When it comes to giving your metal products a sleek, durable finish, two prominent techniques often come to mind: chrome plating and powder coating. But which one is right for your needs? Both methods offer unique benefits and challenges, making the choice between them far from straightforward. In this article, we’ll delve into the key differences between chrome plating and powder coating, breaking down their processes, applications, and performance under various conditions. Are you curious about which method offers superior durability or is more cost-effective for your next project? Read on to discover the comparative strengths and weaknesses of these two popular coating techniques and find out which one aligns best with your specific requirements.

Coating techniques play a crucial role in enhancing the durability, appearance, and performance of metal and other substrates in various industries. Among these techniques, chrome plating and powder coating are two of the most widely used methods. Each technique offers unique properties and benefits, making them suitable for different applications.

Chrome plating, also known as chromium plating, involves the electrochemical deposition of chromium onto a substrate. This process forms a thin, durable, and shiny layer that enhances both the look and protection of the object. The chrome plating process requires immersing the substrate in a chromium solution, where an electric current facilitates the deposition of chromium ions onto the surface.

Powder coating is a finishing process that involves applying a dry powder to a substrate using an electrostatic spray gun. The object is then heated in an oven, causing the powder to melt and form a smooth, solid layer. This technique is praised for its environmental friendliness and versatility.

When comparing chrome plating and powder coating, consider factors like the application process, durability, appearance, and environmental impact.

Chrome plating is best for its classic, shiny finish and hardness, while powder coating stands out for its versatility, better durability, and environmental friendliness.

Chrome plating, also called chromium plating, is a process that uses electricity to coat a metal object with a thin layer of chromium. This technique enhances surface properties such as aesthetics, corrosion resistance, hardness, and ease of cleaning. The process involves several well-controlled stages:

Chrome plating is widely used across various industries due to its versatile benefits. Common applications include:

Powder coating is a process that applies a fine, dry powder to a metal surface using electrostatic charges, resulting in a durable and smooth finish. The process includes several stages:

Powder coatings consist of polymer resins, pigments, curing agents, and flow modifiers. These components create a protective and aesthetically pleasing finish once cured. The process involves:

Powder coating is versatile and used across various industries:

Chrome plating is well-known for providing a hard, wear-resistant surface. This durability comes from the chromium layer, which effectively protects against corrosion and wear, especially when applied in thicker coats, although thinner layers can be prone to brittleness and cracking under stress or impact. However, chrome plating is not suitable for flexible surfaces as it lacks the necessary flexibility and can crack if the underlying material bends.

Maintaining chrome-plated surfaces involves regular cleaning and polishing to keep them shiny. This is particularly important in environments prone to water exposure, as chrome can retain water and develop lime scale buildup if not well-polished. Routine maintenance includes wiping the surface with a soft cloth and using non-abrasive cleaners to prevent scratches. Additionally, periodic inspections are necessary to detect and address any damage early, preventing corrosion from taking hold.

Powder coating is generally more durable than chrome plating, offering better resistance to chips, scratches, and corrosion. The thicker and more consistent coating achieved through the powder coating process provides a robust protective layer. Additionally, powder coatings exhibit excellent UV resistance, which prevents fading or yellowing over time. This makes powder coating particularly suitable for outdoor applications where exposure to the elements is a concern.

Powder-coated surfaces are low maintenance, retaining their appearance with simple cleaning using water and mild detergents. The finish retains its appearance without the need for frequent polishing or intensive cleaning. This ease of maintenance, combined with its durability, makes powder coating an attractive option for applications that require both aesthetics and long-term performance.

Chrome plating is highly valued for its exceptional hardness and wear resistance, thanks to the properties of the chromium layer. This hardness makes chrome-plated surfaces highly resistant to scratches, abrasions, and general wear, which is particularly beneficial in heavy-use industrial applications like hydraulic cylinders, automotive parts, and industrial machinery, where hard chrome plating can achieve hardness levels up to 70 HRC (Rockwell Hardness Scale).

