Imagine a material that balances strength, versatility, and cost-effectiveness, widely used in everything from towering skyscrapers to intricate machinery. Welcome to the world of ASTM A36 steel, a cornerstone of the construction and manufacturing industries. This guide delves into the essential properties and diverse applications of ASTM A36 steel, providing a detailed analysis tailored for intermediate users seeking a data-driven understanding.

We’ll explore its chemical and mechanical properties, compare it with other steel grades like S235JR and SS400, and highlight its practical uses in construction and industrial settings. How does ASTM A36 achieve its unique blend of strength and adaptability? Read on to uncover the key characteristics that make it a preferred choice for engineers and fabricators worldwide.

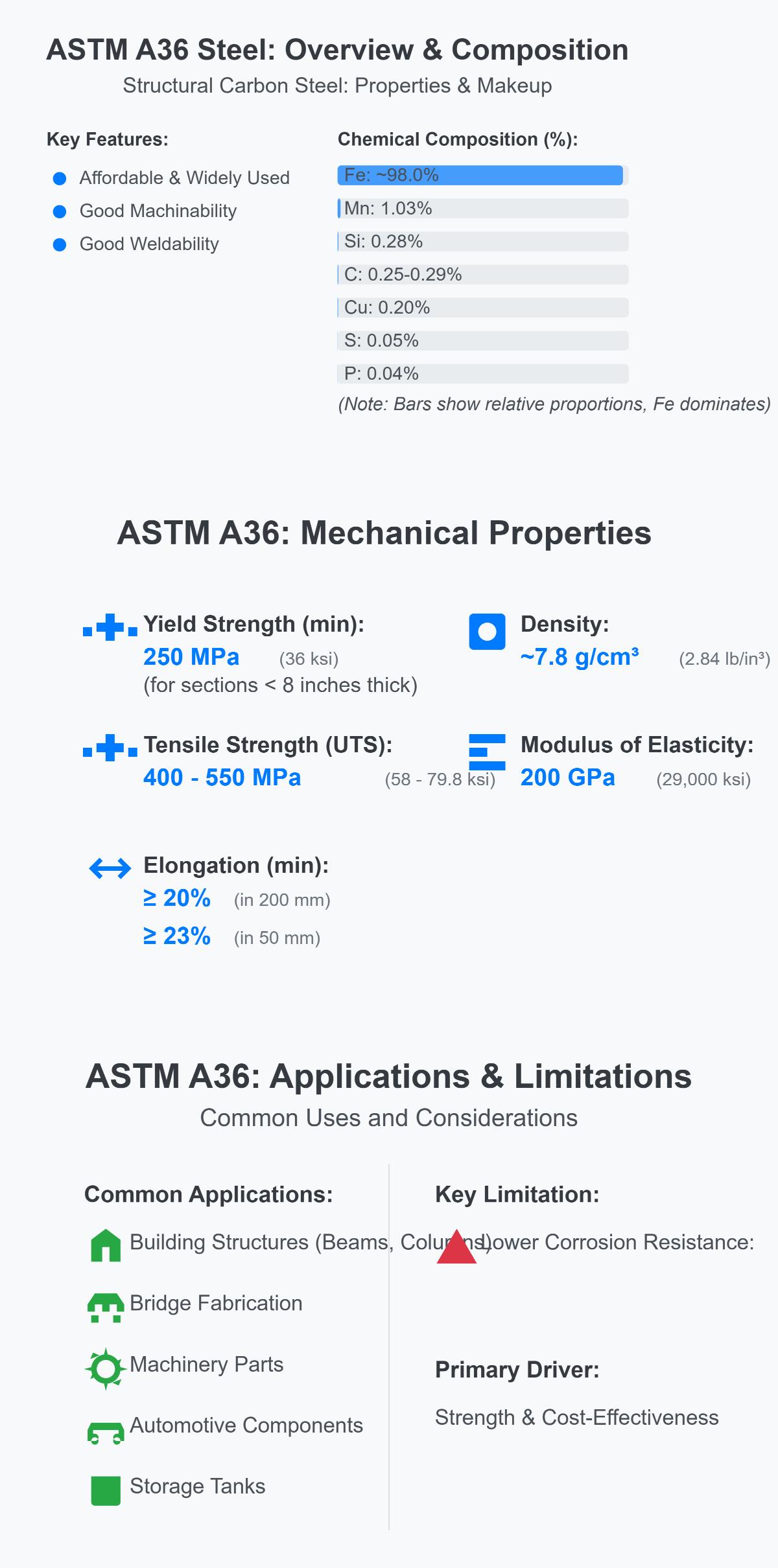

ASTM A36 steel is a widely used carbon structural steel known for meeting standard specifications. It is renowned for its excellent mechanical properties, including good weldability, formability, and machinability, making it a versatile choice for various structural applications. With a low carbon content of around 0.25%, it is classified as mild steel. This low carbon content enhances its ability to be welded and formed without compromising its structural integrity.

