When it comes to ensuring a reliable seal in industrial piping systems, spiral wound gaskets for ASME B16.20 Class 300 RF flanges are a cornerstone of engineering excellence. These gaskets offer a robust solution, balancing flexibility and strength to handle a variety of challenging conditions. But what makes them so integral to such applications? This guide delves deep into the intricacies of spiral wound gaskets, exploring their key components, compliance with ASME B16.20 standards, and the materials that contribute to their durability and performance. Whether you’re an experienced engineer or looking to broaden your understanding, this technical deep-dive will equip you with the knowledge to select, install, and maintain these gaskets effectively. Ready to uncover the secrets behind their widespread use? Let’s dive in.

Spiral wound gaskets are specialized sealing solutions widely used in industrial applications. Designed to withstand extreme pressures and temperatures, these gaskets are particularly valuable in chemical plants, refineries, and power generation facilities. Their unique construction allows them to maintain a reliable seal even under demanding conditions.

Spiral wound gaskets, created by winding alternating strips of metal and filler material around a mandrel, offer several key features that make them indispensable in industrial piping systems:

Spiral wound gaskets are commonly used in several industrial applications, including:

The working principle of spiral wound gaskets involves compressing the metal and filler layers between two flange faces. The metal spiral provides a spring-like action that maintains sealing force despite fluctuations in temperature and pressure. Meanwhile, the filler material adapts to surface imperfections, forming a tight seal that resists leakage. This combination of mechanical strength and chemical resistance ensures long-term reliability and performance.

For ASME B16.20 Class 300 Raised Face (RF) flanges, spiral wound gaskets are the preferred choice due to their ability to handle the high bolt loads and pressures typical of this class. The gasket’s flexible metal winding and resilient filler material accommodate flange surface irregularities and high pressure without compromising the seal integrity. Proper flange face configuration and gasket style (such as Style R) are essential for controlling the compression of the sealing element, ensuring optimal performance.

ASME B16.20 is a vital standard from the American Society of Mechanical Engineers that outlines requirements for different types of metal gaskets, ensuring their reliability in high-pressure and high-temperature environments.

Spiral wound gaskets are constructed using a continuous metal strip and filler material, combining structural integrity with excellent sealing properties. Typically made from corrosion-resistant alloys like stainless steel or Inconel, the metal strip provides resilience, while fillers such as graphite, PTFE, or mica enhance chemical resistance. This combination ensures the gaskets can withstand extreme operational conditions effectively.

Inner rings are crucial in preventing gasket buckling and over-compression, especially in high-pressure situations. These solid metal rings maintain the integrity of the seal, particularly in higher pressure classes like Class 900 and larger nominal pipe sizes. Gaskets without inner rings can be customized for specific applications, offering flexibility in design.

A standardized color-coding system helps identify materials quickly, preventing installation mistakes and ensuring the right gasket is used. This system facilitates easy identification, promoting safety and efficiency during installation.

Precise installation is critical for gasket performance, and ASME B16.20 provides guidelines to ensure alignment and adherence to tolerances, preventing issues that could affect the seal. By minimizing risks associated with eccentric installation and additive tolerances, these guidelines help maintain the gasket’s performance over its service life.

Compliance with ASME B16.20 is essential for manufacturers to produce gaskets that meet stringent performance criteria, reducing the risk of failures and enhancing the safety of piping systems. This standardization allows for interoperability and consistency across different regions and industries, contributing to global standardization.

In response to environmental regulations, specialized low emission gaskets have been developed to exceed standard performance requirements. These gaskets feature modifications in filler thickness and protrusion ranges to enhance sealing performance and reduce emissions, making them suitable for applications where environmental impact is a concern.

Class 300 Raised Face (RF) flanges are designed for medium to high-pressure applications and conform to ANSI/ASME B16.5 standards. The raised face is about 1/16 inch (1.6 mm) above the flange surface, creating a small elevated ring around the bore to improve gasket sealing. This design is crucial for enhancing the sealing capabilities under higher pressure and temperature conditions.

