Imagine this: you’ve just completed a DIY project, only to find stubborn Araldite glued onto your stainless steel surfaces. Frustrating, right? Removing this tough adhesive without damaging the metal can seem daunting, but fear not! This guide is here to help you navigate the tricky task with ease. We’ll explore various methods, from mechanical techniques to chemical solvents, ensuring you have the right tools and knowledge at your disposal. Whether you’re looking for the safest ways to avoid scratches or the most effective solvents for dissolving Araldite, we’ve got you covered. Ready to restore your stainless steel to its pristine condition? Let’s dive in and find the best solution for your needs.

Araldite is a two-part epoxy resin system that consists of a resin and a hardener. When these two components are mixed, they undergo a chemical reaction that forms a strong, durable bond. Araldite is known for its excellent adhesive properties, making it a popular choice for various applications, including metal bonding, construction, and repairs. Due to its robustness, removing Araldite from surfaces like stainless steel can be particularly challenging.

Stainless steel is an alloy made mainly of iron, chromium, and sometimes nickel and molybdenum. Its defining characteristic is its resistance to corrosion and staining, which is achieved through the formation of a passive layer of chromium oxide. Stainless steel is valued for its strength, durability, and aesthetic appeal, making it a preferred material in industries ranging from construction to food processing. However, these properties also necessitate careful handling when removing adhesives to avoid damaging the surface.

Removing Araldite from stainless steel poses several challenges:

Araldite’s strong adhesive properties make it hard to remove without using aggressive methods. Its tenacity can result in residue remaining on the surface even after initial removal attempts.

Stainless steel, while durable, can be susceptible to scratches and other damage if improper removal methods are used. Techniques that involve excessive force or abrasive materials can compromise the integrity and appearance of the stainless steel surface.

Chemical solvents must be chosen carefully to avoid reactions that could damage the metal, and heat application requires controlled temperatures to prevent warping or discoloration.

Understanding these challenges is essential for selecting the right removal method. This ensures the effective removal of Araldite while preserving the stainless steel surface.

Mechanical methods involve physically scraping or abrading the Araldite off the stainless steel surface. This method is effective for larger deposits of adhesive but requires careful execution to avoid damaging the underlying metal.

Chemical removal techniques involve the use of solvents to dissolve the Araldite, making it easier to remove. This method is particularly effective for thin layers of adhesive or residues left after mechanical removal.

Heat application techniques use controlled heat to soften the Araldite, making it easier to scrape off. This method is particularly useful for larger or more stubborn deposits of adhesive.

For particularly stubborn or extensive deposits of Araldite, combining methods can be highly effective.

