When it comes to securing structures, machinery, or any heavy-duty installations, Rawl anchor bolts are an indispensable component in the toolkit of engineers and construction professionals. Whether you’re anchoring in concrete, brick, or other substrates, understanding the nuances of these robust fasteners can dramatically impact the integrity and longevity of your projects. This guide delves into the various types of Rawl anchor bolts, offering insights into their specific uses and the best practices for installation. From structural applications to seismic resistance, we’ll explore the wide-ranging applications and compliance standards that make these bolts a cornerstone in modern engineering. Ready to master the intricacies of Rawl anchor bolts and elevate your next project? Let’s dive in.

Rawl anchor bolts are vital fasteners for attaching objects to surfaces like concrete, brick, block, and stone. These bolts are designed to provide strong, reliable anchorage in various construction and engineering applications, ensuring stability and safety.

Rawl anchor bolts are known for their robust construction and ability to handle significant loads. They come in various types, each offering unique benefits tailored to specific use cases. Common features include:

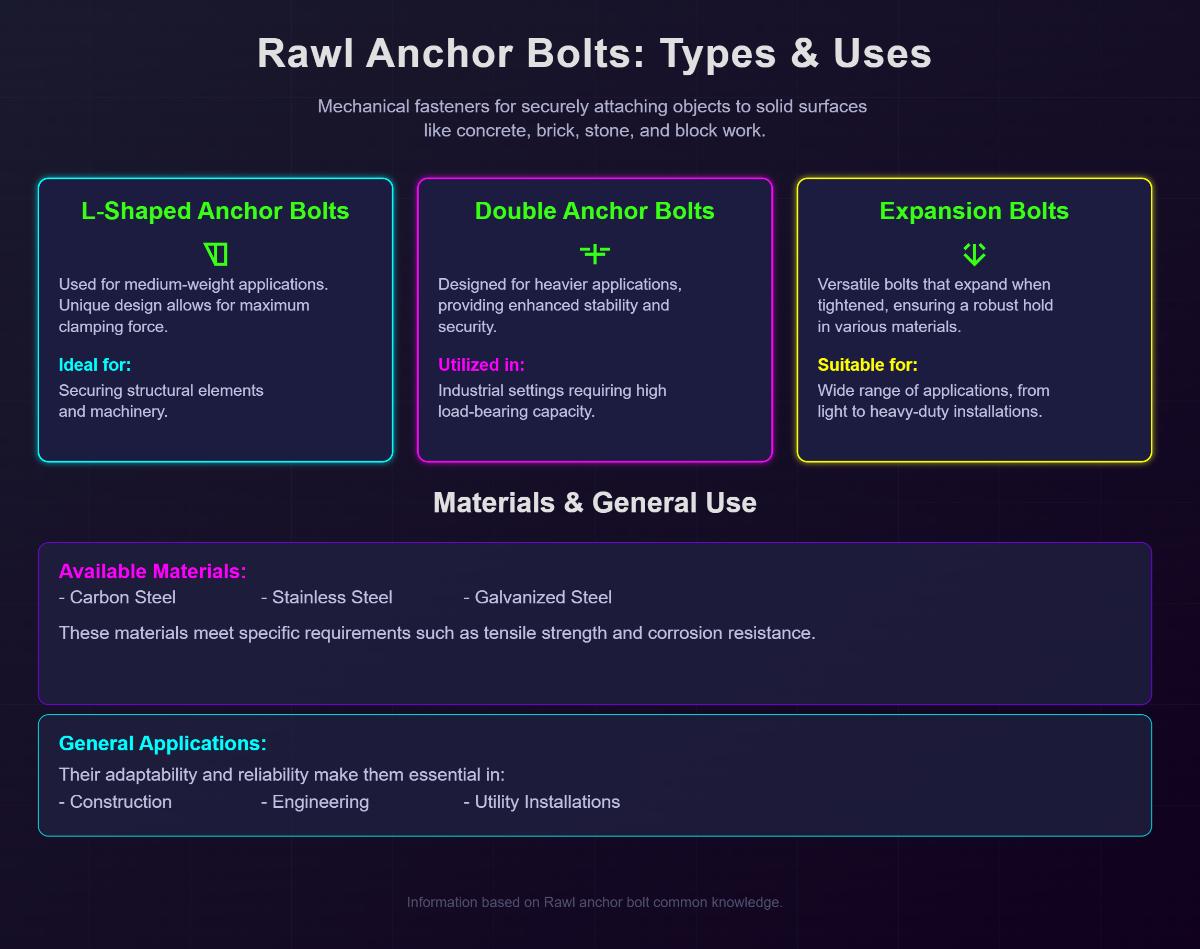

L-shaped anchor bolts, double end rods, headed anchor bolts, and swedge anchors are the main types, each designed for specific applications and providing unique benefits. L-shaped anchor bolts have an L-shaped configuration, providing a secure hold within concrete foundations, often used to anchor beams or columns. Double end rods feature a plate at one end, providing strong hold in both directions and are suitable for applications requiring enhanced stability. Headed anchor bolts have a head at the embedded end, offering additional holding power, particularly useful in high load-bearing applications. Swedge anchors involve a rod that is swaged (deformed) to create a secure hold within the concrete, highly effective in high-load scenarios.

Rawl anchor bolts operate through various mechanisms to ensure a secure hold within the substrate. The primary types include mechanical expansion anchors, which expand when inserted into a pre-drilled hole, tightly gripping the base material.

Torque-controlled anchors expand when the bolt or nut is tightened to a certain level. This action causes a wedge to compress against the material, securing the anchor.

Displacement-controlled anchors use an expansion sleeve and a conical expansion plug. The sleeve is internally threaded to accept a threaded element, creating a secure hold when the plug is displaced.

Rawl bolts are made from different materials, each with its own benefits. Common materials include:

In construction, Rawl bolts play a crucial role in securing columns, beams, and walls to foundations, ensuring stability and support. In engineering and manufacturing, they are essential for anchoring machinery and equipment to concrete floors, preventing tipping, vibration, or shifting during operation, thereby ensuring safety and efficiency. Rawl bolts are also vital in seismic-resistant designs, providing the necessary strength to withstand earthquake forces, ensuring that structures remain secure during seismic events.

