In the world of construction, steel structures stand as monumental feats of engineering, requiring precision, planning, and adherence to safety standards. As an intermediate learner, you might be wondering what makes the steel structure erection process so intricate and vital. This comprehensive guide will unravel the complexities, providing you with a step-by-step journey through the crucial stages of steel erection. From the foundational preparation and anchor bolt verification to the precision techniques ensuring alignment accuracy, we delve into each critical step, offering insights into load distribution, column placement, and beam installation. Safety protocols and OSHA standards are highlighted to ensure compliance and protect workers during the erection process. Whether you’re curious about the strategies for efficient erection sequence planning or the nuances of high-strength bolting, this guide is designed to equip you with the knowledge you need to master the steel structure erection process. Ready to uncover the secrets behind these towering structures? Let’s dive in.

Proper preparation of the foundation is crucial for successfully erecting steel structures. Ensuring that the ground is stable and capable of supporting the intended load is the first step.

Conduct thorough soil tests to assess load-bearing capacity and soil composition. Once testing is complete, evaluate the condition of existing foundations to ensure they can support the intended loads. Identifying and addressing any issues, such as soil instability, is essential to maintain the integrity of the foundation.

Prepare the site by leveling and compacting the ground to ensure stability and even load distribution. This step is vital to prevent uneven load distribution and potential structural problems.

Anchor bolts play a critical role in securing steel columns to the foundation. Proper verification and placement are key to ensuring structural stability.

Anchor bolts must be placed accurately to prevent misalignment and structural weaknesses. Temporary supports may be used during the initial erection stages to maintain stability, ensuring columns are securely anchored.

Ensure anchor bolts are made from strong, corrosion-resistant materials that meet project specifications. Verifying the quality of anchor bolts is essential to the overall stability and longevity of the steel structure.

Load distribution is a crucial concept in steel structure erection, ensuring that the forces acting on the structure are managed and transferred effectively. This strategic placement of structural elements helps minimize the risk of failure.

Dead loads are the permanent forces from the structure’s weight, including beams and columns. Calculating these loads accurately is essential for stability.

Live loads are dynamic forces that change over time, such as those from people moving around or furniture being added. These require flexible designs to adapt to changes.

Environmental loads encompass forces from natural phenomena like wind and seismic activity. These are addressed through robust structural bracing and connection techniques, ensuring the building can withstand external pressures without compromising safety.

Load paths are the routes forces travel through beams and columns to the ground, ensuring stresses are evenly spread to prevent failures like bending or buckling.

Modular steel systems are pre-designed to optimize load paths, making assembly quick and reducing load-related problems. Real-time monitoring with sensors helps engineers spot issues early to maintain safety.

Steel column placement is a crucial phase in building steel structures, requiring precision and planning to ensure the structure’s stability. The following guide outlines the process of placing steel columns effectively.

Temporary bracing is used to stabilize columns during construction, ensuring they remain secure until permanent supports are installed.

Effective hoisting and positioning are crucial in beam and girder installation, involving crane selection, rigging safety, and precise alignment.

Selecting the appropriate crane is essential for lifting beams and girders successfully. Mobile or tower cranes are chosen based on load capacity, reach, and site constraints. Lifting plans must consider the weight of the beams, rigging configurations, and environmental factors to ensure safe and efficient hoisting.

Rigging teams play a crucial role in maintaining load control during lifts, ensuring proper sling angles and load distribution to prevent structural stress and ensure safety. Beams are guided into place using taglines to maintain stability throughout the operation.

Laser-guided systems and BIM-assisted placement tools are often used to achieve precise alignment. Accurate positioning is vital for the structural integrity of the erection process, ensuring beams are correctly aligned with pre-marked column connections.

The connection methods used to join beams and girders are foundational to the structure’s stability and durability, including bolted connections, welded joints, and hybrid systems.

Bolted connections are common for joining beams and girders. High-strength bolts, such as ASTM A325 or A490, are torqued to specified preloads using tension control or calibrated wrench methods, ensuring the integrity and stability of the joints.

Field welding follows AWS D1.1 standards, with preheat and post-heat treatments for high-carbon steel to prevent cracking. Weld inspections, including ultrasonic testing, are conducted to validate the quality of the welds.

