Imagine the power of a material that seamlessly blends strength, versatility, and precision. Cold rolled steel stands as a cornerstone in modern manufacturing, offering unparalleled benefits across various industries. This article will delve into the intricate composition, diverse uses, and dynamic properties of cold rolled steel, providing you with a comprehensive technical reference. Whether you’re curious about its chemical makeup, intrigued by its mechanical prowess, or seeking insight into its industrial applications, we’ve got you covered. How does the chemical composition influence the performance of cold rolled steel, and what makes it a preferred choice in automotive and construction sectors? Discover the answers as we unravel the secrets behind this remarkable material.

Cold rolled steel (CRS) has a specific chemical composition that provides certain mechanical properties and makes it easy to form. The chemical composition includes various elements in controlled proportions, each contributing to the overall characteristics of the steel.

The chemical composition of cold rolled steel typically includes the following elements:

| Element | Typical Content Range (wt.%) | Role and Effect |

|---|---|---|

| Carbon (C) | 0.01% to 0.17% (commonly ≤ 0.12%) | Provides strength and hardness; lower carbon improves formability and weldability. |

| Manganese (Mn) | 0.20% to 0.70% | Enhances hardenability and tensile strength; improves toughness and wear resistance. |

| Silicon (Si) | Up to 0.55% (varies by grade) | Acts as a deoxidizer and improves strength. |

| Phosphorus (P) | ≤ 0.045% | These elements are kept minimal to ensure the steel remains tough and less brittle. |

| Sulfur (S) | ≤ 0.030% | These elements are kept minimal to ensure the steel remains tough and less brittle. |

| Copper (Cu) | 0.25%–0.50% (in corrosion-resistant variants) | Improves corrosion resistance and strength. |

| Nickel (Ni) | Up to 0.50% | Provides corrosion resistance and toughness. |

| Chromium (Cr) | 0.05%–0.20% | Enhances corrosion resistance and hardness. |

| Other elements | Trace amounts of Mo, Sb, Sn, V, Nb, Ti may be present | Used for specialized properties such as grain refinement, strength, and corrosion resistance. |

The chemical composition of cold rolled steel directly affects its mechanical behavior. This includes factors such as strength, ductility, and corrosion resistance. Each element plays a specific role:

Different global standards specify the chemical composition of cold rolled steel to ensure consistency and quality. Here is a comparison based on some common standards:

| Standard | Carbon (C) | Manganese (Mn) | Phosphorus (P) | Sulfur (S) | Other Key Elements |

|---|---|---|---|---|---|

| ASTM A1008/A1008M | ≤ 0.15% | ~0.60% | ≤ 0.045% | ≤ 0.030% | – |

| JIS G 3141 | ≤ 0.12% | ~0.35% | ≤ 0.030% | ≤ 0.035% | – |

| EN 10130 | ≤ 0.12% | 0.25%–0.60% | ≤ 0.045% | ≤ 0.045% | – |

These standards ensure that cold rolled steel produced in different regions meets specific mechanical and chemical requirements, facilitating its use in diverse applications globally. By adhering to these standards, manufacturers can guarantee the quality and performance of the steel for various industrial applications.

Mechanical properties define how a material behaves when subjected to different forces and conditions. For cold rolled steel, these properties are influenced by its chemical composition and the processes it undergoes during manufacturing.

Tensile strength is the maximum stress that cold rolled steel can withstand while being stretched or pulled before breaking. Yield strength, on the other hand, refers to the stress at which a material begins to deform plastically; beyond this point, the steel will not return to its original shape when the stress is removed. Cold rolled steel generally exhibits higher tensile and yield strengths compared to hot rolled steel, with tensile strength often reaching up to 85,000 psi and yield strength around 70,000 psi. These elevated strengths are crucial for applications requiring materials that can endure substantial forces and sustain high loads without deforming or undergoing permanent shape change, making cold rolled steel suitable for structural components.

Elongation indicates how much cold rolled steel can stretch before breaking. Ductility is the ability of the steel to deform under tensile stress, showing its flexibility. Cold rolled steel usually has lower elongation compared to hot rolled steel, with values around 28%. However, it can be made more ductile through annealing, a process of heating and cooling that alters its microstructure and improves formability.

