When it comes to selecting the right steel for your project, understanding the nuances between different alloys can make all the difference. Chrome Vanadium Steel and Chrome Molybdenum Steel are two such alloys that often come up in discussions due to their unique properties and widespread applications. But what sets them apart? Whether you’re an engineer, a mechanic, or a DIY enthusiast, knowing the differences in their chemical compositions, mechanical properties, and suitability for high-stress applications is crucial. In this comparative analysis, we’ll delve into the key characteristics of each alloy, explore their advantages and disadvantages, and help you determine which steel is the best fit for your specific needs. So, which alloy will rise to the occasion in your next high-stress project? Let’s find out.

Introduction to Steel Alloys

Definition and Importance of Steel Alloys

Steel alloys are mainly made of iron and mixed with elements like carbon, chromium, vanadium, molybdenum, manganese, and silicon to enhance specific properties, making them suitable for various industrial applications.

Key Benefits of Steel Alloys

- Enhanced Mechanical Properties: Alloying elements significantly improve the strength, toughness, hardness, and ductility of steel. This makes steel alloys ideal for applications requiring high durability and resistance to wear and tear.

- Corrosion Resistance: Elements like chromium and molybdenum enhance the corrosion resistance of steel, making it suitable for use in harsh environments where oxidation or rusting could be an issue.

- Improved Heat Resistance: Alloys with chromium and molybdenum work well in high temperatures, keeping their strength even when hot.

- Tailored Properties for Specific Applications: By varying the type and quantity of alloying elements, steel can be customized to meet the precise requirements of different industries, from automotive to aerospace and construction.

Overview of Alloying Elements

Common Alloying Elements and Their Effects

- Carbon (C): Mainly increases hardness and strength, but too much can make steel brittle.

- Chromium (Cr): Enhances hardness, toughness, and corrosion resistance. It is a crucial element in stainless steels.

- Vanadium (V): Improves strength, wear resistance, and toughness. Often used in high-speed tool steels.

- Molybdenum (Mo): Increases hardenability and high-temperature strength. It also enhances corrosion resistance in combination with chromium.

- Manganese (Mn): Contributes to strength and toughness. It also improves the hardenability and wear resistance of steel.

- Silicon (Si): Enhances strength and hardness while improving magnetic properties. It also acts as a deoxidizer during steel production.

Comparative Analysis of Key Alloying Elements

Carbon vs. Chromium

- Carbon: Mainly increases hardness and strength, but too much can make steel brittle.

- Chromium: Offers a balance between hardness and toughness while significantly improving corrosion resistance.

Vanadium vs. Molybdenum

- Vanadium: Enhances wear resistance and toughness, making it ideal for tools and automotive components.

- Molybdenum: Provides excellent high-temperature strength and corrosion resistance, suitable for high-stress environments like power generation and chemical processing.

Importance in Industrial Applications

Steel alloys are integral to many industrial applications due to their ability to be tailored for specific needs. For example:

- Automotive Industry: Requires materials that offer high strength, toughness, and wear resistance for engine components and structural parts.

- Construction: Demands steels with high tensile strength and durability to withstand heavy loads and harsh environmental conditions.

- Aerospace: Utilizes alloys with high strength-to-weight ratios and excellent resistance to thermal stress and corrosion.

Knowing each element’s role helps choose the right steel for the job, ensuring it performs well and lasts long.