Rawl bolts adhere to various industry standards, guaranteeing their reliability and performance. Standards include ASTM F1554 for structural anchor bolts and certifications from organizations like FM Global and VdS. These standards ensure that Rawl bolts meet essential safety and performance criteria.

Rawl anchor bolts are crucial in construction and engineering, offering reliable fastening solutions for various substrates. Understanding the different types of Rawl anchor bolts is essential for selecting the right option for specific applications.

L-shaped anchor bolts and double-end anchor bolts are fundamental in foundational anchoring and machinery mounting. L-shaped anchor bolts, with their distinctive L-shaped rod, are embedded in concrete during pouring. This design provides excellent resistance to high-load conditions, making them ideal for securing structural elements such as beams and columns. Double-end anchor bolts feature threaded ends on both sides, allowing secure attachment of multiple components. They are particularly useful for mounting machinery, ensuring a strong steel-to-concrete interface and effective load distribution.

Segment anchors use a unique design that expands to provide a strong hold in materials like brick and concrete. This segmented expansion mechanism ensures robust and reliable anchorage, making them suitable for medium-weight applications.

Expansion anchors work through a mechanical expansion process that occurs upon tightening. This action creates radial pressure, securing the anchor within the substrate. These anchors are highly versatile and can be used in a wide range of materials, including hollow blocks and solid concrete.

Material-specific designs of Rawl anchor bolts cater to different environmental demands. Carbon steel, known for its high tensile strength, is suitable for general construction applications requiring durability. Stainless steel is highly resistant to corrosion, making it perfect for environments exposed to moisture and chemicals. Galvanized and coated variants, such as zinc-plated or epoxy-coated bolts, enhance durability in outdoor settings, providing long-lasting protection against environmental factors.

Rawl anchor bolts come in various sizes to fit different applications, typically ranging from M6 to M24 in diameter and 75mm to 150mm in length. These dimensions accommodate different material depths and application requirements. Additionally, many Rawl anchor bolts come with certifications such as FM Global, validating their fire safety and load-bearing compliance, ensuring reliability in critical installations.

To ensure Rawl anchor bolts are effective and long-lasting, install them properly. Start with correct drilling: use a hammer drill equipped with a carbide-tipped masonry bit to create a hole that matches the manufacturer’s specified diameter and depth. This precision ensures a snug fit and optimal performance. After drilling, clean the hole thoroughly to remove dust and debris, using a combination of a wire brush and compressed air. This step is crucial to prevent any interference with the anchor’s grip.

When inserting the anchor bolt into the cleaned hole, ensure it is positioned correctly. For anchors that rely on tightening to expand, like torque-controlled ones, tighten the nut or bolt head to the specified torque. This ensures the anchor expands properly for the desired holding power.

