Imagine the precision and elegance of flawlessly joining stainless steel components without compromising their integrity or appearance. Brazing stainless steel is a sophisticated technique that, when mastered, can yield incredibly strong and clean joints. Whether you are an intermediate craftsman looking to refine your skills or a professional seeking to deepen your understanding, this comprehensive guide will walk you through every step of the process. From selecting the best brazing rod and flux to mastering the torch brazing technique and preventing oxidation, we cover it all. Curious about how to avoid common pitfalls or the optimal joint design for maximum strength? Read on to uncover the secrets of successful stainless steel brazing and elevate your craftsmanship to new heights.

Brazing offers several benefits over other metal-joining techniques, especially when working with stainless steel:

The choice of filler metal is crucial in brazing stainless steel. Common options include:

Fluxes play a vital role in brazing by cleaning the metal surfaces, preventing oxidation, and facilitating the flow of the filler metal:

Torch brazing is a widely used method for stainless steel:

Vacuum brazing is ideal for oxidation-sensitive assemblies:

Other brazing techniques include induction brazing, infrared brazing, and resistance brazing:

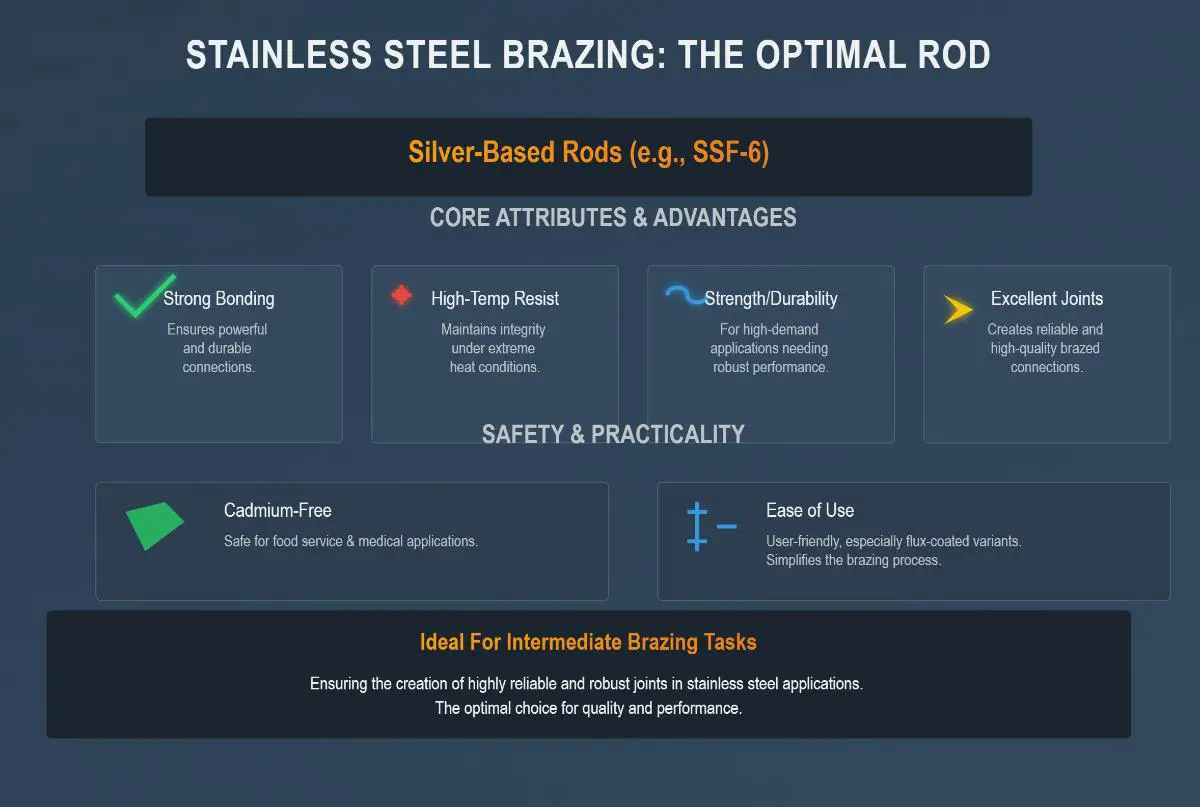

Selecting the right brazing rod is crucial for strong, corrosion-resistant joints when working with stainless steel.

