Imagine a material so versatile that it’s the backbone of skyscrapers, the framework of automobiles, and a staple in engineering projects around the world. This is mild steel—an alloy that combines strength, ductility, and weldability in a way few materials can. But not all mild steel is created equal; different grades have distinct properties and applications that can make or break a project.

In this comprehensive guide, we dive deep into the world of mild steel grades and specifications. From understanding key properties like tensile strength and ductility to comparing popular standards such as ASTM A36, EN S235JR, and JIS SS400, we provide the technical insights you need. Whether you’re selecting the right material for a construction project or exploring sustainable practices in automotive manufacturing, this guide will equip you with the knowledge to make informed decisions. Ready to uncover the nuances of mild steel and its myriad applications? Let’s get started.

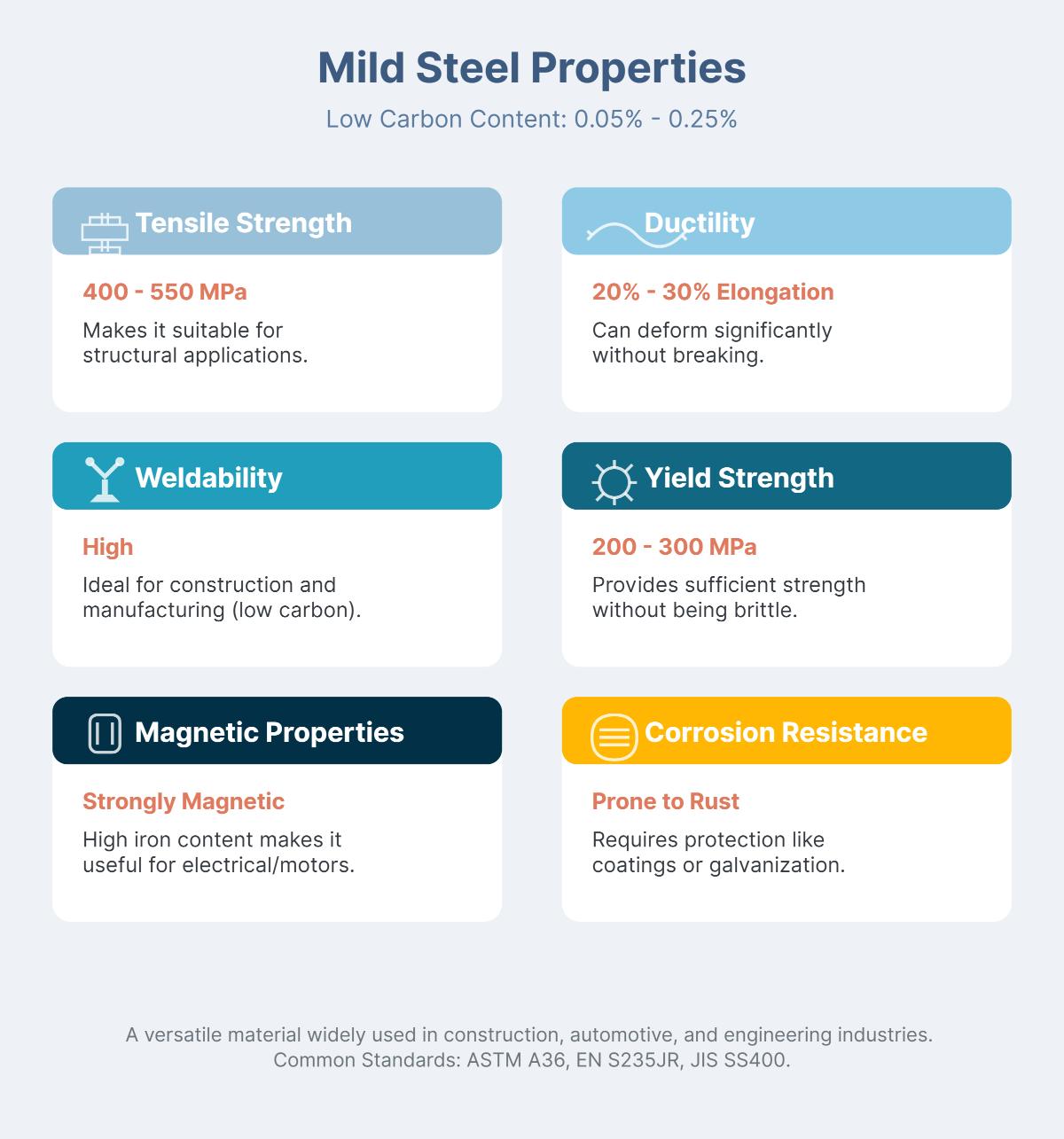

Mild steel, also known as low-carbon steel, is a type of carbon steel characterized by its low carbon content. Typically containing between 0.05% and 0.25% carbon by weight, mild steel is highly versatile and widely used across various industries. The low carbon content ensures that mild steel retains its ductility and malleability, which are essential properties for many fabrication processes.

