When it comes to ensuring the integrity and efficiency of your piping systems, understanding the ins and outs of ASME B16.5 blind flanges is crucial. These vital components play a significant role in sealing off the ends of pipe networks, preventing leaks and maintaining system pressure. But how do you choose the right blind flange for your specific application? And what are the key considerations for installing and maintaining them effectively? In this comprehensive guide, we delve deep into the technical aspects of ASME B16.5 blind flanges, exploring their types, applications, pressure classes, and compliance standards. Whether you’re looking to optimize your installation practices or extend the lifespan of your flanges through proper maintenance, this article provides the detailed insights you need. Ready to enhance your piping system’s performance? Let’s dive in.

ASME B16.5 is a crucial standard developed by the American Society of Mechanical Engineers (ASME) that specifies guidelines for pipe flanges and flanged fittings. It encompasses dimensions, materials, pressure-temperature ratings, tolerances, marking, and testing requirements, ensuring compatibility and safety in various piping systems. The primary purpose of ASME B16.5 is to provide a uniform set of guidelines that manufacturers and engineers can follow to ensure the reliable performance of piping systems.

The importance of ASME B16.5 in piping systems and pressure vessels is significant, as it provides essential guidelines for designing and manufacturing flanges that can withstand various pressures and temperatures. This standard helps prevent system failures that could result in costly downtime, safety hazards, and environmental damage. By adhering to ASME B16.5, industries such as oil and gas, chemical processing, and power generation can maintain the integrity and safety of their operations.

ASME B16.5 specifies the dimensions and tolerances for various types of flanges, including slip-on, weld neck, socket weld, threaded, lap joint, and blind flanges. These dimensions include the flange outside diameter, bolt circle diameter, and flange thickness, among others. The standard ensures that all flanges manufactured to these specifications can be easily assembled with other components in the piping system.

Pressure-temperature ratings are a critical aspect of ASME B16.5. These ratings indicate the maximum allowable pressure a flange can handle at specific temperatures, ensuring safe operation under different conditions. The standard defines different pressure classes (e.g., 150, 300, 600, 900, 1500, and 2500) which indicate the maximum allowable pressure a flange can handle at specific temperatures. These ratings ensure that flanges can operate safely under varying conditions without compromising system integrity.

ASME B16.5 covers a wide range of materials suitable for flange construction, including various grades of carbon steel, stainless steel, and alloy steel. The material selection is crucial as it must match the requirements of the application, considering factors such as corrosion resistance, temperature tolerance, and mechanical strength. The standard also outlines the acceptable manufacturing processes and quality control measures to ensure the flanges meet the required specifications.

Proper marking and testing are essential to verify that flanges comply with ASME B16.5. The standard requires flanges to be marked with crucial information, such as the manufacturer’s name, material grade, pressure class, and size, and mandates various tests, including pressure tests and nondestructive examinations, to verify their integrity and performance.

Adhering to ASME B16.5 ensures that flanges are manufactured to a high standard of quality, providing confidence in their use across diverse industrial applications.

Blind flanges, as defined by the ASME B16.5 standard, are essential for sealing the ends of pipes and pressure vessels. These components come in several types, each designed to meet specific pressure and sealing requirements.

Flat Face (FF) blind flanges have a smooth, flat sealing surface, typically used in low to medium pressure applications. Raised Face (RF) blind flanges, on the other hand, feature a raised sealing surface that concentrates the sealing load on a smaller area, making them suitable for higher pressure applications.

Ring Type Joint (RTJ) blind flanges have a groove for a metal ring gasket, providing the highest level of sealing reliability. This makes them ideal for extreme pressure and temperature environments, such as those found in the oil and gas industry.

Blind flanges are essential in various industries for sealing the ends of piping systems, valves, or pressure vessels. They are used in multiple sectors, each benefiting from their reliable sealing capabilities.

Blind flanges are commonly used to permanently or temporarily seal pipe ends to stop fluid flow. This is especially useful during maintenance, repairs, or system modifications. By isolating sections of the piping system, blind flanges ensure safety and maintain system integrity, preventing unwanted fluid movement and contamination.