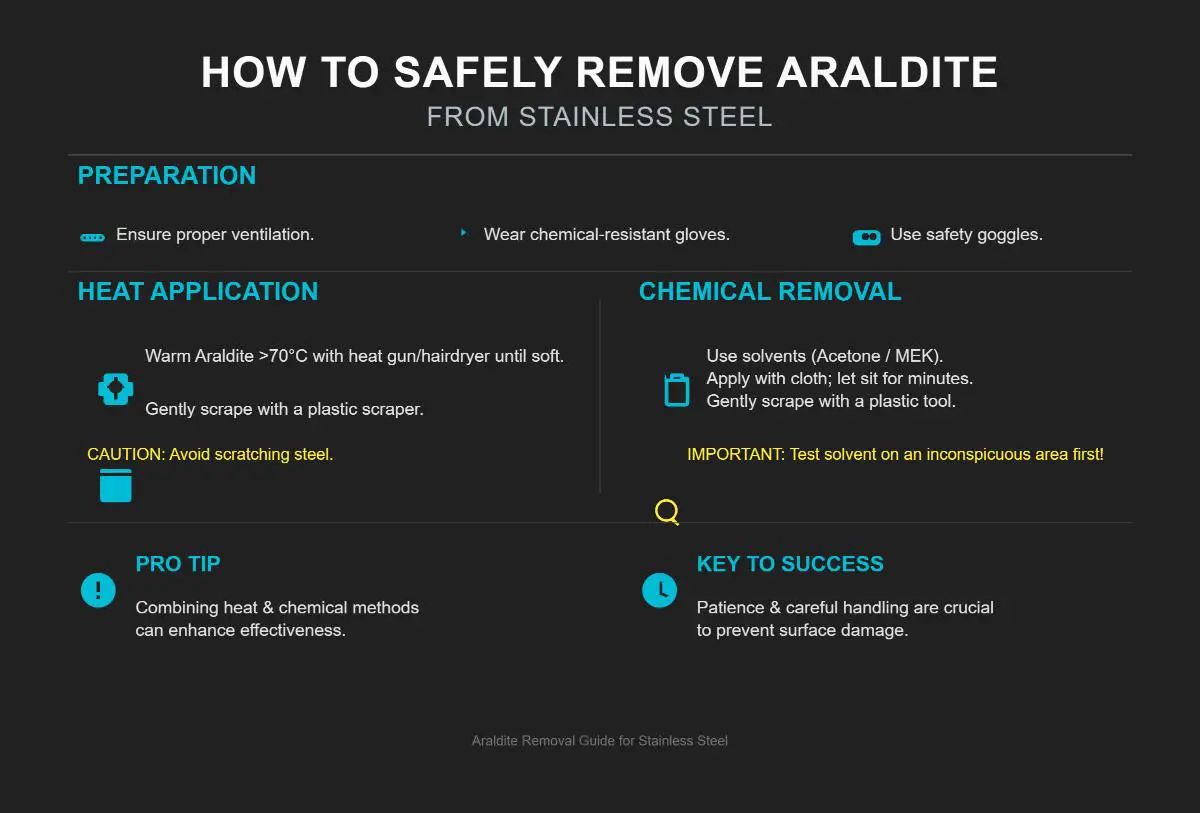

Before you start removing Araldite from stainless steel, it’s crucial to prepare your workspace and gather all the necessary tools. Ensure you have chemical-resistant gloves, safety goggles, and a mask, and work in a well-ventilated area to protect yourself from harmful chemicals or heat. Lay down a drop cloth or cardboard to catch any debris or spills, keeping the area clean and safe.

Heat application is an effective method to soften Araldite, making it easier to remove.

Chemical solvents can dissolve Araldite, making the removal process easier.

Mechanical techniques involve physically removing the Araldite without the use of heat or chemicals.

For particularly stubborn or extensive deposits of Araldite, combining methods can be highly effective.

Araldite adheres strongly to stainless steel, making its removal difficult. Various solvents can dissolve or soften Araldite, facilitating its removal. Understanding the strengths and application methods of each solvent is crucial for effective and safe removal.

Acetone and Isopropyl Alcohol are effective solvents for dissolving uncured or partially cured Araldite. Acetone is highly effective and should be applied with a cloth or cotton ball. Isopropyl Alcohol is milder and best for cleaning residues.

MEK is a potent solvent similar to acetone, known for its effectiveness in dissolving adhesives.

Nitromors is a paint stripper that has been reported to dissolve Araldite, particularly effective after prolonged exposure.

Brake fluid has been used as a solvent for Araldite, though it is not widely recommended due to its corrosive nature.

Solvents break down the polymer chains in Araldite, weakening the bond with the stainless steel surface. Heat or mechanical action can help the solvent penetrate the adhesive layer.

Always work in a well-ventilated area to avoid inhaling fumes. Wear gloves, safety goggles, and a mask to protect yourself. Apply solvents carefully with appropriate tools and dispose of them according to local regulations.

For stubborn Araldite deposits, use heat to soften the adhesive before applying the solvent. Test the solvent on a small area to ensure it doesn’t damage the stainless steel. Be patient and repeat the process as necessary.

Protecting stainless steel from scratches and surface damage during Araldite removal is essential for preserving its quality and appearance. Here are some effective strategies:

Applying protective coatings can help safeguard the stainless steel surface during the removal process.

Maintaining stainless steel after removing Araldite is essential for preserving its appearance and preventing future damage.

By following these preventive measures, you can effectively protect stainless steel during the Araldite removal process and ensure it remains in excellent condition.

Once you’ve removed the Araldite from the stainless steel, it’s important to clean and polish the surface to bring back its shine and look.

Apply isopropyl alcohol to a soft cloth, wipe down the area, and then allow it to air dry or use a clean, dry cloth to remove any excess alcohol.

Put a small amount of Brasso on a clean, soft cloth. Gently buff the stainless steel in circular motions until the desired shine is achieved.

Ensuring the stainless steel surface remains dry and applying protective coatings can help prevent corrosion.

Moisture can lead to corrosion, so it’s crucial to ensure the stainless steel surface is completely dry after cleaning. Use a clean, dry cloth or air dry the surface thoroughly.

Apply the protective coating or wax as per the manufacturer’s instructions, making sure to cover the entire surface evenly.

Dispose of used solvents and materials according to local regulations to prevent environmental harm, and ensure good ventilation during and after the removal process to avoid inhaling fumes.

Regular maintenance is key to keeping stainless steel surfaces in excellent condition.