These rods, which contain 30–56% silver often combined with copper, zinc, or nickel, have a high melting point and offer excellent fluidity and wetting properties. They are highly effective for creating strong, leak-tight joints and require appropriate flux to prevent oxidation during brazing.

Nickel silver rods, composed of nickel, copper, and zinc, are valued for their high tensile strength and good corrosion resistance. These rods are specifically recommended for stainless steel and should be used with bronze paste flux to ensure strong joints.

Consisting of copper with added phosphorus, these rods have self-fluxing properties but are not suitable for stainless steel due to incompatibility with ferrous metals. They are primarily used for brazing copper, brass, and bronze.

While they can join copper alloys and some steel grades, they are less common for stainless steel due to corrosion concerns and the need for flux.

Nickel bronze rods include nickel bronze with added silicon to improve flow. They are suitable for brazing steel, including stainless steel, providing good joint strength when used with bronze flux.

Designed to reduce zinc fuming during brazing, these rods effectively join steel and copper, including stainless steel, while minimizing toxic fumes.

Choosing a rod compatible with stainless steel is vital. Silver and nickel silver rods bond well with stainless steel and maintain corrosion resistance, unlike copper-phosphor rods which are unsuitable for ferrous metals.

The brazing rod must melt below the stainless steel base metal’s melting point to avoid damage. Silver and nickel alloy rods have suitable melting ranges that protect the base while creating strong joints.

Rods rich in nickel and silver enhance tensile strength and corrosion resistance, critical for stainless steel subjected to stress or harsh environments.

Some rods, like copper-phosphor, are self-fluxing but not suitable for stainless steel. Silver and nickel silver rods require appropriate fluxes to ensure clean joints and proper wetting.

Silver brazing rods offer excellent fluidity, ideal for filling fine gaps in stainless steel fabrications. Bronze-based rods provide good flow too but are better suited for more robust joints.

For high-temperature or corrosive conditions, nickel-based rods provide superior heat and corrosion resistance, making them advantageous in demanding stainless steel applications.

Flux is essential in the brazing process of stainless steel, performing several critical functions that ensure a high-quality joint.

Flux reacts with these oxides, dissolving and removing them to expose a clean metal surface, while also acting as a protective barrier against further oxidation during heating.

By removing oxides and protecting the surface, flux helps the filler metal flow smoothly and uniformly into the joint, which is crucial for a strong bond.

During brazing, flux absorbs newly forming oxides, maintaining its effectiveness throughout the heating cycle. It’s important to apply enough flux to prevent it from becoming saturated and losing its effectiveness.

Effective flux formulations not only protect and clean the joint area during brazing but also leave residues that are easier to remove post-brazing. This is important for maintaining the corrosion resistance and aesthetic appearance of stainless steel.

There are several types of flux used in stainless steel brazing, each suited to specific base metals, filler alloys, and brazing conditions.

White paste flux is the most commonly used flux in silver brazing applications, suitable for stainless steel as well as copper, brass, and other steels. It provides excellent oxide removal and protection during the heating process. This type of flux is widely used due to its effectiveness across various metals.

Fluxes designed specifically for stainless steel are more aggressive in removing oxides and offer high-level surface protection. These specialized fluxes are typically applied as a paste using a clean brush before heating. They are formulated to handle the tough oxides that form on stainless steel surfaces.

Some brazing rods come with flux already coated on the alloy. This simplifies the application process and speeds up brazing. However, the flux used in coated rods may be more generic and not optimized solely for stainless steel, potentially reducing flexibility and effectiveness compared to separate paste flux.

Beyond paste fluxes, there are fluxes tailored for specific metals and brazing methods, such as induction brazing or brazing refractory metals. These fluxes are used in specialized stainless steel brazing applications where specific conditions or requirements must be met.