Blind flanges provide convenient points for pressure testing pipelines without the risk of leakage. By sealing off a section of the system, technicians can safely test pressure levels and inspect internal conditions. This application is crucial for ensuring the integrity and safety of piping systems before they are put into service.

Pressure classes in ASME B16.5 define the maximum allowable working pressures for flanges across different temperatures. These classes ensure that flanges can operate safely under specified conditions, preventing failures and maintaining system integrity.

ASME B16.5 specifies seven main pressure classes for flanges:

Each class represents a set of pressure-temperature ratings that depend on the flange material and operating conditions. The pressure classes dictate the thickness, bolt hole diameter, and other dimensions, ensuring the flange can withstand the designated pressure.

Pressure classes are crucial as they indicate a flange’s ability to withstand internal pressure and temperature without failure, with ASME B16.5 rating tables organizing materials into groups and detailing pressure-temperature limits for each class. To select the correct pressure class, understand the maximum operating pressure and temperature, then choose the flange material and class that meet or exceed these conditions.

Blind flanges are solid discs used to seal pipe ends, valves, or pressure vessel openings. They follow the same pressure class structure as other flanges, ranging from Class 150 to Class 2500. Blind flanges do not have a bore or hub; instead, bolt holes are symmetrically drilled around the flange perimeter.

Blind flanges, especially larger ones, experience significant bending stresses at the center due to their solid design under internal pressure. This makes them among the most highly stressed flange types. Their robust construction allows them to safely withstand higher stress levels compared to other flange types.

Selecting the appropriate pressure class for blind flanges involves several key considerations:

| Pressure Class | Pressure Capability (relative) | Typical Application Notes |

|---|---|---|

| 150 | Low pressure | Common in low-pressure piping systems |

| 300 | Moderate pressure | Widely used in many piping applications |

| 400 | Intermediate (less common) | Used in specific cases, less frequent today |

| 600 | High pressure | Industrial and process piping |

| 900 | Higher pressure | More demanding industrial environments |

| 1500 | Very high pressure | Critical high-pressure systems |

| 2500 | Highest pressure (up to 12″) | Specialized high-pressure, small-diameter flanges |

This classification ensures blind flanges are selected correctly for pressure containment, maintaining safety and performance integrity in piping and pressure vessel systems.

The ASME B16.5 standard provides comprehensive guidelines for the manufacturing and application of pipe flanges and flanged fittings, including blind flanges. It specifies the dimensions, materials, pressure-temperature ratings, and tolerances for flanges, covering sizes from NPS 1/2 to NPS 24 and pressure classes from Class 150 to Class 2500. These guidelines ensure piping systems are reliable and safe by setting uniform specifications for manufacturers and engineers.

ASME B16.5 blind flanges are typically made from cast, forged, or plate materials, ensuring they meet specific strength and composition requirements. These materials include various grades of carbon steel, stainless steel, and alloy steel, chosen based on their ability to withstand different pressures, temperatures, and environmental conditions.

The standard specifies precise dimensions for blind flanges, such as the outside diameter, bolt circle diameter, and thickness. These dimensions are essential for ensuring compatibility and proper function within the piping system. Adherence to these specifications helps prevent leaks and system failures.

Blind flanges should be manufactured as a single piece, without welding or bolting multiple parts together. This manufacturing process enhances the structural integrity and reliability of the flanges, ensuring they can withstand high-pressure environments without compromising performance.

Blind flanges must be marked according to ASME B16.5 standards to ensure compliance and provide crucial information. This marking includes details such as the manufacturer’s name, material grade, pressure class, and size. Proper identification helps in verifying that the flanges meet the required specifications and are suitable for their intended application.

Regular inspections help monitor flange thickness and ensure they meet standards. This includes checking for any signs of wear or potential leaks. Nondestructive examinations, such as ultrasonic testing or radiography, may be conducted to detect internal flaws. Pressure tests are also performed to verify the flange’s ability to handle the designated pressure ratings.

For inspection or vent purposes, threaded holes may be tapped into the flange’s center. These holes must meet ASME B1.20.1 standards for effective thread length, ensuring they do not compromise the flange’s structural integrity.

For blind flanges that do not conform to ASME B16.5, they must be designed in accordance with Section VIII, Division 1, UG-34 of the ASME Boiler and Pressure Vessel Code or relevant sections of ASME B31.3. This ensures that even custom-made flanges meet necessary safety and performance standards, maintaining system reliability.