Rawl anchor bolts can be used in various substrates, each with specific considerations. Concrete is the most common and offers excellent holding power. Ensure the concrete is fully cured and free of cracks, and avoid drilling into rebar in reinforced concrete. When working with brick and block, carefully place anchors to avoid mortar joints, ensuring a secure grip. Natural stone can be challenging due to its irregularity and hardness; use a rotary hammer drill with a diamond-tipped bit for precise hole drilling, and select anchors suitable for stone applications.

Several factors influence how well concrete anchoring performs. The anchor type is crucial; choose based on load requirements and environmental conditions. Mechanical expansion anchors, chemical anchors, and screw anchors each offer distinct advantages. Ensure the selected anchor can handle the expected loads, including both dynamic and static forces, by referring to manufacturer specifications and standards like EN 1992-4:2018. Maintain adequate distance from the edge of the concrete and between anchors to prevent cracking and ensure optimal load distribution, following the manufacturer’s guidelines.

To achieve the best results with concrete anchoring, adhere to these best practices. Perform pull-out tests to confirm the anchor’s effectiveness in your chosen substrate. This is especially important for critical applications and when using new or untested anchor types. Consider environmental factors such as temperature, humidity, and exposure to chemicals. Select anchors with appropriate coatings or materials, such as stainless steel or hot-dip galvanized, to withstand these conditions. Regularly inspect installed anchors for signs of wear, corrosion, or loosening to ensure long-term reliability and safety.

Rawl anchor bolts are essential for providing stability and safety in building structures and infrastructure. These bolts are extensively used to secure columns, beams, and walls to concrete foundations. Their high load-bearing capacity ensures that structures can withstand gravity, wind forces, and even seismic activities. The anchoring of guardrails, traffic signs, and lighting fixtures to concrete structures is another critical application, ensuring durability and reliability in challenging environments.

In the construction industry, Rawl anchor bolts play a vital role in securing various structural components. They anchor steel frameworks to concrete bases, crucial for building bridges, high-rise buildings, and other large structures, while also supporting temporary structures like scaffolding and formwork. Additionally, they are used in infrastructure projects to anchor elements such as guardrails and barriers, contributing to road safety and structural integrity.

Engineering applications of Rawl anchor bolts extend to the anchoring of heavy machinery and industrial equipment. In factories and industrial plants, these bolts ensure that machines remain stable during operation, preventing movement or vibration, which can lead to accidents or equipment damage. Their use in securing conveyor systems, robotic arms, and other critical machinery enhances operational efficiency and safety. Furthermore, Rawl anchor bolts are crucial in the installation of utility poles, telecom towers, and electrical cabinets, providing stability against environmental forces like wind and ice.

In manufacturing settings, Rawl anchor bolts are essential for anchoring machinery and equipment to factory floors. This ensures that heavy machines remain stationary during operation, reducing the risk of accidents and maintaining smooth production processes. The bolts’ ability to handle dynamic loads makes them suitable for securing high-speed machinery. They are also ideal for equipment subjected to frequent movements. Their application extends to the anchoring of storage racks, safety barriers, and heavy-duty shelving, contributing to organized and safe manufacturing environments.

Rawl anchor bolts are specifically designed to withstand seismic forces, making them ideal for applications in earthquake-prone areas. Their robust construction and high load-bearing capacity ensure that structures remain secure during seismic events, preventing catastrophic failures. In heavy-duty applications, such as securing large steel beams, bridge components, and industrial machinery, these bolts provide the necessary strength and stability. Their versatility allows them to be used in various substrates, including concrete, brick, and stone, ensuring reliable performance across different environments.

Beyond specialized uses, Rawl anchor bolts are also employed in general fixing applications due to their versatility and load-carrying capacity. They are suitable for securing heavy items like roller shutter doors, fire doors, wall plates, security grills, signs, and fencing. Their adaptability to different hole sizes makes them a favorite choice for diverse applications, ensuring a strong and stable hold regardless of the substrate. This adaptability is particularly beneficial in renovation projects where existing structures need reinforcement.

Adhering to industry standards is crucial for ensuring the reliability and safety of Rawl anchor bolts in construction and engineering applications. Several key standards govern the design, performance, and installation of these bolts.

These standards ensure that anchor bolts can handle the various loads and conditions they will face in construction. ACI 355.2 and ICC-ES AC193 focus on the testing and evaluation of post-installed mechanical anchors in concrete, ensuring they can withstand the demands of construction environments.

The European standard EN 1992-4:2018 provides guidelines for the design of fastenings in concrete. This standard specifically addresses the behavior of bonded anchors under static and quasi-static loads, offering technical parameters to ensure safe and effective anchoring in concrete structures.