Mild steel’s unique combination of properties—affordability, ease of fabrication, and versatility—makes it indispensable in multiple industries. Its widespread use is attributed to its ability to be easily welded, machined, and formed into various shapes without losing strength or structural integrity.

Several global grading systems standardize and ensure the quality of mild steel. Each system categorizes mild steel grades based on their chemical composition, mechanical properties, and manufacturing processes.

The ASTM grading system includes several mild steel grades, such as:

The European Norms (EN) classify mild steel into various grades, including:

The Japanese Industrial Standards (JIS) specify grades such as:

Understanding the mechanical properties of mild steel is crucial for selecting the appropriate grade for a given application. Important mechanical properties to consider are tensile strength, yield strength, elongation at break, and hardness.

Mild steel’s properties make it suitable for a wide range of applications across various industries:

For global projects, understanding the international equivalents of mild steel grades is essential to ensure materials meet the required standards:

These equivalents facilitate material sourcing and compliance with standards across different regions.

Recent advancements in mild steel production aim to enhance its strength and durability while maintaining cost-effectiveness. Innovations in surface treatments and alloying techniques are improving environmental performance, making mild steel a preferred choice for various industries committed to sustainability.

Mild steel is mainly made up of iron with a small amount of carbon, typically between 0.05% and 0.25%. This low carbon content gives mild steel its characteristic ductility and malleability. Other elements present in trace amounts further enhance its properties:

Manganese, present in quantities of 0.5% to 1.5%, and silicon, usually less than 0.4%, both enhance the steel’s strength and hardness. Phosphorus and sulfur are kept below 0.05% to prevent the steel from becoming brittle.

Mild steel exhibits several notable physical properties, which make it suitable for a wide range of applications:

The mechanical properties of mild steel are crucial for its performance in different applications. These include:

Mild steel is standardized under various specifications and grades to ensure consistency in quality and performance across different applications.

ASTM A36 is known for its excellent formability and moderate strength, making it common in structural applications, while ASTM A283 is suited for low-pressure applications due to its good weldability.

Mild steel’s properties make it suitable for a broad range of industrial applications:

Mild steel offers several advantages that make it a preferred choice in various industries:

Mild steel is a fundamental material in the construction industry. Its high strength – to – weight ratio makes it perfect for structural frameworks. Components such as beams, columns, and trusses in buildings are often made of mild steel. These can support large loads. At the same time, they keep the In high – rise buildings, mild steel’s ductility is a crucial advantage. It allows the building to deform without sudden failure. This property helps the building withstand seismic forces. In bridge construction, grades like ASTM A36 and EN S235JR are frequently used. They have good weldability and moderate strength. These steels can be fabricated into complex shapes to meet the specific design needs of different bridge types, from simple beam bridges to large suspension bridges.

The automotive sector makes extensive use of mild steel. For car bodies, mild steel provides the necessary strength and stiffness to protect passengers during a collision. It can be easily stamped into various body panels, including doors, hoods, and fenders. The ductility of mild steel enables it to absorb energy during an impact, enhancing vehicle safety.

In the chassis, mild steel forms the frame, which supports the weight of the vehicle and all its components. High – strength low – alloy (HSLA) steels, a type of mild steel, are often used in critical automotive parts. These parts include engine cradles and suspension components. Using HSLA steels helps reduce weight without sacrificing strength, improving fuel efficiency and overall vehicle performance.

In general engineering, mild steel is used to manufacture a wide variety of machinery and equipment. It is commonly used for shafts, gears, and fasteners because of its machinability. Shafts made of mild steel can efficiently transmit power between different machine components. Gears, which need high strength and wear resistance, can be made from mild steel through proper heat treatment processes. Fasteners like bolts and nuts are often made of mild steel due to its affordability and good mechanical properties.