Proper selection and application of flux are crucial for successful stainless steel brazing. The choice of flux type should align with the specific requirements of the brazing operation, ensuring that oxides are effectively managed and the filler metal flows correctly into the joint.

Proper preparation of stainless steel parts is crucial to ensure a strong and clean brazing joint.

Begin by thoroughly cleaning both parts to be brazed using sandpaper, emery cloth, or similar abrasives to remove any dirt, grease, oils, and oxide layers. Arrange the parts to form the desired joint on a non-conductive barrier, such as a wire or ceramic block, to concentrate heat on the joint area and prevent heat dissipation.

Choosing the right filler metal and flux is vital for a successful brazing operation. Select a silver-based brazing alloy, ideally cadmium-free, with a melting range well below the melting point of stainless steel. This prevents distortion or melting of the base metal and ensures a strong joint. Use a flux specifically formulated for stainless steel brazing to prevent oxidation during heating and promote the flow of the filler metal into the joint. It can be applied separately or come pre-coated on the brazing rod.

Proper heat control is necessary to achieve a strong brazed joint. Use a propane or oxyacetylene torch with a neutral flame setting to avoid oxidizing the stainless surface, which would inhibit brazing. Move the torch continuously around the joint area to distribute heat evenly, avoiding holding the flame in one spot. Heat the stainless steel until it reaches a dull red color, approximately 500-600°C, indicating it is ready for brazing.

Once the joint has reached the correct temperature, touch the brazing rod to the joint to melt a small amount of flux. The flux will melt and flow into the joint, cleaning the metal surfaces and preparing them for bonding. Gradually melt the end of the brazing rod near the joint and allow the filler metal to flow into and around the joint. The molten filler metal should be drawn into the joint by capillary action, filling all gaps. If necessary, add small amounts of flux during the process to maintain oxidation protection and improve filler flow.

Allow the brazed joint to cool naturally in air to avoid stress or cracking. Once cooled, clean off residual flux with warm water and a wire brush to prevent corrosion from flux remnants. Polish or buff the joint area as needed to restore the surface finish.

By following these steps, you can ensure that your torch brazing process is efficient and produces strong, clean, and corrosion-resistant joints suitable for various applications requiring high-quality stainless steel assemblies.

Electron Beam (EB) welding is an advanced technique that uses a focused electron beam in a vacuum to join metals by melting them locally. Because this method doesn’t need filler material, it’s perfect for applications that demand high joint purity.

Laser Beam Welding employs a concentrated laser beam to melt and fuse metals, producing a small HAZ and deep weld penetration. This method works well for joining thin stainless steel sheets and intricate shapes.

Vacuum Brazing takes place in a vacuum furnace, preventing oxidation and producing clean, high-quality joints.

Induction Brazing uses electromagnetic coils to heat the joint area quickly and precisely, making it ideal for high-volume production.

Infrared Brazing utilizes infrared radiation to selectively heat metal parts. This non-contact heating method allows for precise control and reduces contamination risks.

Traditional Torch Brazing is still a popular choice for working with stainless steel. It employs a flame torch to heat the base metal and filler alloy.

| Technique | Heat Source | Flux Required | Heat Affected Zone | Key Benefits | Ideal Applications |

|---|---|---|---|---|---|

| Electron Beam Welding | Focused electron beam | No | Very narrow | Precision, deep penetration, no flux | Aerospace, electronics, dissimilar metals |

| Laser Beam Welding | Laser beam | No | Very narrow | Hermetic sealing, minimal distortion | Sensors, fiber optics, microelectronics |

| Vacuum Brazing | Vacuum furnace heating | Sometimes | Controlled | Oxide-free joints, clean environment | High-purity, aerospace, electronics |

| Induction Brazing | Electromagnetic induction | Sometimes | Localized | Fast, consistent heating | Automotive, HVAC, industrial parts |

| Infrared Brazing | Infrared radiation | Sometimes | Controlled | Precise heating, non-contact | Specialized delicate parts |

| Torch Brazing (Standard) | Flame torch | Yes | Moderate | Flexible, economical | Repairs, small jobs |

Capillary action is crucial in brazing, as it draws the molten filler metal into the joint. The design of the joint must facilitate this action by maintaining a precise clearance between the base metals. This clearance allows the molten filler to flow through the joint by capillary action, creating a strong bond.