Class 300 RF flanges are suitable for pressures up to approximately 740 psi, depending on the material and temperature. These flanges are commonly made from forged steel (ASTM A182 / ASME SA182), stainless steel, and carbon steel, chosen for their excellent mechanical strength and temperature resistance. The bolt holes in Class 300 RF flanges are evenly spaced to ensure secure and uniform bolt loading, with the pattern and number of holes defined for each flange size. The flange thickness and outer diameter are precisely controlled to match the nominal pipe size and ensure proper alignment.

Spiral wound gaskets, made of metallic winding and filler materials like graphite or PTFE, match the flange bore and raised face diameter to provide an effective seal. The materials used in the gasket should be chosen based on the specific operating conditions, including fluid type, temperature, and pressure. The thickness of the gasket must correspond to the flange face width and raised face height to ensure optimal compression and sealing.

In chemical processing plants, Class 300 RF flanges paired with spiral wound gaskets provide the necessary chemical resistance and durability to maintain the integrity of the piping systems. Power generation facilities also benefit from these combinations, ensuring that high-pressure steam lines and other critical systems remain leak-free and operational. Refineries, which handle various hydrocarbons and chemicals at elevated pressures and temperatures, employ these flanges and gaskets to ensure reliable and safe operation, preventing leaks that could lead to hazardous situations.

The outer ring, also known as the centering or guide ring, is crucial for aligning the gasket within the flange assembly, ensuring even pressure distribution and a reliable seal. This alignment is essential for maintaining a uniform pressure and achieving an effective seal. The outer ring also contains the sealing element, preventing it from being extruded under pressure.

Typically made from robust materials such as carbon steel, stainless steel, or other high-strength alloys like Monel or Nickel, the outer ring is designed to withstand harsh operating conditions. Its design ensures a snug fit around the flange, providing support to the sealing element and maintaining integrity under varying pressure and temperature conditions.

The sealing element is made by spirally winding layers of a preformed metallic strip and a filler material around a metal mandrel, creating a resilient and adaptable component capable of withstanding high pressures and temperatures. This construction allows the sealing element to accommodate flange surface irregularities, ensuring a tight, leak-proof seal.

Two winding patterns are commonly used in the construction of spiral wound gaskets: V-type and W-type. These patterns compress under pressure, forcing the filler material into any surface irregularities on the flange faces to ensure a reliable seal.

Common filler materials include graphite, PTFE, ceramic, and other specialized materials chosen based on the application’s specific requirements. Each filler material offers unique properties that make it suitable for different service conditions, such as temperature resistance, chemical compatibility, and pressure tolerance.

The inner ring, though not always present in all gaskets, is crucial for high-pressure applications, as it strengthens the gasket and prevents sealing material from entering the fluid stream. This additional support is essential for maintaining the structural integrity of the gasket under extreme conditions, preventing over-compression and buckling.

Spot welding secures the ends of the metallic strip, preventing unwinding and maintaining the gasket’s structural stability. This ensures that the gasket remains intact during operation, providing a reliable seal.

Spiral wound gaskets are particularly well-suited for use with ASME B16.20 Class 300 RF flanges. Their ability to maintain a tight seal under significant pressure and accommodate flange surface irregularities makes them ideal for these applications. Compliance with ASME standards ensures that the gaskets meet stringent performance criteria, providing reliable sealing solutions in demanding industrial environments.

These gaskets offer exceptional durability, flexibility, and reliability, making them a preferred choice for various industrial applications. Their robust design and material composition ensure consistent sealing performance, reducing the risk of leaks and enhancing overall system reliability.

Gaskets are essential in industrial applications, providing seals that prevent leaks in piping systems. The choice of materials significantly influences their performance and durability. Here, we explore the most common materials used in spiral wound gaskets and their properties.

Stainless steel is a popular choice for the metallic winding strip in spiral wound gaskets due to its excellent corrosion resistance, mechanical strength, and temperature tolerance. Types such as SS304 and SS316 are commonly used:

Alloy C276, a nickel-molybdenum-chromium alloy, is known for its exceptional resistance to a wide range of corrosive chemicals, including sulfuric acid and hydrochloric acid. This material is often used in environments where exposure to highly aggressive chemicals is expected.