ASTM A36 steel plays a crucial role in the steel industry due to its balance of strength, affordability, and versatility, making it ideal for constructing buildings, bridges, and other infrastructure projects. The steel’s mechanical properties make it suitable for manufacturing structural components such as beams, columns, and reinforcements. Its widespread use in the industry is driven by its compliance with ASTM standards, ensuring consistent quality and performance.

The chemical composition of ASTM A36 steel is designed to provide a balance between strength and ductility. Key elements include:

This composition ensures that ASTM A36 steel maintains good weldability and machinability, while providing sufficient strength for structural applications.

ASTM A36 steel exhibits several key mechanical properties that make it suitable for various applications:

These properties make the steel ideal for withstanding significant loads and stresses in construction and industrial applications.

The production of ASTM A36 steel involves a series of steps to ensure its quality and consistency:

ASTM A36 steel is utilized across a broad range of industries due to its mechanical properties and ease of fabrication:

The weldability of ASTM A36 steel is one of its most notable features. It can be welded using various techniques without preheating, making it convenient for construction and manufacturing:

The chemical composition of ASTM A36 steel is designed to balance strength and ductility, making it ideal for structural applications. The primary elements and their respective content limits are:

| Element | Content (% ≤) |

|---|---|

| Carbon (C) | 0.25 – 0.29 |

| Silicon (Si) | 0.280 – 0.40 |

| Manganese (Mn) | ~1.03 |

| Phosphorus (P) | 0.040 |

| Sulfur (S) | 0.050 |

| Copper (Cu) | ≥ 0.20 |

| Iron (Fe) | 98.0 |

ASTM A36 steel has a minimum yield strength of 36,000 psi (250 MPa) for thicknesses less than 8 inches (203 mm) and 32,000 psi (220 MPa) for thicker plates. Yield strength is the stress at which a material begins to deform plastically, indicating the point where it will no longer return to its original shape when the applied stress is removed.

The ultimate tensile strength (UTS) of ASTM A36 steel ranges from 58,000 to 80,000 psi (400 to 550 MPa), indicating the maximum stress it can withstand before breaking.

ASTM A36 steel can elongate at break by at least 20% in a 200 mm sample and 23% in a 50 mm sample, showing its ability to stretch before fracturing.

The density of ASTM A36 steel is approximately 7.8 g/cm³ (0.284 lb/in³). This property is crucial for calculating the weight of steel components in structural and mechanical applications.

The melting point of ASTM A36 steel is around 1,425 – 1,538°C (2,600 – 2,800°F). Knowledge of the melting point is important for processes like welding and heat treatment.

While ASTM A36 steel can be subjected to heat treatments such as annealing and stress relieving, its low carbon content limits the extent to which these treatments can enhance its properties. Carburizing and hardening methods, typically used for higher carbon steels, may be applied but will yield limited improvements.

The production of ASTM A36 steel involves melting iron ore with coal, adding alloying elements, casting the molten steel into ingots or slabs, and hot rolling it to form plates, bars, or structural shapes, ensuring uniformity and enhanced mechanical properties.

ASTM A36 steel is commonly used in constructing structural components such as beams, columns, and girders. These components form the backbone of buildings and bridges, relying on the steel’s yield strength of 250 MPa (36,000 psi) and ultimate tensile strength ranging from 400 to 550 MPa (58,000 to 79,800 psi) to withstand heavy loads. For instance, in multi – story buildings, A36 steel beams distribute the weight of the floors and occupants evenly, ensuring the structure’s stability.

In bridge construction, ASTM A36 steel’s properties make it an ideal choice. Its weldability allows for the seamless joining of different parts. Its strength can endure the dynamic loads of traffic and environmental forces. The elongation at break of up to 20% in a 200 mm gauge length provides the necessary flexibility to withstand vibrations and minor movements, contributing to the bridge’s long – term durability.