The effectiveness of capillary action relies heavily on the clearance between the parts; if too tight, it can block the filler metal, and if too wide, capillary action may be insufficient. Maintaining the correct clearance is essential to ensure the molten filler metal can flow through the joint effectively, resulting in a strong and durable bond.

For brazing stainless steel, the best clearance is between 0.001 and 0.005 inches (0.025 to 0.127 mm). This range is optimal for achieving effective capillary action while maintaining the structural integrity of the joint. A clearance of about 0.0015 inches (0.038 mm) is often recommended for achieving the strongest joints, although precision within the broader range is usually sufficient for most applications.

A clearance that is too narrow can hinder the even distribution of the filler metal, resulting in incomplete bonding and weaker joints. Ensuring the clearance is within the optimal range is essential to allow the filler metal to flow freely and fill the joint completely.

Conversely, a clearance that is too wide can also compromise joint strength. In such cases, the filler metal may not be adequately drawn into the joint by capillary action, leading to gaps and weak points. The joint strength may then be similar to that of the filler metal alone, which is typically weaker than a properly brazed joint.

To ensure a strong brazed joint, parts must be free from contaminants like oil, grease, rust, scale, and dirt, and the stable oxide layer on stainless steel should be removed through mechanical abrasion or chemical cleaning. Clean surfaces ensure proper adhesion and strong bonding of the filler metal.

Applying flux evenly to the surfaces to be joined is critical in preventing oxidation and facilitating the flow of the filler metal. Fluxes containing fluoride compounds are particularly effective for stainless steel, as they dissolve chromium oxides and protect the metal surfaces during heating.

Uniform heating of the joint area is essential to ensure that the filler metal flows and bonds properly. Localized overheating can cause warping or damage to the base metals, while insufficient heating can prevent the filler metal from flowing into the joint. Consistent and controlled heating helps achieve a strong and durable brazed joint.

One common mistake in brazing stainless steel is not cleaning the surfaces thoroughly before starting the process. Stainless steel is prone to contamination from oils, grease, dirt, and other residues that can interfere with the brazing process.

Use solvents or mechanical abrasion methods to thoroughly clean the stainless steel surfaces. Solvents such as acetone or alcohol can effectively remove organic contaminants, while mechanical abrasion with sandpaper or wire brushes can eliminate oxidation layers. Ensure that all parts are completely degreased and free from oxidation before proceeding with brazing.

Another frequent error is using an inappropriate flux, which can fail to remove oxidation effectively and lead to poor bonding. Select fluxes specifically designed for stainless steel to remove the tenacious oxides and ensure complete coverage for optimal performance. Apply the flux evenly to the joint area to ensure complete coverage and optimal performance during brazing.

Inconsistent or excessive heating can cause the stainless steel parts to distort or the brazing alloy to melt incompletely, resulting in weak joints.

Ensure even heating by moving the torch across the joint area without focusing on a single spot for too long. Monitor the temperature closely to ensure it reaches the optimal range for the brazing alloy being used. Heating should be controlled and uniform to avoid localized overheating or insufficient melting.

Poor ventilation during brazing can result in inhalation of hazardous fumes from fluxes and coatings, posing health risks and compromising the brazing environment.

Maintain good ventilation in the workspace by using ventilating fans, exhaust hoods, and air-supplied respirators. These measures will help ensure that fumes are adequately removed from the area, providing a safer working environment and preventing contamination of the brazing process.

Using brazing alloys that contain toxic elements like cadmium or lead can pose significant health risks and contaminate the brazing environment. Additionally, these alloys may not be suitable for stainless steel.