One of the significant advantages of chrome plating is its ability to resist corrosion. The chromium layer acts as a barrier that protects the underlying metal from environmental factors like moisture, chemicals, and oxidation. This resistance is crucial for applications where the metal parts are exposed to harsh conditions, such as marine environments, automotive exteriors, and industrial equipment. However, the effectiveness of chrome plating in preventing corrosion largely depends on the thickness and quality of the plating. Thicker coatings provide better protection but can be more expensive and challenging to apply uniformly.

A key concern is brittleness; chrome-plated surfaces can crack or peel if the base material flexes or if the plating isn’t applied correctly. This makes chrome plating less ideal for applications needing flexibility or impact resistance. Additionally, if the surface is damaged, it can expose the underlying metal to corrosion, potentially compromising the part’s integrity.

Maintaining chrome-plated surfaces requires regular cleaning and polishing to keep their appearance and prevent corrosion. If not properly maintained, chrome plating can retain water and develop lime scale, dulling the finish and reducing protection. Regular inspections help catch and fix damage early, ensuring longevity. This maintenance is often more intensive compared to other methods like powder coating, which usually needs less upkeep.

When comparing chrome plating to powder coating, several factors matter. Chrome plating offers a hard, wear-resistant, high-gloss surface, ideal for applications needing aesthetics and hardness. However, its brittleness and maintenance are drawbacks. Powder coating, on the other hand, provides a thicker, more flexible coating, excellent against chips, scratches, and corrosion, and requires less maintenance. It doesn’t retain water or develop lime scale, often making it more durable in high UV and varying weather conditions, thus preferred for outdoor use.

Powder coating is a robust surface finishing technique known for its durability against various environmental and mechanical stresses. This method is widely recognized for its superior resistance to wear, corrosion, and weather conditions, making it a preferred choice in many industrial applications.

Powder coating offers excellent resistance to environmental factors such as UV radiation, moisture, and chemicals. It can withstand harsh weather conditions without deteriorating, making it ideal for outdoor applications. Powder-coated surfaces exhibit exceptional UV resistance, preventing fading and degradation even under prolonged exposure to sunlight. This characteristic is crucial for applications in outdoor furniture, automotive parts, and architectural elements, ensuring long-lasting color and finish. Additionally, powder coating is highly resistant to chemicals. It can endure exposure to various chemicals and solvents without reacting or breaking down, making it suitable for industrial equipment and components that encounter aggressive substances.

Powder coating is known for its mechanical strength, providing a tough and impact-resistant finish. The electrostatically applied powder and subsequent heat curing process create a resilient layer that can endure physical stress and abrasion. One of the standout features of powder coating is its resistance to scratches and chips. The thick, uniform layer formed during the curing process is less prone to damage from impacts or abrasion compared to traditional liquid paints. This durability is particularly beneficial for high-traffic areas and items subject to frequent handling. Powder coating also offers good flexibility and adhesion properties, allowing it to accommodate minor flexing and bending without cracking or peeling. This makes it suitable for applications involving dynamic or vibrating components, where surface integrity is critical.

Powder-coated surfaces generally last longer than those treated with other methods. For interior applications, powder coating can last between 20 to 40 years, while exterior applications can maintain their integrity for 15 to 25 years, depending on environmental conditions and maintenance practices.

Powder-coated surfaces require minimal maintenance to retain their appearance and protective qualities. Simple cleaning with water and mild detergents is usually sufficient to keep the surface looking new. Unlike chrome plating, powder coating does not necessitate regular polishing or intensive upkeep, making it a low-maintenance option.

Compared to chrome plating, powder coating offers better overall durability. While chrome plating provides a hard, shiny surface that is resistant to wear, it can become brittle and crack under stress. Powder coating, on the other hand, delivers a thicker, more flexible layer that is less prone to damage from impacts and environmental factors. Powder coating is more environmentally friendly than chrome plating, which involves toxic chemicals and heavy metals. The powder coating process produces fewer VOCs and hazardous waste, aligning with sustainable manufacturing practices. Powder coating is generally more cost-effective for large-scale applications due to its efficiency and lower maintenance requirements. The initial setup costs for powder coating equipment can be high, but the long-term savings in maintenance and durability make it a financially advantageous choice.

