When it comes to working with sheet metal, understanding the intricacies of gauges and thicknesses is paramount. Have you ever wondered why a specific gauge is chosen for a project or how these measurements translate to different materials like steel and aluminum? This comprehensive guide is designed to demystify these concepts for you. We’ll delve into the history and measurement of sheet metal gauges, explore thickness variations, and provide insights on selecting the right material for your projects. Additionally, you’ll learn how to read gauge charts, understand their applications in various industries, and ensure compliance with metalworking standards. Ready to master the art of sheet metal? Let’s dive in and discover the details that make all the difference.

A sheet metal gauge is a system used to measure the thickness of sheet metal, which is essential in metalworking, manufacturing, and construction. Understanding sheet metal gauges is crucial for selecting the appropriate material for a project, ensuring structural integrity, and optimizing material usage.

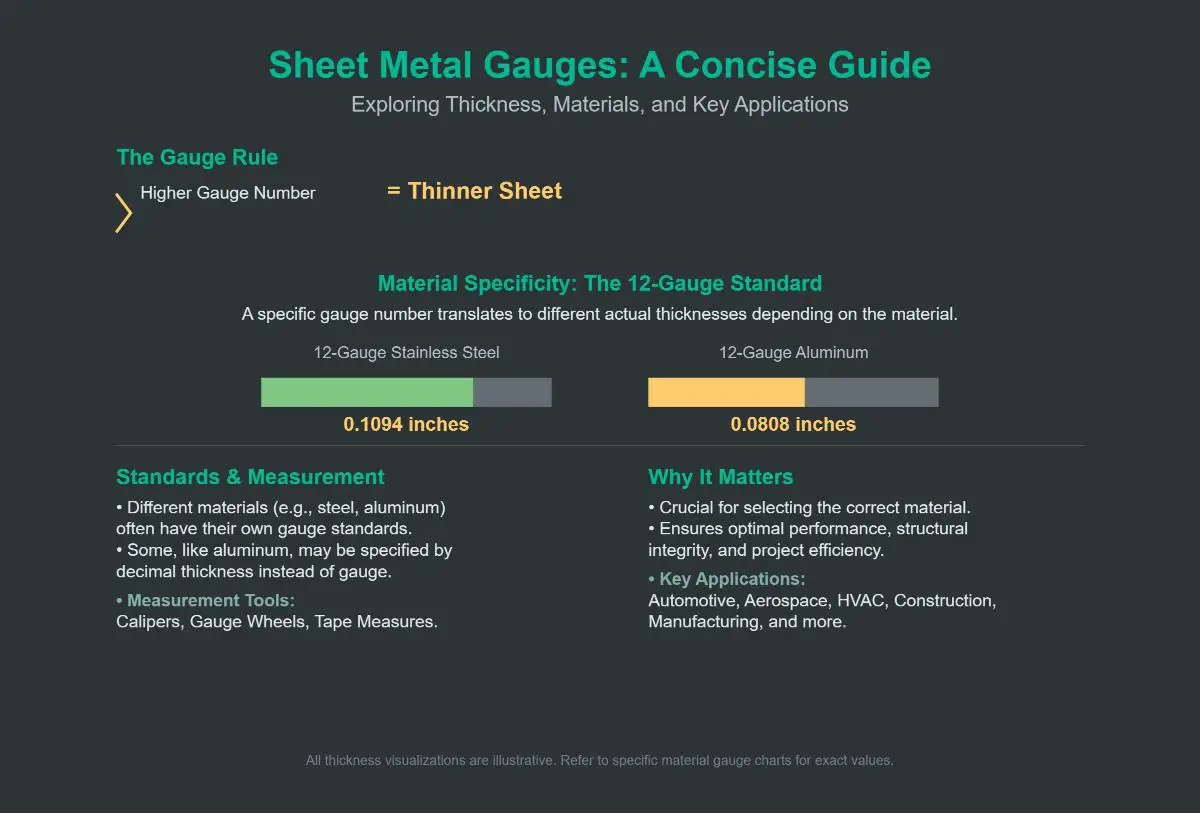

In the gauge system, a higher gauge number means a thinner sheet, and a lower gauge number means a thicker sheet. For example, a 26-gauge sheet is thinner than a 7-gauge sheet. This system provides a standardized way of specifying and comparing sheet metal thickness across different materials and applications.

Different metals have unique thicknesses for the same gauge number due to their varying densities. For example, a 12-gauge stainless steel sheet is thicker than a 12-gauge aluminum sheet. The following are some examples of gauge thicknesses for different materials:

The standard range of sheet metal gauges typically starts at 30 (thinner) and goes down to 7 (thicker). However, in some cases, gauges can range from 36 to 3. The specific range used depends on the material and the intended application. Understanding this range is important for selecting the right gauge for a given project.

