s oxidation and corrosion resistance by forming a protective layer of chromium oxide on the steel surface.

Molybdenum, typically present in amounts ranging from 0.50% to 1.00%, is essential for high-temperature strength and creep resistance, helping the steel maintain its shape under prolonged heat exposure.

Carbon content in Cr-Mo steel is usually below 0.20%, playing a crucial role in increasing hardness and tensile strength for greater durability.

Additional elements such as manganese and silicon may be included to further improve toughness and machinability, depending on specific application requirements.

Chromium-Vanadium (Cr-V) steel incorporates both chromium and vanadium, each contributing unique properties to the alloy.

In Cr-V steel, chromium continues to enhance corrosion and oxidation resistance, similar to its role in Cr-Mo steel.

Vanadium, the key element in Cr-V steel, increases strength, toughness, and wear resistance by refining the steel’s grain structure, leading to better mechanical properties.

Carbon and manganese are also present in Cr-V steels, with carbon enhancing hardness and tensile strength, and manganese contributing to toughness and hardenability. The proportions of these elements are adjusted to meet specific application needs.

In both Cr-Mo and Cr-V steels, chromium provides excellent corrosion and oxidation resistance, making them suitable for environments where these properties are crucial.

Molybdenum’s role in Cr-Mo steel is pivotal for high-temperature applications, enhancing creep resistance and making it ideal for industries like power generation and petrochemical processing.

Vanadium in Cr-V steel provides superior strength and toughness, making it a preferred choice for applications requiring high impact resistance and wear resistance, such as in tool manufacturing and high-strength structural components.

Both alloys utilize carbon and manganese to enhance mechanical properties, with specific roles and proportions tailored to the application, allowing flexibility in performance characteristics.

Cr-Mo steel is defined by its key elements, chromium and molybdenum. Chromium enhances oxidation and corrosion resistance, while molybdenum improves high-temperature strength and creep resistance. Typical alloy compositions include chromium at 0.5–1.5% and molybdenum at 0.2–0.5%.

Chrome Vanadium steel, known as Cr-V, incorporates chromium and vanadium as primary elements. Chromium provides corrosion resistance, and vanadium refines the grain structure, enhancing toughness and wear resistance. The typical alloy mix includes chromium at 0.8–1.1% and vanadium at 0.1–0.25%.

Chrome Molybdenum steel exhibits a tensile strength ranging from 485 to over 620 MPa, making it ideal for high-strength applications. In contrast, Chromium Vanadium steel offers a basic tensile strength of 190–300 MPa, which can be significantly increased through heat treatment.

Cr-Mo steel possesses moderate to high hardness, especially after heat treatment, ensuring durability in high-stress environments. Cr-V steel, on the other hand, achieves high hardness post heat treatment, making it ideal for applications requiring exceptional wear resistance.

Cr-Mo steel is known for its high impact resistance and ductility under stress, making it suitable for structural components. Cr-V steel offers exceptional energy absorption and fatigue resistance, making it a preferred choice for cyclic-loading applications like automotive springs and hand tools.

Cr-Mo steel offers good wear resistance, boosted by molybdenum’s ability to resist creep. Chrome Vanadium steel excels in wear resistance due to vanadium, which improves abrasion resistance, making it ideal for high-wear applications such as tools.

Cr-Mo steel retains its strength at temperatures above 500°C, making it suitable for high-temperature applications like boilers and pipelines. Cr-V steel offers moderate temperature stability, with vanadium providing red-hardness, useful for cutting tools.

Both Cr-Mo and Cr-V steels benefit from chromium’s corrosion resistance. Cr-Mo steel has high corrosion resistance due to its chromium content, while Cr-V steel provides moderate corrosion resistance and requires maintenance in corrosive environments.

Chrome Molybdenum steel excels in high-temperature applications due to molybdenum, which minimizes creep deformation under prolonged stress, making it ideal for boilers and pipelines. Cr-V steel handles moderate temperatures well, with vanadium providing short-term heat resistance, making it suitable for cutting tools.