Hardness is the measure of a material’s resistance to deformation, indentation, or scratching. Cold rolled steel is generally harder than hot rolled steel, with a Brinell hardness number of about 167. This increased hardness enhances wear resistance, making the steel well – suited for applications such as tool manufacturing and machinery parts that demand a durable and precise material.

The mechanical properties of cold rolled steel can vary significantly depending on the specific production processes it undergoes. Cold rolling at room temperature creates a finer grain structure, which increases both strength and hardness. However, this process can introduce internal stresses that might need to be relieved through annealing to avoid warping during subsequent fabrication.

The mechanical properties of cold rolled steel are crucial for its performance in various applications. High tensile and yield strengths make it suitable for structural components in the automotive and construction industries, where materials must withstand significant loads and stresses. The hardness of cold rolled steel is beneficial for manufacturing precision parts that require durability and wear resistance.

In the electrical industry, the formability and smooth surface finish of cold rolled steel are essential for producing components with tight tolerances and high surface quality. The steel’s ductility, enhanced through annealing, allows it to be formed into complex shapes without cracking, making it ideal for intricate designs in appliances and metal furniture.

Data – driven approaches allow for precise control and prediction of the mechanical properties of cold rolled steel. By analyzing the effects of various alloying elements and processing parameters, manufacturers can tailor the steel to meet specific requirements. For instance, increasing the carbon content can enhance tensile strength, while adding manganese improves toughness and wear resistance.

Advanced techniques like continuous annealing and bake – hardening improve the formability and strength of cold rolled steel. Recent advances aim to optimize these properties with sophisticated processing methods. Continuous monitoring and data analysis during production enable manufacturers to produce cold rolled steel with consistent and desirable mechanical properties, ensuring its suitability for high – performance applications across different industries.

Cold rolled steel is extensively utilized in the automotive industry due to its high strength, excellent surface quality, and precise dimensions. These properties are crucial for manufacturing various automotive components that require durability and aesthetic appeal.

Cold rolled steel is a preferred material for car body panels and frames. Its high tensile strength provides structural integrity and safety, which are essential for withstanding impacts and ensuring passenger protection. For instance, the Ford F-150 uses cold rolled steel in its body structure to enhance durability. Additionally, the smooth surface finish enhances the visual appeal of vehicles, a significant factor in the automotive market.

The precision and durability of cold rolled steel make it ideal for critical engine and transmission components. These parts operate under high stress and temperatures, requiring materials that maintain their mechanical properties under such conditions. Its ability to retain strength and formability ensures reliable performance and longevity of these components.

Cold rolled steel is also used in suspension systems and springs, contributing to a smoother and more stable ride. The material’s high strength and fatigue resistance are vital for components that experience constant dynamic loads and stresses.

The construction industry benefits significantly from the use of cold rolled steel, particularly in structural applications where strength, precision, and durability are paramount.

Cold rolled steel is utilized in beams, columns, and framing due to its high tensile strength and lighter weight compared to other materials. This makes it ideal for commercial and multi-story buildings where load-bearing capacity and structural integrity are critical. For example, the iconic Empire State Building incorporates cold rolled steel in its structural framework, facilitating easier assembly and construction processes.

It is often used in roofing and cladding applications. Its durable and weather-resistant finish is essential for protecting buildings from environmental damage. Moreover, the material’s aesthetic qualities enhance the visual appeal of both residential and commercial structures.

Cold rolled steel is employed in various interior and exterior finishes due to its aesthetic appeal and versatility. It is used in decorative elements, facades, and structural components, contributing to both the functionality and design of buildings.

Cold rolled steel’s mechanical properties and surface finish make it suitable for numerous manufacturing applications, including home appliances and machinery components.

It is used in the production of machinery components due to its low yield strength, good mechanical characteristics, and excellent stamping performance. These properties ensure that the components are durable and precise, essential for the efficient operation of production machinery.

Cold rolled steel is found in a wide range of home appliances, such as refrigerators, washing machines, dryers, and microwaves. Its durability, formability, and aesthetic appeal make it an ideal material for these applications, where both functionality and design are important.

The strength, design flexibility, and smooth finish of cold rolled steel make it a popular choice for metal furniture. It is used in the manufacturing of desks, chairs, cabinets, and other furniture items that require robust and attractive materials.

Cold rolled steel is also employed in various other industries, including aerospace, pressure vessels, and packaging.