Compliance with ASME B16.5 standards is essential for ensuring safety, reliability, and interoperability in piping systems. It helps in preventing issues such as leaks or system failures that could arise from incorrect dimensions or materials. Adhering to these standards also facilitates maintenance and inspection processes, as all components are designed to a common set of specifications.

Recent guides emphasize the importance of adhering to ASME B16.5 specifications for materials, dimensions, and manufacturing processes. Best practices involve accounting for corrosion allowances, conducting regular inspections, and adhering to proper installation procedures. These measures help maintain the integrity and safety of piping systems, ensuring long-term performance and reliability.

Proper preparation is crucial for the successful installation of ASME B16.5 blind flanges. This process ensures that all components are correctly aligned and ready for assembly.

Before starting the installation, inspect all components, including the blind flange, bolts, nuts, and gaskets. Check for any visible damage, such as cracks, warping, or surface irregularities, which could compromise the integrity of the seal. Clean the mating surfaces of the blind flange and the adjacent flange. Remove any dirt, debris, or old gasket material to ensure a smooth and effective seal. Use suitable cleaning solvents and tools, ensuring the sealing surfaces remain undamaged.

Proper Alignment: Ensure that the bolt holes of the blind flange align perfectly with those of the adjacent flange. Misalignment can lead to leaks and uneven pressure distribution. Use alignment tools if necessary to achieve precise alignment.

Visible Area Placement: Position the blind flange so that its visible face is directed downwards. This orientation facilitates inspection and maintenance, allowing for easy access to the flange during regular checks.

Bolt Insertion: Carefully insert bolts through the aligned bolt holes. Start by hand-tightening the bolts to hold the flange in place. This step helps to prevent misalignment during the final tightening process.

Tightening Sequence: Tighten the bolts in a cross pattern to distribute pressure evenly across the flange. Gradually increase the torque in stages, avoiding over-tightening, as excessive force can distort the flange and compromise the seal.

Inspect the gasket before installation. Ensure it is in good condition, free from cracks, cuts, or other defects. A damaged gasket can lead to leaks and system failures.

Position the gasket correctly between the blind flange and the adjacent flange. Make sure it is centered and not protruding into the pipe bore. The gasket should cover the entire sealing surface to achieve a tight and effective seal.

Having the right tools and equipment is essential for a smooth installation process. Common tools and equipment include:

To prevent leaks and uneven pressure distribution caused by misalignment, use alignment tools and double-check the alignment before tightening the bolts.

Over-tightening bolts can distort the flange and damage the gasket. Use a calibrated torque wrench and follow the recommended torque values for the specific pressure class and material.

Damaged gaskets can lead to leaks. Always inspect gaskets before installation and replace any that show signs of wear or damage. Ensure proper storage of gaskets to prevent damage before use.

After the installation is complete, perform a final inspection to ensure all bolts are properly tightened and the flange is correctly aligned. Check for any signs of misalignment or potential leaks. Conduct a pressure test to verify the integrity of the seal and confirm that the blind flange can handle the specified pressure.

Regular inspections are essential for maintaining ASME B16.5 blind flanges. These inspections should be conducted periodically to detect early signs of wear, damage, or misalignment that could compromise the system’s integrity. Key aspects to monitor include:

Maintaining the cleanliness and lubrication of blind flanges and associated bolts is essential for ensuring their longevity and ease of maintenance:

Properly tightening and loosening bolts is key to maintaining blind flange integrity:

Verifying the dimensions of blind flanges during inspections ensures compliance with ASME B16.5 specifications:

Verifying that the material and manufacturing process meet ASME standards is vital for flange performance:

For blind flanges with threaded holes used for inspection or venting purposes, proper threading is vital:

These practices can extend the lifespan of ASME B16.5 blind flanges:

Below are answers to some frequently asked questions:

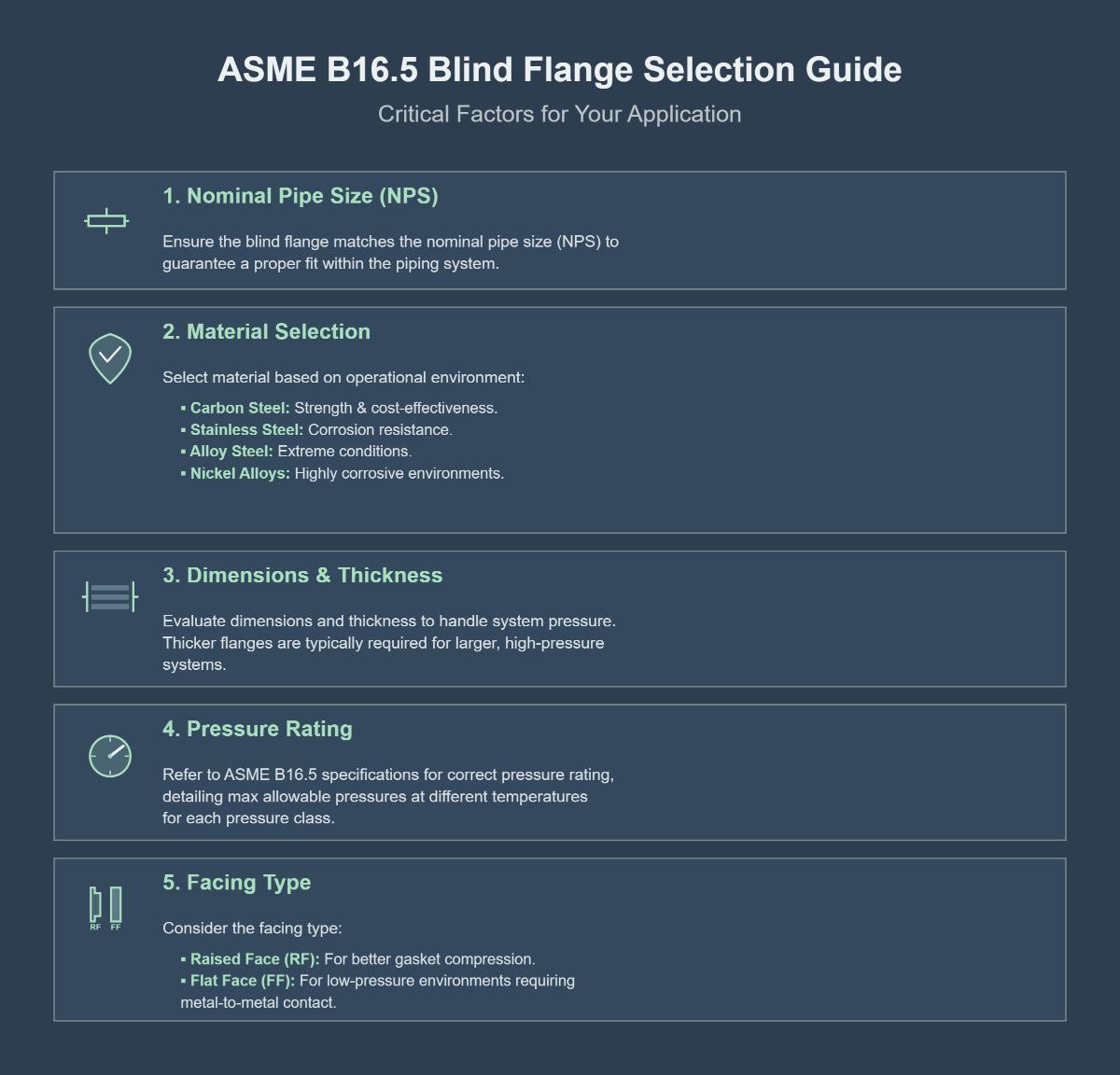

To choose the right ASME B16.5 blind flange for your application, consider several critical factors. First, ensure the blind flange matches the nominal pipe size (NPS) to guarantee a proper fit within the piping system. Next, select the appropriate material based on the operational environment; common options include carbon steel for strength and cost-effectiveness, stainless steel for corrosion resistance, alloy steel for extreme conditions, and nickel alloys for highly corrosive environments.