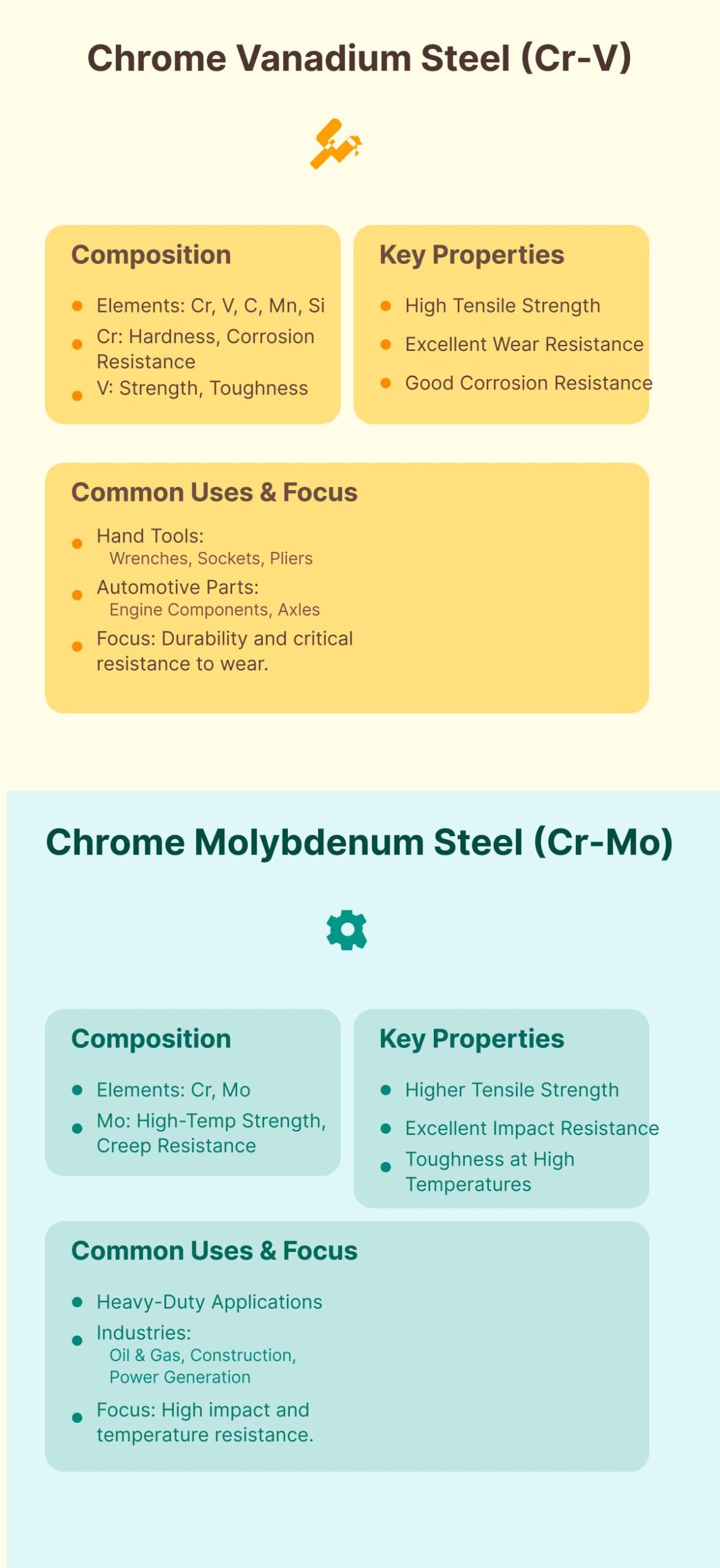

Chrome Vanadium Steel

Chemical Composition

Chrome Vanadium Steel, commonly referred to as Cr-V steel, is an alloy steel made by adding chromium (Cr) and vanadium (V) to carbon steel. The typical composition includes:

- Carbon (C): 0.50% to 1.00%

- Chromium (Cr): 0.80% to 1.10%

- Vanadium (V): 0.18% to 0.25%

- Manganese (Mn): 0.70% to 0.90%

- Silicon (Si): 0.30% to 0.50%

Adding chromium and vanadium significantly improves the steel’s mechanical properties, making it ideal for high-stress applications.

Mechanical Properties

Tensile Strength

Chrome Vanadium Steel offers high tensile strength, typically ranging from 190 to 300 MPa. This makes it suitable for applications requiring materials that can withstand substantial stress without deforming.

Toughness and Hardness

Vanadium refines the grain structure of the steel, enhancing its toughness. This makes the steel more impact-resistant and able to perform well under stress. The steel can become very hard when properly heat-treated, making it ideal for heavy-duty tasks.

Wear Resistance

The alloy provides excellent resistance to abrasion and wear. This characteristic extends the lifespan of tools and components made from Chrome Vanadium Steel, making them durable and reliable over long periods.