Building frames made from ASTM A36 steel can resist various loads, including wind, seismic, and gravitational forces. The steel with a density of about 7.85 g/cm³ makes it easy to calculate the load – bearing capacity precisely. This enables engineers to design efficient and safe building frames that can accommodate different architectural styles and functions.

The ease of machining and weldability of ASTM A36 steel make it a popular choice in manufacturing machinery and equipment. It can be easily cut, drilled, and shaped into various components, such as gears, shafts, and frames. For example, in the production of industrial presses, A36 steel frames provide the necessary rigidity to support the high – pressure operations.

In the oil and gas industry, ASTM A36 steel is used for constructing storage tanks. Its strength and durability allow it to withstand the pressure and weight of the stored liquids or gases. Additionally, the steel’s formability enables the creation of tanks in different shapes and sizes to meet specific storage requirements.

In the automotive sector, ASTM A36 steel is used in vehicle components where reliability and cost – effectiveness matter. It can be found in chassis and frames, providing the necessary strength to protect passengers and withstand the stresses of driving. The steel’s affordability also helps in reducing the overall production costs, making vehicles more accessible to a broader range of consumers.

The steel can be fabricated into parts for tractors and harvesting equipment to withstand harsh agricultural conditions like rough terrain and heavy – duty use.

While ASTM A36 and S235JR share similar chemical compositions, minor differences impact their properties. ASTM A36 contains up to 0.25% carbon, 0.40% silicon, and 1.03% manganese, while S235JR has a maximum of 0.17% carbon, with comparable levels of silicon and manganese. The lower carbon content in S235JR makes it slightly more ductile compared to ASTM A36.

The mechanical properties of these two grades are comparable but vary slightly. ASTM A36 has a minimum yield strength of 36,000 psi (250 MPa) and an ultimate tensile strength ranging from 58,000 to 80,000 psi (400 to 550 MPa). S235JR, on the other hand, has a minimum yield strength of 33,000 psi (235 MPa) and an ultimate tensile strength between 49,000 to 71,000 psi (340 to 490 MPa). This makes ASTM A36 slightly stronger and preferable for higher-strength applications.

SS400, a Japanese standard steel, has a chemical composition and mechanical properties that are similar to ASTM A36. Both steels have a carbon content of around 0.25% and similar levels of silicon and manganese. However, SS400 may have slightly different limits for phosphorus and sulfur.

Mechanically, SS400 has a minimum yield strength of 36,300 psi (250 MPa) and an ultimate tensile strength ranging from 58,000 to 73,000 psi (400 to 500 MPa), which are comparable to ASTM A36. This similarity makes SS400 an alternative to ASTM A36 in applications where Japanese standards are used.

ASTM A36 has several international equivalents, ensuring its global applicability and ease of use in various projects. Some of the common equivalent grades include:

These equivalents share similar chemical compositions and mechanical properties, making them interchangeable in many structural applications.

The equivalence of ASTM A36 with other international grades ensures compliance with global standards, facilitating its use in international projects. This compatibility is particularly beneficial in construction and infrastructure projects that require materials to meet specific regional standards.

ASTM A36 steel has a density of approximately 7.8 g/cm³ and a modulus of elasticity of 200 GPa. These properties are consistent with other equivalent grades. This consistency ensures similar performance in stiffness and load-bearing capacity.

ASTM A36 exhibits a hardness range of 67-83 on the Rockwell B scale. It maintains its strength up to around 343°C (650°F), with higher temperatures leading to a reduction in strength. These thermal properties are comparable to equivalent grades like S235JR and SS400, making them suitable for similar applications.

While ASTM A36 has limited corrosion resistance, it is often used with protective coatings in environments prone to moisture or chemical exposure. This practice is similarly applied to its equivalent grades, ensuring long-term durability and performance.

ASTM A36 steel is widely recognized for its excellent weldability, primarily due to its low carbon content, which reduces the risk of weld cracking. With a carbon content of 0.25% to 0.29%, ASTM A36 steel is ideal for various welding methods.

Proper control of heat input and cooling rates is crucial when welding ASTM A36 steel to maintain its mechanical properties and prevent defects such as warping or cracking.

ASTM A36 steel is known for its reasonable machinability, though it’s not as easily machined as some other low-carbon steels like AISI 1018. The machinability rate of ASTM A36 is approximately 72%, which is adequate for many industrial applications.

For optimal machining performance, the following tooling recommendations should be considered:

The heat-affected zone in welding ASTM A36 steel can be a concern due to the potential for reduced toughness and increased brittleness. To mitigate this, preheating the steel before welding and controlling the cooling rate post-welding can help maintain the desired mechanical properties.