Evaluate the flange dimensions and thickness to ensure it can handle the system’s pressure, with thicker flanges typically required for larger, high-pressure systems. Select the correct pressure rating by referring to ASME B16.5 specifications, which detail maximum allowable pressures at different temperatures for each pressure class. Additionally, consider the facing type—raised face (RF) for better gasket compression or flat face (FF) for low-pressure environments requiring metal-to-metal contact.

When installing and maintaining ASME B16.5 blind flanges, several key considerations ensure proper function and longevity.

Firstly, selecting the appropriate blind flange is crucial. This includes ensuring the flange size and pressure rating match the pipeline specifications and selecting materials compatible with the fluid type, temperature, and corrosion conditions. Common materials include carbon steel, stainless steel, and cast iron.

Before installation, it’s important to clean and inspect pipe ends, ensuring they are free of contaminants. Proper gasket selection is also essential to prevent leaks. During installation, ensure bolt holes align perfectly, and tighten bolts evenly in a crisscross pattern to avoid flange warping.

Maintenance involves regular inspections for leaks, corrosion, and bolt loosening. Retightening bolts should be done carefully, following the same pattern used during installation. Additionally, applying corrosion protection and replacing gaskets and bolts as needed can extend the flange’s lifespan.

Following these guidelines helps maintain the integrity and performance of the blind flanges in piping systems.

Blind flanges offer several benefits in piping systems, making them a valuable component for sealing pipe ends or isolating sections for maintenance and testing. Their solid design, lacking a central bore, ensures a robust, leak-proof seal, preventing the escape of fluids or gases and maintaining system integrity, especially in high-pressure and high-temperature environments.

One significant advantage is their ability to isolate parts of the piping system without shutting down the entire operation. This facilitates safe and efficient maintenance, inspections, or repairs, minimizing downtime and operational interruptions. Additionally, blind flanges enhance safety during hydrostatic or pneumatic pressure testing, as they provide a strong barrier to prevent the escape of potentially dangerous substances, thus protecting personnel and equipment from exposure to hazardous materials.

Blind flanges are versatile, compatible with various piping materials like stainless steel, carbon steel, and alloy steel, and can be customized to meet specific operational demands. Their straightforward design makes them cost-effective and reduces maintenance costs by simplifying the sealing process and preventing frequent repairs. Moreover, they are durable and resistant to corrosion, pressure, and temperature variations, extending the lifespan of piping system components.

Pressure classes are critical in determining the performance of blind flanges as they define the maximum allowable working pressure (MAWP) at specific temperatures. Blind flanges, which are used to seal the ends of piping systems, come with standardized pressure ratings under ASME B16.5, including classes such as 150, 300, 600, 900, 1500, and 2500. Each class corresponds to a different MAWP, influencing the flange’s ability to withstand internal pressures safely.

As the pressure class number increases, the blind flange can handle higher pressures, making it suitable for more demanding applications. However, the pressure capacity varies with temperature; higher temperatures can reduce the material strength and thus lower the allowable pressure. ASME B16.5 provides detailed pressure-temperature rating tables to guide the selection process.

Material selection also plays a role, as different materials have varying pressure-temperature limits. Higher pressure classes often require thicker or reinforced flanges to maintain integrity under increased stress, impacting installation considerations and cost.

Blind flanges, as discussed earlier, are used to seal the ends of pipes in various piping systems. The choice of material for these flanges is crucial to ensure optimal performance and durability. Common materials used for blind flanges under the ASME B16.5 standard include:

Steel: Carbon steel and alloy steel are widely used due to their mechanical strength and cost-effectiveness. Forged steel is preferred for high-pressure and high-temperature applications, while plate steel is suitable for less demanding conditions where cost is a factor.

Stainless Steel: Types such as 304L and 316L are favored for their excellent corrosion resistance, making them ideal for environments like chemical processing and marine applications.

Cast Iron: Though less common, cast iron is used in low-pressure applications due to its affordability.

Other Materials: Aluminum, copper, and plastic are used for specific applications where weight and corrosion resistance are critical factors.

Selecting the appropriate material involves considering mechanical strength, corrosion resistance, durability, and compatibility with the connecting pipe material.

Compliance with ASME B16.5 standards for blind flanges is essential to ensure their safety, reliability, and interoperability in piping systems. The key compliance requirements include:

By adhering to these compliance requirements, blind flanges can ensure the safety and efficiency of piping systems.