Chrome plating has a significant environmental impact because it uses hazardous chemicals, especially hexavalent chromium. This substance is highly toxic and poses serious health risks to workers and the environment. The process involves multiple chemical baths, which emit volatile organic compounds (VOCs) and require stringent waste disposal procedures. Handling and disposing of these chemicals requires strict environmental compliance, which adds complexity and cost. Additionally, the risk of contamination and environmental damage from improper disposal or accidental spills is a major concern associated with chrome plating.

In contrast, powder coating is celebrated for its eco-friendly nature. This process emits negligible VOCs and does not involve hazardous chemicals, making it a safer option for both workers and the environment. The powder used in the coating process can often be recycled, reducing waste and enhancing sustainability. Powder coating aligns well with environmental regulations due to its minimal environmental footprint, promoting safer and greener manufacturing practices. The reduced need for specialized waste disposal further underscores its environmental benefits compared to chrome plating.

Chrome plating is costly due to its labor-intensive process and the need for specialized equipment and chemicals. The process requires precise control over temperature and chemical concentrations, which can drive up production costs. Moreover, the hazardous chemicals require extensive safety measures and environmental compliance, raising costs further. The complexity of the chrome plating process also means higher labor costs, as skilled technicians are required to ensure proper application and handling of the materials.

Powder coating is generally more cost-effective than chrome plating. The process is less labor-intensive and does not require the same level of specialized equipment or hazardous chemical handling. This efficiency translates to lower production costs, making powder coating an attractive option for manufacturers. The ability to recycle overspray powder further enhances cost savings, reducing material wastage and improving overall efficiency. The simpler and safer nature of the powder coating process also means lower labor costs and fewer regulatory compliance expenses, contributing to its cost-effectiveness.

When comparing the environmental and cost factors of chrome plating and powder coating, several key differences emerge. Chrome plating has a higher environmental impact due to its use of toxic chemicals and VOC emissions, requiring careful waste disposal and handling to mitigate risks. In contrast, powder coating is more environmentally friendly, with negligible VOC emissions and recyclable materials, making it a safer and greener choice.

| Aspect | Chrome Plating | Powder Coating |

|---|---|---|

| Environmental Impact | High VOC emissions, hazardous chemicals | Low VOC emissions, eco-friendly |

| Cost-Effectiveness | Highly labor-intensive, costly | Efficient, cost-effective |

| Durability | Durable but can be brittle and prone to cracking | Highly durable, resistant to chips and corrosion |

| Application Flexibility | Limited to rigid surfaces, requires polishing | Can be applied to various substrates |

Both chrome plating and powder coating offer durable finishes, but powder coating stands out as the more environmentally sustainable and cost-effective option. Its flexibility in application and reduced environmental impact make it a preferable choice for many manufacturing needs.

Chrome plating, while offering aesthetic and functional benefits, involves hazardous chemicals that pose significant environmental risks.

One of the primary environmental concerns with chrome plating is the use of hexavalent chromium, a highly toxic and carcinogenic substance. Improper management can lead to serious environmental pollution, such as groundwater contamination, which has been documented in various incidents worldwide.

The chrome plating process generates considerable hazardous waste, including sludges and residues that contain toxic compounds, necessitating careful disposal to avoid environmental damage. The handling of these wastes requires compliance with strict environmental regulations to mitigate the risks of pollution.

Powder coating stands out as a more environmentally friendly alternative to chrome plating.

Powder coating does not use hazardous chemicals like hexavalent chromium, making it safer for workers and the environment. The materials used in powder coating are generally non-toxic, reducing the health risks for workers and minimizing the potential for environmental contamination.