Hybrid systems combine bolts for initial stability and welds for permanent load transfer. This approach is particularly beneficial in seismic zones, where additional structural resilience is required.

Safety and compliance are paramount during beam and girder installation, adhering to OSHA standards and implementing hazard mitigation strategies to protect workers and ensure structural integrity.

OSHA mandates fall protection, such as guardrails and harnesses, for workers operating at heights exceeding 15 feet. Specific training for personnel handling beams during placement is required to ensure safety and compliance.

Job hazard analyses (JHAs) address risks associated with swinging loads, pinch points, and overhead work. Implementing tool tethers can prevent dropped objects, further enhancing site safety.

Inspectors ensure the bolts are tight, weld profiles are correct, and alignments are precise. These checks are crucial before progressing to subsequent phases of erection, ensuring that each step meets the required standards.

Modern techniques and innovations enhance the efficiency of beam and girder installation, reducing time and improving precision.

Beams and girders can be pre-assembled into larger modules on-site. This approach reduces the number of crane lifts required and accelerates the installation timeline.

Technologies like BIM and RFID tracking enable real-time localization of components, minimizing placement errors and enhancing efficiency. Additionally, non-destructive testing (NDT) methods, such as magnetic particle inspection, ensure connections meet design load capacities.

Utilizing the right tools and equipment is essential for successful beam and girder installation.

Laser plumb bobs, electronic theodolites, and 3D positioning systems are critical for precise alignment during installation.

Hydraulic jacks, spreader beams, and load-limiting devices are used to safely lift and position beams and girders.

Torque wrenches, ultrasonic flaw detectors, and thermal imaging cameras are employed to inspect and verify the quality of connections and structural components.

Vertical alignment checks are vital in constructing steel structures, ensuring precise placement of columns and other vertical elements for stability and safety. These checks are essential to maintain the structural integrity of the building, prevent misalignment, and ensure the safety of both the construction process and the completed structure.

Accurate vertical alignment ensures proper load transfer to the foundations. This prevents unwanted stresses and maintains the structure’s stability. Columns that are correctly aligned help distribute loads evenly, reducing the risk of structural weaknesses.

Several tools are employed to verify vertical alignment, ranging from traditional to advanced technological instruments:

The tolerances for verticality are generally within a few millimeters per meter of height, as specified by standards like AS 4100. These standards dictate acceptable deviation levels and guide the methods of correction, ensuring the structure’s performance and compliance.

Ensuring vertical alignment in steel structures involves navigating several challenges:

Precision in erecting steel structures relies heavily on advanced positioning systems, which are essential for the accurate placement of structural elements. These systems, including Building Information Modeling (BIM), laser levels, and electronic theodolites, form the backbone of precise alignment and positioning.

BIM technology allows for the integration of digital models with real-world data, facilitating precise planning and execution of steel structure erection. This technology enables engineers to visualize the entire structure before construction begins, allowing for detailed planning and error minimization. By identifying potential conflicts and optimizing component placement, BIM significantly enhances precision.

Laser levels are critical tools in achieving high precision during steel erection. They emit a laser beam to create a straight reference line, ensuring vertical and horizontal alignments are maintained within tight tolerances. This tool is especially useful for setting anchor bolts and aligning beams and columns accurately.

Electronic theodolites measure angles accurately, ensuring that structural elements are aligned correctly with each other. These instruments provide precise angular measurements, which are crucial for maintaining the correct relative positions of structural components.

A range of specialized tools is employed to ensure the necessary precision in steel structure erection, all aimed at maintaining structural integrity. Digital calipers and optical comparators are used for dimensional audits of structural elements, measuring exact dimensions to ensure they meet design specifications before installation. This prevents misalignment and structural weaknesses. Torque wrenches ensure bolts are tightened to the correct specifications, maintaining joint integrity. Ultrasonic testing verifies weld quality, detecting internal flaws that could compromise stability. Together, these tools are crucial for ensuring that connections between structural elements are sound.

Real-time monitoring systems provide continuous feedback during the erection process, enhancing both precision and safety. These systems utilize advanced technologies to track structural behavior and detect deviations from the planned erection sequence.