In the aerospace industry, cold rolled steel is used for precision components that require high strength and reliability. Its ability to maintain dimensional accuracy and mechanical properties under extreme conditions makes it suitable for aerospace applications.

Cold rolled steel is used in the manufacturing of pressure vessels. Its ability to withstand high pressures and harsh environments without failing is crucial for these applications. This material ensures that the vessels remain safe and functional under intense conditions.

It is also utilized in packing materials, conveyor systems, and various hardware accessories. Its strength, durability, and smooth surface finish make it suitable for these applications, where materials must endure constant use and mechanical stresses.

Silicon steel sheets, also called electrical steel, are a specialized alloy mainly made of iron with 1% to 6.5% silicon. Cold-rolled silicon steel sheets typically have 3% to 5% silicon. They also contain 0.06% carbon, 0.15% manganese, 0.03% phosphorus, and occasionally sulfur and aluminum. The silicon content is a critical factor; a high silicon content (2.8% – 4.8%) enhances magnetism but also increases brittleness.

These sheets possess several key properties:

Compared to general cold-rolled steel, which is used in automotive, construction, and home appliance industries for its strength and formability, silicon steel sheets have a higher silicon content. This higher silicon content enhances their magnetic properties, making them ideal for electrical applications.

Silicon steel sheets are crucial in the manufacture of transformer and generator cores. Their high magnetic permeability and low core loss properties ensure efficient energy transfer and conversion, reducing energy waste and improving the Silicon steel sheets come in two main types: Grain-Oriented (GO) for applications like transformers and Grain Non-Oriented (GNO) for motor cores. Cold-rolled sheets offer better surface quality and magnetic properties than hot-rolled ones.

Cold rolled steel production has significantly improved in energy efficiency. For instance, the U.S. steel industry cut down energy use per ton of steel by about one-third from the early 1990s to 2007. This reduction results from advancements in manufacturing efficiency and the adoption of cleaner production technologies. The cold rolling process, carried out at room temperature, consumes less energy compared to hot rolling. This lower energy consumption directly contributes to a reduced environmental impact, as it leads to lower greenhouse gas emissions and a smaller carbon footprint.

Steel, including cold rolled steel, is one of the most recycled materials globally. It can be recycled repeatedly without any degradation in quality. In the production of cold rolled steel, at least 25% recycled steel content is typically incorporated. Moreover, it supports an end-of-life recycling rate of approximately 95%. This high recyclability minimizes waste and reduces the need for raw material extraction. The recycling process also generates net environmental credits by offsetting the requirement for virgin ore extraction and decreasing greenhouse gas emissions.

The manufacturing methods for cold rolled steel are designed with waste minimization in mind. Steel sheets or coils are precisely formed and cut to order, which significantly reduces offcuts and scrap. In construction, on-site waste is notably lower when using cold rolled steel framing compared to traditional materials like timber. This aligns with lean construction principles, ensuring that material usage is optimized and waste is kept to a minimum.

The enhanced mechanical properties of cold rolled steel result in long-lasting structural elements. These elements require less frequent replacement or repair. Over the building lifecycle, this longevity reduces the environmental impact by lowering the demand for new materials and the associated energy use. Buildings framed with cold rolled steel generally outperform timber or concrete counterparts in terms of durability and resistance to heat transfer, which also improves energy efficiency.

Cold rolled steel components can be designed to reduce heat loss. By reducing heat loss through framing elements, the need for additional insulation materials is decreased, and operational energy consumption for heating and cooling is lowered. This thermal efficiency helps buildings comply with stringent energy codes and contributes to achieving certifications such as LEED and Energy Star.

Cold rolled steel meets or exceeds the requirements of multiple green building certification systems, including LEED, Green Star, WELL, and the International Green Construction Code. The availability of Environmental Product Declarations (EPDs), Life Cycle Assessments (LCAs), and Health Product Declarations (HPDs) for cold rolled steel products enhances transparency and supports sustainable procurement decisions.

Beyond its environmental benefits, cold rolled steel offers significant cost savings. Its reduced material weight allows for easier handling and is compatible with off-site prefabrication methods. These factors lead to shorter construction schedules, lower labor demands, and reduced site disturbances, further strengthening its position as a sustainable material in the construction industry.