The powder coating process produces minimal waste compared to chrome plating. Any overspray can be collected and reused, significantly reducing waste generation. Additionally, powder coatings do not emit volatile organic compounds (VOCs), which are harmful to the environment and human health. This contributes to cleaner air and a safer working environment.

| Aspect | Chrome Plating | Powder Coating |

|---|---|---|

| Chemical Use | Involves hexavalent chromium, highly toxic | Uses non-toxic materials |

| Waste Generation | Generates hazardous waste | Minimal waste, recyclable |

| VOC Emissions | High VOC emissions | No VOC emissions |

| Regulatory Compliance | Requires strict adherence to environmental regulations | Generally compliant with fewer regulatory challenges |

Despite its environmental drawbacks, there are strategies to mitigate the impact of chrome plating:

Switching to trivalent chromium plating can significantly reduce the toxicity of the process. While trivalent chromium is less hazardous than hexavalent chromium, it still requires careful handling and disposal to prevent environmental contamination.

Implementing advanced waste treatment and recycling systems can help minimize the environmental footprint of chrome plating. Effective water treatment systems can reduce the risk of contamination, while recycling practices can lower waste generation.

When evaluating the cost-effectiveness of chrome plating versus powder coating, several factors need to be considered, including production costs, environmental compliance costs, and maintenance expenses.

Powder Coating: Powder coating is typically more cost-effective due to its simpler application process. It requires less time and fewer resources, which translates to lower production costs. While the initial equipment cost for powder coating can be high, it is less specialized and therefore more economical than the equipment needed for chrome plating.

Chrome Plating: Chrome plating is a labor-intensive process that involves the use of toxic chemicals and specialized equipment. The need for multiple applications to achieve the desired thickness further increases the production costs. The complexity of the process and the stringent controls required add to the overall expenses, making chrome plating more costly compared to powder coating.

Powder Coating: Powder coating is more environmentally friendly, emitting negligible volatile organic compounds (VOCs). The ability to recycle overspray not only enhances sustainability but also reduces compliance costs and environmental liabilities.

Chrome Plating: The chrome plating process involves hazardous chemicals such as hexavalent chromium, posing significant environmental and health risks. Compliance with environmental regulations requires extensive measures to handle and dispose of these toxic substances safely, adding to the overall cost. The environmental impact of chrome plating necessitates higher expenditure on waste management and regulatory compliance.

Powder Coating: Powder coating offers a thicker, more consistent finish, which enhances durability. Its excellent resistance to chips, scratches, and corrosion reduces the need for frequent reapplications and maintenance. This long-term durability translates into cost savings over time, as less money is spent on repairs and upkeep.

Chrome Plating: While chrome plating offers durability, it can be prone to chipping or peeling over time, especially if not maintained regularly. Thinner coats can be brittle and less suitable for flexible surfaces. Regular maintenance and potential reapplications add to the overall cost, making it less cost-effective in the long run compared to powder coating.

Powder Coating: Although the initial setup cost for powder coating can be higher due to equipment like electrostatic spray guns and curing ovens, these expenses are often offset by long-term savings from reduced maintenance and fewer reapplications.

Chrome Plating: Chrome plating necessitates continuous investment in specialized equipment and chemicals, keeping both initial and ongoing costs high. The complexity of the process and the need for skilled labor also contribute to higher initial setup costs.

Chrome plating is an electrochemical process where a thin layer of chromium is deposited onto a metal surface. The object is dipped in a chromium bath, and an electric current is applied to deposit the chromium. This technique requires hazardous chemicals, particularly hexavalent chromium, which necessitates careful handling and disposal to prevent environmental contamination.

Powder coating involves applying a dry powder, typically a plastic resin, to a surface using an electrostatic spray gun. The coated object is then cured in an oven, causing the powder to melt and form a continuous, durable layer. This process does not use liquid solvents or hazardous chemicals, making it safer and more environmentally friendly.

Chrome plating provides a hard, shiny, and reflective finish that offers excellent protection against corrosion and wear, particularly when applied in thick layers. However, it can become brittle and prone to cracking if the coating is too thin or if the underlying material flexes. Brittleness can cause water retention and lime scale, which may degrade the coating over time.