Choose high-silver alloys that are free from toxic elements and have lower melting temperatures. These alloys are safer to use and provide strong, reliable joints when brazing stainless steel. Ensure compatibility between the brazing alloy and the stainless steel to achieve optimal bonding and performance.

Preventing oxidation is crucial for achieving a strong, reliable joint. There are several strategies to mitigate oxidation during brazing.

Use active fluxes designed to remove surface oxides during air brazing. These fluxes help maintain a clean surface, allowing the filler metal to flow properly and bond effectively.

Maintain a low dew point and high-purity atmosphere in the brazing environment. This minimizes moisture and oxygen exposure, which contribute to oxidation. Protective atmosphere brazing is particularly effective for sensitive assemblies.

Brazing should be done immediately after cleaning the stainless steel parts to prevent reformation of oxides and ensure the joint remains clean for bonding.

Properly removing flux residues is essential for ensuring the integrity and appearance of the brazed joint.

Quench the assembly in hot water at around 120°F (50°C) immediately after brazing. This helps to crack and remove flux residues effectively. It is important to quench the parts while they are still hot, but after the filler metal has solidified, to avoid damaging the joint.

In the hot water bath, use a wire brush to scrub off any remaining flux, and for more stubborn residues, employ a mild acid solution like hydrochloric acid. This helps to ensure that all flux residues are completely removed.

An ultrasonic cleaning tank can enhance the efficiency of the hot water bath. The vibrations from the ultrasonic tank help to dislodge flux residues more effectively, ensuring a thorough cleaning.

Oxide scales formed during brazing must be removed to maintain the joint’s appearance and performance.

A chemical pickle bath, often using a diluted acid solution like citric acid, is an effective method for removing oxide scales. Citric acid offers a safe and effective solution.

Chemical solutions such as phosphoric acid-based pastes or sprays can dissolve oxides and welding stains on stainless steel. These solutions are particularly effective for removing oxides and restoring the metal’s clean surface.

Addressing discoloration is important for both the aesthetics and the longevity of the stainless steel joint.

A small rotary stainless brush can be used to remove discoloration. This method works best when done soon after brazing, while the discoloration is still fresh.

Phosphoric acid or citric acid solutions can also be utilized to remove discoloration and restore the original appearance of stainless steel. These chemical methods are effective in returning the joint to its desired finish.

Finishing the brazed joint ensures both its durability and its resistance to corrosion.

This technique uses an electrolytic solution and an electric current to safely remove contaminants and restore the stainless steel’s corrosion resistance. It is an effective method for achieving a clean and durable finish.

Utilizing a conductive brush with a cleaning solution and electric current, electrolytic weld cleaning provides precise and effective cleaning of the brazed joint. This method ensures a high-quality finish and helps maintain the joint’s integrity.

Always wear safety gear like gloves and eye protection, and ensure good ventilation when handling chemicals. Safety is paramount when performing post-brazing cleaning and finishing.

Clean the brazed joint as soon as possible after brazing to prevent further oxidation or contamination. Prompt cleaning helps maintain the quality of the joint.

Choose cleaning methods that are compatible with the materials being brazed to avoid damage or deterioration. Selecting the appropriate cleaning technique ensures that the joint remains strong and corrosion-resistant.

Stainless steel is highly recyclable and can be recycled up to 100%, making it an environmentally friendly option. Its long service life further enhances its environmental performance, making it a sustainable choice compared to many other materials. Utilizing stainless steel in brazing supports sustainability initiatives by minimizing waste and conserving resources.

The environmental impact of brazing stainless steel is significantly influenced by the choice of filler metals and fluxes. It is crucial to avoid filler metals that contain toxic elements such as cadmium and zinc, which can produce hazardous fumes during the brazing process. Instead, high-silver alloys are recommended due to their lower melting points and safer environmental profiles. Additionally, brazed joints on stainless steel are vulnerable to interfacial corrosion, particularly in aqueous environments. Applying protective coatings to the brazed joints can prevent environmental exposure of the brazing filler metal, enhancing joint longevity and reducing the risk of environmental contamination.