According to the worldsteel LCA eco-profiles, the cradle-to-gate environmental impact of cold rolled steel production involves:

The LCA adheres to ISO 14040 and ISO 14044 standards and provides a transparent assessment of CO2 emissions, energy use, water consumption, and other environmental indicators relevant for sustainable construction certifications.

Below are answers to some frequently asked questions:

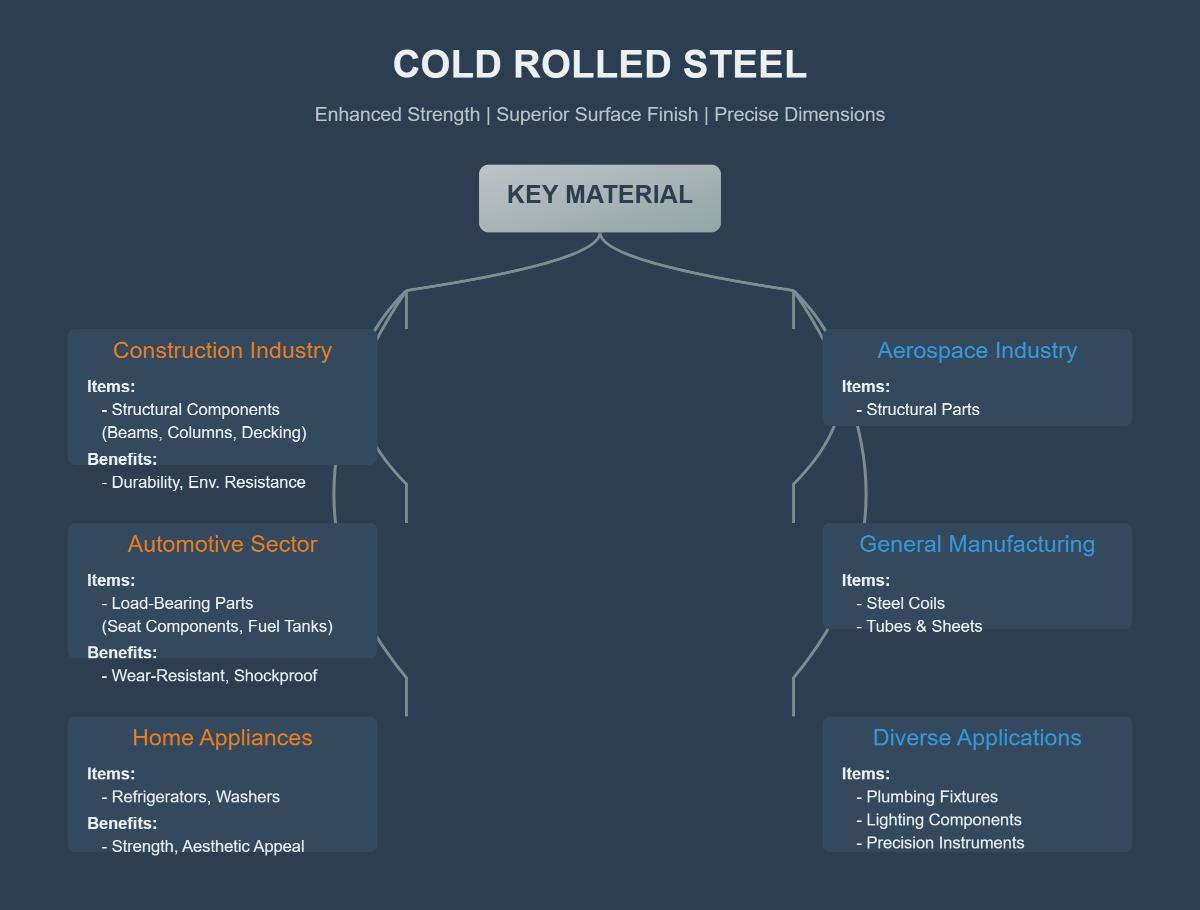

Cold rolled steel is predominantly used across various industries due to its enhanced strength, superior surface finish, and precise dimensions achieved through processing at room temperature. In the construction industry, it is essential for creating structural components like beams, columns, and floor decking, offering durability and resistance to environmental conditions. The automotive sector leverages cold rolled steel for its wear-resistant and shockproof properties, making it ideal for load-bearing parts such as seat components and fuel tanks. Additionally, it plays a crucial role in the manufacturing of home appliances, providing the required strength and aesthetic appeal for products like refrigerators and washing machines. Cold rolled steel is also vital in the aerospace industry for structural parts, and it is used in various manufacturing applications, including steel coils, tubes, and sheets. Its versatility extends to plumbing fixtures, lighting, and precision instruments, making it a preferred material for numerous applications.