Strain gauges measure the deformation of structural elements under load, offering insights into structural performance during erection. Inclinometers monitor the tilt of components, ensuring they remain within acceptable limits. These tools collectively help maintain the integrity of the structure as it is assembled.

Drones equipped with cameras and sensors offer an aerial view of the construction site, allowing detailed inspection of areas that are difficult to reach. Aerial photogrammetry is used to map the accuracy of steel member placement, ensuring alignment with design specifications and enabling prompt error correction.

Precision techniques in steel structure erection involve meticulous planning and coordination of the erection sequence, integrating modern surveying technologies to streamline the process and minimize errors.

Phased assembly involves erecting the structure in pre-determined stages, which helps manage alignment and load distribution more effectively. Pre-engineered sequences, such as grid-by-grid erection, reduce cumulative alignment errors and enhance overall structural stability.

Temporary stability analysis ensures that the structure remains stable during each erection phase by considering the impact of temporary loads and environmental conditions like wind. By planning for these factors, engineers can implement effective strategies to maintain stability throughout the erection process.

Effective planning for the steel erection sequence begins with thorough preparation before the actual work starts. This ensures that all necessary elements are in place for a seamless and safe erection process.

Develop an Erection Sequence Methodology (ESM) tailored to the specific site, detailing the sequence of member installation, temporary bracing, and the establishment of exclusion zones. Verify the foundation and alignment with structural plans to ensure everything is set correctly. Additionally, inspect all steel components to confirm they meet quality standards and project specifications, including verifying the quantity, dimensions, and integrity of materials. Address any discrepancies or defects beforehand to avoid delays and ensure safety.

Ensure that all necessary equipment, such as cranes, slings, and scaffolding, is operational and capable of handling the required loads. Confirm the availability and functionality of mobile equipment like truck cranes and essential hand tools.

A well-structured erection sequence is critical for the stability and safety of the steel structure. The following steps outline the process:

Proper alignment and bolting are crucial for the structural integrity of the steel framework.

Maintaining safety and compliance throughout the erection process is paramount.

Incorporate modern advancements to enhance the erection process.

Utilize 3D modeling software to simulate erection sequences and identify potential clashes before actual construction begins. This approach allows for a more accurate and efficient planning process.

Consider pre-assembling components off-site to minimize on-site risks and delays, leading to a more efficient erection process. This method streamlines operations and reduces the complexity of on-site assembly.

OSHA has set detailed standards to ensure safety in steel erection, outlined in Subpart R of Part 1926, covering site layout, structural assembly, and fall protection.

A site-specific erection plan must be developed before starting, addressing unique hazards and ensuring concrete foundations have the necessary strength to support the steel. This plan should detail the sequence of operations and emphasize the importance of staged structural assembly, with permanent floors installed as the structure is erected to maintain stability.

For workers at heights above 15 feet, employers must provide:

Training is essential for the correct use of this equipment, ensuring workers understand the risks and proper safety practices.

Implementing robust safety protocols is crucial for minimizing risks in steel erection.

Conduct a detailed risk assessment to identify hazards like structural instability, equipment issues, and fall risks, updating it regularly as new risks emerge. This proactive approach helps in mitigating potential dangers.

Workers must be equipped with appropriate personal protective equipment, including hard hats, safety glasses, gloves, and fall protection harnesses. Proper maintenance and usage of PPE are vital for ensuring worker safety.

Comprehensive training programs should be conducted to educate workers on safety procedures and equipment use. Establish clear communication channels to effectively disseminate safety information and ensure it is understood by all personnel on site.

Schedule regular inspections to prevent accidents from mechanical failures, ensuring all tools and machinery are well-maintained. Adhering to maintenance schedules helps in keeping equipment in optimal working condition.

Develop and implement emergency response plans to manage accidents effectively. These plans should include procedures for evacuation, first aid, and communication with emergency services.

To effectively implement OSHA standards, contractors should focus on developing comprehensive site-specific plans that incorporate tailored safety protocols. Compliance with structural assembly guidelines is crucial, ensuring stability through the proper installation of permanent floors and maintaining column integrity. Regular training sessions keep employees informed about safety practices and updates to OSHA regulations. Maintaining accurate records of safety inspections, training, and incident reports facilitates compliance and continuous improvement. By adhering to these standards, the steel erection process can be executed safely, minimizing risks to workers and ensuring regulatory compliance.