The gauge system began in the 19th century for wire measurement, with systems like the Birmingham Wire Gauge (BWG) and the American Wire Gauge (AWG). These systems were later adapted for sheet metal. Over time, standardization bodies like ASTM established guidelines to ensure consistency in gauge measurements, helping manufacturers and engineers communicate specifications accurately.

Today, sheet metal gauges are widely used in industries such as automotive, aerospace, construction, and HVAC. The choice of gauge affects the material’s performance, including its strength, weight, and ability to be formed into different shapes. Engineers and designers rely on gauge charts and measurement tools to select the appropriate gauge for their projects, ensuring that the material meets the required specifications and performance criteria.

Thickness variations in sheet metal are crucial in deciding if a sheet is suitable for specific uses, affecting structural integrity, weight, and manufacturing processes.

Several factors contribute to thickness variations in sheet metal:

Different materials have unique properties that affect their thickness:

The manufacturing processes used to produce sheet metal can also influence its thickness:

Manufacturing tolerances are the acceptable limits for thickness variations. For example, aluminum sheets often have tighter tolerances than steel sheets, leading to more consistent thickness.

Typical thickness ranges are 0.5 to 6 mm for steel, 0.2 to 5 mm for aluminum, 0.4 to 6 mm for stainless steel, and 0.2 to 3 mm for copper.

Accurate measurement of sheet metal thickness is crucial for ensuring it meets the required specifications. The following tools are commonly used:

Understanding and accounting for thickness variations in sheet metal is essential for engineers and manufacturers to ensure the material meets the necessary performance criteria for its intended application. Accurate measurement and consideration of these variations can lead to more efficient and effective use of materials in various industries.

Sheet metal fabrication is a versatile process employed across various industries, including automotive, aerospace, construction, and consumer electronics. The selection of the appropriate material is crucial in determining the performance, durability, and cost-effectiveness of the final product.

The mechanical properties of sheet metal, such as tensile strength, ductility, and hardness, are vital in selecting materials that meet the project’s requirements. For instance, stainless steel’s high resistance to deformation makes it ideal for applications that demand durability and strength. Aluminum, on the other hand, is valued for its ductility, allowing it to be easily formed and shaped.

Materials with high corrosion resistance, such as stainless steel and galvanized steel, are essential in environments exposed to moisture and chemicals. Aluminum also provides excellent corrosion resistance, making it suitable for outdoor applications and environments with high humidity.

For applications involving heat transfer, materials with high thermal conductivity are ideal. Copper is an excellent choice for such applications due to its superior thermal conductivity. Stainless steel is chosen for applications needing insulation.

Budget constraints significantly influence material selection, as higher-quality metals offer better performance but at a higher cost. Carbon steel is a cost-effective option that provides strength and versatility, making it a popular choice in many industries.

The suitability of different materials for various fabrication methods, such as welding, bending, and cutting, is another important consideration. Mild steel is often preferred for welding due to its ease of welding, while certain grades of stainless steel may require specialized techniques. Knowing how each material reacts to fabrication processes ensures efficient manufacturing and high-quality results.

In applications where appearance is critical, the aesthetic qualities of the material, such as color and finish, must be considered. Stainless steel offers a sleek, modern look, making it popular in architectural and decorative applications. Aluminum can also be anodized to achieve various finishes, providing both functional and aesthetic benefits.

Stainless steel is highly valued for its corrosion resistance, ease of fabrication, and good weldability. It is commonly used in food processing, medical equipment, and architectural structures. However, its high cost and limited finish options can be limitations.

Aluminum is known for its lightweight nature, high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. These properties make it ideal for use in consumer electronics, automotive, and aerospace industries. Despite its advantages, aluminum’s higher cost and poor weldability compared to other materials can be drawbacks.

Galvanized steel features a zinc coating that enhances its corrosion resistance, making it suitable for outdoor constructions and building applications. While it offers increased durability, it may not be the best choice for environments requiring high strength-to-weight ratios.

Carbon steel is strong, affordable, and widely available, making it a versatile material for various applications. However, it is prone to corrosion without proper coating, which can limit its use in certain environments.

Sheet metal thickness is often measured using a gauge system, which varies by material. In this system, higher gauge numbers correspond to thinner sheets. For example, a 20-gauge sheet is thicker than a 24-gauge sheet. The specific thickness for each gauge depends on the material’s gauge chart, highlighting the importance of understanding these variations.