Although the low carbon content reduces cracking risks, using compatible filler materials and controlling heat input are essential to prevent weld cracks.

Machining ASTM A36 steel can sometimes reveal hard spots caused by inconsistent microstructure. These can be managed by using slower cutting speeds and ensuring tools are sharp and well-maintained.

ASTM A36 steel’s balance of weldability and machinability makes it a versatile choice for various structural and mechanical applications. By following recommended welding techniques and machining practices, high-quality and reliable components can be produced, ensuring structural integrity and performance.

The production of ASTM A36 steel has several stages that contribute to its environmental impact. First, iron ore is extracted. Then, it is melted in a blast furnace along with coal and other alloying elements. This melting process is energy – intensive. It leads to significant greenhouse gas emissions, mainly carbon dioxide (CO₂). After that, the steel undergoes hot rolling to form various shapes. This rolling process also consumes a large amount of energy. To mitigate these emissions, efforts are being made to improve energy efficiency in the production process and adopt cleaner energy sources.

One significant environmental benefit of ASTM A36 steel is its high recyclability. Steel can be recycled numerous times without losing its properties. This reduces the demand for virgin raw materials and minimizes waste. The recycling process uses less energy compared to producing new steel from raw materials, thus lowering the carbon footprint and greenhouse gas emissions associated with steel production.

While the carbon content of ASTM A36 steel is relatively low, its production process still contributes to its carbon footprint. The main sources of emissions are the combustion of fossil fuels during melting and rolling. The steel industry, including large – scale steel producers and research institutions, is actively exploring strategies to reduce this carbon footprint. For example, they are looking into using electric arc furnaces powered by renewable energy and developing hydrogen – based steelmaking technologies.

ASTM A36 steel is not naturally resistant to corrosion. This can lead to additional environmental impacts due to the need for protective coatings and maintenance. However, galvanizing the steel can greatly enhance its corrosion resistance, reducing the frequency of maintenance and replacements. In construction projects, using steel with better corrosion resistance, like galvanized ASTM A36, in structural components such as beams and columns can contribute to long-term sustainability and cost savings.

The durability of ASTM A36 steel ensures that structures built with it can have a long service life. This reduces the need for frequent replacements. As a result, fewer resources are consumed over time, which is a crucial factor in sustainable construction practices. Durable materials help conserve natural resources and reduce the overall environmental impact associated with manufacturing and transportation.

The widespread availability of ASTM A36 steel globally allows for the use of local supplies. This reduces transportation – related emissions. Using locally sourced materials minimizes the distance the steel needs to be transported, thereby lowering the carbon footprint associated with logistics. This practice supports more sustainable supply chain management in the construction and manufacturing industries.

Encouraging the recycling of ASTM A36 steel at the end of its lifecycle is essential for a circular economy. Recycling helps conserve natural resources, reduces waste, and lowers the environmental impact of new steel production. One simple way to encourage recycling is for construction companies to offer incentives to workers or contractors who properly separate and collect scrap ASTM A36 steel on job sites. This can ensure that the steel can be reused in new applications while maintaining its valuable properties.

Investing in cleaner production technologies is crucial for reducing the environmental impact of ASTM A36 steel. Technologies such as electric arc furnaces powered by renewable energy and hydrogen – based steelmaking processes offer promising ways to significantly lower the carbon footprint of steel production. These advancements can help the industry move towards more sustainable practices.

Using computer tools to make the design of structural components better can reduce the amount of steel needed for an application. This not only saves materials but also makes the structure more efficient. Optimized designs help use resources more effectively and reduce waste.

Promoting policies and practices that boost the recycling rates of steel can further reduce the environmental impact of steel production. Higher recycling rates mean less need for virgin raw materials and less energy for steel manufacturing. Encouraging the use of recycled steel supports the transition to a more sustainable and circular economy.

Below are answers to some frequently asked questions:

ASTM A36 steel is a widely used structural carbon steel known for its excellent mechanical properties and affordability. It primarily consists of carbon (0.25–0.29%), manganese (1.03%), silicon (0.28%), phosphorus (0.04%), sulfur (0.05%), copper (0.20%), and iron (98.0%). This composition provides good machinability and weldability.