Corrosion Resistance

Chromium in the alloy provides a degree of resistance against rust and oxidation. However, proper maintenance is essential in high moisture or corrosive environments to prevent deterioration.

Common Applications

Hand Tools

Chrome Vanadium Steel is extensively used in manufacturing hand tools such as wrenches, pliers, screwdrivers, and sockets. These tools benefit from the steel’s high strength, toughness, and wear resistance.

Automotive Components

The alloy is also crucial in the automotive industry for parts that demand durability and resilience against stress and impact. Typical components include axles, crankshafts, and gears.

Industrial Machinery

In industrial settings, Chrome Vanadium Steel is used for making machinery parts that require high wear resistance and durability. This includes components for heavy machinery and equipment used in manufacturing processes.

Advantages and Disadvantages

Advantages

- High Strength and Toughness: The combination of chromium and vanadium results in a material that is both strong and tough, capable of withstanding high stress and impact.

- Wear Resistance: This excellent abrasion resistance extends the lifespan of tools and components, making them durable and reliable over long periods.

- Hardness: Achievable high hardness levels make it suitable for heavy-duty applications.

- Corrosion Resistance: Provides a reasonable level of protection against rust and oxidation.

Disadvantages

- Welding Challenges: The alloying elements can make welding Chrome Vanadium Steel difficult, requiring specific techniques to avoid cracking.

- Machinability: Although it can be machined, its toughness means harder cutting tools are needed.

- Cost: More expensive than plain carbon steels due to the complex alloying process and the cost of materials.

Chrome Vanadium Steel remains a popular choice for applications where high strength, durability, and wear resistance are paramount. Its balanced properties make it an excellent material for both hand tools and industrial components, despite some challenges in welding and machining.