High-strength bolting is essential for securely fastening steel beams and girders to columns, ensuring the structure’s stability under significant stress. This method utilizes bolts designed to withstand substantial stresses without compromising the integrity of the structure.

High-strength bolts are chosen based on specific design requirements, structural loads, and seismic considerations. These bolts provide robust and reliable connections for beams and girders to columns.

Safe lifting plans and load control measures are crucial during installation to minimize accidents and ensure structural integrity. Proper positioning and alignment of bolts reduce risks and maintain the strength of connections.

Grouting is a vital process that stabilizes steel columns by filling the space between the base plate and the foundation with a durable material, ensuring uniform load distribution and enhancing stability.

Before grouting, the area under the base plate must be thoroughly cleaned to ensure effective bonding. This step is crucial for the grout to adhere properly and provide necessary support.

Regular inspections ensure the grout meets required specifications and is properly cured. This includes checking for signs of cracking or shrinkage and verifying effective bonding with the base plate and foundation.

Below are answers to some frequently asked questions:

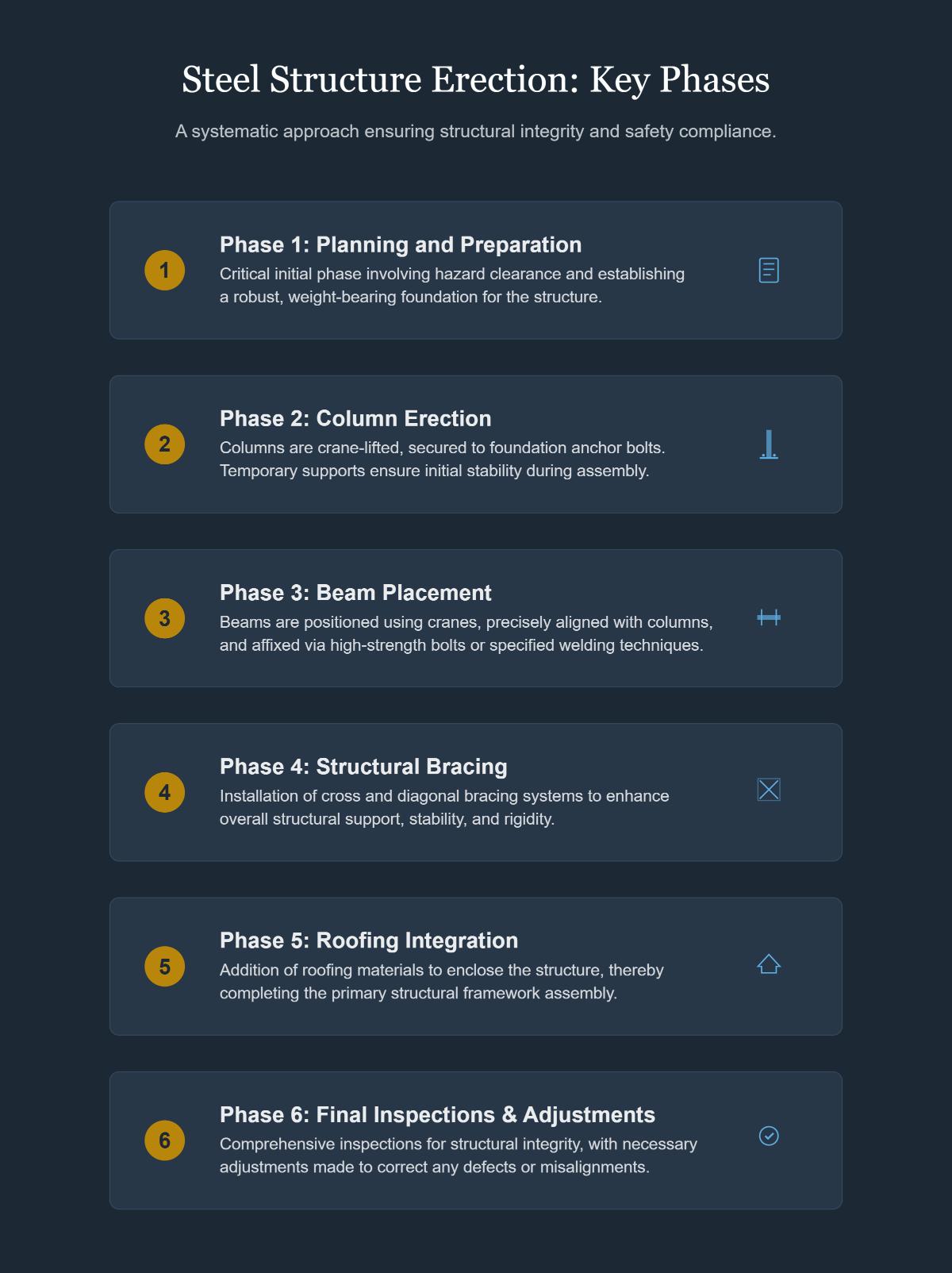

Erecting a steel structure involves several critical steps that ensure both precision and safety throughout the process. Initially, project planning and site preparation are essential to clear hazards and prepare a robust foundation capable of supporting the structure’s weight. Once the site is ready, columns are installed using cranes, and they are secured to anchor bolts embedded in the foundation. Temporary supports may be used to enhance stability during this phase.

Next, beams are lifted and positioned with cranes, aligned precisely with columns, and secured using either high-strength bolts or welding, depending on the design requirements. Bracing systems, including cross and diagonal bracing, are then installed to provide additional structural support and stability.

Following the framework assembly, roofing materials are added to complete the structure. Finally, thorough inspections are conducted to ensure structural integrity, with adjustments made as necessary to rectify any defects or misalignments. Throughout the entire process, adherence to safety protocols and quality control measures is crucial to ensure the project’s success and compliance with standards.

To ensure alignment precision during steel column placement, several key techniques and tools are employed. First, verify the accuracy of anchor rod placement using laser levels to align with foundation cross-lines, ensuring stability from the start. Base plates must be level and aligned, with non-shrinkage mortar filling any gaps post-adjustment.