Inconel alloys, such as Inconel 625, are favored for their high-temperature performance and resistance to oxidation and corrosion. These alloys are suitable for applications involving extreme temperatures and corrosive environments, such as petrochemical processing.

Flexible graphite is a popular filler due to its excellent thermal and chemical resistance, handling temperatures over 500°C, making it ideal for oil, gas, and chemical industries. It maintains sealing integrity under thermal cycling and is suitable for high-stress applications.

PTFE is valued for its high chemical resistance and low friction properties. It is suitable for highly corrosive environments with a wide pH range (0-14) and temperatures up to 260°C. PTFE gaskets often include an inner metal ring (Style CGI) to compensate for PTFE’s lower mechanical strength.

Rubber materials like EPDM (Ethylene Propylene Diene Monomer), NBR (Nitrile Butadiene Rubber), and silicone are used in hybrid gasket designs to enhance flexibility and surface-conforming properties. These materials are suitable for low-pressure steam or chemical systems, combining the crush resistance of metal windings with the elasticity of rubber.

Ensuring material compatibility with ASME B16.20 standards is crucial for the reliable performance of spiral wound gaskets. The standard mandates full traceability of winding strip and filler materials through heat numbers and Mill Test Certificates. Compliance with dimensional requirements, such as the inner ring extending 1.5-2mm beyond the flange ID, is essential to prevent media erosion and ensure the integrity of the seal.

Recent advancements focus on improving performance under extreme conditions, such as modified graphite fillers, which offer better sealing during pressure and temperature changes than standard grades. Additionally, hybrid rubber-metal gaskets are gaining traction in industries like LNG and pharmaceuticals, where flange movement and vibration are prevalent.

A detailed comparison of gasket materials highlights their suitability for various applications:

| Material Combination | Max Temp (°C) | Pressure (Bar) | Primary Industry Use |

|---|---|---|---|

| SS316 + Graphite | 550 | 100+ | Refinery piping |

| Alloy C276 + PTFE | 260 | 40 | Pharmaceutical |

| Titanium + EPDM | 150 | 25 | Food processing |

| Inconel 625 + Ceramic Fiber | 1100 | 200+ | Petrochemical cracking |

When selecting gasket materials, consider corrosion testing with actual process fluids, use stress calculators for optimal sealing, and choose fillers that resist creep over time.

Properly preparing the flange is essential for achieving a reliable seal. Inspect and clean flange surfaces thoroughly to remove any damage, debris, or old gasket material. Additionally, clean the bolt and nut threads and apply a suitable lubricant to facilitate smooth tightening and prevent galling.

Before installation, inspect the spiral wound gasket for any defects or damage. Look for signs of deformation, fraying, or missing filler material, which could compromise the seal. Place the gasket centrally on the flange, ensuring it is aligned correctly with the bolt holes. Proper alignment is essential to achieve an even sealing pressure and prevent leaks.

Insert 2-3 bolts through the flanges initially to help align and center the gasket. Use a calibrated torque wrench to apply a consistent tightening pattern. Tighten bolts in a crisscross pattern, gradually increasing torque to ensure even compression. This method ensures even compression of the gasket, preventing uneven stress and potential leakage.

Store spiral wound gaskets in a clean, dry environment, away from direct sunlight and humidity. Position the gaskets horizontally to prevent warping or deformation. Proper storage conditions help maintain the gasket’s integrity and readiness for installation.

Regularly inspect the gasket and flange assembly for signs of wear or damage. Look for indications of leakage, such as fluid seepage or discoloration around the flange. Early detection of issues can prevent more significant problems and ensure the gasket’s longevity.

Avoid over-tightening bolts, as it can damage the gasket and lead to early failure. Always use the recommended torque values specified by the gasket manufacturer. Over-tightening can also damage the flange surfaces, compromising the sealing integrity.

Apply lubricant only to the bolt and nut threads, avoiding the gasket and sealing surfaces. Lubricant on the gasket surfaces can lead to contamination, reducing the gasket’s effectiveness and potentially causing leaks.

Keep flanges parallel during tightening to ensure even pressure distribution across the gasket, leading to an effective seal. Use alignment tools if necessary to maintain proper flange alignment throughout the installation.