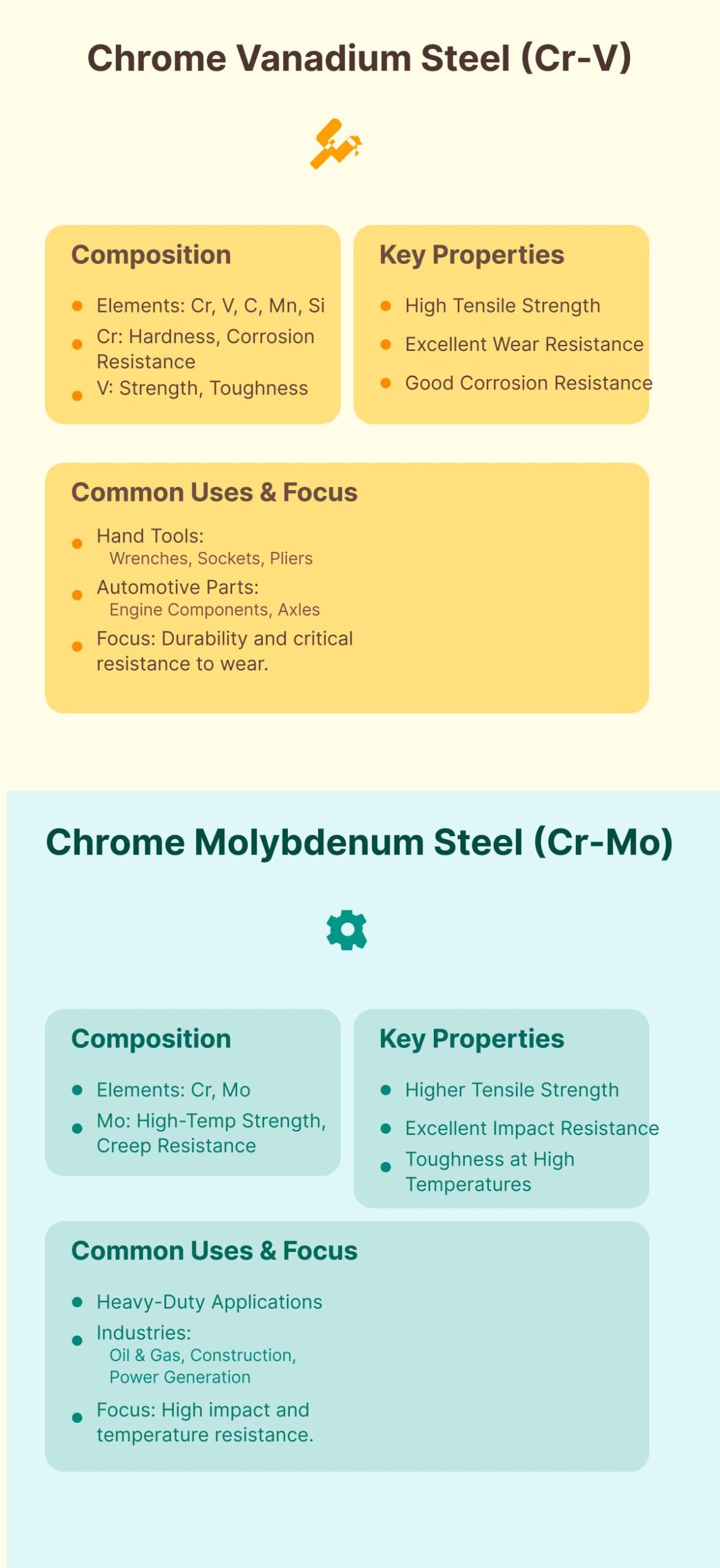

Chrome Molybdenum Steel

Chemical Composition

Chrome Molybdenum Steel, also known as Cr-Mo steel, is an alloy made primarily of chromium (Cr) and molybdenum (Mo). The typical chemical composition includes:

- Carbon (C): 0.15% to 0.30%

- Chromium (Cr): 0.50% to 1.50%

- Molybdenum (Mo): 0.15% to 0.45%

- Manganese (Mn): 0.30% to 0.60%

- Silicon (Si): 0.15% to 0.50%

The addition of chromium and molybdenum significantly enhances the steel’s mechanical properties, particularly its strength and resistance to high temperatures and corrosion.

Mechanical Properties

Tensile Strength

Typical tensile strength ranges from 485 MPa to over 620 MPa, making it ideal for applications requiring high durability.

High-Temperature Resistance

The molybdenum in the alloy boosts its creep strength, helping it stay strong under prolonged stress at high temperatures.

Corrosion Resistance

Chromium provides excellent resistance to oxidation and corrosion, which is crucial in environments like chemical processing and offshore drilling.

Toughness and Ductility

Chrome Molybdenum Steel exhibits a balanced combination of toughness and ductility. The material can absorb significant energy before fracturing, making it suitable for applications that require resistance to impact and sudden stress.

Common Applications

In construction, Cr-Mo steel is used for high-strength, fire-resistant components. The energy sector uses it for boilers and pressure vessels, while the automotive industry relies on it for durable components like crankshafts and gears. The oil and gas industry also extensively uses Chrome Molybdenum Steel for manufacturing components such as pipelines, valves, and drilling equipment, due to its high-temperature resistance and corrosion resistance.

Advantages and Disadvantages

Advantages

- High Strength and Durability: The alloy’s excellent mechanical properties make it suitable for high-stress applications.

- Temperature and Corrosion Resistance: Effective in high-temperature and corrosive environments, extending the lifespan of components.

- Ease of Fabrication: Despite its strength, Cr-Mo steel is relatively easy to weld, machine, and form, allowing for versatile manufacturing processes.

Disadvantages

- Cost: Chrome Molybdenum Steel can be more expensive than other alloy steels due to the cost of chromium and molybdenum.

- Special Handling Requirements: While it is easier to fabricate than some other high-strength steels, it still requires specific techniques and precautions during welding and heat treatment to avoid cracking and other issues.

Comparative Analysis

Chemical Composition

Chrome Vanadium Steel (Cr-V) contains carbon, chromium, vanadium, manganese, and silicon, with chromium boosting hardenability and corrosion resistance, and vanadium enhancing tensile strength and wear resistance. Chrome Molybdenum Steel (Cr-Mo), on the other hand, contains chromium and molybdenum. Molybdenum provides high-temperature strength and creep resistance, maintaining structural integrity under prolonged stress at high temperatures.