Cr-V steel is superior for repetitive stress applications, such as hand tools and automotive springs, due to its fatigue resistance. Cr-Mo steel is better suited for sustained loads, such as structural components, due to its high impact resistance and ductility.

Chrome Molybdenum steel requires pre- and post-weld heat treatment to avoid cracking, making it challenging but manageable with proper techniques. Chrome Vanadium steel is prone to brittleness and requires specialized welding techniques to prevent failure.

Cr-Mo steel is widely used in the energy sector for boilers, pressure vessels, and drilling equipment due to its high-temperature strength and corrosion resistance. In the automotive industry, it is used for crankshafts and gears, where high-stress durability is essential.

Cr-V steel is often used to make hand tools like wrenches and sockets because of its excellent wear and impact resistance. It is also used in aerospace applications for fasteners and landing gear components, where fatigue life is critical.

Chrome Vanadium steel is more cost-effective for mass-produced tools, making it a popular choice for hand tools. Chrome Molybdenum steel’s molybdenum content increases raw material costs, making it more expensive but justified by its high-performance characteristics in demanding applications.

Chrome Vanadium steel requires hardened tooling due to its toughness, presenting challenges in machining. Chrome Molybdenum steel faces similar challenges but benefits from molybdenum’s thermal stability, which can aid in machining under high-temperature conditions.

Recent advancements in Cr-Mo steel formulations focus on improving weldability, particularly for offshore oil rigs, enhancing its application in the energy sector.

Enhanced heat treatment processes for Cr-V steel aim to boost hardness without sacrificing toughness, making it more versatile for high-wear applications.

In the energy sector, Chromium-Molybdenum (CrMo) steel is highly favored for its exceptional stability and corrosion resistance at high temperatures. This makes it ideal for offshore oil rigs and drilling equipment, where exposure to harsh marine environments is common. CrMo’s ability to maintain structural integrity at elevated temperatures makes it a preferred choice for furnace components and transport cars in aluminum smelting operations. Chromium-Vanadium (CrV) steel, with its superior ductility and toughness, is less commonly used in these environments but is valued for components that require moderate temperature handling.

CrMo steel is extensively used for critical components such as crankshafts and gears, ensuring they can withstand the intense heat and stress generated by engines, providing reliability and longevity. CrV steel finds its niche in the production of springs and other components subjected to cyclic loading. Its fatigue resistance ensures that these parts can endure repeated stress without failure, making it a cost-effective option for high-performance and budget-conscious automotive designs.

The construction industry benefits from CrMo steel’s robust properties, particularly in high-stress environments. Its use in conveyors and structural supports is driven by the alloy’s ability to handle heavy loads and resist wear over time. In contrast, CrV steel is less prevalent in large-scale structural applications but is sometimes employed in specialized tools used in construction, where its hardness and wear resistance are beneficial.

CrV steel is a staple in tool manufacturing, known for its impact resistance and ability to maintain a sharp edge. This makes it ideal for producing hand tools such as wrenches, screwdrivers, and pliers, which require durability and precision. The vanadium content in CrV enhances its wear resistance, ensuring these tools maintain their functionality over prolonged use. CrMo steel, while less common in hand tools, can be used in applications where tools might be exposed to high heat or corrosive environments.

In aerospace, the demand for materials that can withstand dynamic loads and fatigue is crucial. CrV steel is used in components like springs and landing gear, which require high fatigue resistance. The vanadium’s ability to improve fatigue life makes CrV a reliable choice for these demanding applications. CrMo’s role in aerospace is more limited but can be applied in parts that need high-temperature stability.

For consumer goods, particularly in high-end bicycles and sporting equipment, CrV steel offers a balance of strength and flexibility. Its lightweight nature combined with durability makes it suitable for components that need to endure constant stress and impact, such as bicycle frames and golf clubs. CrMo steel might also be used in these applications where additional strength and resistance to environmental factors are necessary.