Powder coating delivers a thicker, more consistent coating that is highly resistant to chips, scratches, and corrosion. It offers superior performance in terms of UV light resistance, chemicals, weather, and abrasion. Different plastic resins can be used to tailor durability, making powder coating suitable for many applications. Powder-coated surfaces are low maintenance and generally outperform chrome-plated surfaces in long-term resilience.

The chrome plating process has significant environmental and health impacts due to the use of toxic chemicals like hexavalent chromium. This substance is carcinogenic and poses severe risks to workers and the environment. The process also emits volatile organic compounds (VOCs), requiring strict regulatory compliance for waste disposal and emissions control.

Powder coating is much more environmentally friendly, emitting negligible VOCs and using no hazardous chemicals. The powder overspray can often be recycled, reducing waste and enhancing sustainability. This method aligns well with modern environmental regulations and promotes safer manufacturing practices.

Chrome plating is generally more expensive due to its labor-intensive process, the need for specialized equipment, and the handling of hazardous chemicals. Maintenance costs can be higher, particularly if the plating layer is thin and prone to damage, requiring regular inspections and upkeep to prevent corrosion.

While initial setup costs for powder coating equipment may be higher, long-term savings in maintenance and efficiency often make it more cost-effective. Its durability leads to lower maintenance costs over time, making it an attractive option for manufacturers and end-users seeking long-lasting finishes.

Chrome plating is prized for its bright, reflective metallic finish, which is difficult to replicate with other methods. However, it is typically limited to metal substrates and rigid surfaces, reducing its application flexibility. The aesthetic appeal of chrome plating makes it a preferred choice for applications where appearance is paramount.

Powder coating offers greater flexibility in terms of application, suitable for metals, plastics, and composites. It enables a wide range of colors and textures beyond the metallic chrome look, expanding design possibilities. While the finish may be less shiny than chrome plating, it is more durable and customizable, providing a broader range of aesthetic options for different applications.

Recent advancements in chrome plating technology aim to reduce the environmental and health hazards of hexavalent chromium. Trivalent chromium plating, a safer alternative, uses trivalent chromium, which is significantly less toxic and poses fewer health risks. It offers a similar aesthetic and corrosion resistance to traditional hexavalent chromium plating, making it an attractive option for manufacturers seeking to comply with stringent environmental regulations.

The development of nano-structured coatings has significantly enhanced the performance characteristics of chrome plating. These coatings use nanoparticles to enhance hardness, wear resistance, and corrosion protection. Nano-structured chrome coatings are particularly beneficial for high-stress industrial applications where traditional chrome plating might not suffice.

Pulse plating is another technological advancement in chrome plating. This technique involves varying the electrical current during the electroplating process, resulting in a more uniform and denser chrome layer. Pulse plating reduces the occurrence of micro-cracks and enhances the overall durability of the chrome coating. This technique is especially useful for high-precision, high-performance applications.

One significant advancement in powder coating technology is the development of low-temperature curing powders. Traditional powder coatings require high temperatures for curing, which can limit their use on heat-sensitive substrates. Low-temperature curing powders can cure at temperatures as low as 250°F (121°C), expanding the range of materials that can be powder coated. This innovation has opened up new applications in industries such as electronics and plastics.

Recent formulations of super-durable powders have been designed to withstand extreme environmental conditions. These powders offer enhanced UV resistance and improved color retention. They also provide superior protection against corrosion and chemicals. Super-durable powders are particularly beneficial for outdoor applications such as architectural components, automotive parts, and outdoor furniture.

The integration of anti-microbial properties into powder coatings represents another technological advancement. These coatings inhibit the growth of bacteria, fungi, and other microorganisms on the coated surface, making them ideal for use in healthcare facilities, food processing plants, and public spaces. Anti-microbial powder coatings help maintain hygiene and reduce the risk of contamination.