Mechanical Properties

Strength

- Chrome Vanadium Steel: With a tensile strength ranging from 190 to 300 MPa, Chrome Vanadium Steel is ideal for applications needing materials that withstand substantial stress without deforming.

- Chrome Molybdenum Steel: Exhibits tensile strength ranging from 485 MPa to over 620 MPa, making it ideal for applications requiring high durability and strength.

Toughness and Ductility

- Chrome Vanadium Steel: Known for its excellent fatigue resistance and toughness, making it suitable for high-impact applications.

- Chrome Molybdenum Steel: Its toughness and ductility allow Chrome Molybdenum Steel to absorb significant energy before fracturing, crucial for high-stress environments.

Wear Resistance

- Chrome Vanadium Steel: Offers excellent resistance to abrasion and wear, extending the lifespan of tools and components.

- Chrome Molybdenum Steel: While also wear-resistant, its primary advantage lies in its high-temperature performance rather than abrasion resistance.

Cost

- Chrome Vanadium Steel: Generally more affordable due to the lower cost of vanadium.

- Chrome Molybdenum Steel: Pricier due to the higher cost of molybdenum and complex alloying.

Performance in High-Stress Applications

- Chrome Vanadium Steel: Excels in applications requiring high tensile strength and fatigue resistance, such as hand tools and automotive components that endure repeated stress and high-impact conditions.

- Chrome Molybdenum Steel: Superior in high-temperature environments, making it ideal for the oil and gas industry, power generation, and other applications where thermal stability and corrosion resistance are paramount.

Suitability for Different Industries

- Chrome Vanadium Steel: Preferred in the manufacturing of hand tools, automotive components, and industrial machinery parts due to its strength, toughness, and wear resistance.

- Chrome Molybdenum Steel: Widely used in high-temperature industries such as oil and gas, construction, and power generation, where its high-temperature performance and corrosion resistance are critical.

Detailed Use Cases for Chrome Vanadium Steel

- Hand Tools: Ideal for wrenches, pliers, screwdrivers, and sockets due to its high strength and wear resistance.

- Automotive Components: Ideal for axles, crankshafts, and gears, which need durability and stress resistance.

- Industrial Machinery: Suitable for machinery parts that need high wear resistance and durability, including components for heavy machinery and manufacturing equipment.

Detailed Use Cases for Chrome Molybdenum Steel

- Oil and Gas Industry: Essential for pipelines, valves, and drilling equipment due to its high-temperature resistance and corrosion resistance.

- Construction: Used for high-strength, fire-resistant components in buildings and infrastructure.

- Energy Sector: Utilized in boilers, pressure vessels, and other high-stress equipment that must withstand prolonged exposure to high temperatures.

Industry Standards Compliance (ASTM, SAE)

Both Chrome Vanadium and Chrome Molybdenum steels comply with various industry standards, including ASTM and SAE specifications, ensuring their reliability and suitability for critical applications.

Environmental Impact and Sustainability Considerations

- Chrome Vanadium Steel: Generally has a lower environmental impact due to the lower cost and simpler production process.

- Chrome Molybdenum Steel: While more resource-intensive to produce, its longer lifespan and superior performance in high-stress applications can offset the initial environmental costs, making it a sustainable choice for specific industries.

Cost-Benefit Analysis

To compare the initial costs of Chrome Vanadium Steel (Cr-V) and Chrome Molybdenum Steel (Cr-Mo), consider factors like base material costs, the alloying process, and necessary treatments.

Initial Cost Comparison

Chrome Vanadium Steel (Cr-V)

- Material Costs: Adding chromium and vanadium makes Cr-V steel more expensive than plain carbon steel, but these elements are cheaper than molybdenum, which is used in Cr-Mo steel.

- Alloying Process: Adding chromium and vanadium to carbon steel is straightforward, keeping manufacturing costs low.

- Market Price: Cr-V steel is generally more affordable than Cr-Mo steel, making it a good choice for budget-conscious projects.