Selecting the appropriate gauge involves considering the material’s strength, density, and corrosion resistance required by the project. Stronger materials may allow for thinner gauges, optimizing both performance and material usage.

Different fabrication processes, such as bending or welding, may necessitate specific thicknesses or gauge ranges. Ensuring compatibility with the chosen fabrication methods is essential for achieving desired outcomes.

The need for the part to support weight or flex without breaking influences gauge selection. Thicker gauges provide higher strength, while thinner gauges offer more flexibility.

Balancing thicker gauges or stronger materials with project budgets is crucial. Thicker materials can increase costs, so it is essential to evaluate the trade-offs between material performance and budget constraints.

Gauge charts are essential tools in metalworking that provide standardized measurements for the thickness of sheet metal. They are crucial for ensuring consistency and precision in various industrial applications. These charts list the thickness of metal sheets in gauges, which correspond to specific measurements in inches or millimeters. Understanding how to read and use these charts is fundamental for selecting the right material thickness for a project.

In the gauge system, the thickness of the sheet metal is inversely related to the gauge number. This means that a higher gauge number indicates a thinner sheet of metal, while a lower gauge number indicates a thicker sheet. For example, a 20-gauge sheet is thinner than a 10-gauge sheet. This system can be counterintuitive, so familiarity with specific gauge charts for different materials is essential.

Different materials have unique gauge charts because the thickness for a specific gauge number varies based on the material’s properties, such as density and strength. Here are some examples:

These variations highlight the importance of using the correct gauge chart for the specific material being worked with.

Here’s a comparison of thicknesses for different materials at common gauge numbers:

| Gauge Number | Carbon Steel Thickness (inches) | Stainless Steel Thickness (inches) | Aluminum Thickness (inches) |

|---|---|---|---|

| 8 | 0.168 | 0.17187 | 0.1625 |

| 10 | 0.138 | 0.14062 | 0.1019 |

| 12 | 0.108 | 0.10937 | 0.0808 |

| 14 | 0.075 | 0.07812 | 0.0641 |

| 16 | 0.060 | 0.0625 | 0.0508 |

Gauge charts are vital for achieving the precise thickness needed in various applications. Consistency in thickness is crucial for maintaining structural integrity, especially in construction, automotive, and aerospace industries. Using gauge charts helps ensure that all metal sheets meet the necessary specifications and standards.

Selecting the appropriate material thickness is critical for optimizing material usage and ensuring the structural integrity of the final product. Gauge charts enable engineers and fabricators to choose the right thickness for their projects, which can affect the performance, weight, and durability of the end product.

Common mistakes in using gauge charts include using the wrong chart for the material, misinterpreting gauge numbers, and ignoring material-specific thickness tolerances. Being aware of these potential pitfalls and consulting the correct gauge chart for the specific material can prevent errors and ensure the success of a project.

Gauge charts are essential in metal fabrication for determining the correct sheet metal thickness, ensuring the final product meets design specifications and performance criteria.

Gauge charts play a critical role in the construction industry, where they help verify the thickness of metal materials used in structures such as steel beams, roofing, and cladding. Accurate thickness measurements ensure that these components can withstand the required loads and environmental conditions.

In the automotive sector, gauge charts are used to measure the thickness of metal parts during vehicle manufacturing. This is crucial for quality control, as the thickness of components can affect the vehicle’s safety, durability, and performance.

Heating, ventilation, and air conditioning (HVAC) systems rely on gauge charts to measure the thickness of metal sheets used in ducts and other components. Accurate thickness measurements ensure that these systems operate efficiently and safely.

A sheet metal thickness gauge is a tool specifically designed to measure the thickness of sheet metal. It typically provides readings in both gauge numbers and thickness measurements, making it easy to verify the thickness of a sheet.

Calipers and micrometers are precision tools used to measure the thickness of sheet metal. These tools offer highly accurate measurements and are commonly used in quality control processes to ensure that the metal sheets meet the required specifications.

Ultrasonic thickness gauges use ultrasonic waves to measure the thickness of sheet metal non-destructively. These tools are particularly useful for in-situ measurements where access may be limited, such as in installed HVAC systems or structural components.

Ensure that the correct gauge chart is used based on the type of metal being measured. Different materials have different thicknesses for the same gauge number, so using the correct chart is essential for accuracy.

Consider manufacturing tolerances when selecting material thickness. These tolerances can affect the final thickness of the sheet metal, so it’s important to account for them to ensure that the material meets the project’s requirements.

Be aware of international gauge standards and industry-specific requirements when selecting materials. Consulting these standards helps ensure that the selected material complies with relevant regulations and performs as expected in its intended application.