Advancements in both chrome plating and powder coating technologies have focused on reducing environmental impact. Trivalent chromium and pulse plating in chrome plating offer safer alternatives with reduced toxicity and improved efficiency. On the other hand, low-temperature curing and recyclable powders in powder coating promote energy savings and waste reduction.

Technological advancements have also expanded the application versatility of both coating methods. Nano-structured chrome coatings and pulse plating enhance the durability and precision of chrome plating, making it suitable for high-performance industrial applications. Similarly, low-temperature curing and super-durable powders in powder coating allow for a broader range of substrates and environments, including heat-sensitive materials and harsh outdoor conditions.

In terms of performance, both coating technologies have seen significant improvements. Nano-structured and pulse-plated chrome coatings offer superior hardness and wear resistance, while super-durable and anti-microbial powder coatings provide enhanced protection and hygiene. These advancements ensure that both chrome plating and powder coating can meet the demanding requirements of modern industrial and consumer applications.

By leveraging these technological advancements, manufacturers can achieve better performance, sustainability, and application flexibility in their coating processes.

Below are answers to some frequently asked questions:

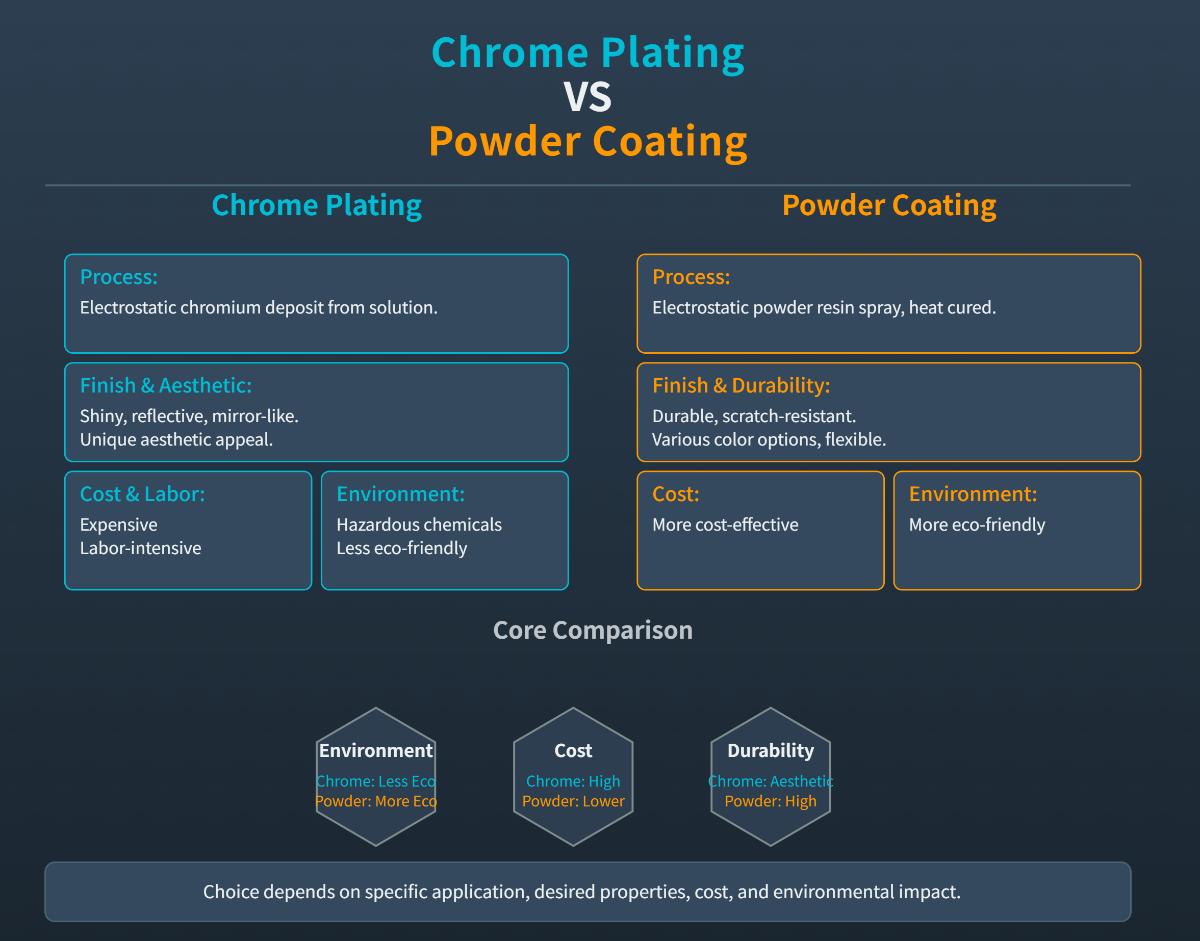

Chrome plating and powder coating are distinct methods for enhancing metal surfaces. Chrome plating involves immersing parts in a chromium solution, using electrostatic charges to create a shiny, reflective finish. It is labor-intensive, expensive, and uses hazardous chemicals, making it less environmentally friendly. Powder coating, on the other hand, applies powdered plastic resin electrostatically and cures it with heat. It is more cost-effective, environmentally friendly, and offers a durable, scratch-resistant finish with various color options. While chrome plating is prized for its unique aesthetic appeal, powder coating excels in durability, flexibility, and lower environmental impact. The choice between the two depends on the specific application and desired properties.

When comparing chrome plating and powder coating in terms of durability and cost-effectiveness, several key differences are evident.

Powder coating generally offers superior durability due to its thicker and more consistent application, providing excellent resistance to chips, scratches, and corrosion. The electrostatic bonding process ensures a strong, long-lasting finish suitable for harsh conditions. In contrast, chrome plating, while offering good corrosion protection, can be prone to brittleness and cracking, particularly in thinner layers, and may require additional maintenance to prevent issues like water retention and lime scale formation.