Chrome Molybdenum Steel (Cr-Mo)

- Material Costs: The cost of molybdenum is higher than that of vanadium, contributing to a higher – Alloying Process: The addition of molybdenum requires specific thermal treatments to achieve the desired properties, increasing the complexity and cost of production.

- Market Price: Typically more expensive than Cr-V steel due to the higher cost of raw materials and more complex manufacturing processes.

Long-term Value and Durability

Chrome Vanadium Steel (Cr-V)

- Durability: Known for its high tensile strength, toughness, and excellent wear resistance, Cr-V steel offers long-lasting performance in demanding applications.

- Maintenance: Requires regular maintenance to prevent corrosion, especially in high-moisture environments.

- Replacement Cycle: The durability of Cr-V steel can reduce the frequency of replacements, offering long-term cost savings.

Chrome Molybdenum Steel (Cr-Mo)

- Durability: Exceptional strength at high temperatures and superior corrosion resistance make Cr-Mo steel highly durable, particularly in harsh environments.

- Maintenance: Lower maintenance requirements due to its inherent resistance to corrosion and oxidation.

- Replacement Cycle: The extended lifespan of Cr-Mo steel components can justify the higher initial cost, resulting in lower long-term replacement costs.

Maintenance and Replacement Costs

Chrome Vanadium Steel (Cr-V)

- Maintenance Costs: Moderate maintenance costs due to the need for regular inspections and treatments to prevent corrosion.

- Replacement Costs: While the initial cost is lower, frequent replacements may be necessary in highly corrosive environments, increasing the total cost over time.

Chrome Molybdenum Steel (Cr-Mo)

- Maintenance Costs: Lower maintenance costs due to its superior corrosion and oxidation resistance, reducing the need for frequent inspections and treatments.

- Replacement Costs: Higher initial cost but fewer replacements required over time, making it a cost-effective option for applications demanding long-term durability.

Application-Specific Cost-Benefit Analysis

High-Stress Applications

- Chrome Vanadium Steel (Cr-V): Suitable for applications requiring high tensile strength and wear resistance, such as hand tools and automotive components. The lower initial cost is beneficial for projects with budget constraints.

- Chrome Molybdenum Steel (Cr-Mo): Preferred for high-temperature environments, such as in the oil and gas industry and power generation. The higher initial cost is offset by its long-term performance and lower maintenance requirements.

Industry-Specific Considerations

- Automotive Industry: Cr-V steel is often favored for its balance of cost and performance in manufacturing durable automotive parts.

- Construction and Industrial Equipment: Cr-Mo steel is ideal for construction and industrial equipment due to its high-temperature performance and long-term durability, justifying the higher initial investment.

Choosing between Cr-V and Cr-Mo steel depends on your application’s needs. Cr-V steel is cost-effective for many high-stress uses, while Cr-Mo steel excels in high-temperature and corrosive environments.

Technical Reference

Detailed Technical Specifications

Professionals in the engineering and manufacturing industries must understand the detailed technical specifications of Chrome Vanadium Steel (Cr-V) and Chrome Molybdenum Steel (Cr-Mo). This knowledge is crucial for making informed decisions.

Microstructure Diagrams

Chrome Vanadium Steel (Cr-V):

- Microstructure: Typically features a fine grain structure due to the presence of vanadium, which acts as a grain refiner. This fine grain structure, which enhances the steel’s strength and toughness, consists of a mix of ferrite and pearlite phases.

- Heat Treatment Effects: Quenching and tempering Cr-V steel form martensite, which significantly increases its hardness and tensile strength.

Chrome Molybdenum Steel (Cr-Mo):

- Microstructure: Exhibits a tempered martensitic structure with fine, evenly distributed carbides. Molybdenum contributes to the formation of stable carbides, which improve high-temperature strength and creep resistance.

- Heat Treatment Effects: Similar to Cr-V, Cr-Mo steel can be quenched and tempered to achieve a martensitic structure, but with better high-temperature stability due to molybdenum.

Standards and Certifications

Chrome Vanadium Steel (Cr-V):

- Commonly adheres to ASTM A231 and A681 standards.

- Classified under SAE 6150 for its use in high-stress applications.