In the energy sector, mild steel is used to construct pipelines for transporting oil, gas, and water. Its weldability ensures leak – proof joints. Its durability allows it to withstand the pressure and environmental conditions of long – distance transportation.

The industry now considers sustainability a key factor in the use of mild steel across industries. In construction, mild steel can be recycled at the end of a building’s life cycle. Recycling mild steel requires significantly less energy than producing new steel from raw materials. This reduces the carbon footprint of the construction industry. The ability to reuse mild steel in new construction projects also conserves natural resources.

Many green building projects now incorporate mild steel in their designs. For example, pre – fabricated steel structures can be quickly assembled on – site. This reduces construction time and waste. The high strength of mild steel allows for more open floor plans. These plans can increase natural light and ventilation in a building, reducing the need for artificial lighting and heating.

In the automotive industry, using lightweight mild steel alloys helps reduce fuel consumption and emissions. Additionally, the recyclability of mild steel in automotive components contributes to a circular economy. In engineering, manufacturers are increasingly using mild steel with improved corrosion resistance. This reduces the need for frequent replacements and minimizes waste.

The Burj Khalifa, the world’s tallest building, uses mild steel in its structural framework. The high – strength mild steel components were fabricated off – site and then assembled on – site, ensuring precision and quality. The mild steel’s ductility allows the building to flex and bend slightly in high winds. This flexibility distributes the wind forces evenly across the structure, preventing concentrated stress points that could lead to damage. During seismic activity, the ductility enables the building to absorb and dissipate the seismic energy. It deforms in a controlled manner, protecting the building from catastrophic failure.

Tesla’s Model 3 uses mild steel in its body structure. The combination of different grades of mild steel provides the necessary strength and safety features while also optimizing the weight of the vehicle. This has contributed to the vehicle’s long – range performance and energy efficiency.

A large – scale power plant uses mild steel for its pipeline systems. Mild steel’s weldability allows for easy and secure joining of pipeline sections, ensuring no leaks. Its durability means the pipelines can operate under high – pressure conditions for a long time without the need for frequent repairs or replacements, enabling the power plant to run smoothly.

Mild steel grades differ widely in their properties and uses. Understanding these differences is crucial for selecting the right grade for specific projects, so below is a detailed comparison of some common mild steel grades, highlighting their key characteristics and suitable applications.

ASTM A36 is one of the most widely used mild steel grades. It is known for its excellent strength, formability, and weldability.

EN S235JR is a European standard structural steel grade with moderate strength and good weldability.

JIS SS400 is a Japanese standard mild steel grade known for its excellent machinability and weldability.

ASTM A572 Grade 50 is a high-strength, low-alloy steel that offers better performance in terms of strength and corrosion resistance compared to low carbon steels.

EN S355J2 is another high-strength structural steel grade with excellent ductility and toughness.

ASTM A283 Grade C is a carbon-manganese steel offering moderate strength and good weldability.

EN S275JR is a higher strength grade compared to S235JR, making it suitable for more demanding applications.

ASTM A516 Grade 60 is a medium carbon steel known for its balanced strength and ductility.

When choosing a mild steel grade, consider several factors to ensure the best performance and value:

Selecting the appropriate mild steel grade ensures that the material will meet the specific needs of a project, balancing performance, durability, and cost-effectiveness.

The mild steel market in emerging economies has experienced notable growth. Valued at around USD 150 billion in 2024, the market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% from 2026 to 2033, reaching USD 210 billion by 2033. The driving forces behind this growth are the surging demand for infrastructure development in emerging markets and the progress of manufacturing technologies.

The Asia – Pacific region, especially China and India, holds a dominant position in the mild steel market. Rapid industrialization and urbanization in these countries are key factors. The demand for new factories, homes, and commercial buildings has significantly increased the need for mild steel.

Emerging market governments are heavily investing in infrastructure projects. These include building roads, bridges, railways, and ports. Such projects require vast amounts of mild steel for structural components, thereby driving up the demand for this material in the construction sector.

The growing demand for vehicles, including electric vehicles, in emerging markets is fueling the need for mild steel components. Mild steel is used in car bodies, chassis, and various other parts due to its strength, ductility, and cost – effectiveness.

Fluctuations in the prices of iron ore and scrap metal, which are the primary raw materials for mild steel production, pose significant challenges. These fluctuations can raise production costs and impact the profitability of manufacturers.

The shift towards sustainable production methods presents both challenges and opportunities. On one hand, manufacturers need to invest in new technologies to reduce the environmental impact of production. On the other hand, this transition can open up new markets as there is a growing demand for eco – friendly steel products.