Below are answers to some frequently asked questions:

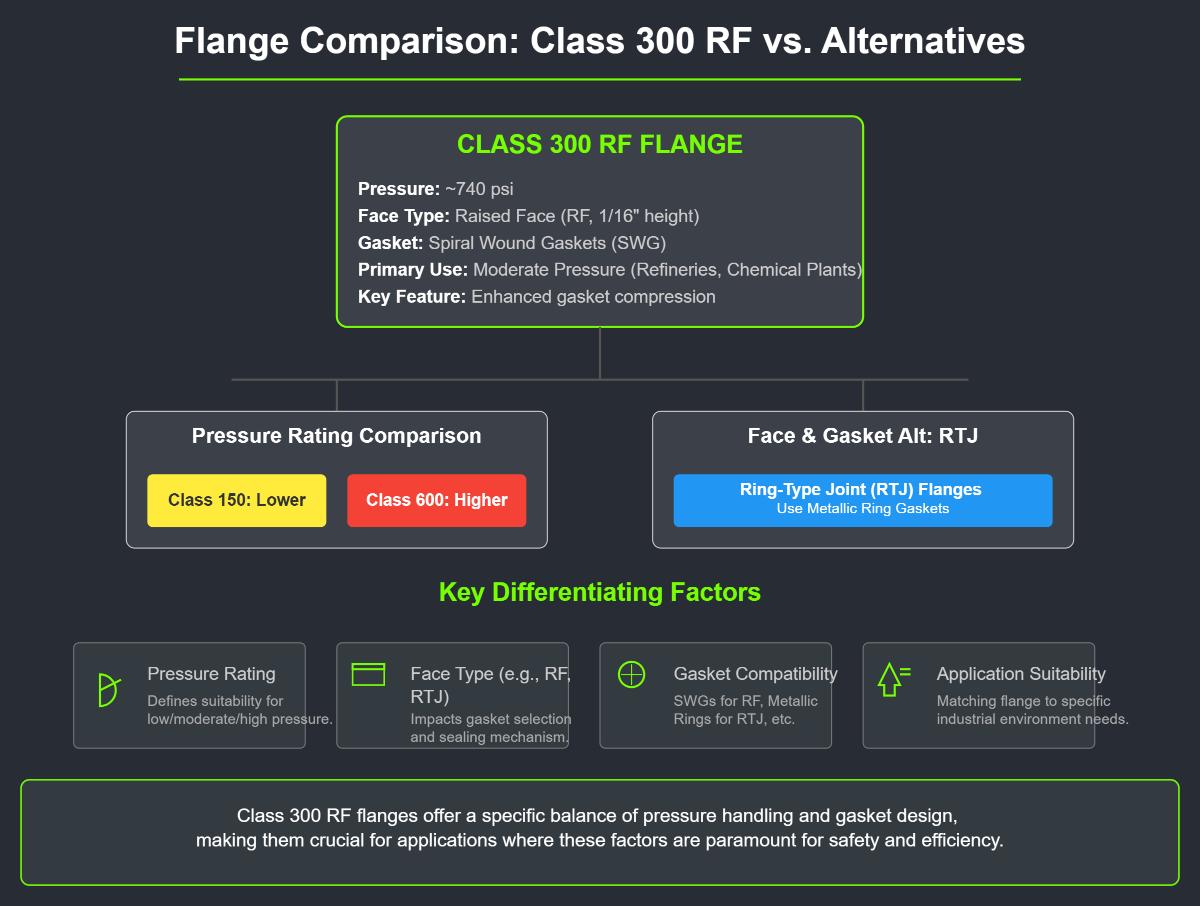

Class 300 RF (Raised Face) flanges are distinguished from other flange types primarily by their pressure rating, face type, and application suitability. Specifically, Class 300 flanges have an intermediate pressure rating, capable of handling approximately 740 psi at ambient temperatures, making them suitable for moderate-pressure applications like those in refineries and chemical plants. The raised face design, standard with a 1/16″ height, enhances gasket compression, optimizing their use with spiral wound gaskets (SWGs).