Chrome Molybdenum Steel (Cr-Mo):

- Typically meets ASTM A335 and ASTM A387 standards.

- Often falls under SAE 4130 and SAE 4140, denoting its suitability for aircraft and other high-stress applications.

Material Properties Comparison

- Chrome Vanadium Steel (Cr-V):

- Hardness: 48-52 HRC

- Yield Strength: 620 MPa

- Tensile Strength: 190-300 MPa

- Chrome Molybdenum Steel (Cr-Mo):

- Hardness: Up to 55 HRC

- Yield Strength: 435-635 MPa

- Tensile Strength: 485-620 MPa

Heat Treatment Processes

Chrome Vanadium Steel (Cr-V):

- Annealing: Performed at 850-900°C followed by slow cooling, which improves machinability and reduces hardness.

- Quenching and Tempering: Heated to 850-900°C and quenched in oil or water, followed by tempering at 400-600°C to achieve desired hardness and toughness.

Chrome Molybdenum Steel (Cr-Mo):

- Annealing: Conducted at 800-850°C with slow furnace cooling, enhancing machinability.

- Quenching and Tempering: Typically heated to 870-900°C, quenched in oil, and tempered at 540-680°C, optimizing strength and high-temperature performance.

Welding Considerations

Chrome Vanadium Steel (Cr-V):

- Preheating: Required to prevent cracking, typically at 200-300°C.

- Post-Weld Heat Treatment (PWHT): Necessary to relieve stresses and ensure structural integrity, usually conducted at 550-650°C.

Chrome Molybdenum Steel (Cr-Mo):

- Preheating: Essential to prevent hydrogen-induced cracking, usually at 150-300°C.

- Post-Weld Heat Treatment (PWHT): Critical for stress relief and to restore mechanical properties, typically performed at 600-750°C.

Environmental Considerations

Chrome Vanadium Steel (Cr-V): Lower environmental impact due to simpler production processes and lower alloying element costs.

Chrome Molybdenum Steel (Cr-Mo): Higher initial environmental impact due to the energy-intensive production process and the cost of alloying elements, but its longer lifespan and superior performance in demanding applications can offset this over time.

Frequently Asked Questions

Below are answers to some frequently asked questions:

What are the differences in properties and applications between Chrome Vanadium Steel and Chrome Molybdenum Steel?

Chrome Vanadium Steel (Cr-V) and Chrome Molybdenum Steel (Cr-Mo) differ significantly in their properties and applications due to their distinct chemical compositions and resultant mechanical characteristics.

Chrome Vanadium Steel contains chromium, vanadium, carbon, manganese, and silicon. Chromium enhances its hardness and corrosion resistance, while vanadium increases strength and toughness. This alloy is known for high tensile strength, excellent wear resistance, and good corrosion resistance, making it ideal for hand tools (wrenches, sockets, pliers) and automotive components like engine parts and axles, where durability and resistance to wear are critical.

Chrome Molybdenum Steel, on the other hand, includes chromium and molybdenum. Molybdenum significantly enhances high-temperature strength and creep resistance. This steel offers higher tensile strength, excellent impact resistance, and the ability to maintain toughness at elevated temperatures. It is well-suited for heavy-duty applications requiring high impact and temperature resistance, such as in the oil and gas industry, construction, and power generation.

Which steel alloy is more suitable for high-stress applications?

Chrome Vanadium Steel (Cr-V) and Chrome Molybdenum Steel (Cr-Mo) are both high-performance alloys suited for demanding applications, but their suitability for high-stress environments varies based on their properties.

Chrome Vanadium Steel is known for its high tensile strength (190-300 MPa), excellent wear resistance, and good corrosion resistance. It maintains hardness at elevated temperatures, making it ideal for tools that experience frequent friction and automotive components that require durability and impact resistance.

Chrome Molybdenum Steel, on the other hand, offers superior tensile strength and enhanced resistance to high temperatures and creep due to the presence of molybdenum. Its superior corrosion resistance, especially in high-temperature environments, makes it suitable for structural applications in industries like oil and gas, construction, and aerospace.