The adoption of advanced manufacturing technologies, such as 3D printing and automation, offers opportunities for the mild steel industry. These technologies can enhance production efficiency, reduce waste, and enable the creation of more complex and precise components.

Below are answers to some frequently asked questions:

Mild steel grades are characterized by their low carbon content, typically between 0.05% and 0.25%, which imparts several key properties. These properties include:

These properties make mild steel a versatile material widely used in construction, automotive, and engineering industries. Different standards such as ASTM A36, EN S235JR, and JIS SS400 specify the properties and applications of various mild steel grades.

Different mild steel grades are tailored for specific applications based on their mechanical properties and chemical composition. For example, ASTM A36 is a general-purpose mild steel known for its good strength and formability, making it suitable for construction and structural applications. In comparison, ASTM A516 is employed in pressure vessels due to its higher tensile strength and corrosion resistance.

EN S235JR is commonly used in lighter structural applications, offering moderate strength and good weldability, while EN S355J2 is preferred for heavy-duty, high-stress structural applications due to its higher strength. JIS SS400 is widely used in general structural applications due to its excellent weldability and machinability.

The choice of grade depends on the specific requirements of the application, including factors such as yield strength, tensile strength, weldability, and cost-effectiveness. For instance, construction applications may favor grades like ASTM A36 and EN S275JR for their balance of strength and affordability, while heavy-duty engineering projects might opt for EN S355J2 for its higher strength and durability.

Common specifications for mild steel focus on its chemical composition and mechanical properties, which are essential for various industrial applications. Mild steel typically contains low carbon content (0.05% to 0.25%), with iron being the primary element. Small quantities of other elements like manganese, phosphorus, and sulfur may also be present to enhance certain properties.

Key mechanical properties include:

Common grades include ASTM A36, EN 10025 S235JR, S275JR, S355JR, and JIS G3101 SS400, each with specific strengths suited to various structural and engineering applications.

To choose the right mild steel grade for a specific project, first understand the project’s requirements, including mechanical properties, corrosion resistance, workability, temperature conditions, and cost. Familiarize yourself with different mild steel grades, such as those under EN 10025 (e.g., S235 for light structures, S275 for medium – load structures, and S355 for high – strength load – bearing structures). Ensure the selected steel meets relevant standards like ASTM, EN, or JIS. Evaluate the steel’s workability and weldability, as different grades vary in this regard.

ASTM (American Society for Testing and Materials) and EN (European Standards) provide guidelines to ensure mild steel meets specific quality, safety, and reliability standards for various applications.

The primary difference lies in their scope and focus. ASTM standards, such as ASTM A36 and A283, emphasize physical characteristics and application contexts. For instance, ASTM A36 is valued for its strength and formability with a tensile strength range of 58,000 to 80,000 psi and a minimum yield strength of 36,000 psi. ASTM standards are widely used in construction, automotive, and pressure vessels.

EN standards, like S235JR, S275JR, and S355J2, focus on the composition and mechanical properties such as weldability, ductility, and tensile strength. For example, S235JR has a minimum yield strength of 235 MPa, suitable for structural uses in Europe. EN standards are more prevalent in European construction projects.

Both standards ensure low carbon content for ductility and ease of fabrication, but slight variations exist based on specific grades and applications. The choice between ASTM and EN standards depends on geographical location, specific application requirements, and the desired mechanical properties of the mild steel.

Mild steel is extensively used in sustainable construction practices due to its recyclability, energy efficiency, and adaptability. It is 100% recyclable, which significantly reduces the need for mining natural resources like iron ore and coal. This recycling process saves up to 74% of the energy required to produce new steel and reduces greenhouse gas emissions by approximately 1.5 tons of CO2 per ton of recycled steel. Additionally, modern steel production methods, such as electric arc furnaces, further enhance energy efficiency by utilizing scrap steel.

Innovative construction techniques, such as prefabrication and modular construction, benefit from mild steel’s properties. These methods involve manufacturing components off-site, minimizing construction waste and improving project timelines. Mild steel’s versatility also supports adaptive reuse, allowing existing structures to be repurposed, which reduces the need for new materials and lowers waste.

Overall, mild steel’s integration into sustainable construction practices supports resource conservation, reduces environmental impacts, and contributes to a circular economy, making it a preferred choice for environmentally conscious projects.