Vertical alignment is checked using plumb bobs for basic structures or more advanced tools like theodolites and total stations for high-rise projects, offering precision within ±5mm. Horizontal alignment is achieved by matching column orientation with structural load paths and using steel punches for precise base alignment.

Adjustment protocols involve iterative measurements at various stages, using cranes for fine-tuning base elevation to ±1mm. Slotted holes and filler plates are used to accommodate tolerances in connections, ensuring accurate load transfer before final bolt tightening. These practices collectively ensure precise alignment and structural integrity.

Safety standards for steel erection are primarily governed by the Occupational Safety and Health Administration (OSHA) under Subpart R (29 CFR Part 1926 Subpart R). These regulations are designed to address the specific hazards associated with steel erection, including falls, structural instability, and equipment misuse. Key sections, such as 29 CFR 1926.750-761, provide detailed guidelines on maintaining structural integrity, utilizing proper equipment, and implementing fall protection measures.

Ensuring worker safety involves several preventive measures: using fall protection systems, properly maintaining equipment, and providing adequate training and supervision. Compliance with these standards is essential not only for legal reasons but also to minimize risks and prevent accidents. Employers must ensure that workers are well-informed and adhere to these safety protocols during steel erection activities to maintain a safe working environment.

To plan an efficient erection sequence for steel structures, start with thorough pre-planning and coordination. Assess the site for terrain conditions, space constraints, and access points to facilitate the smooth movement of equipment and materials. Develop a detailed sequence of operations that minimizes risk, optimizes efficiency, and adheres to timelines. Coordinate closely with all stakeholders, including engineers, fabricators, and contractors, to ensure alignment on design specifications and resource availability.

Safety considerations are paramount; comply with OSHA and AISC guidelines, implement fall protection measures, and conduct regular inspections of tools and equipment. Use 3D structural analysis to manage structural behavior throughout the erection process, accommodating deflections and rotations.

Begin with foundational steps such as equipment checks and column erection, followed by the installation of rafters and braces. Make final adjustments to calibrate the structure and ensure all bolts are snug. Continuously monitor the process in real-time to address any site-specific challenges and document the sequence for future reference. This approach ensures an efficient, safe, and structurally sound erection sequence.