For high-stress applications involving wear resistance and impact strength, Chrome Vanadium Steel is a strong candidate. However, for applications that also demand high-temperature resistance and superior strength, Chrome Molybdenum Steel is the better choice.

How do the costs of Chrome Vanadium and Chrome Molybdenum compare?

When comparing the costs of Chrome Vanadium (Cr-V) and Chrome Molybdenum (Cr-Mo) steels, several factors influence their pricing. Chrome Vanadium steel is generally more cost-effective due to the lower cost of its alloying elements, chromium and vanadium, and simpler manufacturing processes. This makes Cr-V a popular choice for hand tools like wrenches and sockets, providing good performance at a lower price point.

On the other hand, Chrome Molybdenum steel, which includes the more expensive element molybdenum, is typically more costly. The manufacturing process for Cr-Mo is also more complex, often requiring specific thermal treatments to enhance its high-temperature strength and corrosion resistance. As a result, Cr-Mo steel is favored for high-stress and high-temperature applications, such as in the aerospace, oil, and gas industries.

What are the typical industries that use Chrome Vanadium and Chrome Molybdenum steels?

Chrome Vanadium Steel and Chrome Molybdenum Steel are both widely used in various industries due to their unique properties.

Chrome Vanadium Steel is typically used in industries that require high tensile strength and wear resistance. This makes it a popular choice for:

- Hand Tools: Wrenches, screwdrivers, and sockets due to its toughness and ability to withstand impact.

- Automotive Components: Springs, gears, and other parts that require durability and resistance to fatigue.

Chrome Molybdenum Steel (CrMo), on the other hand, is favored for its high-temperature stability, strength, and corrosion resistance. It is commonly utilized in:

- Oil and Gas Industry: For pipelines and offshore rigs, where materials need to resist corrosion and maintain structural integrity under high pressure and temperatures.

- Construction: Structural components that benefit from enhanced fire resistance.

- Nuclear Industry: Applications requiring high resistance to radiation and heat.

- Automotive Industry: High-performance parts such as crankshafts and clutch systems.

- Aerospace: Aircraft frames and suspension systems, where a high strength-to-weight ratio and impact resistance are critical.

Both alloys serve distinct purposes and are chosen based on the specific requirements of the application.

Are there any environmental impacts associated with these steel types?

Both Chrome Vanadium (Cr-V) and Chrome Molybdenum (Cr-Mo) steels have notable environmental impacts primarily associated with their production processes. The extraction of vanadium for Cr-V steel can lead to environmental contamination, affecting soil and water quality. Molybdenum, used in Cr-Mo steel, is often a byproduct of copper mining, which can also result in water pollution and habitat destruction if not properly managed.

However, both steel types offer environmental benefits during their usage. Vanadium microalloying in steel production can enhance material efficiency, reduce energy consumption, and minimize waste by eliminating certain heat treatment steps. Both Cr-V and Cr-Mo steels possess high corrosion resistance and durability, reducing the frequency of replacements and associated waste generation. These properties contribute to more sustainable manufacturing processes despite the initial environmental challenges related to resource extraction.

How do the maintenance and replacement costs compare for these steels?

When comparing the maintenance and replacement costs of Chrome Vanadium (Cr-V) steel and Chrome Molybdenum (Cr-Mo) steel, it is important to consider factors such as durability, impact resistance, and application suitability. Cr-V steel is known for its high tensile strength and wear resistance, making it suitable for standard hand tools. However, it can be brittle in high-impact applications, leading to more frequent replacements. This brittleness can increase maintenance costs if tools are used inappropriately.

On the other hand, Cr-Mo steel offers excellent impact resistance, high-temperature strength, and superior durability in demanding environments. This results in fewer replacements and lower long-term maintenance costs. Although Cr-Mo steel might have higher initial production costs due to the expensive molybdenum content, its longevity and reduced need for frequent replacements can make it more cost-effective over time.

In summary, while Cr-V steel may have lower initial costs, Cr-Mo steel’s enhanced durability and impact resistance can lead to significant savings in maintenance and replacement expenses in high-stress applications. The choice between these alloys should be based on the specific demands of the application and the balance between initial investment and long-term performance.