ASTM F1554 sets the rules for anchor bolts, including what materials to use, how strong they need to be, and how they should be tested. This standard ensures that anchor bolts used in construction applications possess the necessary strength and durability to perform under high-stress conditions.

Technical approvals, like the ITB Technical Approval in Poland, confirm that anchor bolts are safe and effective for local construction projects. These approvals validate the performance and suitability of the bolts based on national and regional regulations.

This approval is particularly important for KOELNER RAWL R-DCA wedge anchors used in construction projects in Poland. It confirms that these anchors meet the necessary requirements under Polish regulations, including the need for a national declaration of conformity and proper product marking.

The selection of materials for Rawl anchor bolts must comply with industry standards to ensure their performance in various environmental conditions.

Rawl bolts are typically made from carbon steel or stainless steel, both of which offer specific benefits. Carbon steel provides high tensile strength, making it ideal for high-load applications. Stainless steel offers superior corrosion resistance, suitable for environments exposed to moisture or chemicals.

Proper installation and testing are critical to ensuring the effectiveness of Rawl anchor bolts.

Using carbide-tipped drill bits ensures the holes are the right size, which is essential for the anchors to work properly. The installation process requires precision, including the use of these specific tools to create holes that match the anchor diameter. Ensuring the correct embedment depth is crucial for optimal anchor performance.

Anchors are designed with inspectable torque values and length indications to facilitate proper installation and embedment. Regular testing and verification of these parameters ensure that the anchors are securely embedded and functioning as intended.

Manufacturers must adhere to various regulatory requirements to ensure their products are compliant with local building codes and standards.

Conducting conformity assessments and issuing declarations of conformity are essential steps for manufacturers. These assessments verify that the anchor bolts meet relevant standards and regulations, ensuring their suitability for use in construction projects.

When selecting anchor bolts for construction and engineering applications, it’s crucial to compare the different types available to ensure optimal performance for specific needs. This analysis focuses on mechanical expansion bolts, chemical anchors, and Rawl anchor bolts, highlighting their unique features and applications.

Mechanical expansion bolts use a physical expansion mechanism to secure the bolt within the substrate. These bolts expand when a nut or bolt is tightened, creating a friction lock with the surrounding material, making them suitable for a wide range of substrates, including concrete and stone. Their advantages include ease of installation and suitability for various substrates. However, they may not perform as well in environments with dynamic loads or where substrate quality is variable.

Chemical anchors use adhesive compounds to bond the anchor to the substrate, providing excellent load distribution and effectiveness in cracked or compromised concrete. These anchors are ideal for applications requiring high load capacities and vibration resistance. They offer superior performance in corrosive environments due to their sealed bonding process. However, the installation process is more complex, requiring precise hole cleaning and curing time for the adhesive.

Rawl anchor bolts combine the benefits of mechanical expansion and material versatility, making them suitable for various substrates like concrete, brick, and stone. Their mechanical expansion mechanism ensures a strong hold, while their availability in different materials, such as stainless steel and carbon steel, allows them to be used in diverse environmental conditions. Rawl bolts are particularly advantageous in applications where rapid installation and high load-bearing capacity are essential. They also offer excellent resistance to environmental factors, making them suitable for both indoor and outdoor use.

In a recent wind energy project, Rawl anchor bolts were used to secure wind turbines, demonstrating their effectiveness in handling substantial dynamic loads and environmental stressors. This application required bolts capable of withstanding high winds and varying temperatures, ensuring the stability and safety of the turbines.

A manufacturing facility faced challenges with machinery stability due to floor vibrations. By integrating Rawl anchor bolts, the facility achieved significant improvements in equipment stability. These bolts provided the necessary load distribution and vibration damping, resulting in enhanced operational efficiency and reduced maintenance costs.

In an earthquake-prone area, a construction company employed Rawl anchor bolts for seismic retrofitting of existing structures. These bolts were chosen for their ability to handle seismic forces and their ease of installation in various substrates. The project highlighted the bolts’ capacity to enhance structural resilience without requiring extensive modifications to the existing infrastructure.

Below are answers to some frequently asked questions:

Rawl anchor bolts, commonly known as Rawl anchors, are mechanical fasteners designed to securely attach objects to solid surfaces like concrete, brick, stone, and block work. They come in several types, each suited for specific applications:

Rawl anchor bolts are available in different sizes and materials, including carbon steel, stainless steel, and galvanized steel, to meet specific requirements such as tensile strength and corrosion resistance. Their adaptability and reliability make them essential in construction, engineering, and utility installations.