Chrome Molybdenum (Cr-Mo) and Chrome Vanadium (Cr-V) steels are integral to various industries due to their exceptional strength and durability. The standards governing these materials ensure they meet stringent requirements for safety and performance, aligning with specific industry needs.

Cr-Mo steel is subject to several ASTM standards that guarantee its suitability for high-temperature and high-pressure applications:

Cr-Mo steel must also comply with international standards, which ensure the material’s reliability and safety:

Cr-V steel is governed by ASTM standards that assure its effectiveness in tool and spring manufacturing:

Cr-V steel must adhere to international standards to ensure its performance in specialized applications:

Both Cr-Mo and Cr-V steels must comply with industry-specific regulations, ensuring their applicability and safety in various fields:

The table below highlights the differences in applications between Cr-Mo and Cr-V steels, helping to clarify their distinct roles in various industries:

| Aspect | Chrome Molybdenum (Cr-Mo) | Chrome Vanadium (Cr-V) |

|---|---|---|

| High-Temperature Service | ASTM A335, ISO 9329-2 | Not typically specified for high-temp |

| Pressure Vessels | ASTM A387, EN 10216-2 | Not typically specified for pressure |

| Springs | Not typically specified for springs | ASTM A231, ISO 4957 |

| Tool Steels | Not typically specified for tools | ASTM A681, ISO 4957 |

| Automotive Components | SAE J404 | SAE J438 |

| Aerospace Components | SAE AMS 6415 | SAE AMS 6484 |

This comparison underscores the unique applications and standards compliance for Cr-Mo and Cr-V steels, guiding industry professionals in selecting the appropriate material for their specific needs.

When selecting the appropriate steel alloy, various factors will influence the material’s performance, durability, and suitability for specific applications.

Knowing the mechanical properties of Chrome Molybdenum (Cr-Mo) and Chromium-Vanadium (Cr-V) steels is essential for making an informed choice.

The environmental conditions in which the steel will be used play a significant role in alloy selection.

Different applications require specific properties that can influence the choice between Cr-Mo and Cr-V steels.

For heavy-duty applications, such as construction and energy sectors, Cr-Mo steel is often the preferred choice due to its superior tensile strength and high-temperature resistance. Common uses include:

Cr-V steel is predominantly used in the manufacturing of hand tools and automotive components that require high wear resistance and toughness.

Cost is also an important factor when choosing the right steel alloy.

Ensuring compliance with industry standards is essential for the reliability and safety of the steel alloy in specific applications.

Below are answers to some frequently asked questions:

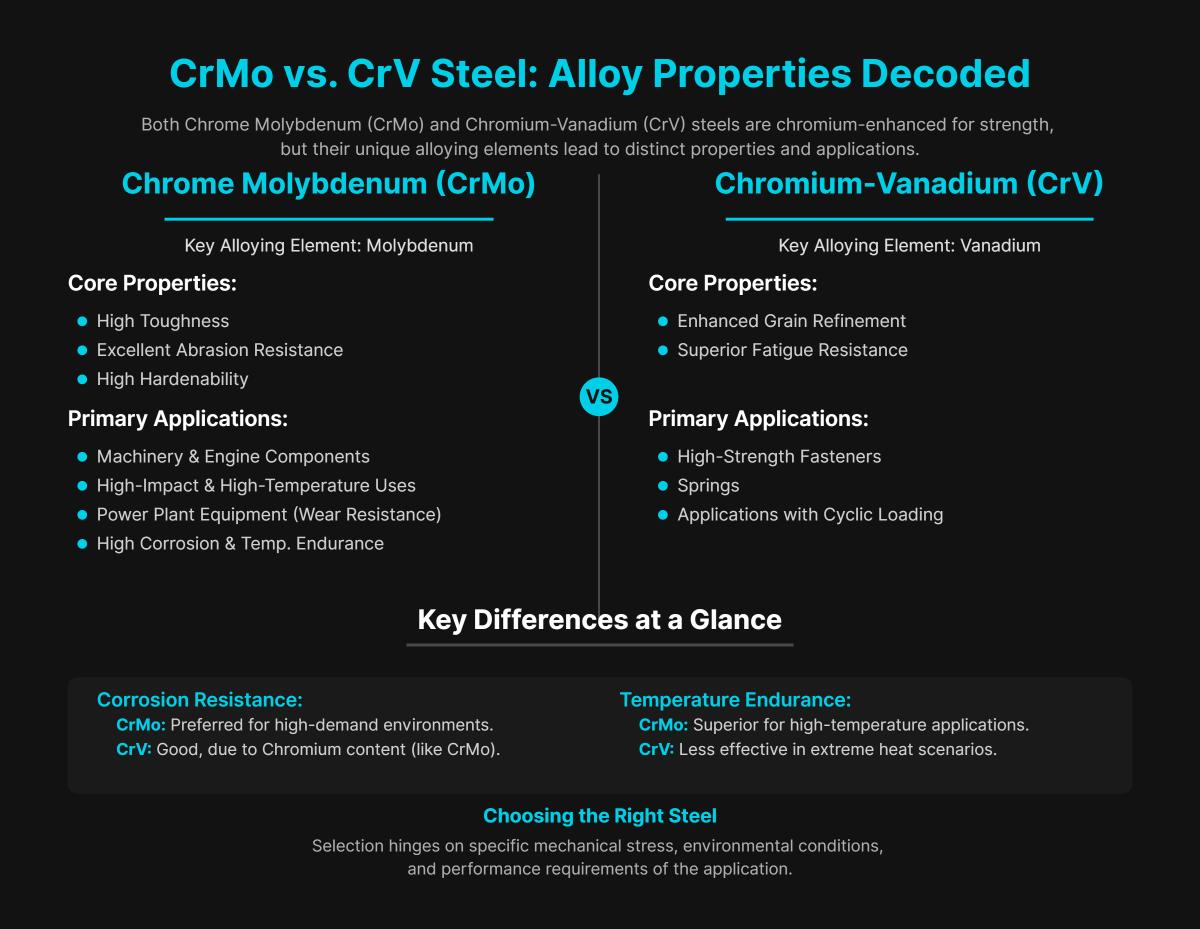

Chrome Molybdenum (CrMo) and Chromium-Vanadium (CrV) steels are both enhanced with chromium, offering improved strength and hardness. However, their distinct alloying elements—molybdenum in CrMo and vanadium in CrV—result in different properties and applications. CrMo steel, with its composition of 0.38-0.43% carbon, 0.90-1.20% chromium, and 0.15-0.25% molybdenum, is renowned for its toughness, abrasion resistance, and high hardenability. This makes it suitable for high-impact and high-temperature applications, such as machinery and engine components, where wear resistance is crucial.

Conversely, CrV steel incorporates vanadium, which enhances grain refinement and fatigue resistance, making it ideal for high-strength fasteners and springs. While both alloys offer corrosion resistance due to their chromium content, CrMo is preferred for environments demanding high corrosion resistance and temperature endurance, such as in power plants. CrV, though less effective in extreme heat, excels in applications involving cyclic loading due to its superior fatigue resistance. Ultimately, the choice between these alloys depends on specific application needs, including mechanical stress and environmental conditions.

Chrome Molybdenum (Chromoly) steel is generally better suited for high-temperature applications compared to Vanadium steel. Chromoly contains chromium and molybdenum, which enhance its strength, toughness, and heat resistance, making it ideal for environments like power plants where high temperatures and pressures are prevalent. It is commonly used in steam and gas turbines due to its ability to maintain structural integrity under extreme conditions.