Regularly clean the stainless steel surface with mild soap and water to prevent dirt buildup, which can lead to scratches or corrosion. Clean the surface periodically based on usage and exposure, using soft cloths and non-abrasive cleaners.

Avoid using harsh chemicals or abrasive cleaners on stainless steel as they can damage the surface. Choose cleaning products specifically designed for stainless steel and follow instructions for use to avoid damaging the surface.

By following these post-removal care steps, you can maintain the integrity and appearance of your stainless steel surfaces after removing Araldite adhesives.

Below are answers to some frequently asked questions:

To safely remove Araldite from stainless steel without damaging it, start by preparing the work area with proper ventilation and protective gear, such as chemical-resistant gloves and safety goggles. One effective method is applying heat: use a heat gun or hairdryer to warm the Araldite above 70°C until it softens. Then, gently scrape the softened adhesive with a plastic scraper to avoid scratching the stainless steel.

Alternatively, chemical removal can be employed using solvents like acetone or Methyl Ethyl Ketone (MEK). Dampen a cloth with the solvent, apply it to the Araldite, and let it sit for several minutes to break down the adhesive. Follow this by gently scraping with a plastic tool. Always test the solvent on a small, inconspicuous area first to ensure it does not damage the stainless steel.

Combining heat and chemical methods can enhance effectiveness. Patience and careful handling are crucial to prevent surface damage.

The most effective solvents for dissolving Araldite, an epoxy resin adhesive, are acetone and Nitromors. Acetone is particularly useful for uncured or partially cured Araldite, as it can dissolve the resin effectively. Nail polish remover, which contains acetone, can also be used in these cases. For fully cured Araldite, Nitromors, a strong paint stripper, can soften and dissolve the adhesive when applied over an extended period. When using these solvents, it is crucial to handle them with care, wearing protective gear and ensuring good ventilation to avoid any health risks. Always test the solvent on a small, inconspicuous area first to ensure it does not damage the stainless steel surface.

Heat application can potentially damage stainless steel if not applied correctly. Excessive heat can cause discoloration, known as “heat tint,” due to the formation of a chromium oxide layer. While this aesthetic change does not affect the structural integrity or safety of the stainless steel, it can be undesirable. To avoid such damage when removing Araldite, it’s crucial to apply heat gently and uniformly.

Using tools like a hairdryer or hot air gun on a low setting can soften the adhesive without overheating the metal. Always monitor the temperature closely and avoid prolonged exposure to high heat. After heating, use a plastic scraper to remove the softened adhesive, minimizing the risk of scratching the surface. Proper technique ensures effective Araldite removal while maintaining the appearance and integrity of the stainless steel.

To prevent scratches during the removal of Araldite from stainless steel, several protective measures can be taken. Firstly, use plastic scrapers or putty knives instead of metal tools to gently lift and remove softened or dissolved Araldite. This reduces the risk of scratching the stainless steel surface. Secondly, fine-grit sandpaper can be used for buffing residual adhesive, ensuring you sand with the direction of the metal grain to avoid damage. Non-abrasive pads are helpful for polishing the area after sanding, restoring the original shine of the stainless steel. Preparing the work area by covering surfaces with protective layers like drop cloths or cardboard can prevent accidental scratches from spills and debris. Wearing safety gear such as gloves, goggles, and a mask also helps maintain focus and safety during the process.

Yes, there are alternative methods for removing Araldite from stainless steel beyond the commonly recommended heat, chemical, and mechanical techniques. One such alternative is using brake fluid, which some users have found effective as a solvent for epoxy adhesives like Araldite. This method requires caution due to the chemical nature of brake fluid. Another option is a mixture of baking soda and lemon juice. While primarily used for other adhesive types, this combination may work on Araldite, though its effectiveness can vary. Regardless of the method chosen, it is essential to test on a small, inconspicuous area first and ensure proper ventilation to avoid inhaling fumes. After removal, clean the surface thoroughly to maintain the integrity of the stainless steel.

The best tools for mechanical removal of Araldite from stainless steel include plastic scrapers, putty knives, and non-abrasive pads. Plastic scrapers are preferred as they lift softened Araldite without scratching the stainless steel surface. Putty knives can provide additional leverage but should be used carefully to avoid damage. Non-abrasive pads are ideal for delicate scrubbing. Before mechanical removal, soften the Araldite using heat (e.g., a heat gun or hairdryer) or chemical softeners like Nitromors. Ensure you wear protective gear and work in a well-ventilated area. After removal, clean the surface with isopropyl alcohol and polish with Brasso for a smooth finish.