Key mechanical properties include a minimum yield strength of 250 MPa (36,000 psi) for sections less than 8 inches thick, and an ultimate tensile strength ranging from 400 to 550 MPa (58,000 to 79,800 psi). The steel also exhibits an elongation of at least 20% in 200 mm and 23% in 50 mm, a density of approximately 2.84 lb/in³ (7.8 g/cm³), and a modulus of elasticity of 200 GPa (29,000 ksi).

ASTM A36 is predominantly used in construction and industrial applications due to its strength and cost-effectiveness. Common uses include building structural components such as beams, columns, and reinforcements, as well as bridge fabrication. It is also utilized in manufacturing machinery parts, automotive components, and storage tanks. However, it is not ideal for environments prone to corrosion due to its lower corrosion resistance.

ASTM A36 steel is often compared with other grades like S235JR and SS400 due to their similar applications and mechanical properties. ASTM A36 has a yield strength of 250 MPa (36 ksi) and tensile strength ranging from 400-550 MPa (58-80 ksi), making it suitable for construction and structural components. S235JR, a European grade, has a slightly lower yield strength of 235 MPa but comparable tensile strength of 360-510 MPa. SS400, a Japanese grade, also has similar tensile strength (400-510 MPa) but a slightly lower yield strength of 245 MPa for thinner sections.

While ASTM A36 and SS400 share similar chemical compositions, SS400 typically offers better corrosion resistance, making it preferable in environments where rust prevention is crucial. Additionally, SS400 is known for its strength-to-weight ratio, making it ideal for applications requiring lighter materials with sufficient strength. S235JR is commonly used in European projects and offers similar weldability and mechanical properties to ASTM A36.

When considering welding and machining ASTM A36 steel, several factors need to be taken into account to maintain its structural integrity and performance.

For welding, ASTM A36 is highly weldable due to its balanced mechanical properties and low carbon content, which reduces the risk of weld cracking. Various welding methods, such as Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW), are suitable for this steel. Using appropriate electrodes, like E6010 or E7018 for SMAW, and shielding gases like an argon-CO2 mix for GMAW, helps ensure high-quality welds. It’s crucial to control the heat input and cooling rates to minimize the Heat-Affected Zone (HAZ) and prevent the loss of mechanical properties.

Machining ASTM A36 steel requires careful consideration of tooling and conditions. With a machinability rate of about 72%, it is relatively easy to machine but demands precise tooling practices. High-Speed Steel (HSS) or carbide tools are recommended for drilling, tapping, turning, and milling. Optimal cutting speeds, feed rates, and the use of cutting fluids are essential to reduce tool wear and achieve clean results. Additionally, proper selection of grinding wheels and speed control is necessary for achieving fine surface finishes.

ASTM A36 steel offers notable environmental and cost benefits, making it a preferred choice in construction and various industries. Environmentally, A36 steel is highly recyclable, which reduces waste and conserves natural resources. Recycling steel requires less energy compared to producing new steel from raw materials, thereby lowering From a cost perspective, ASTM A36 steel is economically advantageous due to its simpler production process and chemical composition, which result in lower production costs compared to other steel grades. Its high strength and durability contribute to the longevity of structures, reducing maintenance and replacement expenses over time. Furthermore, its versatility and ease of machining and welding enhance construction efficiency, saving on labor costs and project timelines. These factors collectively make ASTM A36 steel a cost-effective and environmentally friendly option for numerous applications.

Yes, there are several equivalent grades to ASTM A36 steel in other international standards. These equivalents ensure compatibility and facilitate global application in various engineering and construction projects. Some of the commonly recognized equivalent grades include:

These equivalent grades provide similar performance characteristics, making them suitable for various engineering and construction projects around the world.

ASTM A36 steel is extensively utilized in construction and industrial applications due to its favorable mechanical properties, affordability, and ease of fabrication. In construction, it is commonly used for structural components such as beams, columns, and reinforcements in building and bridge fabrication. Its good strength-to-weight ratio makes it ideal for structural frames, supports, and enclosures, and it is also crucial in infrastructure projects like pipelines, railway tracks, and highway barriers.

In the industrial sector, ASTM A36 steel finds applications in the automotive industry for vehicle bodywork and machinery parts, and in the oil and gas industries for general mechanical engineering purposes. It is also used in manufacturing machinery components such as gears, shafts, and frames for industrial machines and agricultural equipment. The steel is available in various forms including sheets, bars, plates, and hot-rolled shapes, making it versatile for different uses. Its excellent weldability and adaptability further enhance its utility in both construction and industrial contexts.