Vanadium steel, while offering enhanced strength, toughness, and wear resistance, may not match Chromoly’s performance in ultra-high-temperature scenarios. It is often favored for applications requiring high strength and durability, such as aerospace and automotive components, rather than environments characterized by extreme heat.

Chrome Molybdenum (Cr-Mo) and Chromium-Vanadium (Cr-V) steel alloys comply with ASTM and SAE standards by meeting specific requirements related to their chemical composition, mechanical properties, and testing methods. ASTM standards, such as ASTM A387 for Cr-Mo steel, provide guidelines for pressure vessel plates, ensuring high-temperature and corrosion resistance. These standards are crucial for applications in industries like oil and gas, where durability under stress is essential.

For Cr-V steel, compliance with ASTM standards focuses on toughness and wear resistance, attributes valued in hand tools and industrial machinery. While specific SAE standards for these alloys might not be explicitly detailed, they generally adhere to SAE’s material specifications, ensuring suitability for automotive and aerospace applications.

When selecting between Chrome Molybdenum (Cr-Mo) and Chromium-Vanadium (Cr-V) steel alloys, environmental considerations play a significant role. The extraction of molybdenum for Cr-Mo steel can lead to habitat destruction and acid mine drainage, posing ecological risks. In contrast, vanadium extraction requires high energy input and generates substantial tailings, impacting the environment.

From a manufacturing perspective, Cr-Mo steel demands precise heat treatment, which is energy-intensive, whereas Cr-V steel requires specialized machining tools due to its hardness, potentially increasing production energy costs.

Operational performance also influences environmental impact. Cr-Mo steel’s excellent high-temperature resistance reduces material degradation and waste in energy systems, while Cr-V steel’s superior wear resistance minimizes material waste from premature failures in tools and machinery.

Both alloys face recyclability challenges due to contamination risks and high energy requirements for reprocessing. Emission profiles differ, with Cr-Mo steel producing higher CO₂ output due to its higher melting point compared to Cr-V steel. Additionally, Cr-V steel’s inherent corrosion resistance reduces the need for protective coatings, thereby lowering VOC emissions during maintenance.

Real-world case studies are invaluable for understanding the practical applications and performance of Chrome Molybdenum (Cr-Mo) and Chrome Vanadium (Cr-V) steel alloys. By examining these cases, engineers and material specialists can gain insights into the specific conditions under which each alloy excels. For instance, in the automotive industry, Cr-V is often chosen for hand tools and vehicle components due to its balanced tensile strength and corrosion resistance. Conversely, Cr-Mo is favored for high-stress, high-temperature components like crankshafts and gears, thanks to its superior tensile strength and creep resistance.

In the energy sector, Cr-Mo’s high-temperature resilience makes it ideal for pressure vessels and boilers, highlighting its reliability in extreme conditions. These case studies illustrate that the choice between these alloys should be guided by the application’s performance requirements and environmental challenges, thus ensuring the selected material meets the specific needs of the project.

In a cost-benefit analysis of Chrome Molybdenum (Cr-Mo) and Vanadium (V) steel alloys, several key factors should be considered. Material costs are a primary concern; Cr-Mo typically has a higher initial cost due to its alloying elements, which enhance high-temperature strength and corrosion resistance. In contrast, Vanadium can be less expensive in moderate amounts but may rise in cost with higher content.

Mechanical performance is crucial, with Cr-Mo offering superior creep resistance and tensile strength at elevated temperatures, making it suitable for high-stress environments. Vanadium excels in improving toughness and fatigue resistance, beneficial for applications like automotive components.

Manufacturing considerations also play a role. Cr-Mo requires specialized processes such as pre/post-weld heat treatment, increasing costs, while Vanadium is easier to process with standard techniques, reducing production expenses.

Lifecycle economics should be evaluated, as Cr-Mo offers durability and reduced maintenance in corrosive environments, potentially offsetting its higher initial cost. Vanadium may be more cost-effective for applications that don’t require extreme temperature resistance.