Sheet metal gauges are vital in metalworking, impacting the material’s strength, flexibility, and application suitability. Understanding how different gauges are applied across industries helps professionals select the right gauge for their specific needs.

The automotive industry extensively uses sheet metal of varying gauges to meet diverse requirements:

Thicker gauges, such as 18 or 20, are used in structural components like chassis and frames due to their strength and durability, ensuring the vehicle’s integrity and safety. Meanwhile, thinner gauges, such as 22 or 24, are employed for body panels and exterior parts, offering the flexibility needed for complex shapes while maintaining sufficient strength to withstand impacts.

Gauges around 24 to 26 are preferred for heat shields and insulation, providing effective thermal barriers without adding too much weight.

The aerospace industry requires materials that offer high strength-to-weight ratios, making the selection of appropriate gauges critical:

For aircraft skin, aluminum sheets with gauges ranging from 22 to 24 are used. These gauges are lightweight yet strong enough to maintain structural integrity.

For internal components like brackets and supports, gauges around 18 or 20 are used. These thicker gauges offer robust support while still being lightweight enough for aerospace applications.

Thin gauges, such as 26 or 28, are utilized in ducting and exhaust systems. These gauges allow for easy forming and effective airflow management within the aircraft.

The HVAC industry relies on sheet metal gauges to construct efficient and durable systems:

Thinner gauges, such as 24 or 26, are commonly used in ductwork. These gauges provide the necessary flexibility for installation while being lightweight and cost-effective.

For ventilation systems, gauges around 22 to 24 are preferred. These gauges ensure durability and efficient airflow management without compromising structural integrity.

Thicker gauges, such as 18 or 20, are used for equipment housing and enclosures. These gauges offer the strength required to protect HVAC components from environmental factors and physical damage.

An automotive manufacturer used 24-gauge aluminum sheets to produce lightweight body panels for a new electric vehicle model. The choice of gauge helped reduce the vehicle’s An aerospace company optimized their aircraft skin using 22-gauge aluminum sheets. This selection balanced the need for lightweight materials with the strength required for high-altitude flight, resulting in improved fuel efficiency and performance.

An HVAC contractor used 26-gauge galvanized steel for ductwork in a large commercial building. This thinner gauge made installation easier and reduced material costs while ensuring the ductwork’s durability for long-term use.

Metalworking is a crucial industry involving processes like welding, machining, and metal finishing. Adhering to industry standards is essential for ensuring the safety, quality, and regulatory compliance of metalworking operations. These standards provide a framework that guides the production and use of metal products, helping to maintain consistency and reliability across different applications.

Sheet metal thickness is measured using a standardized gauge system. This system is inverse, meaning that lower gauge numbers indicate thicker sheets, while higher gauge numbers indicate thinner sheets. For example, a 10-gauge steel sheet has a thickness of approximately 0.1345 inches. Understanding and correctly applying these standards is crucial for selecting materials that meet the specific requirements of different projects, ensuring both structural integrity and compliance with specifications.

Environmental compliance is a significant aspect of metalworking. Facilities involved in metalworking operations such as welding, dry grinding, and machining must adhere to regulations set by environmental agencies like the EPA. For instance, the EPA’s National Emission Standards for Hazardous Air Pollutants (NESHAP) Rule 6X targets the reduction of hazardous air pollutants (HAPs) by monitoring emissions. Compliance requires using tests like Method 22 to ensure dust and fume collection systems meet EPA standards.

Metal finishing operations, including electroplating and anodizing, are subject to stringent wastewater discharge regulations under the EPA’s Metal Finishing Effluent Guidelines. These guidelines aim to control the discharge of pollutants into water bodies, ensuring that metal finishing facilities operate within permissible limits. Recent rules target the discharge of PFAS from chrome finishing facilities, showing evolving environmental compliance needs.

Safety is paramount in the metalworking industry due to the inherent risks associated with handling metals and operating machinery. Workers must follow strict safety standards, including the use of personal protective equipment (PPE), proper handling of chemicals, and adherence to safe operating procedures. Regular maintenance and inspections of machinery are essential to prevent accidents. Increasingly, automation and AI are being used to improve workplace safety.

By adhering to these standards and best practices, metalworking operations can achieve compliance, enhance safety, and improve efficiency. This not only ensures the quality and reliability of their products but also promotes a sustainable and safe working environment.

Below are answers to some frequently asked questions:

Sheet metal gauges are a system used to specify the thickness of sheet metals. The gauge number is inversely related to the thickness—higher gauge numbers correspond to thinner sheets, while lower gauge numbers indicate thicker sheets. The actual thickness associated with a specific gauge can vary significantly depending on the material. For example, a 12-gauge stainless steel sheet measures 0.1094 inches in thickness, whereas a 12-gauge aluminum sheet measures 0.0808 inches.