Proper installation of Rawl anchor bolts in different substrates involves several key steps to ensure secure and reliable fastening. Begin by drilling a hole of the appropriate diameter and depth into the substrate. It’s crucial to avoid drilling into mortar joints when working with brickwork, as they are typically weaker than the brick itself. Once the hole is drilled, clean it thoroughly using a brush and pump to remove debris, which ensures a snug fit for the anchor.

Next, remove the bolt and washer, and insert the shield anchor into the cleaned hole, ensuring it is properly seated. Position the fixture over the hole and align it with the anchor. Insert the bolt with the washer through the fixture and into the shield anchor, then tighten it to the recommended torque to achieve secure fastening. Be cautious not to over-tighten, as this can damage the anchor or substrate.

Choosing the right substrate is essential: concrete is suitable for heavy loads, while brickwork and stone require selection of strong sections for anchoring. Regular inspection and maintenance are advised to check for wear or damage, ensuring long-term stability. By adhering to these procedures, you can effectively install Rawl anchor bolts across various substrates.

Rawl anchor bolts are commonly used in construction and engineering to secure both structural and non-structural elements to various substrates such as concrete, brick, block, and stone. In construction, they play a critical role in anchoring structural columns and foundations, ensuring the stability of buildings and bridges by absorbing forces from environmental stresses like wind and earthquakes. In industrial settings, they are essential for anchoring heavy machinery and equipment, enhancing operational reliability by reducing vibrations and increasing equipment lifespan. Additionally, Rawl anchor bolts are used in utility installations to stabilize utility poles, telecom towers, and electrical cabinets, contributing to the reliability and safety of utility services. They are also versatile in general fixing applications, securing items like roller shutter doors, security grills, and signs to different substrates. Compliance with industry standards and the use of durable materials like carbon steel and stainless steel make Rawl anchor bolts reliable in various harsh environments.

Rawl anchor bolts are designed to perform effectively in seismic conditions, making them a reliable choice for projects in earthquake-prone areas. These bolts are constructed from robust materials such as zinc-plated carbon steel, galvanized carbon steel, and stainless steel, which provide varying levels of corrosion resistance and strength, essential for enduring the dynamic forces encountered during seismic events. They are typically listed for use in seismic zones A and B, which indicates their capability to withstand moderate seismic activity. However, for higher seismic zones, specific product details should be reviewed to ensure compatibility. While Rawl anchor bolts are particularly suitable for masonry applications, for structural applications requiring high tension and shear loads in seismic areas, mechanical anchors with designated seismic ratings may be more appropriate. It is crucial to assess the load-bearing capacity of the substrate and select the correct type and size of bolt to ensure optimal performance in seismic conditions.

In the United States, Rawl anchor bolts must adhere to standards set by the American Concrete Institute (ACI) and the American Society of Civil Engineers (ASCE). Specifically, ACI 318 outlines guidelines for the design and installation of anchor bolts in concrete, focusing on aspects such as load capacity, material specifications, and proper installation practices to ensure safety and structural integrity.

In Europe, the design and installation of Rawl anchor bolts are governed by EN 1992-4:2018, which pertains to fastenings in concrete under static and quasi-static loads. Additionally, the European Technical Approval Guidelines (ETAG) provide a framework for the technical approval of construction products, including anchor bolts, ensuring they meet necessary performance criteria.

Following these standards ensures that Rawl anchor bolts are used correctly, providing reliable and safe anchoring solutions in various construction and engineering applications.

Yes, there are several case studies comparing different types of anchor bolts, which provide valuable insights into their performance and applications. One notable study involved an automotive manufacturing facility, where wedge anchor bolts were used to secure an automated assembly line. These bolts were selected for their ability to withstand heavy loads and ensure stability, thereby minimizing malfunction risks and enhancing productivity.

Another case study focused on structural support in a large commercial building, where adhesive anchor bolts were utilized to secure columns and beams. These bolts demonstrated superior resistance to tension and shear forces, ensuring the stability of the structure.

Additionally, in a commercial building construction project, L-shaped anchor bolts were cast into the concrete foundation to attach steel columns. This provided a strong and permanent connection crucial for the building’s integrity.

Comparative analyses also highlight differences in pullout strength between headed and hooked anchor bolts, with headed bolts generally offering better performance. Dyna bolts, using an expansion mechanism, are suitable for medium-duty tasks, while traditional anchor bolts are preferred for heavy-duty applications due to their higher load capacity and long-term stability.

These case studies and comparisons underscore the importance of selecting the appropriate type of anchor bolt based on specific project requirements, ensuring structural integrity and efficiency.