Brazing stainless steel can release harmful fumes, including hexavalent chromium compounds, which are very toxic and pose serious health risks. Effective ventilation measures, such as exhaust hoods, ventilating fans, and air-supplied respirators, are essential, especially in confined spaces, to ensure the safety of workers.

Personal protective equipment (PPE) is essential during brazing. Heat-resistant gloves and shaded goggles protect against burns and intense light, while respirators prevent inhalation of harmful fumes and particles.

Effective heat management is crucial to minimize the formation of chromium carbides in stainless steel, which can impair its corrosion resistance. Applying heat carefully, starting with more conductive metals if used, ensures uniform temperature distribution without overheating the stainless steel base metal. Controlled heating also reduces the risk of oxidation and filler metal defects.

Flux residues left after brazing are corrosive and must be thoroughly removed to prevent ongoing corrosion and environmental contamination. Effective cleaning methods include water rinsing, chemical cleaning, or mechanical means to ensure all residues are eliminated.

Preventing oxide formation on stainless steel surfaces is crucial for maintaining joint integrity. Using active fluxes during air brazing or maintaining low dew point, high-purity atmospheres in controlled brazing environments can prevent oxide formation. Additionally, avoiding off-gassing from metallic elements like cadmium and lead reduces contamination and void formation in the braze joint.

Below are answers to some frequently asked questions:

The best brazing rod for stainless steel is typically a silver-based brazing rod. Silver-based rods, such as SSF-6, are highly recommended due to their strong bonding capabilities, high-temperature resistance, and suitability for applications requiring high strength and durability. These rods are cadmium-free, making them safe for use in food service and medical equipment contexts. Additionally, they provide excellent joint strength and are relatively easy to use, especially when flux-coated, which simplifies the brazing process by reducing the need for separate flux application. Silver-based rods ensure reliable and robust joints in stainless steel brazing applications, making them the optimal choice for intermediate-level brazing tasks.

To prevent oxidation when brazing stainless steel, follow these strategies:

By combining these methods, you can effectively prevent oxidation and achieve strong, durable, and corrosion-resistant brazed joints in stainless steel applications.

The proper technique for torch brazing stainless steel involves careful preparation, precise heat application, and correct use of flux and filler metal. Start by thoroughly cleaning the stainless steel surfaces to remove oxides and contaminants, ensuring a sound joint. Position the parts with the recommended clearance—typically 0.05–0.2 mm—for optimal capillary action. Use a torch with a neutral flame to evenly heat the joint area; look for a dull red color as an indicator that the material has reached the appropriate brazing temperature (about 1100–1400°F/600–760°C). Apply a stainless steel-specific flux to prevent oxidation and promote filler metal flow. Select a suitable filler metal, such as a cadmium-free silver alloy, and feed it into the joint—the heat from the base metal should melt the filler, not the direct torch flame. After brazing, thoroughly clean off any flux residues to prevent corrosion and inspect the joint for integrity. This approach yields strong, corrosion-resistant brazed joints.

Brass rods can be used to braze stainless steel, but they are not the most recommended choice. While brass rods are relatively easy to use and do not require specialized equipment, they have lower strength and corrosion resistance compared to other brazing materials. This can lead to weaker joints and potential issues in corrosive environments.

More suitable alternatives for brazing stainless steel include silver-based and nickel-based brazing rods. Silver-based rods, in particular, offer excellent strength and corrosion resistance, making them highly effective for stainless steel applications. Nickel-based rods are ideal for high-temperature and demanding environments due to their superior performance in harsh conditions.

The recommended joint clearance for brazing stainless steel typically ranges from 0.001 to 0.005 inches (0.025 to 0.127 mm). This range ensures effective capillary action, which is crucial for distributing the brazing filler metal throughout the joint, leading to strong and reliable bonds. An optimal clearance of around 0.0015 inches (0.038 mm) is often cited for achieving maximum joint strength, particularly with certain silver brazing alloys. Too narrow a clearance can impede filler metal flow, while too wide a gap can reduce capillary action, both of which can weaken the joint. Maintaining the recommended clearance range is essential for achieving the desired joint strength and integrity.