The typical chemical composition of cold rolled steel generally includes low levels of carbon and manganese, with stringent controls on impurities such as phosphorus and sulfur. Specifically, the carbon content is usually less than 0.12%, while manganese ranges from approximately 0.4% to 0.6%. Phosphorus and sulfur are typically limited to below 0.045% each. These compositions can vary slightly depending on specific standards and applications, such as ASTM, JIS, and EN.

For specialized applications like cold rolled silicon steel sheets, the composition includes higher levels of silicon, typically between 3% to 5%, to enhance magnetic properties. This precise control of chemical composition ensures that cold rolled steel meets the required mechanical properties and performance criteria for various industrial applications.

Cold rolled steel exhibits varying mechanical properties based on its processing, composition, and temper designation. The cold rolling process enhances tensile strength and hardness due to strain hardening and grain refinement but reduces ductility. For example, tensile strength can increase from approximately 67,000 psi in hot rolled steel to around 85,000 psi in cold rolled steel, while elongation decreases from 36% to about 28%. Various tempers, such as No. 1 (Hard) or No. 2 (Half-hard), further influence these properties, with harder tempers showing higher tensile strength and lower ductility. Additionally, annealing post cold rolling can restore ductility and relieve internal stresses, allowing for tailored mechanical properties suitable for specific applications.

Cold rolled steel compares favorably to other steel types in terms of sustainability, particularly when considering energy efficiency, recyclability, and material usage. The cold rolling process operates at or near room temperature, which reduces the energy required for heating compared to hot rolled steel. This makes it more energy-efficient, though the additional processing steps can increase costs. Cold rolled steel is highly recyclable, contributing to waste reduction and the efficient use of resources.

Compared to cold-formed steel (CFS), cold rolled steel offers precision and a superior surface finish, making it ideal for applications requiring tight tolerances and aesthetic quality. However, CFS stands out for its high strength-to-weight ratio, minimal waste production, and exceptional recyclability, making it particularly suitable for sustainable construction projects. The choice between cold rolled steel and other types depends on specific project needs, including cost, precision, and environmental considerations.

The chemical composition of cold rolled steel (CRS) varies according to global standards such as JIS (Japan), ASTM (USA), and EN (Europe). These standards reflect differences in applications, mechanical property targets, and manufacturing processes.

Japanese JFE standards (JIS-based) typically allow higher carbon (C) content, up to 0.14-0.17%, and include significant alloying elements like copper (Cu), nickel (Ni), chromium (Cr), and molybdenum (Mo) for corrosion resistance and mechanical strength. In contrast, ASTM A1008 standards in the USA limit C to a maximum of 0.10% for commercial quality steels, with specific grades allowing lower C content (e.g., 0.02-0.06%) for deep drawing applications. Manganese (Mn) content can range from 0.30-0.80% in ASTM standards, enhancing strength but controlled to maintain formability.

European EN standards, such as those from Tatmetal, specify even lower carbon content for deep drawing steels (e.g., DC05 at 0.06%) and have stringent controls on phosphorus (P) and sulfur (S) to ensure high ductility and quality. Silicon (Si) is used as a deoxidizer across all standards, with varying limits.

Microalloying elements like vanadium (V), niobium (Nb), and titanium (Ti) are incorporated in high-strength low-alloy (HSLA) steels in ASTM standards to achieve improved mechanical properties.

Cold rolled steel plays a vital role in sustainable development across various industries. Its production is energy – efficient compared to hot rolling, consuming less energy and generating less waste. With a high strength – to – weight ratio, it reduces the overall material needed for projects, lowering raw material extraction and transportation emissions. It is 100% recyclable, which significantly cuts the demand for virgin raw materials and associated carbon emissions. In construction, it’s used for durable infrastructure, while in buildings, it supports green certifications by improving energy efficiency. In automotive and manufacturing, it aids in making lighter, more efficient products. Economically, it’s cost – effective and helps conserve resources and enhance resilience.