In contrast, other flange types, such as Class 150 or Class 600, have different pressure ratings, making them more suitable for low or high-pressure environments, respectively. Additionally, while Class 300 RF flanges typically use SWGs with centering rings, other flange designs like Ring-Type Joint (RTJ) flanges require metallic ring gaskets. The compatibility with specific gasket types and the bolt configuration, such as the 8-hole pattern for Class 300 RF, also differentiate them from other classes and face types. These characteristics make Class 300 RF flanges ideal for specific industrial applications where pressure and gasket compatibility are crucial considerations.

Spiral wound gaskets comply with ASME B16.20 standards by adhering to specific material, dimensional, and performance criteria set forth for their use, particularly with Class 300 RF flanges. ASME B16.20 specifies acceptable metal and filler combinations, such as stainless steel and graphite, and establishes color coding for easy identification. This ensures that the gaskets maintain their integrity and performance under varied industrial conditions.

Dimensional requirements are detailed, including precise measurements for sealing elements and outer rings, which ensure compatibility and effective sealing with flanges. The standard also mandates compression testing to verify the gasket’s ability to maintain its structure under pressure, addressing the need for reliable sealing performance.

Moreover, ASME B16.20 includes optional design elements such as inner rings, which can enhance structural stability, and emphasizes the importance of material-grade compliance for high-pressure and temperature applications. Recent developments focus on improving leak-test standardization and optimizing material selection to meet evolving industry demands.

Spiral wound gaskets are crafted using a combination of metallic windings and soft filler materials, making them highly effective for industrial applications that demand robust sealing under high temperatures and pressures. The metallic windings are typically made from stainless steel, Monel, or Inconel, chosen for their excellent resistance to corrosion and thermal stability. These metals ensure the gasket’s structural integrity and recovery properties. The soft filler materials are generally graphite, PTFE, or ceramic. Graphite is favored for its high-temperature resistance and chemical stability, while PTFE offers excellent chemical resistance and low friction. Ceramic fillers are used in extreme temperature environments. Additionally, spiral wound gaskets often include outer and inner rings made from carbon steel or stainless steel to prevent over-compression and enhance durability. This combination of materials ensures that spiral wound gaskets meet the rigorous requirements of ASME B16.20 standards, particularly for Class 300 RF flanges.

To ensure the effective installation of spiral wound gaskets on ASME B16.20 Class 300 RF flanges, follow these best practices:

By adhering to these best practices, you can ensure a reliable seal, maintain the integrity of the industrial system, and extend the service life of the equipment. Always consult the manufacturer’s guidelines for specific recommendations and compliance with industry standards.

To troubleshoot common issues with spiral wound gaskets in ASME B16.20 Class 300 RF flanges, start by identifying the specific problem. For inward buckling of windings, ensure the gasket includes an inner ring to prevent deformation and use calibrated torque tools to apply the correct bolt tension, adhering to ASME standards. If you encounter metal-to-metal contact, which can cause leaks, select gaskets with appropriate thickness to maintain compression and avoid using painted rings. For sealing material extrusion, avoid over-tightening bolts and choose filler materials suitable for the operating conditions, such as PTFE for cryogenic applications or graphite for high temperatures. Installation-related leaks can be minimized by inspecting flange flatness and surface finish, using alignment pins, and ensuring correct gasket placement. Regular post-installation inspections can help detect over-compression, and following ASME PCC-1 guidelines for bolting procedures will ensure uniform gasket stress.

When selecting gasket materials for specific applications, several key factors should be considered to ensure optimal performance and reliability. Firstly, environmental factors such as temperature, pressure, and exposure to elements like sunlight, moisture, and ozone must be evaluated. These conditions can significantly impact the material’s durability over time. Secondly, the material’s resistance to the media it will encounter, including primary fluids, gases, and other substances like cleaning agents, is crucial. Thirdly, the pressure the gasket will face and its ability to maintain a seal under compression are vital considerations; materials like Inconel and stainless steel are preferred for high-pressure scenarios. Compliance with industry standards, such as ASME B16.20, is also essential for safety and reliability. Additionally, material properties like hardness and compression set should be assessed to ensure the gasket can maintain its sealing capabilities. Finally, the thermal stability of the material is important, especially for applications involving extreme temperatures. By considering these factors, users can select the most suitable gasket materials for their specific needs.