Different materials have different gauge standards. Standard steel gauges are widely used in construction and manufacturing, while materials like aluminum might be classified by their decimal thickness rather than gauge numbers. Tools such as calipers, gauge wheels, and tape measures are used to accurately measure sheet metal thickness.

Understanding these differences is crucial for selecting the appropriate material for various applications, ensuring optimal performance and efficiency in projects ranging from automotive and aerospace to HVAC and construction industries.

To choose the right gauge for a sheet metal project, consider several key factors to ensure the material meets your project’s requirements. Firstly, understand that gauge numbers indicate thickness, with higher numbers representing thinner sheets and lower numbers thicker ones. Each material type, such as steel, aluminum, or stainless steel, has its own gauge chart due to varying properties.

Assess the material’s strength, density, and corrosion resistance relative to your project’s needs. For structural applications requiring rigidity, opt for thicker gauges. Conversely, for applications needing flexibility and reduced weight, thinner gauges are suitable. The choice also impacts fastening methods; thinner materials might need specialized fasteners, while thicker materials can accommodate standard threaded fasteners.

Consult gauge conversion charts to translate gauge numbers into actual thickness measurements. Use tools like calipers for precise thickness verification. Lastly, collaborate with manufacturers to confirm the availability of the chosen gauge and account for tolerances to ensure compatibility and performance. This careful selection process ensures your sheet metal project is both functional and efficient.

To measure sheet metal thickness accurately, several tools are commonly used, each suited to different precision needs and applications.

A sheet metal thickness gauge is a straightforward tool often used for quick, everyday inspections. It consists of a disc or flat bar with slots of varying sizes, where each slot corresponds to a specific gauge number. By inserting the metal into the slots until it fits, one can read the gauge number, although this method may lack high precision.

Calipers and Vernier calipers offer more precise measurements. Calipers measure thickness by placing the metal between their jaws and reading the measurement on a scale or digital display. Vernier calipers, with their finer scale, provide even more accuracy, making them suitable for precision machining and laboratory work.

For non-contact measurements, laser thickness gauges use laser beams to determine thickness based on reflection time, ideal for continuous measurements on large coils or areas where contact is impractical. Similarly, ultrasonic thickness gauges use sound waves to measure thickness, especially useful for materials accessible from only one side or with rough surfaces.

Digital thickness gauges often employ ultrasound or similar methods to provide quick, precise readings with digital displays and memory features, suitable for industrial settings.

While a tape measure can be used for rough estimates, it is not recommended for precise measurements due to potential inaccuracies. Selecting the appropriate tool depends on the required precision and specific project needs, ensuring accurate thickness measurements in various applications.

Thickness variations in sheet metal manufacturing occur due to several factors related to the production process, material characteristics, and supplier standards. Different manufacturing techniques, such as cold rolling and hot rolling, contribute to these variations. Cold rolling generally produces sheets with tighter tolerances, while hot rolling results in larger variations due to the nature of the process.

Material type also plays a significant role. For instance, aluminum typically has tighter thickness tolerances compared to steel. Additionally, the inherent properties of materials like carbon steel can lead to greater variability in thickness.

Supplier and mill standards, such as ASTM and ISO, define acceptable thickness variations, but actual dimensions may still vary slightly. It’s important to work with reliable suppliers and specify clear tolerances in engineering designs to manage these variations effectively. Using precise fabrication techniques and accurate gauge charts can help ensure the selected material meets project requirements.

To ensure your project complies with metalworking standards, it is essential to follow a systematic approach encompassing several key areas. First, familiarize yourself with the relevant standards for your specific project, such as ASTM, ISO, and BS, which provide guidelines on material properties, manufacturing processes, and quality control. Adhering to these standards ensures that your project meets industry requirements for safety, performance, and reliability.

Next, use appropriate gauge charts to select the correct sheet metal thickness for your materials, whether it’s steel, aluminum, or galvanized steel. Accurate measurement and specification of thickness are crucial to maintaining structural integrity and functionality.

Employ precise tools, such as micrometers and calipers, to measure sheet metal thickness and verify that it matches project specifications. This helps in maintaining consistency and quality throughout the manufacturing process.

Implement rigorous quality control procedures, including regular inspections and testing, to ensure all components and assemblies meet the defined standards. Documentation of these processes and results is vital for traceability and compliance verification.

Finally, ensure all workers are trained on safety practices and standards compliance, and maintain a clean and organized workspace to minimize risks and enhance efficiency. By integrating these practices, you can achieve compliance with metalworking standards, ensuring the success and safety of your project.