From a cost perspective, powder coating is typically more cost-effective. Its simpler application process, which uses fewer resources and no toxic chemicals, results in significant cost savings. In contrast, chrome plating is more labor-intensive, involving hazardous chemicals and specialized equipment, which drives up production costs.

For automotive applications, chrome powder coating generally proves to be the better method compared to traditional chrome plating. This is due to several factors:

Chrome plating and powder coating comply with environmental regulations in distinct ways due to the nature of their processes and materials. Chrome plating involves the use of hexavalent chromium, a known carcinogen, which is subject to stringent air quality regulations. Facilities must adhere to emission limits, such as California’s 2023 ATCM limit of 0.00075 mg/amp-hr by 2026, and employ tank covers, fume suppressants, or air pollution control devices to minimize emissions. Continuous monitoring, performance testing, and comprehensive recordkeeping are mandatory to ensure compliance.

In contrast, powder coating is inherently low in volatile organic compounds (VOCs) as it contains no solvents, aligning well with EPA and local air district standards. The process generates minimal hazardous waste, and any overspray can often be recycled, further reducing environmental impact. Powder coating requires periodic particulate checks and maintenance of application equipment to comply with particulate matter regulations.

Recent advancements in coating technologies for chrome plating and powder coating focus on enhancing performance, sustainability, and smart functionalities. Chrome plating has seen innovations such as self-healing coatings, which use microcapsules or nanotechnology to autonomously repair minor surface damage, improving durability and reducing maintenance. These advancements are transforming chrome plating from purely protective to more functional and adaptive applications.

In powder coating, significant progress includes ultra-low cure technologies, which allow curing at lower temperatures, expanding its use to heat-sensitive substrates like plastics and composites. This development enhances energy efficiency and broadens application scope. Additionally, high-performance finishes with improved chemical resistance, UV stability, and mechanical toughness are now possible. Smart and responsive coatings, incorporating thermochromic and photochromic additives, enable powder coatings to change color or properties in response to environmental stimuli, providing new functional and aesthetic possibilities.

These innovations ensure both chrome plating and powder coating remain vital in various industries, balancing performance, environmental impact, and technological advancements.